Making blackpowder.

Retrieved: 08/23/2016

Last Post: 02/13/2015

Would someone on here please post a couple of links for me to go to which will explain exactly how to do it?

Beagle-zebub

March 15, 2008

http://www.musketeer.ch/blackpowder/recipe.html

http://www.musketeer.ch/blackpowder/homemade_bp.html

This website is pretty stinkin' great.

GENTLEMAN OF THE CHARCOAL

March 15, 2008

Beagle-Zebub... Thanks!

Reading this will help me pass my weekend and maybe learn something to.

I didn't know exactly how they done it. I knew the ingredients and all and about milling it and whatnot, but after that I was kind of lost.

I knew that like anything else there was an art to it.

JCT

March 15, 2008

- Ingredients needed: 99%+ pure; Sulfur, KNO3 ( Potassium Nitrate ) and Willow or Alder Charcoal

- Materials needed 1: ball mill aprox. 1 gallon size, with half the jar filled with .45 to .50 hardened lead balls (mill media)

2: Screens/strainers to sift out media and to granulate BP

3: Digital scale: 500 gram minimum +/- .01 gram accuracy

4: Other useful: Isopropyl Alcohol, pyrex measuring cup, plastic buckets, wood spoons, storage for finished BP

- Steps:

#1: Weigh; 75% KNO3, 15% Charcoal 10% Sulfur. For a 500 gram batch (just over 1 lb), that's 375 grams KNO3, 75 grams Charcoal and 50 grams Sulfur. Weigh each separate and zero scale each time for accuracy. Pour all powder into mill jar with media already in jar. Seal mill jar.

#2: Run mill 3-6 hrs.

#3: Empty mill jar into strainer over newspaper or bucket, sift out lead, place back into jar

#4: Powder is now "mill dust" Black Powder, it can be granulated next...

#5: Wet powder with water and about 10% alcohol to aid absorption into dry powder. Mix by hand or spoon until it's a clay like consistency.

#6: Rub the ball of BP through screen to granulate, dry outdoors, not in direct sun (slow drying makes better BP)

That's it, store properly. This powder is more fragile than commercial, since it's not been compressed to 1.7g density, it takes up more space per load, but is more powerful too.

zxcvbob

March 15, 2008

"Clay-like consistency" means a stiff clay that almost crumbles. If you get it too wet, you won't be able to screen it. (don't ask me how I know this)

JCT

March 15, 2008

I've over wet it more than a few times. It'll clog up your screen and make large grains of BP, too big for revolvers.

Moist enough to bind the BP, but dry enough to allow it to be screened into the size you want. I'm not picky about FFFg, FFg size. Homemade powder ends up being a mix from FFFFg to Fg, but works great and is so clean! I shot about 50 rounds through the Walker yesterday and couldn't see fouling except on the base pin, chambers were clean, bore was clean! Hotter BP = cleaner BP. I most likely won't ever use GOEX again, but I would buy and use Swiss if it were sold anywhere around here, just for the convenience and durability of commercial BP. My homemade doesn't work well in the powder flasks, probably because I leave to many bigger chunks of BP in there too. Sometimes, I just use a Lee dipper or powder measure and work from a container of my BP.

Beagle-zebub

March 15, 2008

JCT, do you get reasonable accuracy with your powder? The thing about the grain-size being all over the place made me wonder that.

EDIT: Also, it seems like fireworks people believe that higher density is a good thing, which they put into action with big presses. What's the deal with that. Both you and the Swiss website that I originally posted would seem to contradict that, even accounting for the fact that the firecrackers aren't worrying about messiness.

You being able to get off fifty shots from your Walker is danged impressive! Now I'm even more excited about this stuff...

JCT

March 15, 2008

I'm getting good groups, all my BP revolvers shoot high, but I'm working that out lately too. I just don't think the grain size makes enough difference. I also remember reading about a mix of FFg and FFFg that used to be used for revolvers for some reason.

Firecrackers are usually made with a different powder altogether; Flash powder, which is still a fuel oxidizer mix (KCLO4 and Aluminum powder).

Fireworks use all grades and densities of BP. Lift powder is usually pressed, but doesn't have to be. Powder for blackmatch fuse, rockets, fountains..etc is unpressed, mill dust BP, just like mine. They use mallets and rammers to load the cardboard tubes and create the solid fuel grains.

I've never tried Swiss BP, but may break down and order some this summer to compare to mine. I'll have to buy a chronograph someday too just to be more scientific when working up loads. I like how the fouling stays nice and soft when using real BP, that's an advantage over the substitutes which seem to have dry and hard fouling.

I almost got into pressing my homemade powder, but it's just not needed. While a 50 grain spout of my powder probably only weighs as much as a 45 grain spout full of GOEX, the power is greater. The lower density may also allow it to burn faster. I don't bother with the spouts most times, I can just fill the cylinder and since my powder will compress, I can fit the wad and ball still and it ends up being a good load.

Zoogster

March 15, 2008

I ran across the musketeer site long ago and it is good.

He even demonstrates he made saltpeter from naturally occuring saltpeter from a wall. It was just as effective even with some contamination. However contamination can easily be removed (and for general use should be as it can be hard enough to scratch the barrel.)

Some additional highly valuable information:

Saltpeter can in fact be made by anyone just be leeching soil if necessary. Essentially it can be made from animal waste, (even human waste, but for the same reason they don't use human waste for agricultural purposes you should avoid that.)

A really informative reading would be to look up early saltpeter production.

Specifically Nitre beds.

That will teach you how to make black powder from scratch even in a doomsday scenario with no chemicals or commerical products.

Bottom line, you could make gunpowder from your own bodily wastes if you wanted.

Of course you could also make smokeless powder and even high explosives from scratch by making some acids from scratch, nitrating and then purifying various things with everything you could aquire on a deserted island.

Some of the most informative reading when read with the understanding of modern chemistry is very old historical alchemy experiments many done as early as the 800's. They are some of the simplest, and generally used materials you could collect outdoors.

Be sure to double check them with modern chemistry, but the correct ones are great.

Knowing such information could allow you to make even some of the most powerful modern explosives and propellants on a deserted island so is quite valuable.

Such information is also very important to spread as with it widely known it is apparent that firearms and firearm technology could never be controlled or eliminated.

Of course currently you can just purchase saltpeter and sulphur, and make your own charcoal (the most important part.)

There is various methods to combine them. JCT gives a great one.

For safety purposes be sure to use all non sparking equipment. For an electrically powered mill that includes making sure no fine powder will reach the motor (and some can become quite fine dust). Many mills also come with or suggest steel media or ball bearings for other purposes. DO NOT USE any material that will or can spark, including iron or steel. Lead works well for this purpose.

oneiron

March 15, 2008

Nitrates

I am a farmer and I use to get potassium nitrate to spray on my cotton in late season. What we call spoon feeding it. Now you can't find a source. You can't buy ammonium nitrate any more. The only thing I can buy in bulk is urea which is 45% CO(NH2)2. The twos should be subscripted in the last formula.

Can urea be use to make bp?

zxcvbob

March 15, 2008

Quote:

Can Urea be use to make bp?

Spray-grade KNO3 fertilizer is still available (but it's hard to find) and it should be high enough purity to use for making BP. I think it is just technical grade, which is what you want. Prilled KNO3 fertilizer can also be used, but you'll probably have to purify it to make *good* BP.

Urea won't work at all. It's not oxidized nearly enough.

berkmberk1

March 16, 2008

From what I read on Ulrich Bretscher's Black Powder Page, I could extract saltpeter from the manure collected from my friend's stable... she also has a large willow tree... hmmmmmmmmm

I wonder what practical amount of time is required for the process... I guess however long it takes to boil down the "brine"?

GENTLEMAN OF THE CHARCOAL

March 16, 2008

Yeah, I'm learning a lot here. Good way to spend a weekend.

I heard a long time ago or read it in a book somewhere that you can get all the nitrate you need under the cow piles.

I also know where there's a couple of pools of sulphur water. That must mean there's lot's of sulfur in the ground there. I'll have to find a site and read on the computer maybe how to get it from the soil. Hell, it might just lay around in chunks like rocks for all I know.

I know I drink a lot of coffee and I piss a lot. I think what one would have to do is place the urine like in a can and cover it with a cloth. The cloth would allow the moisture (steam) to escape and would also hold in the nitrate.Probably be kind of smelly but it's better than dying. I'vd also got to find out about cow piles and how to get the nitrate down to a reasonably pure form. (if I can)...

Macmac

March 16, 2008

All ears hear and another thread to book marked. It already is...

G of C here are more links I got mostly from these guys.

http://www.unitednuclear.com/mills.htm

http://www.micropyrotechnics.com/willowcharcoal.htm

if I don't learn and do another thing this summer I will gather the tools and do this.

JCT

March 16, 2008

United Nuclear sells Harbor Freight tumblers at a huge markup. These mills will make decent small batches of BP, but buy the mill from Harbor Freight for about $25!

