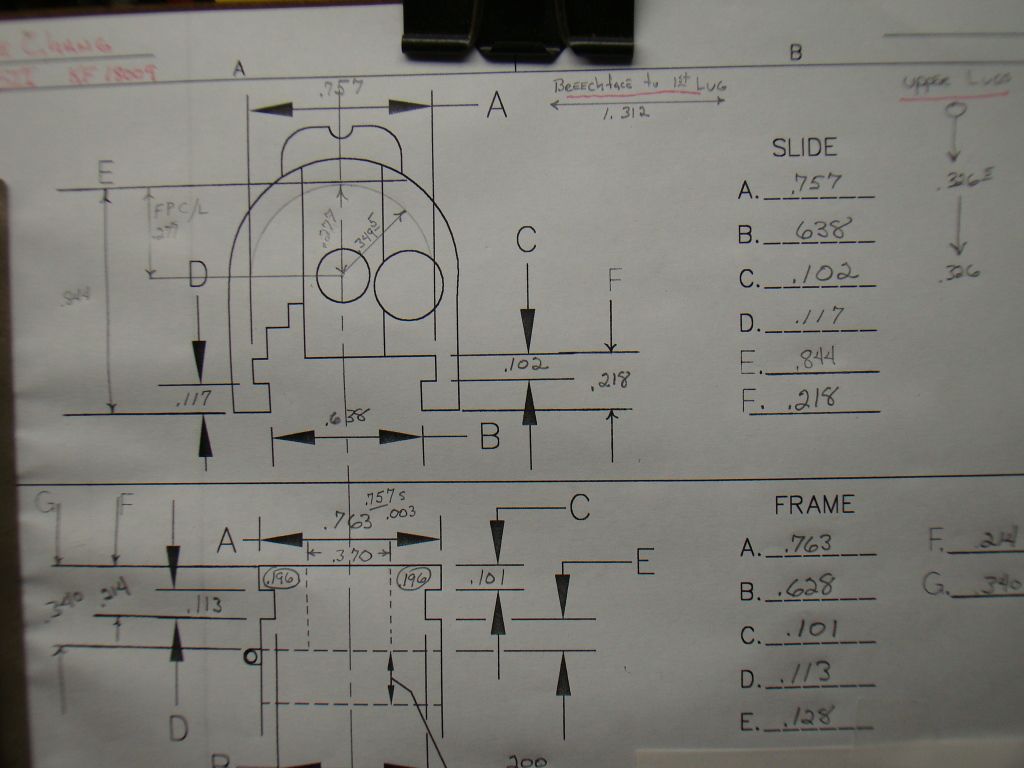

Mapping document. If you don't know where you are... then you don't know which way to go...

