Last Post: 05-20-2016

Captured: 01-20-2010

Updated: 05-20-2016

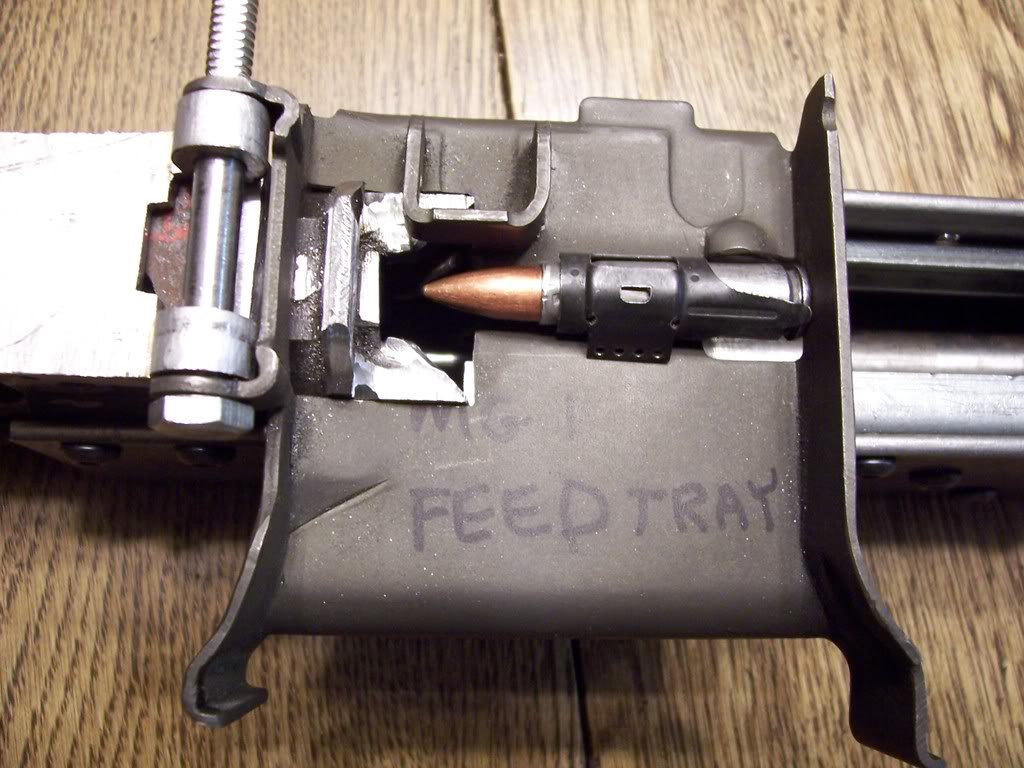

I just recentlly finished a beltfeed ak-47 base fire arm with a scratch built receiver, a MG-3 top cover/belt feed mechanism, FAL fcg, scratch built stock, grip frame & grips and forearm, k98 rear sight and m60 return spring. You can see photos of it on PHOTOBUCKET, search for 300 WSM FAL or SHARPSSHOOTER5090.

The barrel, trunion, bolt, and bolt carrier are ak-47. The receiver is scratch built from 1 1/2' by 2' rectangular steel tubing. The bolt carrier has a piece welded on the back of it for a M60 return spring to connect to. The weld piece also has a slot machined into the bottom for an extended FAL hammer to swing into to stike a spring retun extended AK firing pin. On top of the welded piece is mounted a roller that rides in the feed cam slot of a MG-3 top cover/feed mechanism.

The gas tube is made out of a 12 ga barrel section and a larger gas piston is silver soldered to the originial AK gas piston to give the bolt carrier extra push to operate the beltfeed. The belt is MG3 which holds the 7.62x39 cartridge not as tight as a RPD belt. The gas relief holes in the gas tube are drilled at the end of the gas piston stroke to make the system a long stroke piston, again to give the bolt carrier extra push to operate the feed mechanism.

It ejects down low to the left and the ejected cartridges just miss the SAW- 249 50 round cloth cartridge bag. Rear sight is K98. There is a front barrel extension fitted to the AK barrel to keep the pressure up longer in order to aid in operating the feed mechanim. The butt stock, pistol grip assy and the forearm are scratch built. The FCG is FAL. Flash hider is L1A1. The gas port is drilled out to .187 dia. The bipod is import RPK style. The feed tray is also scratch built.

I saw that on the MG42 forum - and I must say that is absolutely AWESOME! My hat's off to you - that is something I'd like to do myself.

RELIABLE CYCLING

I want to install a longer barrel in order to keep the pressure in the barrel/gas piston up longer to more reliablly cycle the bolt carrier all the way back. Right now, it moves back just enough to cycle but not always. I have opened up the gas port but the pressure drop off too quickly because of the shortness of a standard AK barrel. The barrel appears longer but thats because there is an extension on the front that is larger than the bore and a point of pressure loss.

You must have read my mind - I was going to suggest a longer barrel, but thought it might be taken as nitpicking.

Now that you mention it!...

You could do well, I think, with a 24" barrel which is a standard RPK size. Give it a longer piston, like a PSL/Dragunov piston length, and give it a longer gas tube. That would increase velocity a considerable amount, something like around 200-400 FPS, and that would no doubt help.

You could use any 7.62x54R sized barrel, which means any Mosin barrel rebuild option that is out there. Chamber it up and lathe it to the right diameters, "done".

The problem - obviously - is that you have is that the 7.62x39 just doesn't have that much power, and you've reverse-engineered a recoil-operated system into a gas-operated system. That in itself shouldn't be too great a concern, considering the FN Minimi, and the Stoner 63, and the fact that there is a 5.56 version of the MG-42 which was a Spanish design IIRC.

Do you know the muzzle velocity?

I wonder if you can benefit from a muzzle booster, like an AKSU (aka Krinkov) style booster? Would be worth a try, that expansion chamber was designed to boost velocity on the AK-74 based design, so in theory it would help your design as well.

I also wonder if you have the "hammer hump" problem? That seriously robs my .308 bullpup of power to the point that it doesn't always reliably feed. Grind the hump and try it- you never know.

Also, what kind of piston do you have? Home made? Original factory? Reason I ask is that if the piston bleeds enough gas by being narrow enough to make a poor seal, it will let enough gas bleed-off to affect functionality. I had an AK-74 malfunction due to a piston I made being too narrow diameter. Possibly a longer piston head would help, I don't know.