Steve Baron at Micropyro has a great reputation for good prices and quality charcoal, but it's so easy to make your own if you have Willow or Alder.

Phil at www.ihaveadotcom.com sells KNO3 and Sulfur at fair prices, he's a nice guy and good to deal with.

Macmac

March 16, 2008

I see Harbor Freight has 2 sets of tumblers, but I am not familar with either.

It causes me to wonder if the double drum has the same motor the single drum has.

This causes me to wonder if the double drum motor is stronger and so using a single drum on the double drum frame might be a way to go.

zxcvbob

March 16, 2008

Originally Posted by Macmac

This causes me to wonder if the double drum motor is stronger and so

using a single drum on the double drum frame might be a way to go.

That's what I do. It seems to work OK. (the single-drum tumbler probably has the same motor, but I wasn't sure so I paid the extra $5 for the double)

Macmac

March 16, 2008

Thank you for the info. I simply must do this and succeed no later than late summer.

It is hard times here and deep snow. "Things" are expensive and just being here for me at this time is a fight in survival right now.

Like anyone else I must budget items.

I am sure once I have this figured I can work backwards taking more time but no power and still make it, but I want to do this way now.

To me it is life, and a long reached goal. It will be closure on 4 decades in related effort.

berkmberk1

March 16, 2008

Couldn't these mills also be used as rudimentary brass tumblers?

I saw one of the 15 lb tumblers at an antique mall for $99. I wonder if its still there?

JCT

March 16, 2008

I use my mill to tumble my brass

Ebay seller hobfir sells a great ball mill if you don't want to build one.

scrat

March 17, 2008

GOC you got my wheels spinning again. However im not going to go with a ball mill. I'm going old style. The way it was originally made. Mortar and pestle. I found a good cheap site that sells them. I paid less than 10.00 for a decent one being shipped to me now. Lookse like no turning back.

here is the site

http://www.fantes.com/mortar-pestle.html

GENTLEMAN OF THE CHARCOAL

March 17, 2008

Scrat, good morning. I just went to the link you posted on the mortar and pestle. Hell, it say's it will grind peppercorns and coffee beans, so you know it will grind powder. I'm going to buy one of them today.

It says that as you turn the inside part in a circular motion it will actually pull the substance into it so to speak. That's alright.

Macmac

March 17, 2008

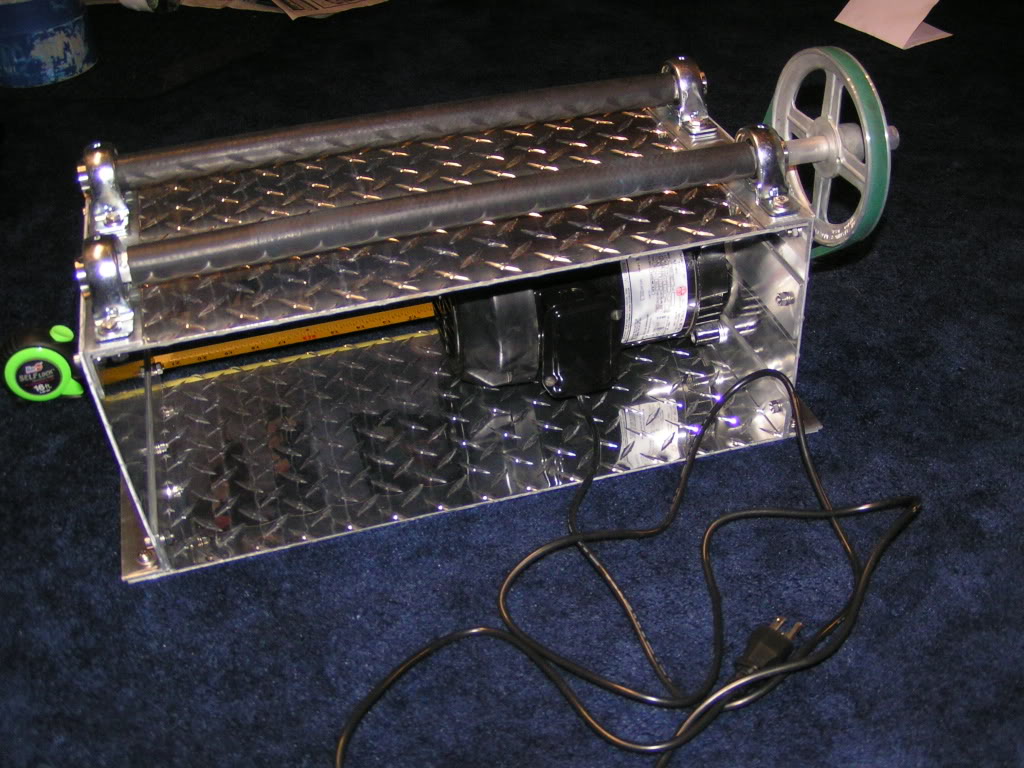

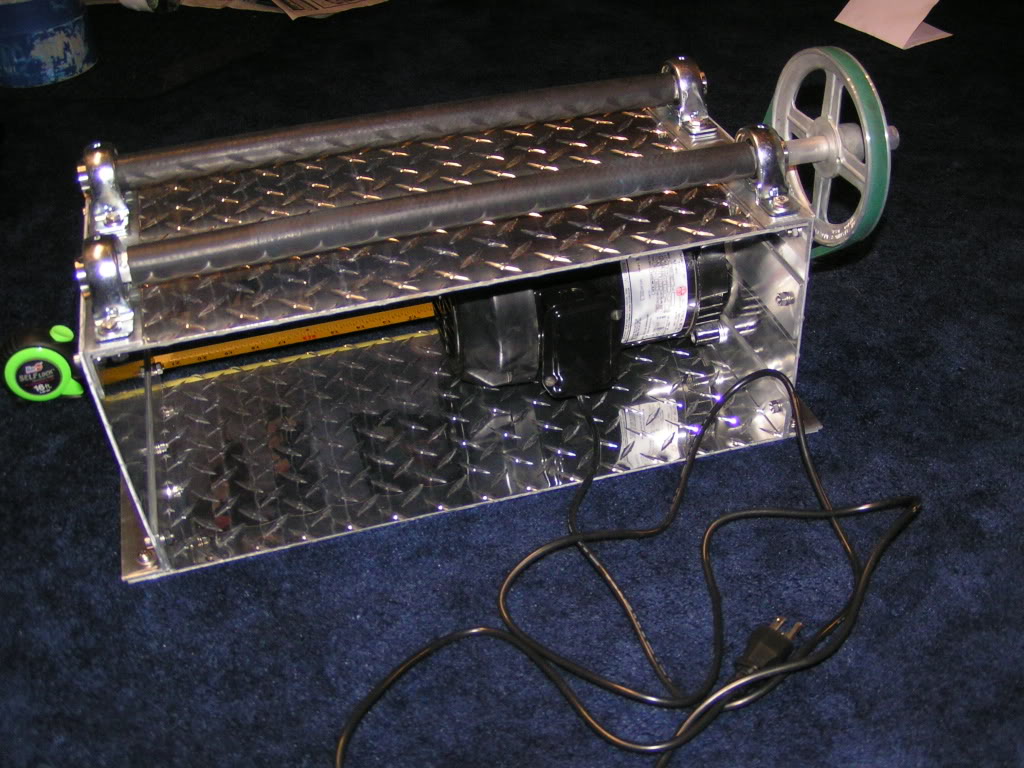

JCT, Would it be a bother to get a pic of the drum up as well.

This photo is far better than the others, as i can see the construstion is better.

What are the rollers from, possibly a larger scanner printing bed?

If you know what is the rpm of the drum?

What is the rpm of the motor?

Does the drum have internal fins of any type like a common back yard cement mixer does?

As an aside I can see working backwards and getting to a mortar, but I'd rather use water power if no other was available to drive a drum. Time is still time.

scrat

March 17, 2008

I ordered the black and white one. Third from top I believe. I know it's going to be small but thats how i intend to start out small. Still doing a lot of reading. Then I have to research where to get the ingredients.

scrat

March 17, 2008

ok Im sure a lot of us will have pros and cons on this. For one he did not clump it up then grind it to get a 3F or 2F. Then he did not let it dry for days on end. However here is a good sample video on making black powder from a mortar and pestle.

http://www.youtube.com/watch?v=DtHKiRdtEGc

Take a look GOC

scrat

March 17, 2008

OK GOC i got your message. I called them up and changed my order to the wooden one. The one they had available was the bamboo one #120840. $9.99. Still not a bad deal. Mine is being shipped out today. Thanks for the tip.

JCT

March 17, 2008

All that work he put in with the mortar and pestle and his BP didn't do so well in the test at the end. See all the large sparks in the air? These are large particles of charcoal that were not ground well enough. It's usable powder, but most likely not as good as commercial powder. A good mill makes a huge difference.