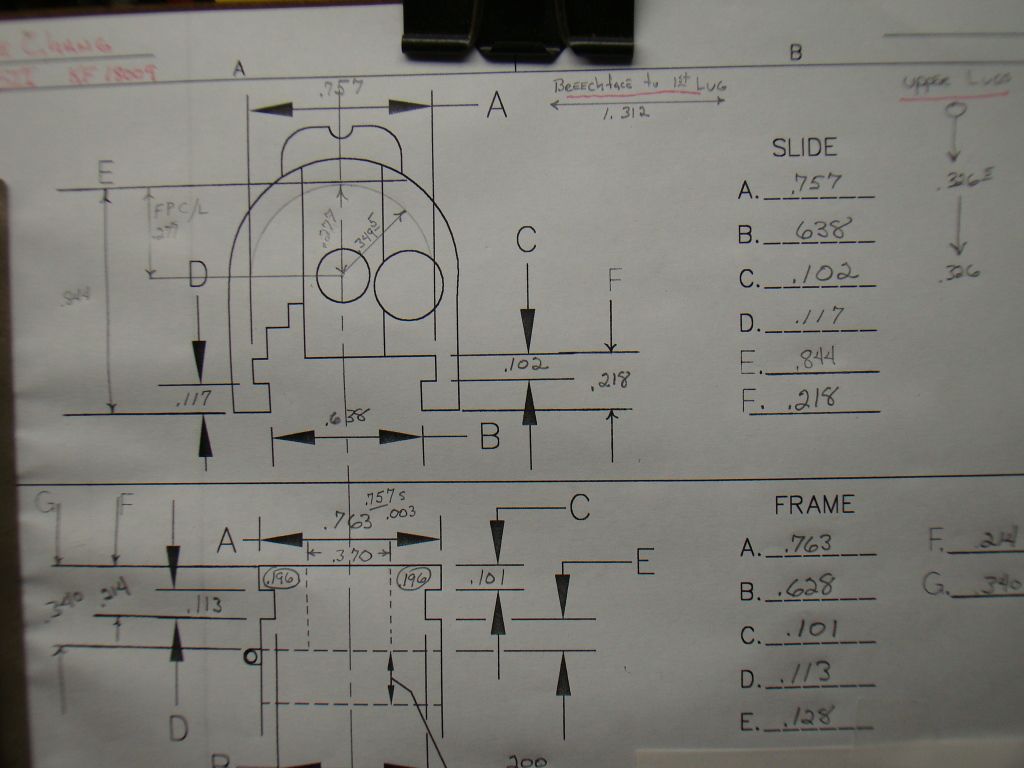

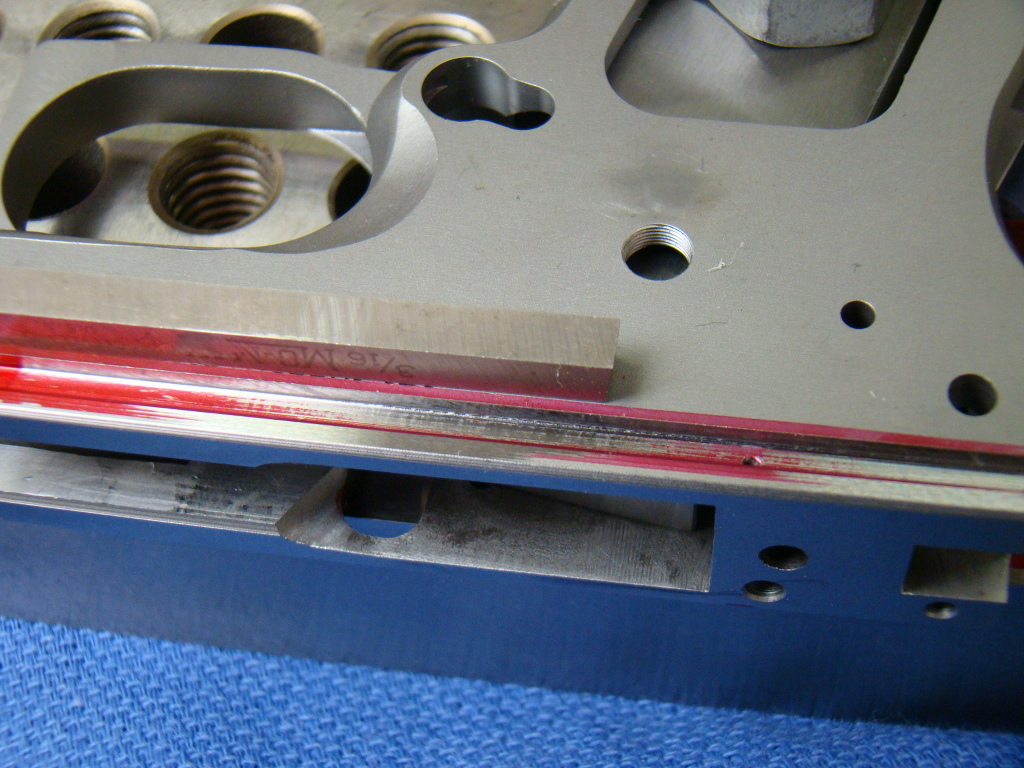

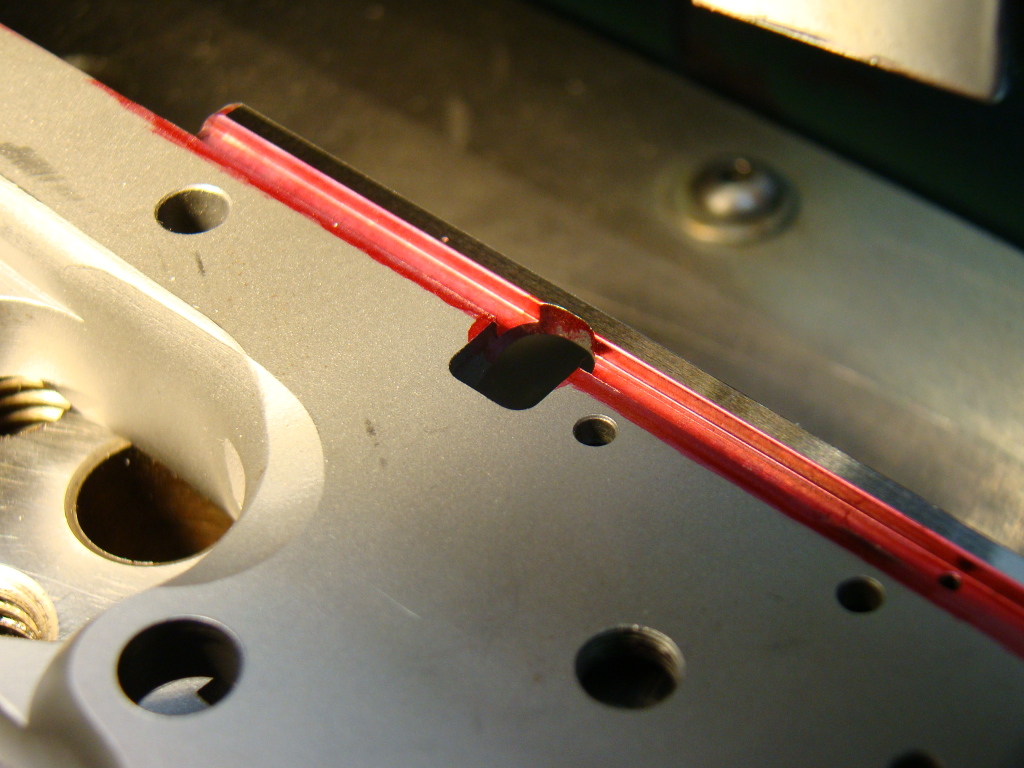