All good points. An RPD works with the low power 7.62x39 so this should work also if I get all the variables right. The gas tube is made from a 12 ga. barrel and the gas piston has only .005 to .010" diameter clearance and is about .875 " long. The stroke is as long as the beltfeed cam allows and the gas releaf hole in the gas tube is right at the end of the stroke. I wish I knew what the internial pressure curve v.s. barrel length is. I am not sure that the standard gas block placment from the breach is optimal or needs to move either forward or aft. I do need to make a tighter seal of the gas tube to the gas block though.

I am definitely losing some pressure there. The hammer cocking hump is just large enough to assure reliable re-cocking. I have some thought of installing a roller on the hump to reduce friction. I have only tried it with the 124 gr bullets but I am going to try the 154 gr soft point bullets. The heaver bullets should have higher pressure if the powder charge is the same.

SHARPSSHOOTER5090 - This is a nice build and I see myself coming back to this thread over and over. It is definitely a very nice build that looks well thought out.

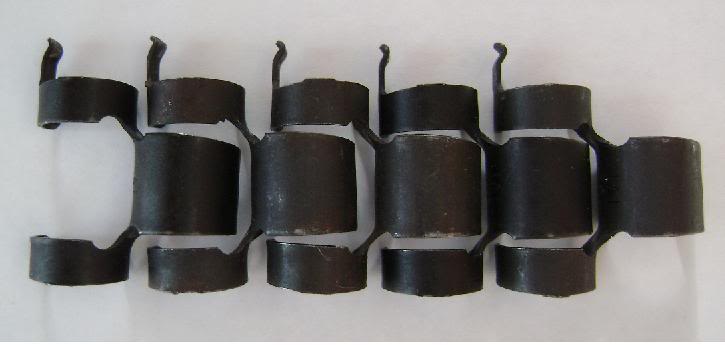

Are the links push through or pull out? How do the loose cartridges get moved to the chamber?The links are MG3 8mm/308 non-disintegrating push through with a standard MG3 beltfeed mechanism.

Hey SS I had a thought - I remember someone, and I think it was Kevin_M4, who had a loose gas block on their Saiga conversion, and silver soldered it onto the barrel. That may be a quick-and-dirty way to help your loose gas block issue.

The fact that it bleeds gas around the port will definitely cause lower barrel velocity, obviously resulting in less energy to cycle the weapon.

Another thought, and I learned this from my MG42 build, and that is to degrease everything, use a Sharpie or two and cover all the moving parts in black, and cycle the action by hand. The chafe marks are where rubbing is taking place, and in theory there should be very few places that rub. I found several areas that rub using this method. The areas were small, and I ignored them until I polished them one by one, and the net effect was a smoother action.

Hopefully this helps out. The piston size should still be considered as a to- do item, but if you do these things first it may not matter.

Hcpookie,

The gas leak I had was between the gas block and the gas tube not between the gas block and barrel. That is still a press fit and gas tight. Last week end I bored out the end of my gas tube and soldered in a brass bushing. I machined out the I.D. of the bushing to be a zero clearace to the gas block nose. I now requires a few taps from a hammer to get the gas tube in place. That should stop the gas leak there. Ther other thing I did was remove the L1A1 flash hider and built a Krinkov style booster/gas accumulator to hold the gas pressure up a little longer. I also bought a Yugo RPK barrel which is about 4" longer that the standard AK barrel and am going to install that along with the Krinkov booster/flashhider cone. Hopefully I can try it this week and will post the results.

I may need to install a roller on the hammer cocking hump on the bolt carrier as there is some resistance when the hammer is pushed to the re-cocking position as the bolt carrier rides over the hammer.

I just received a Yugo RPK barrel and gas block that I might put on my beltfeed. This barrel is 21 inches v.s. 16 inches of the standard Romey Ak-47 barrel. Hopefully the longer barrel will keep the gas pressure up enough to reliabally cycle the bolt carrier all the way back every time. I built and installed a Krikov style booster and tightened up the joint between the gas block and gas tube but have not had a chance to try it. I took it to the range to test but somebody was shooting a 50 BMG with API bullets and caught the dry grass at the range on fire and they closed it before I had a chance to try the modifications. Since then I also installed a roller on the bolt carrier to so the hammer rolls over it to cock instead for sliding on steel to steel. Back to the range to try it as soon as I get a chance. I hope I don't have to put on the RPK barrel as it means that it will esentially will not be a belt feed Ak-47 but a home made RPK. That's OK but I started the project out to see if a beltfeed could be made based on cheap AK-47 parts. (Although the fat RPK barrel will look a lot better than the skinny AK-47 barrel.)

It does have a surprising amount of recoil for a 14 lb 7.62x39. I attribute that not to true bullet recoil but to the bolt and bolt carrier hitting the bolt stop. I need to make a more effective buffer than just a 1/8" piece of rubber. Maybe a spring setup. One other option is to make the gas block regulatable like a FAL. Before I sealed up all the gas leaks the bolt would not go back with enough force to reliably cycle the belt feed mechanism, now it is almost to much. And yes, it does throw you off target somewhat but then again so does a MG-42.

One other thing I have to change is to raise both the front and rear sights. They are just to low to re-aquire in a hurry.

Thats an awesome build. I am a little puzzled about the recoil though. Would it lessen the recoil if You moved the vent hole on the gas tube forward a little to bleed off pressure at the rear of the piston stroke so that the carrier isn't slamming into the buffer as hard? I've never even looked at belt fed so I don't know what all is involed, but it seems logical? Maybe?You are probably right. Right now the gas bleed off hole is right at the rear most travel of the bolt carrier. My 300WSM FAL has multiple gas relief holes in the gas tube and a sleeve that I can slide fore and aft to cover and uncover the holes. I think I will try your suggestion and do the same thing.

The other thing I think I will do is drill and tap a hole in the gas block that intersects the gas port. I can then put in a tapered screw and adjust the gas port hole area. You can buy a similar gas regulator block system for a Mini-14.

LOL that same thing happens on my MG42. You know the new MG3 covers have a spring that braces the cover open.Another video:

Last night I moved the rear sight to the back of the feed cover and soldered a peep sight aperture to it to increase the sight radius and make it easier to see the front sight after each shot. The excessive recoil causes you to loose the sight picture easily with a blade and partridge slot type rear sight.