You can mill about a 150g batch in the small harbor freight mills. Use buckshot or a handful of hardened lead ball for media.

berkmberk1

March 17, 2008

JCT... Just to verify... 150 GRAMS, correct? About 1.3 lb?

JCT

March 17, 2008

150 grams is .33 lb (1 lb is 454 grams). That's about all you can effectively mill in the Harbor Freight mill, I have one and started with it. It works well enough though and is what I still use for test batches if I try other woods or make different mixes for BP rockets.

Beagle-zebub

March 17, 2008

I've heard that a meat-grinder can be used. Can anyone comment on this? The Phil's General Store said that you can even use them to make air-float.

zxcvbob

March 17, 2008

You could use a meat grinder to pulverize the charcoal before milling it, but that's about it. A Corona grain mill would get you a lot closer. I just crunch it up with my hands (wear a dust mask)

JCT

March 17, 2008

You don't need airfloat charcoal anyway when making BP. The course charcoal will soon be airfloat when in the mill with the S and KNO3.

When the mill walls are caked and the BP is caked into big dense chunks, then you know you have good BP and you're mill is working right.

Macmac

March 17, 2008

The little details are sticking up their little heads now... All noted in the noggin, and I have this thread marked...

berkmberk1

March 17, 2008

Excuse the 1.3... mis-keyed... should have been 1/3... they're right next to each other...

berkmberk1

March 17, 2008

Assuming max 1/3 lb at a time, are the recipes able to be duplicated close enough from batch to batch to make home manufacture practical with one of these mills... or maybe the two drum model? I shoot, but not enough to be burning pounds of the stuff every month... heck, I'd probably spend more time making than shooting...

berkmberk1

March 18, 2008

There's a Harbor Freight right down the street from me. I went in there tonite and they had both models. I'll reserve my opinion of them for now, but the display models didn't impress me much... maybe too much handling. Anyway... the lids/caps seemed pretty difficult to install... I couldn't get one on, and I couldn't get the cap off one canister. They look like simple little machines but don't look like they would hold much...

xcvbob

March 18, 2008

It's a cheap knockoff of a Lortone tumbler. Seems to work OK. I'm sure a Lortone or a Thumblers would last a lot longer.

I've made two 1/2-pound batches so far.

JCT

March 19, 2008

Thought this was funny; description from a manual on making BP, being sold on gunbroker;

*DO-IT-YOURSELF GUNPOWDER COOKBOOK by Don McLean Learn how to make gunpowder from such items as dead cats, whiskey, your living room ceiling, manure and maple syrup with simple hand tools and techniques that have been used for centuries. This is a practical and safe approach to making the oldest propellant/explosive known. For information purposes only. 5 1/2 x 8 1/2, softcover, illus., 80 pp.

I guess if you have some extra dead cats kicking around and you've decided to do away with a ceiling and you have some extra maple syrup you won't be using, you'll be all set

scrat

March 20, 2008

Mortar and pestle on its way and so is 1 lb of Potassium Nitrate KNO3 99.9% pure. 1/2 way there.

jimrbto

March 20, 2008

That book was/is available to download free in pdf format. I did it a long time ago and can't remember the site I was at to do the download. Maybe you can find it if you "Google" the title.

Zoogster

March 21, 2008

Quote:

Mortar and pestle on its way

I would not use a mortal and pestle.

Black powder can be set off by both static electricty and sparks. A tiny piece of metal or impurity could spark causing explosion during grinding.

The risk of an accident is low with proper and safe techniques, but it is always there even if reduced to something small. With a mill you can be removed from the danger zone throughout most of the process.

With a mortar and pestle you will likely lose your hands from burns, and perhaps your eyesight, along with serious burns if you ever have a problem.

Lots of static in the air? Might be your last day of eyesight, so be sure to enjoy the ability to see now!

The individual components are one thing, but actualy combining it in a pestle is a risk I wouldn't decide to routinely take.

mykeal

March 21, 2008

The static electricity legend has pretty well been debunked by now; sparks are an issue, however.

Black powder is ignited by heat, not electricity. It is a conductor, not a resistor, and as such will not build up heat when subjected to an electrical charge; it simply passes the electrons through.

However, there is still a danger: if the powder is contaminated with small bits of metal or a resistive material that does heat up when subjected to electricity, that heat buildup could cause ignition of the powder. The bits of metal become, in effect, sparks, such as those given off by a flint scraped on hardened metal.

The use of a mortar must consider whether the scraping motion results in enough friction to heat up the powder locally and thus cause ignition. The mortar and pestle materials certainly play a part in that, as does the speed of the grinding motion.

JCT

March 21, 2008

Making BP is no more dangerous than using BP when loading your gun. I've seen first hand, archs from electricity and static generators, that won't set off BP. It's possibly the most stable "explosive" in existence. It's a fuel/oxidizer mix, not a true "explosive" anyway. A mortar filled with BP can burn you, but that's it, you won't have an open air explosion with BP until it hits it's self confinement point, around 500lbs of BP for that.

You should be wearing safety goggles and leather gloves, as you would for any safe lab procedure anyway. People are quick to condemn what they don't understand...

Pyrotechnicians commonly work with far, far more dangerous compositions, flash, whistle, etc... they do explode in open air and are friction, static, and impact sensitive, yet they can be worked with safely and never have accidents if they use common sense and common safety.

Zoogster

March 21, 2008

Quote:

Pyrotechnicians commonly work with far, far more dangerous

compositions

I have worked with such things myself.

Hand grinding a highly combustable mix of dry chemicals just does not pass the safety test, even a mixture only marginaly susceptible to friction ignition.

Working with a pile of it by hand is different than intentionaly applying large amounts of friction to something which is intentionaly unstable and can explode or in this case deflagrate, while standing over it, with your hands and arms right in the direction the heat and energy would be directed. A minor impurity in the mix could leave the person disfigured and possibly disabled for life.

Making black powder can be safe. However an error, even not due to the individual and instead the supplier of a chemical or an impurity from another item getting in the mix can be disasterous.

In a mill the low chance of problems from someone taking proper precations is acceptable in small batches, especialy in a mill located in a location that even a minor explosion poses little risk of harm to anyone.

In a mortar and pestle that low chance just became unacceptable in my opinion.

Even factories that produced black powder were made so that in case of an explosion the forces would be directed in a harmless direction, usualy through one wall intentionaly built to give.

While this would instead burn rapidly and not explode, the same concept applies. The direction of the burning and heat would be straight up from the pestle. Right where the hands, arms, and possible face of the person is.

That is simply not a safe practice.

If we have different opinions on acceptable risk that is fine.

JCT

March 21, 2008

Black Powder is not friction or impact sensitive though. If for some reason there was some perchlorate impurity in the KNO3 ( most likely impossible...) then there'd be a slight, possible, remote chance of friction ignition, but that same impurity would bow up your ball mill during operation too. I've never heard of one single account of BP going up on anyway in milling, rocketry, pyrotechnics... etc. It's quite stable.

In a mortar and pestle, you have to grind a small amount anyway, I can't imagine that you can do more than 100 grams at once in a average size mortar. Still best to follow safety anyway (gloves and goggles). I'd use a ceramic mortar.

Grind all 3 ingredients separate at first so they're all super fine powder. Then mix the 3 and work them together until homogenous.

Personally I wouldn't bother much with a mortar and pestle, it's a nice idea, if you have no power or no mill, you can make your BP this way, but why not just mill up a bunch now and store it so when you have no power and have to be self reliant... you have plenty of BP ready to go! A mill will make better powder than you can do by hand anyway.

scrat

March 21, 2008

I'm going to have to agree with JCT especially when there is about a hundred or so videos on all video hosting networks showing people make it this way.

I'm not going out to make a 5lb batch. I'm going to try to make as small amount as possible im going to try to see if I can duplicate or make better than goex. I'm sure its possible. but I'd rather start out small. Then if it works get a mill.

Same time people have been making black for thousands of years. Only about for two hundred years was man using a mill. Mills I'm sure were first powered by water then steam then gasoline then electricity. but before that it was mortar and pestle. Same time there are so many different mortars and pestles out there to do the job. Safety of course is my main concern and will be followed.

lgsracer

March 22, 2008

Check out this site lot of good info:

http://fogoforum.us/blackpowder.php

These are some very good links to check out too:

http://www.pyrotechs.org/component/option,com_weblinks/catid,15/Itemid,23/

http://www.pyrotechs.org/component/option,com_weblinks/catid,14/Itemid,23/

JCT

March 23, 2008

Scalper, I had typed all this, but your thread got closed!

There's at least 2 or 3 recent threads all about making your own BP. At least a few people here and at TFL make their own.

The most important variable is the charcoal. Low density hardwoods seem to be the way to go. I use Willow, but Alder, Balsa, Paulownia and Grapevine work great (I've tried all but Paulownia myself). Willow makes fast and hot BP. Hot BP = clean BP since the combustion leaves little residue.

