Topic: Automag II chamber

Retrieved: December 07, 2013

While examining the rest of AMT's product line I encountered the Automag II. It's a blowback in .22 Magnum. Since this cartridge wasn't designed for use in a blowback action the case might fail during extraction, so Wikipedia says:

"There were a number of engineering challenges to overcome in designing an autoloading .22 WMR handgun. Not the least of which are extraction problems. The extraction problems stem from the fact that the slow burning rifle powder of the .22 WMR cartridge develops a late peak pressure. This can cause the case mouth to expand and jam in the chamber when fired from a handgun. AMT overcame this issue by drilling 18 holes at 90 degrees to the chamber. A sleeve was then welded over the chamber; providing a tiny amount of clearance for the excess gas to escape from the first set of holes on back to the second set, thereby relieving the pressure enough to prevent the case from sticking."

The American Rifleman .PDF on amtguns.info says 16 holes, but I'm not picky...

This sounds like the same basic idea as the fluted chamber in the CETME and various H&K guns; use gas to reduce the grip of the case on the side of the chamber for extraction.

Does anyone know the size and location of those holes, or what the clearance of the sleeve was? And since the sleeve was welded on, why didn't it eventually fill up with crud that couldn't be cleaned out?

TRX302

Oct 15 2012

Hmm. Looks like High Standard (which is now a brand under "The Crusader Gun Group") is still making new AM2s. They've supposedly improved the sear and are using threaded instead of brazed barrels. The same site (gunblast.com) also said: "High Standard also eliminated the tiny chamber holes".

Hmm. Presumably Larry Grossman wouldn't have put the holes there if the gun would have worked without them. Unless modern .22WMR is using thicker brass?

wbautomag

Oct 15 2012

If using flake powder cartridges they will stop up and they are not easy to clean best to use ball powder cartridges

jurras

Oct 15 2012

I distinctly remember Harry stating to use one particular brand of ammo, that it was the only brans that worked. He did not elaborate, and the caliber was too small to be of interest to me. But I soon found that Harry was correct. IIRC it was Federal brand. I found it suitable for rats in the city dump when it functioned properly. Its possible that Federals propellant profile fit this platform. Just food for thought. Cheers

XP001

Oct 15 2012

I just looked up this question about the ammo. Found it stamped on the inside of the AutomagII box cover and printed inside the instruction manual of my 4.5 version. I think this is an early version because it was in a heavy duty box like the other AM III-V. I also check my 6" version which is a flimsy box with plastic insert holder, found no markings on the inside box cover or in the manual about ammo selection BUT it had a paper insert in the box with advice on what ammo to use.

I always heard about using ball powder to avoid cloggin the bbl ports holes.

It was said the reason for the ports was to slow the extraction of the shell till the pressure spike drops down. I had a friend who designed his firearms and he said the trick was to get the brass to "stick" inside long enough till the pressure dropped. He wanted to make one but found too many issues with pressure and just stuck with the 22LR, 9mm and 45acp.