It sure sounds like the gas hole is too big. Maybe you should install a valve to adjust the amount of gas going to the operating piston. You might be able to use a surplus one from a WWII machine gun.I think I will remove the booster cone and put the L1A1 flash hider back on as it now functions fine without the booster cone. That should lessen the recoil a bit. I am also going to drill some gas relief holes in the gas tube about 1/2" forward of the ones in the tube now. That should allow the bolt carrier to slow down a bit befor it hits the bolt stop/buffer.

Drilling holes on the gas cylinder might work. I did the same thing to an M-1 Garand thirty years ago, and it helped.

A valve is a better way to go, for better troubleshooting instead of jumping in to conclusion first, try it on before drilling these relef holes which is a one way step, not to mention that your gun is a first experiment that requires a lot of trying and experiments before you get it tuned up to get the best of it.Finally got around to removeing the booster cone and re-installed the L1A1 flash hider. Also, I drilled a gas relief hole about 1/2" farther forward of the current location. It made quite a differance in the apparent recoil. As soon as I get back out to the desert, I will take a long video of loading, charging and long rapid fire. Next, I want to try one of those 10/22 gatling gun trigger cranks that actuate the trigger 4 times per handle revolution and see how fast I can get it to cycle. Before that though, I need to open up the back of the ejection port. I might also install a longer buffer to limit the rear travel of the bolt carrier so the bolt doesn't out run the ejecting case. That might stop the ejected case from hitting the back the ejection port and occasionally bouncing back in.You may try different tension on your retention spring too, the improper tension may cause instability of the gun I guess, I assume that you don't have enough tension.

I am a-building! Received a new Miller 'Econotig' today. I have been without gas for too long - my little non-gas MIG (HF) even did a few HK cocking tubes with aluminum foil to shield the splatter (at times it's taken 3 attempts) but where there's a will there's a way.

Sharpshooter - I have devised a way to make a 'bracket' to extend the the rear of the bolt carrier for mounting feed stud & recoil spring guide. An "L" shaped piece, mounted alongside the 'recoil spring tube' which runs back (behind the hammer arc) then goes up, with the top bent over in the rear. Screwed on the carrier (for adjustment, then welded) to mount the 'feed stud' on top of the bent-over back of the 'L'. Could not have done this without you leading the way - will keep you posted -

That sounds like a good solution without having to mill a piece welded to the back of the bolt carrier like I did. I see no reason that shouldn't work fine. Glad to see that somebody can make use my lead.

I was wondering if the M60 recoil spring is strong enough without the buffer assembly to absorb recoil from the bolt at the end of the recoil movement.MG47 Buffer

With out the buffer the bolt carrier slaps the back of the receiver (butt stock assembly) very hard. If the M60 spring was longer, it would probably act as a buffer. I cut if off when I was having trouble with the bolt carrier getting full stroke. The problem was a gas leak at the gas tube to gas block joint. With the leak stopped, I get too much pressure and I need to install a gas regulator to cut the gas pressure down so the bolt carrier just stops at the rear most travel. With that, a buffer would not be necessary.

Just finished mine and will attempt to post some pics.

[picture 404]

[picture 404]

[picture 404]

[picture 404]

MG3 topcover, MG1 tray, MG42 gripstick with AR FCG (tight fit!) G3 stock, inspired by Sharpshooter. Sleeved a Chinese barrel to save pennies but won't to that again. Lathe MIG grinder/Dremel (no mill) and determination; about $300 into it. I'm hoping ejected casings will clear the RPD drum. Still need to devise a 'safe' in the gripstick. It weighs 13 lbs 14 oz w/o the drum.

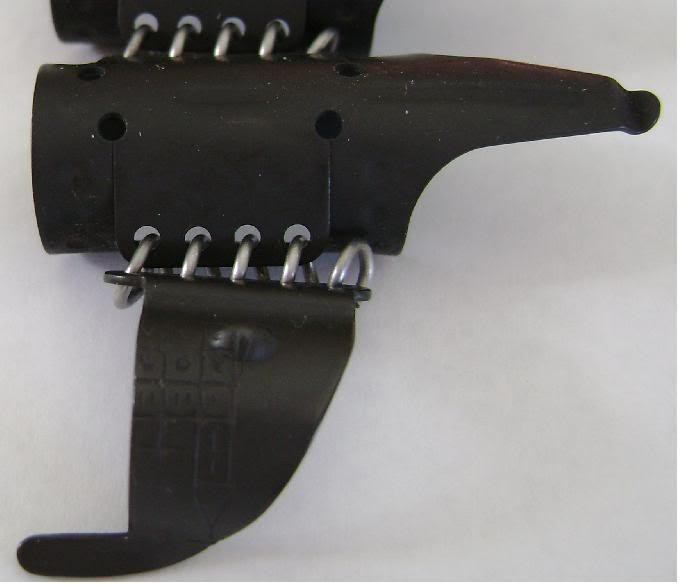

Cold-rolled BC extension, 5/16" cap screw feed stud, epoxy to fit the stock, non-reciprocating MG42 cocking-handle fixed to a plate, with a 'step' up front to engage BC.

[picture 404]

Bolt stripping lug tapered slightly, standard piston but ultra-tight gas tube (light mallet-fit) gas port .191 (hitting milk jugs @ 150 yrds consistently) chrome-lined Chinese barrel. Front sight post protrudes 1/8" above the ears for correct elevation using the HK drum sight.

Topcover/feed tray combo for $85, empty gripstick for $12

http://www.robertrtg.com/mg1topcover.html

Robert is the best to deal with. Also sells DM1 links/belts and starter tabs as cheap as anywhere. I believe there's about to be a rush on them. When I ordered an MG1 combo, it was the first time he was ever out of them (they couldn't figure out why) so I settled on an MG3 TC to get started

Pookie -

Hearing that from you is gratifying. I have been an admirer of your builds (esp your .308 bullpup) for several years. Feel free to use any pics I've posted.

[picture 404]

The BC slides freely and it's headspaced. 4130 gas tube was too long - port too close to the muzzle (would only eject w/o with the recoil spring) Shortened it to standard size; has a TIGHT SEAL (mallet-tapped) with the GB. Sleeved a chromed-lined Chinese barrel to an oddball trunnion; used a misc rear sight block which had no sight leaf. Perfect candidates for as cheap as I am.