There's no need to make anything other than the standard 75% 15% 10%, KNO3, Charcoal, Sulfur. You could leave the sulfur out, but it's there for a reason. It lowers the ignition temp of the oxidizer/fuel mix and regulates the burn for a consistent and even reaction. This is where products like Pyrodex and 777 can have issues and non fires at times. They have very high ignition points, good BP doesn't.

March 24, 2008

JCT, I understand willow and alder are the best woods to char, but yesterday I was burning white pine to make maple sugar from sap. I got to wondering if I should be saving the charred wood left over after the burn as there is some.

Also I got to wondering if the sugar sand, seemingly minerals that accumulate also called 'Niter' are something I should be saving.

Is that book serious about maple sugar? I took it all as a joke, but now I am not so sure it is really a joke after all.

campbell

March 24, 2008

I've had good luck with United Nuclear for supplies, and Skylighter also has a great selection, so long as you don't mind 5 lb. minimum orders on some products.

Skylighter has a very fine mixed hardwood charcoal powder they call "air float" for blackpowder and such. Look under "C" in the chemicals section.

JCT

March 24, 2008

If you want to buy good charcoal: http://www.micropyrotechnics.com/willowcharcoal.htm

If you're rich and have too much money, www.unitednuclear.com

Otherwise, www.firefox-fx.com or my preferred supplier: www.ihaveadotcom.com

White pine will make hot BP, it's a great charcoal for glitters and tails in rockets/comets or stars in pyrotechnics. It will be a dirty BP though.

Macmac

March 25, 2008

JCT, Whats the deal with maple sugar then? Everyone uses white pine to boil of the sap. So is the 'niter' sugar sand something to save?

scrat, Fruit woods are usually hard, real hard, and make good mauls and wood chisel handles, besides good woods to use in a smoke house.

I never got to play with any of eucalyptus, or even read about it, so I can't help on that score.

Knowing the properties of alder, a shrub like tree right where I hate them fly fishing, and willow are, I would bet that some desert cactus would make dandy charr.

I have linden wood also called bass too. One I wonder about is larch, also called tamarack. This looks like an ever green but isn't. amd once dry works well for a bow drill.

Making char is what you do with a bow drill to get fire, so I suspect stag horn sumac might also make good gun powder char.

I just don't know if there is any in cal.

With that said I wonder if the stalks on mullien wouldn't make a good char for BP in guns too?

So many little plants, so little time..

When I was in Cal, it was on a big fat bike, a Nomad. Traffic in Cal is a tad fast to look at trees too. Never the less, I managed a good long glimpse of a brown bear just the same!

Willow, Bass, Alder are not resinous woods, and not very hard woods either. More or less cedar isn't really resinous.

I wonder if eucalyptus might be in the cedar family? I hear cedar like trees in different names than I am accustomed to hearing, and so I wonder if this might be one of them?

If you can get a stick from one and whittle on it some, maybe inspect the tree for pitch, and find none, it could be something with in reason.

You could char pine, what ever that means as we have a lot of different pines here.

That way you can see how light pine is and compare to that with eucalyptus and a little store bought cedar. Can you buy real red wood anymore? I once worked with that wood and while it was rot resistant, I never found any pitch.

JCT

March 25, 2008

I would think the sediments and debris while boiling sap are just silicates and dirt from the tree. I don't think it's of any use.

There's plenty of Concord grape in NH though, grapevine makes good BP. I think any low density hardwood (sap, not pitch) should work good. I made one small batch with store bought balsa once, it might be the hottest BP I've seen, but the balsa is so light, it's hard to work with and to mill real well.

The only problem with Willow is that it's not native here. Usually willows are in people's yards. You can check golf courses, they always have them and trim each year. Swamp alder is easy to find and is just as good as Willow. Swiss BP is made with Alder.

Macmac

March 25, 2008

Yes there is a yard willow here, that I could get branches from.. Alder is more common. No native grape right here in my woods, but I know it is around. It was common wild in the area in Mass north of Boston.

When I can get grape vine bark I will collect it as a good source if tinder.

The coment I was wondering if it was real came from you and the bit on cats and maple sugar. I just washed my filters so that mung is gone.

I guess it was more a joke than any real recipe for maple sugar at all, but since I am making maple sugar, I wanted to be sure it wasn't the sand that forms at about 217' degrees.

I hear ya on balsa, and while I don't know, after charring that I might dampen it and mill it alone, just to give it weight.

My idea is to learn and mimic your way as best I can, then take that education and work it in reverse for a no power whatsoever tech, so I will never again be without powder for so long as the wind blows and the rivers flow.

What I like best is the fact you claim I can make better powder than I can buy. I can't beat that with a stick 10 feet long.

I will have no choice but to buy KNO3, and sulfer. A small problem just now is being between any decent work. I get by finding odd jobs right now, but when summer comes I hope to find better working conditions.

Then get the tools I have learned about reading all this information.

I am sure there is alder right here along side the brook, just now that one for me is hard to tell from witch hazel. Not to mention I have something everywhere call snow 3 to 4 feet deep! Most of those little trees are 7 feet tall and only the tops show today.

scalper

March 26, 2008

This thread is very thorough about making BP, however, I guess I am puzzled about how to make the various powder sizes F, FF, FFF, and FFFF. I understand that you use screen with bigger holes and you will get bigger pellets of powder.

Can we get a bit more specific? I am after BP for my revolver so I am kind of after FFF. If I make it too fine like FFFF, what will happen to my revolver? Will it still work? How will this increased burn rate affect me (accuracy, residue, etc)?

I guess I am just looking for more direction on this aspect of powder manufacturing. Maybe screen sizes for various powder sizes or something more specific?

lgsracer

March 26, 2008

http://fogoforum.us/blackpowder.php

Has a paragraph on corning and screening.

scrat

March 26, 2008

I have read and heard a lot about using cheese graters. I am going to try that out. If it gets to find. from what I understand you can wet it again, bunch it up and do it again.

JCT

March 26, 2008

Of of the great things about BP has always been that when its wet you can just dry it out and it's as good as new. Try that with smokeless or substitutes.

Kitchen strainers work fine. What I end up with is probably 2F or so, but it's fine in my revolvers and .45 LC cartridges.

scalper

March 26, 2008

What if too fine (like FFFF)?

Out of curiosity, what happens if I make too fine powder like a FFFF and use it in my revolver? Seems like one of the videos floating around made some BP using a mortar and pestle and was really, really fine. Would it not work?

scrat

March 26, 2008

Speaking of mortar and pestle I recieved mine today.

Beagle-zebub

March 26, 2008

So what was the verdict on compressing BP when making it for firearms? The fogo link compresses it into those cakes, but the website appears to be aimed towards fireworks, not firearms. What say you?

zxcvbob

March 26, 2008

Compressing it has to be a good thing, but JCT says his powder is quite good without it. (because he uses better charcoal than Goex does)

In another week or two it should be dry enough here that I can test my powder again. I didn't compress it because I don't have a hydraulic press (and the pressing and corning is a little bit scary) My powder looks about like commercial FFF but it's duller in color. I used very good charcoal and very impure KNO3 and sulphur. (I don't think the low-grade sulphur matters, but the KNO3 and the charcoal do)

I'll look for a local source of good KNO3 this summer.

JCT

March 26, 2008

Pressing makes a denser and more durable grain. It allows you to fit more BP into a smaller area. Those are the advantages.

My unpressed powder, since it's less dense, takes up more space for equivalent weights of pressed powder, an example a 50 grain spout throws 46 grains in weight of GOEX. The same spout throws 37 grains in weight of mine. This is good since I don't shoot max loads anyway and 37 grains of my powder is as powerful as the 46 grains of GOEX.

I can fill my .45 LC cases to the top with my BP and seat a bullet to compress the powder. In weight, it's about 27 grains of BP, perfect really. Using GOEX would give me just about 35 grains. 35 grains is a heavy load in a SAA, but to back it off, you need wads or fillers. With my less dense powder I need no fillers.

I've tried dust straight from the mill, it fires fine, but is messy and hard to deal with in a powder measure. Granulating it is easy.

Also, I think the lower density grains allow the BP to burn up faster which yields more initial pressure, which should mean more accuracy.

Beagle-zebub

March 27, 2008

Could you compensate for using less or no sulphur by corning/sifting to a smaller grain-size?

JCT

March 27, 2008

You can leave out Sulfur if you like, it'll raise the ignition temperature though and the BP will probably not burn as hot or fast, which would mean it'll be dirtier.

At least a few times I've shot the Dragoon or Walker and not cleaned until 2 days later and I never see signs of rust. I think substitute powders are more corrosive anyway.

jimrbto

March 27, 2008

Why go through all the bother of pressing the powder, then letting it dry and then pound and crush it in order to make it into grains? Would it not be possible to take a pressed cake and force it through a screen before it dries? I understand that the finished product may have a density less than commercial but surely would be more that unpressed powder?