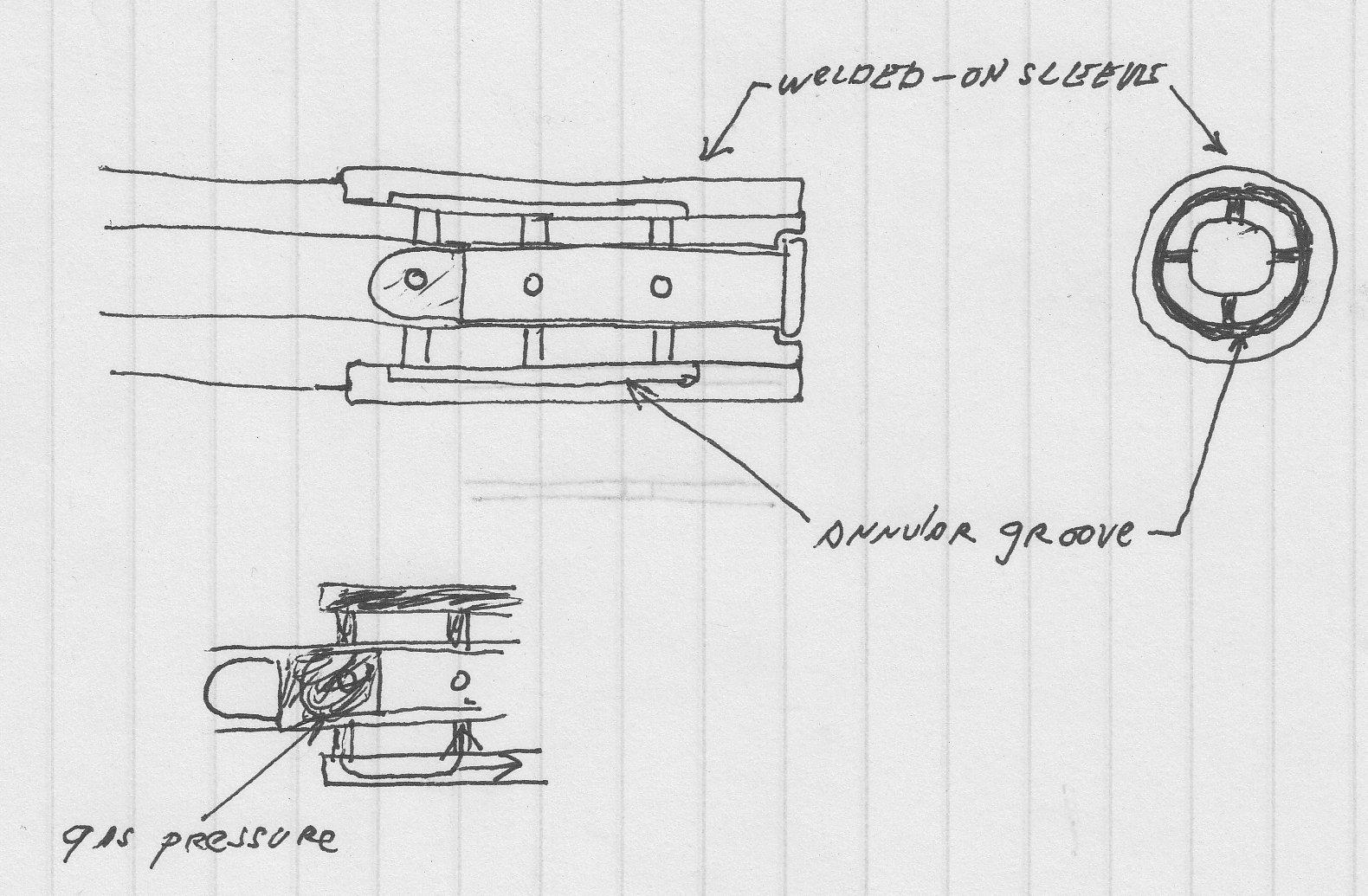

I know the Grendel P30 22Mag has "flutes" inside it's chamber. I wonder what the Kel-Tec PMR pisol uses.

Now why are these things needed? It made sense that if pressure is high that the brass would stick inside the dimples holding it there till pressure goes lower then start to extract and as doing it is doing this the gas then pushes inward thru the holes to the chamber releasing the brass grip, what you think?

jw4570

Oct 15 2012

It was my understanding the gas holes in front of the chamber allowed gas to vent back and put pressure on the case, slowing it, and once the bullet left and/or the pressure dropped, then the case could continue back and open the action. Cleaning it out is tricky, lots of solvent, and lots of drying time.

Does this sound right?

I use the Remington V-max ammo. It's great. Shoot it at 100 yards. Flattest shooting pistol I have.

I've been wanting a Keltec PMR. Sold one of my II's a year or more ago to fund the purchase. Just waiting for the price to be reasonable.

TRX302

Oct 15 2012

What I *thought* the AM2 was doing, was floating the case on a gas film to ease extraction. Not trying to delay extraction, like a ringed chamber.

H&K makes various models of autoloaders with fluted (longitudinally grooved) chambers. The first model was the G3 rifle, using the 7.62x52 NATO (.308 Winchester) round. The G3 isn't a locked-breech design; it's delayed blowback. The rollers slow the opening rate down, but the case starts moving back as soon as the powder ignites. Since combustion pressure locks the brass case against the chamber walls, the rifle would just blow the head off the case when fired. So they added eight to a dozen shallow grooves in the chamber, running from the mouth of the case almost to the opening. When fired, combustion gas goes down the grooves and floats the case in the chamber, sort of like the puck on an air hockey table. The rollers and the mass of the bolt keep it deep enough in the chamber to keep from blowing out a side before the bullet leaves the muzzle. If you search on "H&K roller locked" you can come up with better explanations with diagrams and pictures.