Slide fitting bars and Dykem Hi Spot... No Lappping Compound!

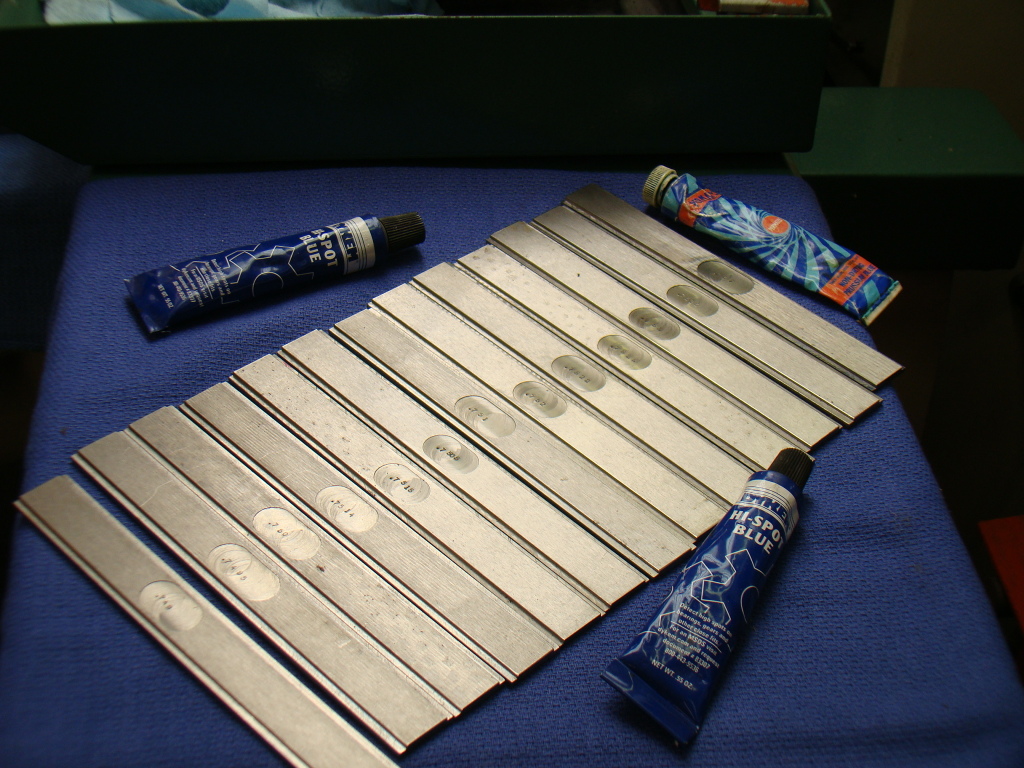

Setting up the frame for the cuts..