P.S. Just been offered an unlimited supply of alder.

zxcvbob

March 27, 2008

That description about pressing the powder into a puck is a little misleading. The powder should be pressed at a high enough pressure that the sulphur plasticly flows and binds it all together. (I doubt that you need any water at all for this to happen.) The puck will be too hard to grate it or screen it without crushing first.

JCT

March 27, 2008

You don't need water when pressing BP. The pucks you end up with remind me of clay pigeons or bricks. They're rock hard, you need to break them up to use any of it. I've pressed BP on a small scale, with comet pumps and star pumps, I just find that unpressed powder works great too.

scalper

March 28, 2008

Sulfurless BP

JCT and others have mentioned that sulfur is not required when making BP. However, he did say that the ignition temp will go up. Seems like the stink and maybe some corrosion might go down (just a hunch).

So two questions for anyone who knows:

1) What are some successful proportions (like 80% KNO3/20% charcoal) used by others in making sulfur-less BP?

2) What other properties are noticeable from leaving sulfur out? Projectile velocity? Pressures? Corrosive residue?

scrat

March 28, 2008

i have heard a few people mentioning replacing the sulfur with sugar. So whats the difference

JCT

March 28, 2008

Sugar is just another fuel, you can just use KNO3 and sugar only if you like, that's getting closer to Pyrodex, which I think uses fructose and KCLO4.

Sulfur is a fuel too, but I think it's role is as a catalyst or stabilizer. I'd have to read up again about that, I see no reason not to use sulfur, we all clean the guns after shooting anyway, the smell is part of it all

scrat

March 28, 2008

Ya I'm just going to have to do another internet order. I have checking every friggen pharmacy, drug store, hardware store for Sulfur. I can't seem to find any locally. I have the KNO3 just arrived today. So I have 1 lb of KNO3 and my mortar, pestle, and a four type cheese grater.

zxcvbob

March 28, 2008

Check the local garden centers for "dusting sulfur." It's only 90% pure though, so don't go hog wild with it until you've made a small batch of BP and tried it. (I think the purity of the sulfur is the least important of the ingredients, but I don't have any data to back that up)

scrat

March 28, 2008

You know what I did see some sulfur at Home Depot in the garden department. In fact I'd did say 90% pure. So I was not too sure of getting it or not. So your saying 90% is ok.

scalper

March 28, 2008

Interesting. I just located a database online entitled the PFP database with various pyrotechnic formulas. For sulfurless BP, they showed to following proportions (I assume the names are various expert preferences):

SULFURLESS BP -------------------------Lancaster------- Noble------ Noble------ Thomas Potassium nitrate-----------70.5------------80---------87.1---------70 Charcoal--------------------29.5-----------20---------12.9----------30and they had this interesting one under rocket propellants...

NITRATE/SUGAR BASED PROPELLANTS ----------------------------Candy propellant------Teleflite propellant Potassium nitrate-----------------74.5--------------------63 Sucrose--------------------------25.5--------------------27 Sulfur-----------------------------------------------------10It almost sounds like experimentation with various propellant formulas could be as much fun as that of reloading. Things sure get more interesting the more you learn.

JCT

March 28, 2008

I make BP rockets too, the only major difference is they use some air float charcoal, but some course charcoal too for tails. The KNO3 percentage varies depending on rocket size, but is between 65% - 70%. I add 3% baby oil to all that BP which keeps dust down and makes solid fuel grains that don't crack easily, so they don't CATO (Blow up).

zxcvbob

March 28, 2008

Quote:

So your saying 90% is ok.

I'm saying I think that's OK, I should know for sure next Tuesday if it's not raining or snowing. That's when I go to the range, and I'm gonna take some .45 LC cartridges filled with stump remover KNO3, cedar charcoal, and garden sulfur BP. (it didn't work very well last fall when the powder was still damp, but it did show some promise.)

The stuff is so cheap, how could you not try it before placing another internet order and paying shipping charges again? Just don't make a big batch the first time and possibly waste too much of your potassium nitrate.

scrat

March 28, 2008

You need to PM me as soon as you try it. If it works I'm on my way to Home Depot.

That or I'm going to be grinding a lot of match sticks. hahaha. Can that be done. I know its more than sulfur though.

zxcvbob

March 28, 2008

Don't even think about it. Match heads are totally different and they contain at least a little potassium perchlorate (very powerful oxidizer that could make your BP friction sensitive)

scalper

March 28, 2008

zxcvbob, why not let us all know how the low grade 'garden store' sulfur works out (in addition to PMing scrat).

zxcvbob

March 28, 2008

I intend to. But if it doesn't work satisfactorily, we won't know if it's the low grade S or the low grade KNO3. (or maybe even the charcoal) This is my first batch; I've got a lot of book knowledge but not a lot of practical experience yet But I'll get there.

JCT

March 28, 2008

I think the 10% impurity in the dusting sulfur is clay and other silicates. Maybe it's ok, maybe not. That's just more material that isn't part of the reaction and leaves fouling and dirt.

It's a one time expense to buy your chems and can work out to about $3 to 4 a pound for you finished BP.

zxcvbob

March 28, 2008

Oh, I understand and agree with that. But I had the dusting sulfur and the stump remover already, and it is doing a fine job for a "proof of concept" batch of powder. I think the 10% impurity is probably insignificant because S only makes up 10% of the mix, so it's only 1% impurity in the final product -- and the sulfur is the least important ingredient. The limit with my ingredients is probably gonna be the impurities in the stump remover. I should either purify it next time, or find a much higher-grade source of potassium nitrate.

scalper

March 29, 2008

When I get a bit more time, I am going to try some of these alternative formulas for BP (sulfurless BP and nitrate/sugar BP) and post the results. The goal being to create something that packs a bit more wallop. Anyone else done anything like this?

zxcvbob

March 29, 2008

I suspect the nitrate/sugar gunpowder is really gonna mess up your gun with sticky residue and be hard to clean.

There's a difference beween making small arms propellant, rocket propellant... and quarry-blasting powder for that matter. Stick with the classic, make small adjustments if necessary, and work on your technique.

scalper

March 29, 2008

You are probably right, though I have a couple of 'junk' guns I use just for things like this. After wasting a bunch of time reading various post all over the Internet from experts, novices, and the companies that make it, it sounds like searching for an improved BP substitute is a bit like trying to invent a perpetual motion machine. You can't improve on what is already perfect.

Still, curiousity gets the best of me. And this sugar/KNO3 version really has me curious too, since apparently some of the substitutes use fructose, obviously a close chemical cousin to sucrose. It makes me wonder what the reasons for using carbs was? Was it to burn cleaner?

I am also curious what 'rocket fuel' it might do to the old chronograph.

JCT

March 29, 2008

Sugar is very hygroscopic though, it'll make your powders clump and pull moisture from the air.

The only think I'd be interested in trying someday would be "Benzolift." It's about 2 times more powerful than BP. It's a mix of whistle mixture (KCLO4, Sodium Salicylate and Iron oxide) and Black Powder. Pyros use it for lift charges, rockets, burst charges... etc. It's supposed to be very safe to deal with, and might make a good gun powder. I'd definitely want to do some tests first.

Here's a great page on BP (I should have posted this awhile ago!)

http://www.wichitabuggywhip.com/fireworks/blackpowder2.html

scrat

March 29, 2008

Part I hate was saying you can get sulfur powder at any drug store. Ya right.

zxcvbob

March 29, 2008

Check with the pharmacist. You might also check someplace that sells farm supplies (like Fleet Farm) in the veterinary aisle.

Beagle-zebub

March 29, 2008

It occurs to me that if you were to perform mass-spectrometry on a sample of charcoal that had been well homogenized, you could find out the optimum proportion of KNO3 for that sample, unless not all the atoms that could react with the KNO3 were able to break the molecular bonds of the charcoal; even if that were the case, it might be easy enough to figure out from the atomic proportions in the charcoal what the composition was, with particular interest towards finding parts of the molecule(s) to rule out as reactants.

Where, you might ask, would one find a mass spectrometer? Well, I know my old high-school had one, so that's the one I would try to use. You might be forced to consult a company like LabCorp, which may or may not be worth your money.

Pulp

March 30, 2008

I just ordered KNO3 and S from Phil. 5lb and 3lb respectively. Total with shipping, $35.73. That should make 6.57 lbs, for a price/pound of $5.34. Plus I'll have a whole lot of S left over since I'll only use 1/2 pound of it. Sure beats the $20.00/lb BassPro tried to charge me in Tulsa awhile back.

BTW, I saw pawlonia wood mentioned as a good wood for charcoal. I have a pretty good sized chunk of that.

woad_yurt

March 30, 2008

I read somewhere that they used to use urine to wet the powder way back. A wine drinker's urine was prefered to a beer drinker's, in case you want to go totally traditional. I haven't read all of the posts so: Has anyone mentioned that they called the wetting/making granules process "corning?"

zxcvbob

April 1, 2008

Quote:

zxcvbob, why not let us all know how the low grade 'garden store' sulfur

works out

I loaded six .45 Colt cartridges with about 27 grains of my powder (stump remover, garden sulfur, and cedar charcoal) and a 230 grain bullet. I could have got about 28 or 29 grains of powder in if I had really compressed it. I also took a couple of smokeless powder cartridges with the same bullet for comparison. (I think they were 7 grains of Red Dot, but they might have been 7.5 grains)

I just had a few minutes to shoot outdoors before going in to the indoor range where I was on duty tonite.