[picture 404]

I mimicked a pressure plate with my fingers, and pushed the BC to chamber the cartridge. Had already seen Sharpshooter's vids, and now was convinced I could build this. Did it for a couple hours - amazed that it was this simple. TRIM YOUR TRUNNION CONSERVATIVELY.

[picture 404]

1/16" wall on the bottom, 1/8" wall on top. When complete, there wasn't much 'top' left. Above post shows reinforcing rails made from 1/2" ange iron, file- fit to center the TC 'skirts' firmly.

[picture 404]

Starting to take shape

First attempt (of 3) building an "L" BC extension - too heavy to cycle, hardly enough hammer clearance. Seperated the RS guide, and later made a cocking handle 'plate' (above, in earlier post) for the handle, with a 'step' that engages the front of the BC when cocking. It's non-reciprocating, like a G3.

[picture 404]

Top Honors go to Sharpshooter for turning a wild thought into reality - I can't imagine how much effort went into making this design work. I just copied his. First saw it 11-09-07 and had to have one. Thanksgiving trip was already planned, to visit an AK-builder friend in UT for a parkerizing party and camaraderie. so now a visit with Sharpshooter was on the agenda. Took a bottle of Crown along (to bribe him) and my half-done receiver. I would consider this "THE BUILD DESIGN of 2007"

As soon as mama lets me buy another AK kit, I'll make a tutorial with pictures and circles and arrows and a paragraph on the back of each one explaining what it's all about to be use in a court of law against me, Oh wait, that's a line from "ALICE'S RESTAURANT". Disregard that last statment. I will make a tutorial of a simpler build using my ideas, Cntrailrider's and one other build that I know is been done. I will shelve my RPK based build and go for the cheaper "Romy" kit build for now.

So, where are you guys finding .065 or .06 wall 1.5 x 1.5?http://www.speedymetals.com/s-205-square-tube.aspx

Doubletapme designed and built the first 9mm Suomi-drumfed AKs. They are really fun builds!

I sent him pics of my MG47 build as it progressed, hoping he'd jump onboard - and here's what he built.

[picture 404]

[picture 404]

[picture 404]

[picture 404]

[picture 404]

[picture 404]

[picture 404]

[picture 404]

[picture 404]

[picture 404]

[picture 404]

[picture 404]

[picture 404]

[picture 404]

*Receiver and lower is semi-only* so please, no tangent remarks on that, please.

Doubletapme is a REAL machinist (unlike myself) as the pics show. You see what he did differently, inside.

Here's some video of my first testfires.

[video 404]

[video 404]

I switched alot of things as I went, but yes I had to cut the drum bracket off the MG3 tray for the ejection port.

I can run either feed tray. MG3 tray has the spring-loaded cartridge stop (easier handcycling & test-feed during the build) but the MG1 tray seems to feed/shoot better. Remember I am running a stock piston - don't have excess pressure to waste, driving springs, generators, appliances etc.

Bought my tubing at the local steel supply for about $30 (enough for two) I call first, @ $3 a gallon.

Doubletapme built this ingenious twin-spring set-up.

[picture 404]

[picture 404]

A BF Pistol build is possible.

cntrailrider +sharpsshooter

I am ordering the things I need this week.

Please check me on this:

Romy kit (have)

MG 1 feed tray assembly (robertrtg)

Links and drum? what links are the ones cntrailrider is using?

Stock (have)

1.5"x1.5" tubes .120 thick How long?

pistol grip Cetme (have)

In the post they use 8mm links, just wondering what mods were done to us rpd links. Same spacing etc.

Cheapest place for RPD?

what links are the ones cntrailrider is using?The links are German DM1 links made for German 7.62 Nato beltfeds like MG1, MG3, HK21, etc. They are sold by RobertRTG and fit the MG1 cover combo perfectly. The RPD links are a different pitch and will not work with the MG1 cover.

I have a few thousand M60 links, is the pitch the same as MG42, MG1, MG3?

My MG47 has a Romey barrel, bolt carrier and bolt, homemade gas piston, gas tube made out of a Revelation 12 ga barrel, FAL fire control group, L1A1 flash hider, MG3 top cover, K98 rear sight, MG53 belt links, M60 return spring, homemade butt stock, gripstick, and forearm, SAW 249 belt pouch, Chinese bi- pod.

My receiver tube is 15 3/8" long 1-1/2" x 1-1/2" x .120 wall square tube.

Ok, so you have to crush the links a bit to hold 762x39?

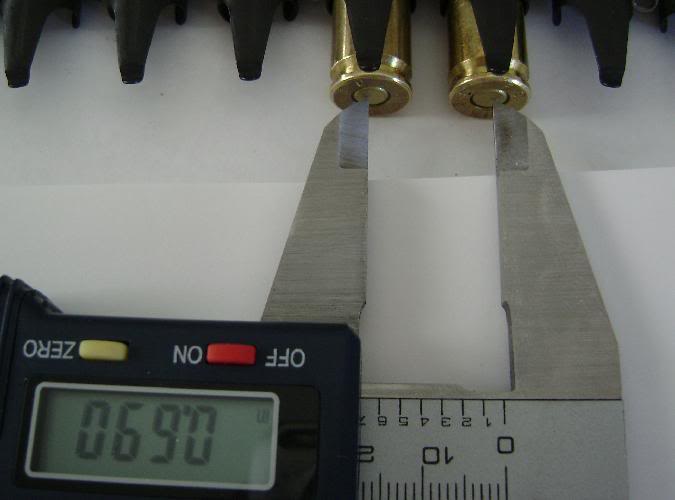

Could you measure the pitch of the links youre using when you have a minute?

VZ58 7.62x39 fit fine into mg3 links without not crushing, just not as tight as 8mm/308. The MG3 link pitch is approximately .66"

The link question is not about pitch, its about length as they are all using regular sized similiar cartridge cases. The links are a certain length and the feed trays are designed with a bullet stop/link stop that helps keep the bullet from lurching forward and cant off center thus causing jamming. The Link/bullet stop holds the last spent link in place when the bolt strips a round out of the belt. If you have shorter belts than the one designed for the feed tray you are going to get one jam after the other. You will have to modify the bullet/link stop position to the RPD Link length. That's why they are successfully using the 7.92 x 57mm parts together, only the 7.62 bullet is short... not the belt links.