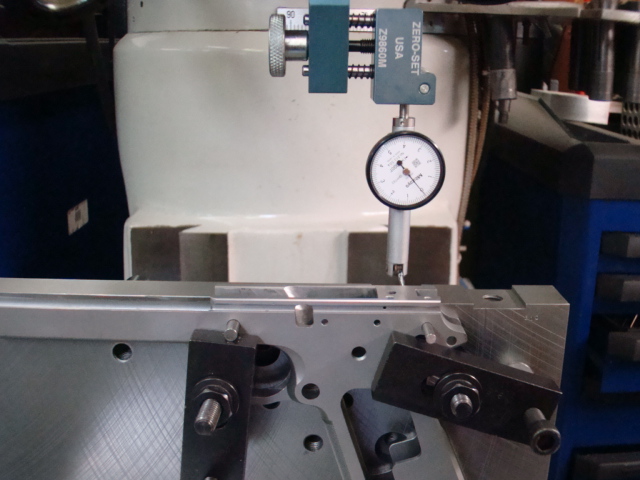

Indicating in the frame

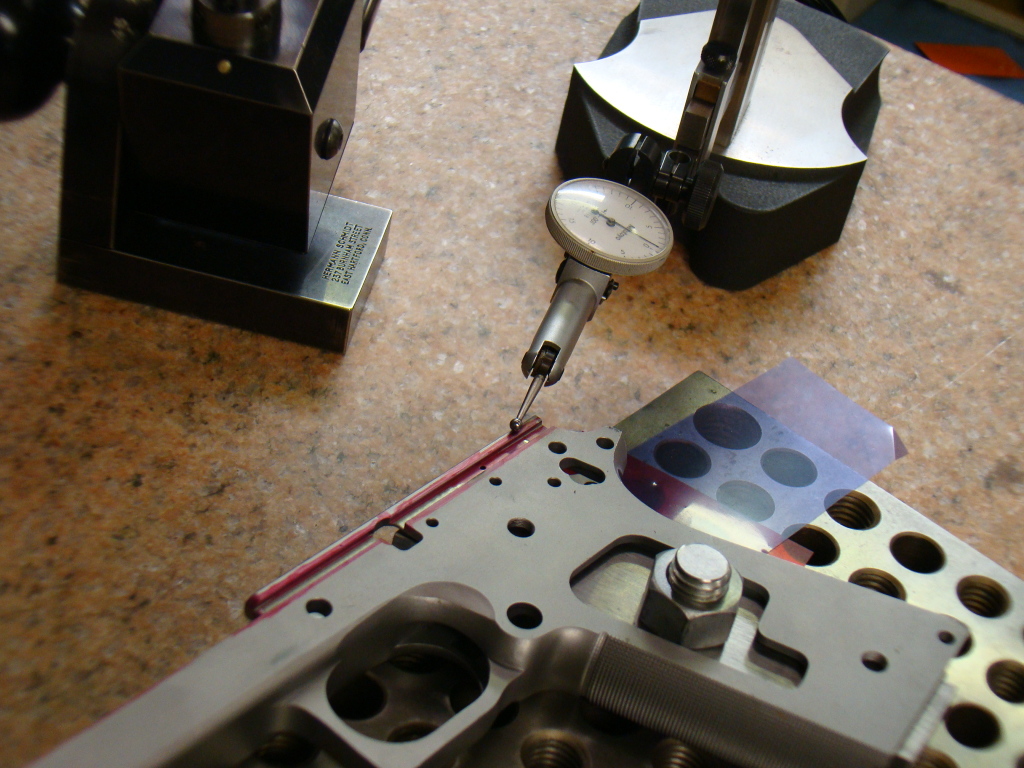

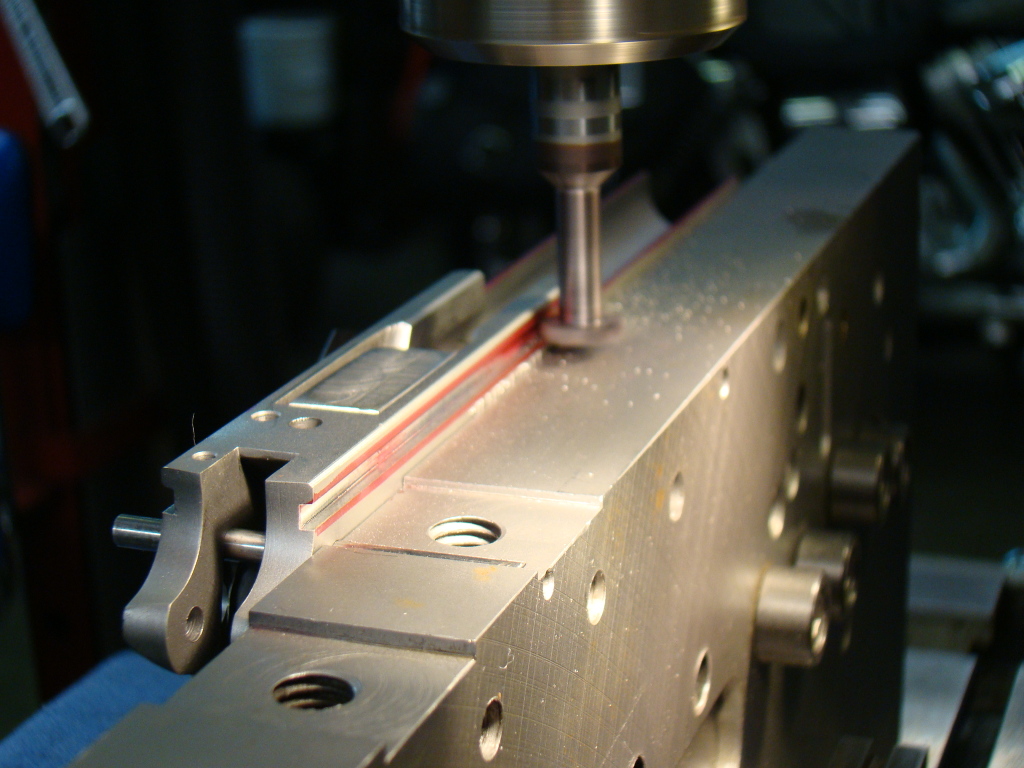