The powder worked great. The recoil was about the same as the smokeless loads. Of course they sounded much different. BOOM! I was just taking one-handed quick shots at a 9x11" target someone had left set up at 75 feet, and all 8 rounds hit the target.

I have 2 more pounds of stump remover that I bought on clearance at Walmart for $1 a pound. This summer I'm gonna check at all the grain elevators and farm co-ops around here to see if any of them sell (or can get) "spray grade" potassium nitrate. It should be less than $20 for 50 pounds, the hard part is finding it. I could order a bag from a place in Florida, but it would cost $50 to ship it that far.

The garden sulfur obviously is good enough. The stump remover KNO3 is good enough but probably has much room for improvement.

Beagle-zebub

April 1, 2008

zxcvbob, that's fantastic news! I can't wait to try this myself, but it won't be until this summer at earliest.

Shotgun Willy

April 1, 2008

I've been reading this and thinking about whether I want to try it or not. One thing that came to mind was that my wife has started buying hardwood charcoal in 10 lb bags. I'm not talking briquettes either, it's actually chunks of charred wood. The name of the company is Ozark Oak. It doesn't say exactly what trees they use but I'm pretty sure we can assume it's mostly oak. When I googled it there was some speculation that it might have some hickory in it too. I believe she gets it at Wallyworld for $5 or $6 a bag. Anybody know anything about oak and/or hickory in BP?

lgsracer

April 2, 2008

Ran across some different black powder formulas:

http://www.thegreenman.me.uk/pfp/bp.html

Pyro Database - Black Powder.pdf

scrat

April 2, 2008

Excellent job ZXCVBOB looks like im going to get that 90% Sulfur.

scalper

April 2, 2008

This is really good news ZXCVBOB. I already have my saltpeter (10 pounds) and the willow charcoal (2 pounds) enroute. Now all I have to do is head to Wallyworld or some other garden shop to get the sulfur and I'm in business. I am figuring that I will be paying about $50 for 13.33 pounds of BP. So the final tally is about $3.75 a pound. Since I get about 350 shots out of a pound (I shoot 20 gr in my BP revolver and 7000 gr=1 lb), that works out to a little more than a cent per shot (for the propellant only). How's that for economy. This has my factory ammo buying non-BP buddies drooling. :-)

I also just got one of those el-cheapo Super Comanches that shoot 45LC and .410 shot shells. I am going to try some BP reloaded 45LC in it on it's debut at the range in addition to my C&B revolver.

Also, just got McLean's book (The Do-it-yourself Gunpowder Cookbook) and he discusses "red-or-white propellant" that uses saltpeter, sugar (sucrose), and ferric oxide (rust). He mentions the hygroscopicity of the final product but I get the impression that it performs about like BP. I know we have discussed the sucrose idea, but anyone know what the rust does? Does it somehow lower the ignition temp or function similar to sulfur?

lgsracer

April 2, 2008

I really like the idea of using rye straw charcoal (see post 120). That was the last black powder formula the US military used up through the Spanish- American War.

scrat

April 3, 2008

Of all places I ordered sulfur from amazon.com. So my stuff is on the way.

zxcvbob

April 3, 2008

Quote:

anyone know what the rust does? Does it somehow lower

the ignition temp or function similar to sulfur?

The iron oxide is a catalyst that speeds up the reaction (I'm not sure how in this case.) The type of iron oxide used is Fe2O3, which is available as red jewelers rouge powder.

I suspect this is more of a rocket propellant rather than a small arms propellant because it would be easily cast or pressed to make hollow tube- shaped cores.

scrat

April 11, 2008

I have all my ingredients ready to mix. This afternoon I'm going to spend some time making a small batch of BP the old way. So wish me luck

SIGP2101

April 11, 2008

When you guys mixing ingredients, how do you measure them individually. By weight or by volume?

scrat

April 11, 2008

Grams scale. By weight.

Redd Flynt

April 12, 2008

I've always used metric weight. Office Depot has some good postal scales that are digital and work well.

scrat

April 12, 2008

Redd how much are them scales they have?

scalper

April 12, 2008

You can measure by volume if you do your homework.

It may be obvious to you all, but you only need to measure by weight the first time. Once you know the correct volumes that make up these weights, you can then use volume. Assuming your supplies are relatively consistent, this should work well. Then you can treat it as a recipe (1 cup of this, 2 tablespoons of that, etc.)

Sort of the idea I took away from those little Lee's powder scoops that eliminate the need for a reloading scale. I've used this approach in reloading for years with great success and fewer headaches.

The key is to be careful and double check the weight of your predetermined volumes. It also might be wise to double check the weight when you are using a new supply of raw materials (for instance, the charcoal may not be as finely ground making the volume a bit larger for the same amount of weight).

Sorry, if I am stating the obvious, but thought it might be important to mention since we are talking scales.

scrat

April 12, 2008

You know what, that's a good idea. As soon as I perfect what I'm doing I will use the Lee dippers to figure out how much.

JCT

April 12, 2008

It's worth weighing and being accurate with powder.

Check eBay for an Ohaus Scout or Adventurer. I found a used Adventurer model that sold new for $580, I paid $55! Great lab scale with 2000 gram capacity. I even use it to weigh smokeless when reloading.

scrat

April 12, 2008

Ya I'm using an electric that I use for reloading now. but it sure would be good to be able to use a dipper. I guess you're right though you need to be very accurate.

Rachen

April 12, 2008

I always leave out the sulfur, and add a little more charcoal. It helps burn cleaner, and with less smoke.

scrat

April 12, 2008

Well my first three batches were all duds.

1st batch after all said and done I put a 1/2 teaspoon on a brick and lit it. It kinda went pooof.

2nd batch same thing but this one went poooooof.

3rd batch same thing but this one went pooof.

Then I put about 1/2 teaspon of Goex 3F on the brick and lit it. POF. really quick with a quick round cloud.

So ya, back to the drawing board. Only fun I had with mine was putting it in an envelope and throwing it in the bbq. Made a nice flash pooof.

scrat

April 12, 2008

I doubt this would be able to shoot through a gun. It burns but slow burning.

1st batch formula was 93 grains KNO3, 16 grains charcoal, 12 grains sulfur

2nd batch was 100 grains KNO3, 18 grains charcoal, 16 grains sulfur.

3rd test an experiment I used 100 grains KNO3, 14 grains charcoal, 12 grains sulfur, 10 grains sugar.

Yep I am doing very small batches. I'm trying to perfect my skills before going bigger.

zxcvbob

April 12, 2008

My first batch was like that -- turns out it was still too damp when I tested it. I put it in a very warm place for a couple of days to dry (on top of a heat duct in the basement); it actually changed color from black to dark gray. When I tested it again it worked great.

scrat

April 12, 2008

Really. interesting. I have a small amount of batch 1 and 2 left. I guess I will wait a few days and try it again. The sugar I would not recommend. It leaves a white residue all over. I read and heard it does but did not know how much. Well it does. I really don't think it improved anything either. I have been using rubbing alcohol to mix, not water. Next I want to try the same procedure but with acetone. Need to see if there is a big difference or not.

Redd Flynt

April 12, 2008

The scale I bought is a Pelouze model SP5 2.2 kg. I've had it for several years now and don't recollect the price. I'm sure they have gone up in price but it was a heck of a lot cheaper than a digital powder scale.

Redd Flynt

April 12, 2008

Scalper;

I made some dippers (3 each) from PVC pipe and cut them just shy of the proper weight and then top off with the scale. The charcoal is a bit difficult due to the way it settles and or has some small chunks. The Nitrate and Sulphur (if I use Sulphur) work quite well.

scrat

April 12, 2008

Hey can some of you guys check my formulas. I know this is small scale but I am just feeling the waters and doing small batches. This is what i used.

1st batch formula was 93 grains KNO3, 16 grains charcoal, 12 grains sulfur

2nd batch was 100 grains KNO3, 18 grains charcoal, 16 grains sulfur.

zxcvbob

April 12, 2008

The following in grains to test, and grams to do a usable small batch (and ounces for a very big batch ):

100 KNO3

20 charcoal

13.3 to 14.6 sulfur

scrat

April 12, 2008

Cool thank you thank you thank you.

I guess I know what batch number 4 is going to be.

Pulp

April 13, 2008

I was kinda forced into the following, since I had a major malfunction in the charcoal making process. I ended up with 41 grains of charcoal, which is 15% of 275 grains of KNO3 and then 27.5 grains of S.