If you've ever picked up an empty case at the range and seen dark stripes running from mouth to base, it was fired from an H&K or a CETME. The stripes are from the flutes in the chamber.

As far as I know H&K uses EDM to flute the chamber; it's not easy to do any other way. What I thought Larry was doing was using holes and an annular gap formed by the sleeve to do the same thing as the flutes on the H&K.

Several net.sources claim the AM2's holes were intended to *delay* extraction, which sounds bassackwards. And one report says High Standard has done away with them. So now I'm just confused.

XP001

Oct 16 2012

Wow, open a can of worms here,lol. Maybe the chamber needs to measured to pin point where the holes really are in relationsip to the shell. If a set of holes is in front of the shell then that would allow gas into the chamber to all the others, locking the shell by gas pressure. Once pressure gets lower it would no lower hold it, thereby the remainder pressure cycles the action. Sounds reasonable

If the gas allows the case to float for ease of extraction(as stated in top post), wouldn't that allow it to cycle too fast thereby allowing hot gas to blow out as it ejects?

I do remember hearing that this AMT Automag II is a "gas operated" pistol action which would make the above a true function of the pistol.

I was told the brass just sucks into the dimples until pressure drops, allowing the brass then to retract to normal unlocking it from them dimples and allowing the leftover pressure to cycle the action.

I do know the Grendel P-30 pistol 22mag uses flutes in it's chamber.

Lots of ways to skin a cat so to speak I guess.

Anybody have a Kel-Tec PMR Pistol to check how they do it?

Anybody know to true function of the ports and flutes? To hold the shell or allow ease of extraction or both?

XP001

Oct 16 2012

ok, just checked my Automag II

Early version made in Covina, Ca. has 18 holes-6 spots with 3 hole rows going into chamber the farest into chamber is located right before the rifling so the bullet leaves the shell 1/16ish-1/8ish before the gas enters into that gas hole.

My 4 1/2 and shooter 6" also have the same. The rows going into the chamber are not extactly the same on any of the bbls. one had set at 430o'clockish, then 5o'clock and 530o'clock but never at 6, always equal space 60degrees from each row.

Another interesting thing, the Early version had black Hammers without a half- cock notch and the slide lock does not have the nub to puch it out from right side but sits flush with the frame. Need to use a punch to push it out.

Early version also had that flimsy box with plastic insert for firearm to sit it, later boxes were the firm cardboard style.

Early edition just had paper slip about ammo choice- no information in manual

Later edition inside cover

Later edition manual

Luc V.

Oct 16 2012

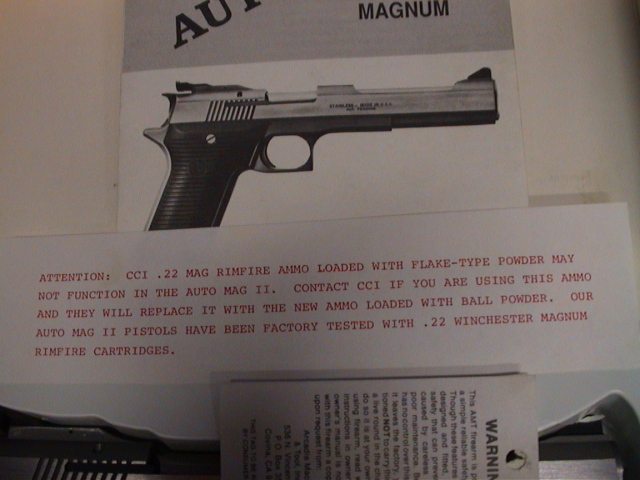

To make it more visible, some pics:

The barrel:

The fired cases:

The working of this "system" is just the opposite as the flutes in the chamber of the HK G3 or Sig Stg 57.

The chamberflutes in the rifles are cut all the way into the throat of the chamber to let gas escape BETWEEN the chamberwall and the case. This makes extraction easier since the case does not stick as much to the chamberwall, sort of making the case "floating" in the chamber.