DMI Link= 1.437" Pitch 0.66 (2nd confirmed above)

NATO 7.62 Link = 1.333" Pitch same 0.66"

NATO 5.56 Link = 1.058" Pitch is 0.500" (1.097" with round inserted)

RPD links = 1.196" loaded x Pitch 0.66" (RPD info by Sharpshooter5090)

and that's not loaded with rounds, you have to measure the length needed with loaded belts.

So what is the bullet stop/Link stop length for the guns using MG1/3/42/53 parts? compared to the loaded link length? and there is your tolerance to add

edited to add: The RPD Pitch would be close to the above 0.66 since the rounds are not "AS TIGHT" as 7.92/308... so you're talking thousandths of an inch difference and the MG1/3/42/53's have bullet guides to center the cartridge in the feed slot once the feed pawls move it into position. So the Pitch would be of minimal concern... the link length however is paramount to stripping without jamming.

RPD link length measured from the base of a cartridge inserted in the link to the square shoulder of the link that will bare on the link stop on the feed tray is 1.196. There are 2 types of RPD links, one that snaps into the extractor groove and one the is bent over the back of the cartridge. Thats why the measurement is from the base of the cartridge.

So do RPD work? M60 work? Do you have to do anything to the DMI to hold the 39?

Even though I have both types of RPD links and M60 links I have not yet tried them. Will some time, just haven't had the chance.

RPD Belt noted 1.196" using extractor groove type. A suspect the pitch is very close to 0.66" based on your statements of "not as tight" as 308 etc.?

Give us the 2nd type length for complete info too.

and the length of the MG3 belt loaded, please.

What is the bullet stop width (from rear inside feed tray to bullet stop) for the DMI Links on the MG1/3/42/53 Feed tray?

RPD link length measured from the base of a cartridge inserted in the link to the square shoulder of the link that will bare on the link stop on the feed tray is 1.196. There are 2 types of RPD links, one that snaps into the extractor groove and one the is bent over the back of the cartridge. Thats why the measurement is from the base of the cartridge. The length is from the base of a cartridge inserted in the link. It is the same measurment from the base of the cartridge to the square shoulder on either type of link. The measuement I gave is not from the extractor groove, it is from the base of the cartridge. The pitch is .66 on both types of RPD links.

Thanks SHARPSSHOOTER5090, I understood you about top of link to base of cartridge.

So what's the width of the link slot in the feed tray? (Bullet stop end to rear inside feed tray, where the links push through and fall out)

Sounds like there would be minimal play for any of the belts using intermediate rounds.

My homemade feed tray measures 1.535 while my MG53 feedtray measures 1.510, a bit shorter.

OK so to educate the ignorant: (that would be me)

You can cut out and replace a stop on these?

So the more critical thing is the pitch must match?

How are you securing x39 rounds in the 308 links?

When I try it in the M60 links the rounds are way too small.

M60 links are too big. You have to use MG3 belts even though MG3 shoots the same 7.62 NATO.

M60 links only work in an MG3 with an MG3 feed cover and feed tray. They will not work with the earlier MG1 & 2 parts.

Yes the DMI links are tight fitting compared to the M13 links for sure;

DMI inner dimension is 0.400," M13 link is 0.458" very noticable to the eye even and Sharpshooter says the M43 rounds are not as tight even in the tighter DMI link.

All 3 types have the 0.66" Pitch

DMI Link= 1.437" , Pitch 0.66, Inner dimension 0.400"

NATO 7.62 Link = 1.333" ,Pitch 0.66", Inner dimension 0.458"

RPD links = 1.196" (loaded) x Pitch 0.66" ID ? (RPD info by Sharpshooter5090)

MG53 Feed Tray Bullet Stop link space: 1.510" , MG47: 1.535"

Hey Sharpshooter what do you get for an ID for the RPD link? I just measured width across widest point inside using my digi-caliper.

Anyone want to load up a DMI (MG1 etc.) link a post a length loaded? Also a loaded M13 (M60) link loaded? I have all the links but no rounds for them. Top of link to base of cartridge.

Do you need two recoil springs to have enough force to strip the round or is there another reason for 2 springs?

M60 links 1.367" from base of round to front edge of link. there are a couple that are 1.371" link but that is the exception.

I have another set of links that came of the M240 and some off the M249. The M60 and 240 appear the same.

Since the drum is interfering with the clearing of spent rounds ejected low left, how about a pic of the underside clearance between drum and receiver? I have an idea.

The I.D. of my RPD links is .373 to .378.

Originally Posted by MkCanuck9rSo there's a .022" to .027" difference.

DMI Link= 1.437" , Pitch 0.66, Inner dimension 0.400" RPD links = 1.196" (loaded) x Pitch 0.66" ID ? (RPD info by Sharpshooter5090) Quote: The I.D. of my RPD links is .373 to .378

Would that be to tight to extract the round from and RPD link? I don't think it would be.

RPDs extract the 7.62x39 round from the that tight of link but to push one out of the link by hand is very hard. They must have very strong return springs.

DM6 Link= 1.437"; Pitch 0.66; Inner dimension 0.400"

NATO 7.62 Link = 1.371"(loaded); Pitch 0.66"; Inner dimension 0.458" (Loaded by vz58)

RPD links = 1.196" (loaded) x Pitch 0.66" ID .373 to .378 (RPD info by Sharpshooter5090)

(Note: Measurements taken from top of link to base of Cartridge, thus "loaded")

MG53 Feed Tray Bullet Stop link space: 1.510";

MG47 Feed Tray Bullet Stop link space: 1.535"

Links unloaded;

DM6 Link = 1.437"; Pitch 0.66";Inner dimension 0.400"

M13 Link = 1.333"; Pitch 0.66"; Inner dimension 0.458"

RPD Link = ?.???"; Pitch 0.66"; Inner dimension .378" nominal

M27 Link = 1.058"; Pitch is 0.500" (1.097" with round inserted)(5.56 NATO)

vz58 i used the larger size. The M60 and M240 use the same M13 link design as does NATO which i have here (cdn made). The M249 link is just a reverse engineered M13 Link to fit 5.56 NATO Rounds and renamed M27

SS: Thanks for the RPD I.D. would it be safe to say most are .378"?

SS: One more measurement? DM Link loaded with M43?