Scrat, I'd think you'd want 100, 15 and 10. That would be the 75-15-10 ratio. Don't quote me, but it sounds like you used a bit too much charcoal and S for the amount of KNO3.

zxcvbob

April 13, 2008

Pulp, your doing the math wrong. 41 grains of charcoal shoulda given you 205 grains potassium nitrate and 28 grains of S to give you a 15:75:10 ratio.

scalper

April 13, 2008

Redd - I like the 'scoops made from PVC' idea. You guys are all so original in your thinking. That is why I enjoy reading this thread so much.

Scrat - so on your testing, are you using the cheese grater to make the granules of BP? How dry is your wadd of BP clay getting before you use the cheese grater? Are you sure your final powder is dry enough?

scrat

April 13, 2008

Well I think that may be some of the problem but not all of it. Yesterday was 90 degrees here. So I left it out in my back porch until the afternoon. It was grated down. I used a cheese grater. Then I chopped it up some more as it looked more like 2F than 3F. So I'm pretty sure it was dry. I'm going to try out the remaining of the 2 batches I have left tomorrow. That will be 3 days. As far as how dry it was when i grated it. I would say not that dry as if you pushed your finger in it wet spot would come out. I put down a coffee filter and put the powder on top of it. Found that the coffee filter will quickly absorb the moisture. It just seemed like a huge difference between Goex and mine. The Goex burnt fast, very fast. Just a big POF. Mine was more of a poooof. You could not count to 1 with 1/2 a teaspoon of goex. Mine you could count to 2, almost 3.

JCT

April 13, 2008

Scrat, I think that's about as good as it gets with a mortar and pestle. A properly charged ball mill really makes a huge difference. A chunk of my powder out of the mill displaces all the air around it. It's extremely fast and hot BP. Noticeably faster than even GOEX.

scalper

April 13, 2008

Being the impatient man that I am, I had tried using a mortar and pestle too. I just mashed and mashed the ingredients till I had a really super duper fine powder. Heck, I thought it looked like a 10Fg powder, it was so fine.

When I tested the fine powder it burnt really fast. After asking many on this board on a thread about using 4Fg powder in a gun, I decided it would not be a very prudent substance to put in my gun. I haven't done anything with my 10Fg yet, but I suppose the next step is to make my little clay ball and get the cheese strainer out. (BTW-It would sure be nice to buy strainer with various size holes that would stack and that would sort out the powder into various sizes. I have seen these, but don't know where to buy it.)

So hang in their scrat and keep pluggin' away. I know the ingredients will work, it is just a matter of slowing the burn rate down a tad by creating larger granules. Maybe the stuff wasn't dry enough or maybe the granules too big, but keep trying cause will get the right mix hammered out.

Scrat, maybe you should try creating the raw powder that I did and then do a test burn. That might at least verify that the ingredients are good enough.

Anyone else have any 'foolproof' ways to get the right size granules? I am targeting 3Fg, but anything that gets me close will work. Any better suggestions than cheese graters? What about these tray sortin thingies that I mentioned, anyone have a clue where to get them?

Oh, yeah, and my favorite 'grain-based' BP recipe:

75 grains Saltpeter

15 grains Charcoal

10 grains Sulfur

Sorry, couldn't resist. I prefer simplicity.

scalper

April 13, 2008

I guess the stuff I created is called 'meal powder'? Supposedly, it burns uncontrolled, which I can verify does work! For sure!

I just read this on the muskateer.ch site and thought it was pertinent.

So, scrat, I would suggest the idea again of testing some of your 'meal powder'. Don't use water or any other solvent. Just mix up the ingredients really well and super fine. Test it. Then we will know if your ingredients are good enough to go to the next step.

Oldnamvet

April 13, 2008

Screening blackpowder.

If you have a lot of $$ to spend, testing sieves will get you a very fine particle cut. I used to use them for various things when I was employed.

http://www.coleparmer.com/catalog/product_index.asp?cls=2885

these are the screens I am referring to. They come in brass or stainless but are brutal on your checkbook -- especially when you are trying to minimize costs of your hobby.

DutchmanDick

April 13, 2008

Buy Foxfire: Volume 5. It has a complete section on building muzzleloaders the REALLY old-fashioned way, as well as the directions for making blackpowder like they did in the Appalachians right up into the 20th century. For that matter, get the entire Foxfire series of books. Really interesting reading for anyone on the THR forum!

scalper

April 13, 2008

Quote:

These look things really look great, but you are right, they are pretty

pricey. They will have to go on my 'wish list'. Probably should buy the ball

mill first. Gonna have to work on the wife first.

Lets see now, screens. Walmart, two three drawer plastic stack boxes. Junk

store, frying pan splatter guards, several mesh sizes. Back to Walmart craft

dept. Plastic mesh used for embroidery, comes in diferent mesh sizes.

Cut the bottoms out of all but one drawer and cut the tops out of the support

frames. Cut the bottom out of one frame. Fasten the whole operation to some

scrap plywood and hold together with bungee cords (Dollar Store).

Fasten an orbital sander to the plywood next to the stack drawers. Pour the

powder from the broken cake in the top.

Next and most important step. Put the whole kit and kaboodle inside a large

clear plastic trash bag and secure the open end around the drawers and board.

LEAVE THE SANDER OUTSIDE THE BAG. If it's not obvious by now please know that

the motor in the sander can make electric sparks. The sparks will set off the

fine dust and then the whole shebang goes BANG

Turn on the sander and watch the powder sort its self out.

The top box holds the very large chunks and obviously the bottom catches all

the very fine grains and LOTS of dust. The dust is simply reintroduced to the

next batch and re-pressed.

I made some really fancy wood screen boxes that are air tight just for fun.

The main point is that screens don't have to be expensive. I don't try to

match the grain size of commercial powder but rather get a variety of sizes

that I can duplicate in a consistent manner.

I just use a 6" kitchen sieve that I had already. It's made of coarse

stainless steel mesh.

You're trying to make it too complicated. Until you start pressing and corning

your BP, you don't need multiple sieves.

I just got through wetting and screening my first batch. Again, I had charcoal

making problems and ended up with about 170 grains of charcoal. Boy, it takes

a LOT of charcoal to weight 170 grains.

Anyway, before I wet and screened it, it burned very quick with a good PHOOF.

Now I just got to wait for it to dry. Gotta work tomorrow and Wed., so maybe

Thursday I'll be able to test the final product.

I just used a kitchen screen sieve for screening, powder looks about like

FFg.

Well Pulp, sounds like you got the mix down pretty well. You are right about

the charcoal, it takes a lot of it to make the 15 percent.

Keep practicing with the charcoal making, it'll get easier as you tweak the

process.

My little tin can kiln holds ten pounds of wood and yields two pounds of

charcoal. It's all in the charcoal.

Bingo. Got the mix right. Tried a small amount today and PUF. Burnt about the

same as Goex. This mix has only been drying for about 24 hours. Will try it

again then probably hit the range on Sunday.

I usually let mine dry for about 12 hours. You can tell when it's dry enough.

BP can be overdried. I think having a very small amount of moisture left in it

allows it to be more powerful due to the extra gases. I don't mean wet BP, but

don't over dry it either. 12-16 hrs should be more than enough.

Quote:

I know, but being able to see my targets more clearly right after I fire is

also important.

Question on mixture

Ok Question i have on the mixture from what i think having just the right

amount of nox to charcoal will give you effective results. Having a little

more nox will give you better. having too much will start to give bad results.

Or is it having more charcoal that gives you better results which is it. Im

right where i think i need to be. But was thinking what would i have to do to

make it better add more nox or more charcoal.

So scrat, what did you do different this time that made such a difference in

the results?

I changed the formula then made it the dangerous way.

150 grams kno3

Put a bottle of rubbing alcohol in the freezer.

Grinded KNO3 to a fine powder with mortar and pestle. Then put in cup. Put

charcoal and sulfur in mortar and blended them to a very fine mixed powder.

Got out the pan turned on the overhead fan. Put the stove on medium heat.

Poured in 3/4 cup of water. Added the KNO3 then stirred it until it was

completely dissolved. Then slowly added the charcoal sulfur mix. Then started

mixing it and mixing it. As the water started to evaporate and filter in the

mix. I lowered the heat. At first i did not like the look to well so I added

some more water to keep it wet until I felt it was really mixed. Then I added

some alcohol to the mix under a low low flame and kept stirring. As the water

evaporated I turned off the stove added some more alcohol. Then stirred it up

some more. By this time it was really thick and pasty. So I gathered it all

up. Put out some new papers. Put the big hot ball on the paper. Took out the

cheese grater. Then grated it all up. At first it looked more like 2f. So I

took out a long fine knife and slowly went over all of it to make sure it

looked like 2ff. Then I had it spread out pretty big. Left it that way for

about an hour. Then put it all in a cleaned up plastic coffee container. Then

put the lid on it. Yesterday after about 2 hours. I could tell the stuff was

going to be powerful as you could really smell the alcohol and powder.

Today when i lit it. The stuff was strong, very strong. Good strong smoke too.