On the AMT II pistols, the "dents" in the chamber have the purpose to make the case stick longer into the chamber. Sort of making the extraction a delayed blowback. On ignition, the case expands into the dents, and the force of the pressure on the slide (which is equal in all directions) then resizes the dents on the way out to the extraction, just to keep the slide/barrel combo closed a tick longer as a straight blowback.

I hope my theory is somewhat clear.

About the brand of ammo, mine work well with Federal, but back in the days it was told NOT to use this brand. I think someone said that federal changed the powder in the 22WMR.

TRX302

Oct 16 2012

Early version made in Covina, Ca. has 18 holes-6 spots with 3 hole rows going into chamber the farest into chamber is located right before the rifling so the bullet leaves the shell 1/16ish-1/8ish before the gas enters into that gas hole.

Okay, XP001's gun sounds like it works like I described earlier, by using gas to make it easier to extract the fired case.

But Luc's picture shows only eight holes in two rows, and none of them are ahead of the mouth of the case?

Luc's photo looks like the chamber was a thin sleeve pressed into the end of the barrel. The usual description is of a thin sleeve is on the outside of the barrel. I wonder if that's a misunderstanding propagated over time, or if there have been more variations of the AM2 chamber...

Verry interresting...

Luc V.

Oct 16 2012

No, the barrel of my AMT II is not sleeved in the chamber.

I guess it's made like this: Make the barrel with a smaller step on het chamber end, and press it into the barrelblock and weld together. (sorry, just a fast drawing, hope you "get the picture)

When put everything together, you will have cavities inside the chamber so the case can expand first, and later resized due to the extraction. Just my thought.

TRX302

Oct 16 2012

The descriptions (at least, of the earliest AM2s) made it sound like something like this:

Luc V.

Oct 16 2012

Okay, then I have a couple of questions:

If the way it works as in your drawing, I guess the marks on the case should be " inward dents" instead of sort of "nippels on the case" due to the pressure points? (sorry for the strange expression)

If I look and feel at the empty cases from my II, you can feel the marks are on the outside of the case, not pushed inwards.

Second question: what should be the benefit of making the case easier to extract? Shouldn't this be more dangerous since the 22 Magnum works at higher pressure as the 22Lr, so the slide will be fly back with higher speed?

TRX302

Oct 16 2012

In the case of the H&K rifle, gas grooves were supposed to keep the case from sticking when the bolt moved back and paused due to the rollers. Without the grooves, the head of the case would break off just above the inside bottom, so the grooves prevented this from happening.

At least, that's the explanation I've always heard...

Much later, Seecamp came out with a blowback pocket pistol. Because the slide was really too light for it to function properly, they cut a rounded groove all the way around the inside of the chamber. Pressure forced the brass into the groove, then it had to swage back out as the case moved back. This slowed the action down enough to keep the slide from beating the frame to death.

Your gun doesn't have any holes in front of the case mouth, so it must be using the dimples=delay idea. But XP001's pistol has twice as many holes, with the third row ahead of the case mouth. The third row of holes would have no function unless they were designed to feed gas back to the rear holes.

I think I'm getting a headache...

Luc V.

Oct 16 2012

OK, I understand what you're saying, but what I find "weird" is why would you (they) go to all the trouble -in the AMT II- to make the case extract more easy as in a simple blowback?

As in G3 etc rifles, the action use the rollers to DELAY the opening of the bolt untill the pressure drops to a safe level, the AMT II has nothing but the (weak) recoilspring and hammerspring to keep it locked to the barrel. I guess this will be not enough to hold the slide/barrel closed as in "locked". So I think the dimples must be there to help keeping the case longer in the chamber, not making it getting out easier.

I think you can't compare this two designs.

Well, my guess is as good as anyone else. Any others??

TRX302

Oct 16 2012

I don't know. I'm thoroughly confused now.

XP001

Oct 16 2012

Luc,

I almost did what you just did! I took mine apart and threw a patch thru the

chamber just to polish it first. Then took a light and magnifier and look into

the chamber and found 6 rows 60 degrees around the chamber with only 2 holes.