Sounds like if you want to use the RPD Links you better use the dual Return Spring option to have positive stripping force, a good fitting bullet stop (to link length) and a feed tray modified to size of round length to hold everything from flopping all over and causing jams.

edited to add all the data and change DMI to DM6 as this is the MG3 Belts. DM1's are WWII-MG1. There is suppose to be a pitch difference between them. It appears i have the DM6 variant.

I have spent the last 30 min or so playing with a receiver and bolt. I like the idea of a drum but since the rounds eject between the belt and the drum you could have issues.

You can get the MG47 to BOTTOM eject and even a little bottom right eject. OK OK I know your saying I forgot about the gas piston. No I haven't, think BREN, the piston is on 2 arms running on either side of the receiver with a big open hole in the middle. The standard ejector and extractor will throw the round to the lower left but the receiver wall is in the way. The round is knocked off the extractor and aided by gravity falls between the two rails for the gas piston and out of the receiver. Now the question is will there be enough room under the receiver and above the drum?? Dunno need to see a pick.

But if you had a rounded chute to slide the case more bottom right I think it would consistanly eject down and slightly right.

Pics of the receiver and drum anyone?

MkCanuck9r you are right, I just pulled a couple of cases of belted 308 out and every case has M13 on them in one place or another.

Quote:

The link question is not about pitch, its about length as they are all using regular sized similiar cartridge cases.

All 3 types have the 0.66" Pitch

They are definately different pitch as well as length. If the DMI is .66 pitch and the RPD is .59 pitch then there is about .07" difference. I am not saying you could not get it to work with some modification. I'm just saying you would likely have to make modifications to deal with reliability issues. The Stoner 63 links and SAW M27 links are almost identical in every dimension except for pitch. Yet if M27 links are used in the Stoner it has such adverse affects on reliability that they are not considered interchangable.

Quote:

Do you need two recoil springs to have enough force to strip the round or is there another reason for 2 springs?

My reason for using two springs was that I wanted full length springs contained within the receiver. I accomplished that by locating the springs to the sides and swinging the hammer between them. The dual springs also allow greater momentum in both directions of the bolts travel to overcome heavy belts and improve reliability. My buttstock is quick detachable and the weapon functions with or without the buttstock attached. I have a tendency to make parts overly complicated but I can't help it because I enjoy machining and love uniqe weapons.

Quote:

Since the drum is interfering with the clearing of spent rounds ejected low left, how about a pic of the underside clearance between drum and receiver? I have an idea.

I made a short ejection chute that directs the spent rounds straight down but I have not tested it yet.

MkCanuk, grab a bolt, receiver and round. (no carrier) now put the bolt and round togther in the receiver and chamber. Get a CD case or something flat and put it on the extractor side with the gun upside down. Pull back sharply on the bolt and wala! The round strikes the ejector and the mouth comes down, hits the cd and ejects straight down with force. It will work if the drum is not in the way. Now if there is room between the grip and drum make it eject there by moving the ejector further back.

I am thinking of using a M44 barrel. I can shorten and turn it down can anyone suggest someone to cut a x39 chamber?

doubletapme thanks for the RPD update

DM6 Link = 1.437"; Pitch 0.66"; Inner dimension 0.400"

M13 Link = 1.371"(loaded); Pitch 0.66"; Inner dimension 0.458" (Loaded by vz58)

RPD link = 1.196" (loaded) x Pitch 0.59" ID .378 nominal

(Note: Measurements taken from top of link to base of Cartridge, thus "loaded")

MG53 Feed Tray Bullet Stop link space: 1.510";

MG47 Feed Tray Bullet Stop link space: 1.535"

Links unloaded;

DM6 Link= 1.437"; Pitch 0.66";Inner dimension 0.400"

M13 Link = 1.333"; Pitch 0.66"; Inner dimension 0.458"

RPD Link = ?.???"; Pitch 0.59"; Inner dimension .378" nominal

M27 Link = 1.058"; Pitch is 0.49" (1.097" with round inserted)(5.56 NATO)

Edited to add: I checked and double checked, even using extra light and magnifying glass all the Links i have and the numbers are correct (+/- 0.003). I used a digital caliper to get the results. DM6, M13 and M27 is all i have. 0.49" on the M27 will consistantly center on c2c of links, center of bullet tips and center of primers.

Having built several belt feds, 1919s, MG34s, MG42s and an FN30, I can tell you that the link pitch is important. MG3/42 belts are readily available for less than RPD belts that are different and more than likely won't worth in an MG1/2 feed asembly. also the only variant of the MG42 the MG3 is the only one to use links. M60 links work but only with an MG3 feed cover and feed tray, covers and trays from an MG 1 & 2 won't strip or feed them.

Ok since I am going to order tomorrow if possible..

MG3 tray and upper is $90+45=135

MG1 tray and upper is =$85

Will the MG3 links work in the MG1? using the 762x39

Will the RPD links work in a MG1 tray?

Should I spend the extra for the MG3 or not?

Anyone who KNOWS please advise.

To use M60 links you need the MG3 feed cover AND MG3 feed tray. Combinations of trays and covers will not work for links. I have already been through that with my MG42.

Also keep in mind that while the M60 links work, the MG42/1,2,3 belts work better.

The belts are readily available and are cheap. Personally I think a non disintegrating link belt is better than links. They are a PITA to load and pick up off the ground.

As I stated in a previous post you need to use the links that the feed mechanism was designed for. Kind of like loading an AR15 mag with 5.45 ammo and trying to use it in an AK.

I failed to mention one more thing. Will MG3 belts and M13 links use the same tray and cover? I don't mind having to modify the cartrige stop if ness.

FYI, some of the cover/link/belt info can be found on the FAQ posts on the MG42 website:

VZ, the MG3 is the only MG42-style cover that can use the M60 links in addition to the German design links and belts.

Hcpookie, outstanding site cleared things up nicely.

Looks like a MG3 tray and cover and M60 links=M13 links

Looks like a MG3 tray and cover and M60 linksLike someone said already, that combination works for .308 but 7.62x39 fits too loosely. I would recommend you go with the MG1 top cover, feed tray, and belts because we already know that combo works with 7.62x39.

Yup gotta agree... stick with what is proven. MG1 Cover, Tray and DM1 Belts.

MG3 uses DM6 and M13 links, but I have already shown that the M13 link.

Inner dimension is 0.058" larger than DM6 links (0.400) so the M43 cartridge would be a sloppy fit indeed, if they don't fall out.

Note that SS used a homemade feed tray made to fit the shorter length M43 cartridge, but you can just put in a spacer in the MG1 tray to fill in the space.