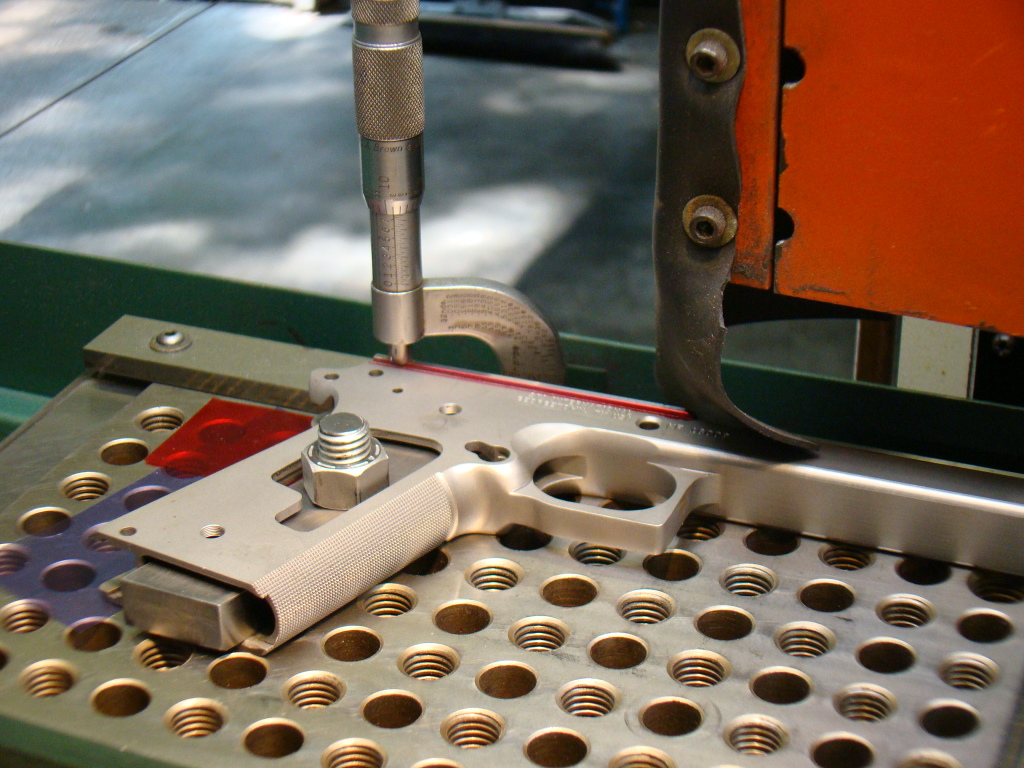

Setting the tool height

Harvey carbide cutter making a smooth clean pass.