I took all 3 of mine apart to find this but it stuck in my head 10ish years

ago I thought I seen 3 holes rows, my friend had me look for this as he was

into firearm design and had issue with pressure. So my next move will scare

some of you so here goes, I took a small paper clip and formed a short hook at

the end. Then slowly move it into the chamber and felt the farest hole and

then move it towars the muzzle/rifling and BAM! the clips fell into the third

hole right at the start of the rifling so close you can't see it hiding there.

So go ahead and check your bbl with a hook clip and I'll bet you'll find it

too. Your photo looked exactly what my bbl's do but the hook showed/felt the

third hole in mine.

I'll also state this, I'm really bad at cleaning up bbl's and will in the day or so get out the cleaning bottles, and soak my bbl's and really clean them. I bet I will see all them holes a lot better then, also my eyes are 15ish yrs older!

As for function, I'm leaning that it works like this. As it is fired the shell expands into the holes holding it a split/split/split/split second just enough to allow pressure to drop, then the pressure on the outside hole system now overcomes the inside chamber/shell pressure which now pushes the brass back out of the holes and causes it to float making extraction easy. Remeber these are short bbl and only need fraction seconds to make a big effect.

Anybody else have ideas of why/how this vent hole system works?

TRX302

Oct 16 2012

XP001 wrote:

As it is fired the shell expands into the holes holding it a

split/split/split/split second just enough to allow pressure to drop, then the

pressure on the outside hole system now overcomes the inside chamber/shell

pressure which now pushes the brass back out of the holes and causes it to

float making extraction easy

That makes a demented kind of sense... aaargh!

Luc V.

Oct 17 2012

Well XP001, you're right!!

The photos I posted earlier, are stored on my computer and are "from back in the day" (that hurts to say it ..

I never paid much attention to it, but now it made me curious.

Here are som new pics from my barrel, made with a better camera, and bingo the three ports are visible.

Not easy to see, but they are there. Why the third hole marks are not shown on the cases in the other pictures -or at least some part of it- is not clear. Eighter the pictures are not good enough, or the federal cases are shorter as they should be??

Your theory on the way it works sound the best I heard so far.

XP001

Oct 17 2012

When I found that third hole by the rifling I also rough measured the amount of clip inside the chamber and found that it is longer then the case. Therefore I assume the gas enters into the third holes once the bullet is starting into the rifling, thereby pressurizing the other holes and also taking in some of the spike powder pressure(hmm) Since the hole is in FRONT of the case you won't see any marks.

TRX was correct with his drawing and had the last part of the system correct but I always heard these had a "DELAYED gas assisted blow-back system"

My thoughts

Pressure builds up in case pushing it(the case) into the chamber holes(causing dimples in casing), now the case is stuck in the chamber, bullet then releases from the case and starts down bbl, passes third set of holes, gases expand into the hole chambers(taking some powder spike with it) bullet almost out, pressure pushes inward on stuck case in chamber thereby releasing it's hole grip and system starts the reload cycle.

Sounds the best I heard yet, any comments?

Thank you all as you now made me clean/oil all 3 of my Automag II's to research this question. Now if I can only get the rest of them firearms done, maybe someday, lol.

XP001

Oct 19 2012

I know I said some of this at the beginning but I'll say everything that I noticed while cleaning and putting them back together.

First version pistol

Has a darkish almost black hammer without the half-cocked notch in it. There was an noticed posted in ads to send them back for FREE half-cock installation.

The take down lever is flush with the frame on the right side so you need a punch/pointed tool to push it out to left side for dis-assy.

The cocking serations on the hammer are course(prob 5-7 lines v 7-10 thin lines on other versions that I have)

Comes in the flimsy box with plastic insert

I'm sure markings like caution/pat pend and such are different but I didn't note them yet, next time I will.

I'm not sure about this mag issue but will state what I found out.

The orange follower mags have very weak springs in them and will not activate the slide hold open. I found 2 orange and both fail to work the slide hold open on all 3 of my firearms. I also found 2 mags that had a black follower and they did operate the slide hold open feature.