MkCanuck -

No been busy with other stuff. Drum report may take awhile. I made an additional drum bracket, rotated about 60 degrees to feed from 9:00 (instead of 11:00) for more clearance. '42 gripstick is mounted about 1/2" further aft so that should help too.

DM1 links are proven to work. No reason to get off track.

$95 for a '42 gripstick drilled to accept AR FCG @ Weaponeer - a used stripped gripstick from Robert is $12, you drill your own holes; needs some milling which can be done using large bits on a press.

Ok, MG1 tray and cover.

DM1 link (didn't see on Robert's web site?)

May go with the 42 stick as i have a milling machine.

Need to find a spare front trunnion.

Ok, RPK parts kits from Inter-Ordinance are on their way,

Steel from Speedy Metals.

Feed tray and top cover from Robert's RTG.

Can we get some dimensions from the guys that have gotten the guns to work good, ie: what is the dimension from the bottom of the receiver to where the feed tray rests?

I have noticed that on subsequent builds it appears that there are upper rails inside as well but appear milled (don't know how that is) but any advice would be great.

Going to use CETME semi auto trigger housings on my builds and attempt to concoct some type of AR-15 dust cover because it would appear hat since ther'e a heck of a gap between the rounded bolt and the square receiver that might catch some dirt.

My build will hopefully end with a SAW style butstock and a quad-rail Picatinny handguard system. Have also been thinking about welding a scope rail onto the side for quick attachment of Euro style mounts for an EOTECH.

Where should I get belts?

Do you gurus think I will have a problem if I just use a stock RPK barrel setup and gas tube? I notice most have customized theirs. I plan on adopting a duel recoil spring setup utilizing two AK springs.

I also plan on trying to construct it with some hard mounting points so it will attach to my MG3 tripod.

Two last questions, one regarding the welding together of the two 1.5" square tubes. On the finished guns the sides look so smooth, are the welds ground down and blasted to blend in or are they just hidden in the pictures?

Can I headspace the barrel into the trunion without the trunion being riveted/screwed into the homemade receiver?

[picture 404]

It can be headspaced as soon as the trunnion is mounted and the BC is sliding on the 'lower' rails (tube cut-out) and locking up. My receiver length is 15- 3/16". Be sure to go long.

[picture 404]

Trim/grind/mill the trunnion & FT (conservatively) until it chambers. You won't need to trim it this far. Experience = litany of mistakes. I have lots of experience. Positioning the FT so it chambers is critical. I carefully modified the slot. Use your fingers as a pressure plate. When mine first chambered, I got light-headed, realizing this build was going to work. A beltfed = alternative mechanical feeding device.

[picture 404]

Recess, cut to position the tray where it chambered best (MG3 drum latch was removed later)

[picture 404]

Now you have a very close estimate of where the TC will be positioned. At this point I joined the halves

[picture 404]

Cut then file so feed lever movement will just barely clear the sides.

I opened up the top rear and replaced the latch section, later. Study SharpShooter's closely.

Then it's time for the BC extension, and making a belt of 7.62x39 feed & chamber through a .308 feed mechanism. It's starting to look like a gun and the fun has be-GUN

----------------------------------------------

[picture 404]

The length of your BC extension will be determined by what FCG/lower you choose. Mock up your lower, extend the hammer to reach the FP, measure arc, then determine BC ext. length. I know no short-cuts. It needs to clear the BASE of the feed stud, and that will be TIGHT. Where you position your lower will determine whether you can use a drum (ejection path) The further aft, the more options for belt storage - taking the hammer arc/feed stud clearance into consideration.

----------------------------------------------

MG42Gripstick w/AR15 FCG - my first & successful conversion (skipping way ahead here)

[picture 404]

The existing trigger axis pin hole can be used (it's already the same size) for an AR15 trigger - but it will be a VERY tight fit.

[picture 404]

Opened the lower using a drill press and large bits. Outside E-clips hold the long hammer pin in place. Pin in the rear is a trigger stop, until I get a F-S selector made. Movement is about 1/4". If the trigger pivoted any further, trigger slap would result. Tight fit.

[picture 404]

Hammer (extended) is concave on top for BC clearance. It's very tight - uses the front hangar hooks, and mounts flush with the tops of grip panels.

[picture 404]

The MG47 is a very aggressive build. I don't know of any short-cuts, other than the logical sequence I've shown here.

Test fired mine with the RPD drum today in 30 - 40 MPH winds (sandstorm) and all casings cleared it and the belt. It didn't jam but I got sand-blasted head to toe. Vid hopefully this weekend.

Gonna deal with the ejection issue down the road, right now deliberating how to go about installing the upper rail(s). Do you guys suggest one upper rail on the left as in the recent build photos, or two? I was going to mill down some bar stock and then spot weld them inside. Do you think a small angle would be better with a screw/rivet set up?. Also, what have folks been using as a makeshift mounting point for the feed tray other than a cross pin. ie: what are the ears made out of?

ctlaw74, seems to me if you do what cntrail did (rotate the drum 90 deg) that is the absolute simplest way to get it to work. (as far as ejection goes).

Here's video with the drum, which came loose but you'll get the idea. Ejected casings do clear it. Disconnector sticks; needs polished, hence the jerky trigger finger.

http://media.putfile.com/Before-the-bracket-came-loose

Originally Posted by glock cool now if I can just rack my puny brain on how to build this. I'm far from being able to mill or weld yet.Thinking aloud here.

You may be able to rivet the receiver. Maybe. Looking back at Sharps' original receiver pics.

You could get 1.5 x 2 tubing and something smaller that fits inside for the rear buttstock mount. Get some 1" tubing, or equivalent, for the rails.

The mount point for the top cover could be done with a shim that you place in- between the mounting hardware (rivets or bolt) and the tubing. You may be able to use just a piece of square stock that fits in-between the mount holes on the top cover. Drill holes on the sides of the tubing and dremel it to shape. Then

Bolt or rivet the trunion to the front of the tubing.

Bolt or pin the buttstock tubing to the receiver. That way you can disassemble it later.

Rivet (or bolt?) the rails onto the sides in the same way that you would on a completely screw-together AK build. Rails could be cut from square .064" tubing.

Have I missed anything? Cut the ejection hole and hole for the charging handle.