Our light touch of .0002 shows things are very good to begin with as far as being true and square.

Checking the front/on the money.

008-1.jpg">

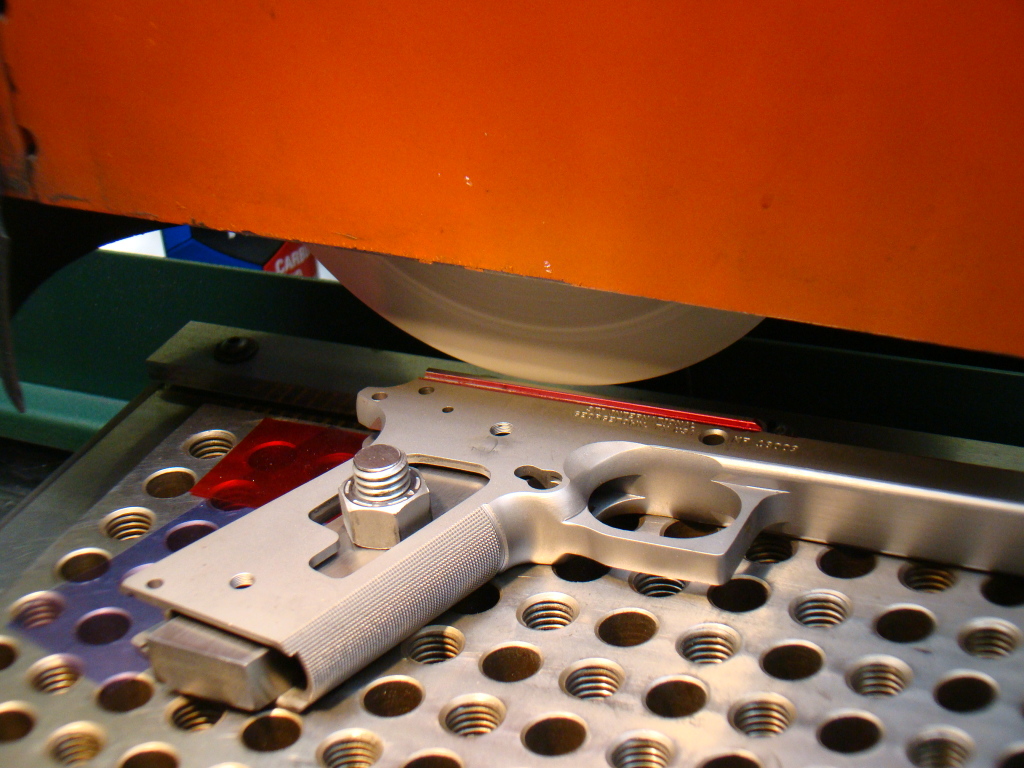

Checking the rear/same as the front... I love a surface grinder.

Pretty!

RogerH wrote:

Jerry, I follow everything except setting the tool height picture. Can you

explain more there?

Roger;

The height gage is reading .5935 .. That is the Z distance from the bottom

of the frame rail to the tool setter.

Now I touch the tool setter with the bottom of the carbide cutter, adjust the machine table Z axis (DRO) to .5935 and the cutter is now on the same axis as the frame rail. I still ease in a 10th or two at a time until I smear the dykem. Use gage blocks, Go/NoGo for slot width. Now I cut both sides of the frame in the same set up, which insures both rails finish on the same plane... same width. The cutter is made by Harvey Tool and is the best cutter for this process that I have ever used. Not cheap. Standard Woodruff cutters do not work well.

John McKenzie wrote:

Jerry, it looks like in this post that you are machining only the frame. Do

you do any work to the slide or do you do all the machining to the frame?

When measuring, filling out the mapping sheet, it is determined then, whether or not the slide needs to be trued/squared, or other... It is far easier to machine the frame opposed to the slide. Todays frames and slides are far more precise than those of yore... and many slides, as this one, do not need further work.

It takes several hours of work to setup, layout, and precisely measure the set. This is a very critical phase of the process. From fitting the slide/frame set to barrel fitting. Knowing each dimension is essential.

If anyone wants a copy of Jerry's "map sheet," you can download a copy below.

Here is the link: 1911map.pdf

When you click on the link, your browser should open a PDF file. Once open you can print it or save it in your computer.

You can also enter any other data you feel necessary, as you do the measuring.

You see from the one in the post, that I scribble in things such as the upper lug spacing, upper lug radius, firing pin C/L distance to the upper lug, etc. Whatever meets your needs.