1 firearm had orange follower (early version)

1 firearm had black follower (high serial number)

1 firearm had both

Spring differences

orange spring measured 4 1/4" with 17 coils @1/4 turns"

black spring measured 5 5/8" with 18 1/2coils @ appox 5/16-3/8" turns

Mags body and floorplates are also different

orange followers dropped free of mag body

black followers are held captive because the mag body fold tabs to hold plate are folded inward more

orange body fold tabs are 1/8" fold inward, blacks are 3/16" folded inward

orange floorplate butts against the rear side of the mag and stops

Black floorplate is longer and goes UNDER the rear side of the mag

Looking at the backside of the mags, black mag is 1/8"shorter sort of notched in back to allow the floorplate to go under it

Also the first version pistol bbl had rough looking bbl/chamber weld, sort of like it doesn't matter about the looks move it out. It never shows until you break it down. My other 2 later version ones had the weld cleaned up a lot compared to the first one. Maybe they just got better at welding also, lol. It's been fun and hope everybody learned something, I did

Luc V.

Oct 19 2012

Thanks for the extra info XP001.

Yep, I learned something here. I need to look better, or I need a borescope.

TRX302

Oct 19 2012

Back to the original question, then - doesn't the area between the sleeve get filled with unburned powder and crud? And if so, how do you get it out?

I guess most of it would blow through the rearmost holes, but it still looks like crud would build up over time.

Luc V.

Oct 19 2012

Yes, the "gasroom" will get dirty and you never get it all out, but with good solvents the most of it will come out, enough to make the system working OK. The high gaspressure from the next cartridge will blow hard enough to get small particles out of the way;-)

Same thing with the Desert Eagle pistols, you can't clean the gas channel eighter. Just soak and dry with compressed air is the best solution to keep things going.

On the other hand, is it really necesary to get it clean as in brand new? If it works, it's all whats needed is my opinion.

XP001

Oct 19 2012

I poured some solvent into a jar with about 2" deep and sat my bbl with chamber down into the solvent. Let sit for 1 day and then cleaned up the rest normal like and re-assy. Looked brand new again. my 1-6" was shot a lot and very dirty at the chamber block, rifling liked fair dirty but once it soaked all I had to do is wipe it down and what was left of the crud was gone, no scubbing at all. A few strokes of a patch thru the bbl and all was new again.

now I can't wait to play with the 6" again and make sure it works.

sirsaka

Oct 19 2012

Not having been on here for a while I missed all of the entries until now. I could write a book, replying to every concern but I will hit on just a couple of things as my memory serves. From the onset of Larry's design, I always thought of it as a retarded blow back action. I even list it as such in the Reference Manaul. However, I was just recently corrected by someone more knowledgable than myself in this area. As stated earlier in this thread, the gas system is indeed meant to float the long case in the chamber in order to achieve extraction. As I understand it, it creates an Air Bearing effect in the chamber, countering the pressure from within the round. I do remember Larry going through painstaking efforts to get the holes correctly sized and placed as well as the area inside the gas channel in order to achieve extraction safely and on a consistant basis. Back when Larry designed the gun he used Winchester Super X brand because it was cleaner and slower burning than the others. CCI was hot and a very fast burner and would blow the heads off the cases, leaving the brass in the chamber. Federal ammo was very dirty and clogged up the gas ports almost immediately. (in most cases, 3-5 rounds of Winchester will eventually clean out the residue and the gun is back in action). Another issue was indeed the omition of the half cock notch on the early guns. I remember the notices being sent out as stated here and replacing the hammers as they came in. The hold open was also re-engineered due to the little ball bearing not being strong enough to keep the lever from shifting to the hold open position during recoil, holding the slide back. If there was one issue that we found most AM II's had when in for repair, it would have to be tight chambers. A quck ream and polish usually sent the gun back to the owner. I hope this helps answer some questions.

Luc V.

Oct 20 2012

Thanks for the info Brian.

I have some more questions, if I have it right, you mean that the longer (magnum) case will get "glued" to the chamber because of the higher pressure as in the 22Lr? So if the chamber is not gas operated, the extractor will probably rip out the rim of the shell.