Just like Goex, maybe even better. I want to try this again with some willow

charcoal. Also want to know what i can do to make it better add more KNO3 or

more charcoal.

Dangerous?? No kidding. Alcohol + open flame + blackpowder = KABOOM

Potassium nitrate is very soluble in water so heating is not needed. Getting

the slurry mixed well could be done with a kitchen wisk, no flame needed.

I think the only problems in adjusting the ratio is that the KNO3 is the

oxidizer, the Charcoal is the fuel. You can use more KNO3, then the fuel is

burnt up faster, but you have less gases since there's less fuel. In a

revolver, that might be ok. In a rifle I'd think you'd want a more gradual

pressure build and slower powder is ok.

75% 15% 10% works so good I never saw a need to try anything else in shooting.

I do other ratios for BP rockets though.

I just came across a bunch of swamp alder, I'll be making a batch with it to

compare to willow. It should be as good, possibly better. The hottest BP I've

ever seen was when I made a batch using balsa wood. It was lighting fast and

bright too (hot). That might be the ideal BP, but Balsa is so light it's

tough to mill.

So one of you guys have to give me a deal on buying some charcoal from. I

tried that one site listed on page one. Sent the guy an email and I still have

not heard from him. I'm having a heck of a time getting good charcoal that's

the problem.

This is the method i used.

CIA BLackpowder

http://krimzonpyro.com.ve.carpathiahost.net/rat/compositions/ciabp.html

Ok this is all i can find. anyone know if this will work or do they put

additives in it?

Do you really want to pay almost $12 for a half an ounce of charcoal?

Sugartown Products Inc, Gladwin MI makes charcoal from mixed hardwoods with no

additives. A 10 lb bag costs around $9 the last time I bought some. REally

great for grilling, which is the market. Looks like the chunks of wood it was

formed from. Wonder if it would be of any use? Considering the trees in this

area, it is probably made mostly from maple and oak, with some poplar,

cottonwood, etc thrown in.

http://www.micropyrotechnics.com/willowcharcoal.htm was this the site you

already tried?

Stop by the google group recreational pyrotechnics. there's people there with

hoards of Willow charcoal that will help you out. Tell them you're already

making BP but need better charcoal.

Yep, emailed him twice have not heard from him so far. Ok so now try the

Google group recreational pyrotechnics. How da heck do I find them. ok

searching google.

Here it is;

http://groups.google.com/group/rec.pyrotechnics/topics?lnk=lr

I used to post there a lot, but it has so much spam now... A few people in the

group are pro pyro display builders, they have complete facilities to make

charcoal, BP, shells, mortars... etc.

Scrat, I just bought from Steve at:

http://www.micropyrotechnics.com/willowcharcoal.htm

Nice guy and the charcoal is great. Are you sure he isn't going into your spam

filter or something?

He takes PayPal too which made the whole thing real easy.

Instead of charcoal, has anyone tried plain old coal?

My father-in-law used to get coal delivered by the truckload in central TN; he

used it for heat. I always meant to get a piece or two as a souvenir when I

was visiting, but never remembered when I was there.

For making BP I had a coffee grinder that worked very well to mill the KNO3 in

but only a mortar and pestle for mixing all ingredients together... but yes I

tried a very VERY small batch of coal based powder, it did not work very great

but it would move a bullet with deadly force no doubt.

I think charcoal works better because it has so many pores that the actual

surface area is really very huge... I think United Nuclear stated something

about this on there site, but coal is very hard (hard enough to break my

coffee grinder blades, sadly) and smooth so the sulphur and KNO3 would have a

problem reacting with this...

Little bit more info, you dont need coal or charcoal you can use confectioners

sugar, regular sugar for smoke bombs LOL, graphite or any other readily

avilable source of carbon, maybe powdered milk or creamer too? Sugar is messy

and makes things get wet too fast and I think charcoal is pretty easy to make,

put some willow or grape vine in a coffee can with lots of tin foil on top and

a match stick sized hole, and chuck it in the fire till smoke stops coming out

the little hole... umm... don't take off the tin foil till it cools off either

or it will catch on fire and burn up.

Okay, I'm making progress. I have my digital scale and a precision Ohaus

balance scale, stump remover ($5 at Lowe's), 90% sulfur ($7 at the local ACE

Hardware), a bag of ordinary Kingsford charcoal, a bag of cedar chips, a box

of thoroughly dried pine board scraps, a bag of confectioner's sugar, and a

box of coal. There's no coal here, but a 'net buddy said he would send me

some. He sent 32 pounds of it. I guess when you're heating with it, "a little

bit of coal" is a somewhat larger amount than when experimenting with

gunpowder... I also have a homemade ball mill and a couple of cans of

commercial black powder to use for comparison testing. I still have to acquire

a gun to use for experimentation; I don't want to use any of the ones

currently own.

The plan is to build a spreadsheet of powder mixtures and preparation types,

then load a small batch of each to get a quickie idea of smoke and fouling,

then refine the cleaner ones down by bullet weight, primer type, etc. At this

time I'm more interested in getting a clean burn than muzzle velocity.

I'll be testing all the usual BP formulations, including the sulfurless ones,

coal, different charcoals, sucrose, fructose, corn syrup, molasses, etc. I've

probably been reading way too much rocket motor stuff, but the idea of simply

casting cylindrical propellant charges, dropping them into the cases, and

seating the bullets appeals to me more than making powder.

I don't know what formula or instructions that you're following, but here's

information about how to make charcoal for black power:

And from the same source, here's how to make home made black powder:

I hadn't seen that one, but it's the same basic process I've seen elsewhere.

However, it's one of the very few that doesn't start with "first you get a 55

gallon drum..."

OK first of all I would scrap the materials and start all over. Been there

done that. You need black willow charcoal powder. Re read what was in the

pages a few back. A good source for NOX potassium nitrate is eBay or Amazon.

Same with sulfur. You need to get pure ingrediants. Charcoal briquettes won't

work - you will make black powder that will fizzle but not be good for anything

else. Re read everything. Pure ingrediants and a ball rotary tumbler are the

best to use. There are several methods of making it some work better than ever

and some don't.

Something I might be able to add to this...

Here's some information you may find useful or interesting. I suggest you

actually buy the Von Maltitz and Sponenburgh books as these are living authors

who deserve something for their efforts. If you're broke or don't care, you

can download these from the net for free - Tenney Davis has passed on (and is

out of copyright), the US Gov't. will be happy you bothered to download (and

follow!) the federal explosives laws.

Getting Legal:

BATFE "Orange Book" (Federal Explosives Laws & Regulations):

Ian Von Maltitz, Black Powder Manufacturing, Testing & Optimizing:

http://pyrotechnic.narod.ru/Black_Powder.pdf

Sponenburgh, Ball Milling Theory and Practice:

pyrotechnics_ball_mill_theory_sponenburgh.pdf

Tenney Davis, Chemistry of Powder and Explosives:*

the_chemistry_of_powder_and_explosives.pdf

Look at the history of the DuPont family. Notice all the dead (mangement

level!) people, and blown up mills?

Google the names of any black powder maker, historical or modern along with

"explosion", "deaths", etc. You will find plenty.

After Du Pont sold the last powder mill in the USA to GOEX, there were a

series of problems. A lot of you know about the GOEX production moving out of

PA, then moving again- The meaty part starts at page 10.

http://www.laflinandrand.com/madmonk/history.pdf

The below is a re post of some BP information I put up elsewhere-

In my research regarding powder mills in the Texas hillcountry and Bexar that

supplied the Confederacy, it is interesting to note that they made powder

using cedar charcoal, nitre from bat guano, and sulfur imported from Mexico,

kinda like John Glanton and the Judge did in "Blood Meridian" in the cave they

were hiding in.

I am a novice and have nothing to offer at this point but I find this all very

enlightening. I want to extend thanks to those whose wisdom I will pilfer as

often as possible.

Being a nube, I feel somewhat intimidated by posting this here; but, after

looking around a while, this is the best site I've found on how to make diy

bp. Almost forgot, but this page lists the best charcoals to use (some way too

fast for our use, more like flash powder without dark german aluminum - makes

one wonder how fast they'd be if the alum was added). The chemicals could be

picked up at Lowes or Homo Depot (Gardening sections, just "Dusting" sulfur

[check the purity, 98% or better is what you'd want], and ol' reliable "Stump-

Out" [again, check chemical purity for 98% or better].). Most of the time (as

far as home maker's are concerned,) it's the type of charcoal (not the

chemical purity-) as well as the fineness of that charcoal (i.e., ballmilled

for 76 hours v/s. being pulled out of your bbq pit 10 minutes ago-) that

determines the quality of your home-made bp. Also, (I could be wrong, not a

lawyer but rather what little sense God gave me, you'd need to check it out

for yourself-) as long as you've less than 50 lbs. of small arms propellant bp

(rather than a "commercial" 51 lbs.; or 30 lbs. of aluminized bp or something