Yeah I know, more questions, but I'll try to understand this unusual way of working...

sirsaka

Oct 22 2012

As with any semi-auto (and of course full autos), the case expands in the chamber and there is some drag as it's being extracted. Nothing new here. However, the .22WMR ratio of diameter vs length causes more area of drag, thus not allowing it to extract properly. As I mentioned before, the redirection of the gas to the chamber causes an air bearing of sorts. If you've ever worked with tool and cutter grinders, the puller is actually a shaft inside of a cylinder. When the air is not on, it's very difficult to move. But when the air is on, it's as smooth as silk, allowing for a nice grinding job of the tool.

The extractor will not pull the head off the case since it is much to weak to do so. In fact, on most rimfire's the extractor is really nothing more than a guide to hold the round in place as it's moving rearward to be ejected. The problem with the CCI (at least in the early days) was that it is both too hot and too fast for this application, the case adheres to the walls and the head is actually blown off.

I welcome anyone to reign in here pro or con to what I'm saying since I am not an engineer. Our friend Ric Mutascio sure would be able to give us a lesson on this.

sirsaka

Oct 24 2012

With all this talk about the AMII and while currently having one in for repair I decided to go the extra mile on cleaning the gas chamber. I made this tool which fits tightly in the chamber via O-Rings and traps the two sets of gas ports that are in the chamber. I drilled two sets of 6 holes matching the same location as the chamber ports, intersecting the thru hole I drilled form the end. Using an off-the-shelf can of "Dust Destroyer", I made the hole in the end to fit the red plastic tube that comes with the can. Inserted into the new tool, I attached it to the can and pulled the trigger. The air goes into the gas system and blows the residue out thru the ports that sit in front of the chamber. It works great! Thought I'd share it with you all.

jw4570

Oct 24 2012

When will we see the infomercial? And if we order today, do we get two for the price of one?

I would think you could reduce the diameter between the two o rings and just drill a few holes, as the air would be pushing through. I agree lining up the holes is best though.

Luvz2Shoot

Oct 24 2012

I plan on shooting and thoroughly cleaning my AMT-II afterwards, can you put me down for one of those? Any help in thoroughly cleaning it afterwards would be a benefit.

sirsaka

Oct 25 2012

Jim, Thats a good idea. I wipped this out kind of quickly without putting a whole lot of thought into it. I'm thinking maybe reducing only the area where the holes are and keeping the center part the same in order to give more area for the blast yet constricting it from going elsewhere. Does that make sense.

John, I didn't think of producing these but I wonder if there would actualy be a market. There are a lot of AMII's out there.

Luvz2Shoot

Oct 25 2012

Yes, there are a lot of AMT-II's out there, and they all need cleaning....

jw4570

Oct 26 2012

Brian,

You could reduce just the area where the holes are, allowing the user not to

have to align the holes. Does the flange at the end stop it at the rear of

the barrel/chamber and provide proper alignment to the holes? (or reduced

area)?

I could make that, but I couldn't "whip it out quickly". Your work on the retaining ring tool was well worth it, so I was thinking if you made some of these, I would like one.

sirsaka

Oct 26 2012

Jim, yes the flange stops the tool and puts the holes right in line with the vents. I drilled 6 holes at both locations because it's imposible to line them up radially. I guess I may have to make a few. Assuming the plastic "straw" is of a generic size, one could first spray a solvent to loosen the dirt then the air to clean it all out.

jw4570

Oct 26 2012

The plastic straws are generally the same size. Once in a while some are different sizes.

XP001

Nov 09 2012

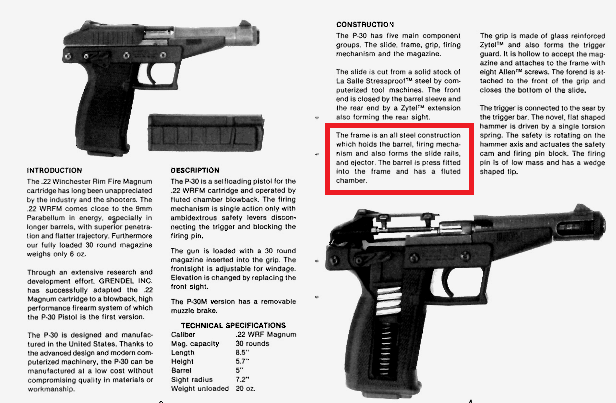

As long as we are talking about the chamber issue, the Grendel P30 22mag was made using a fluted chamber to avoid such clog issues the Automag II had with flake ammo/dirty powder. Here are some pics of my RARE 8"bbl with muzzle brake showing it.

I'm thinking they seen the Automag II and re-worked the chamber to avoid ammo/powder issues. Not sure who really came first. Anybody want to look up the dates of production of them? Now I will finally clean this one up as long as it's broke down. One more cleaning done out of the way, so many left to do tho. I received this one dirty and at least I know it did work at one time. I never shot it so I can't tell how well it really works yet.

TRX302

Nov 09 2012

Fluted chambers appeared around WWII. They work very well for providing a gas layer for extraction. The Spanish CETME and most of H&K's rifles use fluted chambers.

However, cutting the flutes is a nontrivial operation. As far as I know the big guys do it with EDM, which is basically a spark erosion method. Special carbon electrodes have to be made, then the electrodes are run into the chamber very slowly, over a period of minutes, or tens or minutes, until the chamber conforms to the shape of the fluted electrode.

For a small company like AMT this is a problem since the machines and their consumables are expensive, and moving the operation out to a job shop doesn't help much. Even on the Auto Mag they moved from EDM back to broaching on the receiver lugs on the later guns.

Larry's solution was something that was cheap and easily done with conventional equipment, or could probably be jobbed out to a screw machine shop for less than they could make it themselves. (a "screw machine" is a generic term for an automated lathe that turns out small parts unattended)

The fluted chamber is probably the best mechanical solution. That Larry didn't use it almost certainly means he investigated it and found it was too expensive to maintain the profit margin at the gun's price point. Stainless steel is more expensive than carbon steel, and harder on cutters, plus California wages and overhead. The Grendel has a plastic frame and is made in Florida, so there was probably more money left in the budget for things like fluted chambers.

---

Hmm. Reading back over that, somehow it comes across like I'm talking down to you. That was absolutely not my intention; I'm not very ept this morning, or something. I was trying to show, not necessarily to you, but others who might be reading the thread, why one designer might opt for one solution, and a different designer might opt for a different solution. And, of course, I'm theorizing the reasons for decisions made two decades ago by people I've never met.

sirsaka

Nov 09 2012

I believe the Grendel was out long before the AMII. I don't remember Larry even considering it but I was not always kept in the loop on project development. Also, as far as the fluted chambers go, I believe the flutes were (and are still) broached. But again I could be mistaken.

Luc V.

Nov 09 2012

I'm pretty sure that the HK flutes in the chamber are made when the barrels are cold forged for rifling AND chamber. All they need to do is reaming (finishing) the chamber. The flutes will still be there after the reaming.

I don't know about procedure to other manufacturers.

To XP001, all I know is now that you have that pistol out of the dark, you should shoot it first, report back with results and clean afterwards...

TRX302

Nov 09 2012

Actually, for a straight case cartridge they might well be broached. I'm used to thinking of bottleneck cartridges.

XP001

Nov 09 2012

Luc,

I was thinking the same thing BUT if I put it back together and shoot it there

will not be time to clean it. At least that's what I always say afterwards.

It's a mindset I need to break, lol. I do want to clean it first because it

will give it a fresh start to see what it can do clean first. So I will clean

it early Sat., shoot mid morn. and then have time to clean it maybe.

TRX,

I didn't take it as talking down as you were giving facts. I'm sure it was

made as a "cheap" firearm and that's ok because I just love odd/rare ones and

this is one. When "cheap" firearms are made they sometimes go under fast, that

makes them rare to me, lol.

Thanks for the history of fluting chambers, didn't know it was around that long ago. I did read you comments about the HK but thought only about the news ones, HK91 or HK93, although I'm not sure how old/new those models are either.

XP001

Nov 10 2012

Also forgot to mention

Most firearms that start out as "cheap" and long after the company goes under, people then decide, like normal, that they want what they can't buy(production) and that cheap firearm now becomes expensive, lol.

It's funny that if them people purchased this for the new "collector" price that company would still be around as happens to many companies. Supply/demand, hmm.

Just a few facts about this make.

These then cheap pistols cost about $500 for the more common 5"bll and up to 1K for the 8"bbl w-muzzle brake and about 1300 for the 10"bbl pistol. The rifles also are rare and seen them go for up to $1600!

These old/rare things just make it interesting to me.