Again, thinking out loud. There could be some engineering challenges I missed, but this could be the basis of a "no-weld" build. You'd still have to come up with a trigger group and mount for it. But you could attach the mount with rivets even.

Sharps, all of my prototypes are too labor intensive! That's why I can't bring myself to redo parts of my 308 bullpup build yet. It is frustrating that you have to redo something you may have spent so much time getting right the first time.

I have been reconsidering the 5.45 belt feed RPK. I have some SAW links and I've already decided that yes, it can be done and look similar to the Russian prototype, but the problem today is finding an affordable SAW top cover.

I know that there was a 5.56 MG3 design that never really did get into production. Or if it did, I don't know how far it got.

Another source may be the HK belt feed parts. The HK21 is at its heart, basically a G3 converted to belt feed.

Pirate, or anyone, do you think that you could facilitate a caliber conversion based on the use of brand new feed pawls?

Here's my thought - take for example an MG3 top cover. Keep all the parts EXCEPT the feed pawls. Measure and machine new feed pawls based on the new cartridge's links. In this case, the SAW links.

Question - would the travel arm need to be replaced as well?

ETA - I have somehow misplaced the pics of the RPK beltfeed prototypes. One of them had a coil-wound drum. Does anyone have a copy of those pics?

Pookie, basically the pitch of the belt determines the location of the feed pawls and the travel of them. it is not so much the shape.

The problem here is that cheap feed covers ie the 1919 or MG3 are too big for most of the applications you want to try. the hk21 is extremely hard to find and expensive.

If you are really hell bent on a X39 build bite the bullet and buy a RPD kit. I was going to buy a top cover and feed tray at Knob Creek but didn't and have kicked myself for not getting it.

This is for Pookie, Glock and anyone else who wants to do a 5.45 or 5.56mm build.

It eliminates the need for a purchased top cover but you will need to do more work, but its a simple system. The Israelis developed it for their LMG, you just make the bolt carrier like Doubletapme, but with a ramp on the side to activate the lever which is pinned on the side of the receiver. Pitch is what you make it to work with your links/ammo combo.

I flipped the pic for you to see what I mean.

This one shows the Negev is designed to take Galil Mags as well.

Here's the Bolt Carrier system. As you can see its very similiar to Doubletapme's design;

Here is a pic of the Negev LMG with the Feed Lever Cover RED Circled to show you where its located for LHF.

...just reverse it to the RHS for RHF.

As you can see the feed cover is just a box with cartridge retainer and Alignment pawls, no need for big engineering computations. Find the pitch for your belt/ammo and make your feed arm to match.

I have been taking pics of DM links loaded, M13 links loaded as well as 5.56 M27 links loaded with digi-caliper for this thread to help out anyone wanting to build one like this.

I will post those pics as soon as i finish the 5.56 pics... some didn't turn out clear enough for publication.

edited to add;

One more pic to show feed lever cover, plus show the cool Negev with Mag inserted

That Negev feed pawl is Kalashnikov's PKM design adapted to a smaller scale and I'm sure the feed actuator is a different shape. Looks like the same idea as that prototype belt-fed RPK.

I'm not scrambling for a SAW-style belt fed at this point. Yes, I have fit 5.45 ammo into the SAW links and it fits, and yes, 5.45 ammo is cheap right now. But I have too many irons in the fire. I've got to make progress on some other builds before I consider a 5.45 belt-fed.

What was the name of that other belt fed 5.56 that also has a drum? The one from Taiwan or Korea or something? Seems there were parts kits for that from Orin (aka 7.62x51) at one time. That one seems pretty straight-forward in concept.

My tray is less than 1/4" above the new 'upper' rails - one with ejector tip. Position your tray on top of the bottom tube with clamps, and cycle your BC, adjusting FT height (I used two 3-way C-clamps) until the bolt will chamber rounds. Look close at my trunnion and tray pics - save them to file and zoom in. Where it's positioned in the pic is where I got it to feed best. Look at the 3rd pic in post 193; the back lip of the tray is flush with the top of the upper tube. That will get you very close.

[picture 404]

Here's another pic of the front - placement relative to the trunnion PLUS the recess in the back (for the bolt-stripping lug / almost touching) is the starting point.

[picture 404]

Before reinforcement rails & 'bridge' were added.

Quote: Originally Posted by hcpookie That Negev feed pawl is Kalashnikov's PKM design adapted to a smaller scale and I'm sure the feed actuator is a different shape. Looks like the same idea as that prototype belt-fed RPK. I'm not scrambling for a SAW-style belt fed at this point. Yes, I have fit 5.45 ammo into the SAW links and it fits, and yes, 5.45 ammo is cheap right now. But I have too many irons in the fire. I've got to make progress on some other builds before I consider a 5.45 belt-fed. What was the name of that other belt fed 5.56 that also has a drum? The one from Taiwan or Korea or something? Seems there were parts kits for that from Orin (aka 7.62x51) at one time. That one seems pretty straight-forward in concept.As i posted earlier the feed pawl is indeed a Kalashnikov type but according to reports i read it is taken from early post war Czech MG designs...but you can definately see where the Isreali's got the idea having thousands of captured PKM's and RPD's.

Good to hear the 5.45 will fit in M27 Links... thanks for that... care to post some pics for comarision... I am posting dozens in a minute Glock can use that info for a belt fed MG47 in 5.45x39mm using the feedlever design.

The gun you are thinking about is the Ultimax 100 Mk4. It is not belt fed, only drums and mags like a RPK... so you would mount your drum on top on a MG47.

http://www.ultimaxsaw.com/Ultimax%20100%20Models.html

Negevs are awesome guns and i saw that parts kit two years ago and it still hasn't sold... why spend $5000 on it when you can use SharpShooter's concept, add the Negev type lever/cover and build one for $500.00 or less using whatever belts you have that fit the ammo of your choice.

OK, belts. I have spent a long time getting these, the 5.56 took the longest to get good pics of. I must have taken 200 pics all together to get this handful. These were taken to help anyone wanting to build a MG47 in 5.45/5.56 using a AK74 parts kit, SharpShooter's design concept and adapting it to use a RH Feed Lever via Negev type feed lever posted ealier.

I cannot take pics of RPD Belts loaded as I don't have any, sorry. I only had DM6 links (I take them to be DM6 as they are definitely not DM1s), NATO M13 links and NATO M27 links.

7.62 x 51mm NATO was used in the DM6 and M13 links as I have no M43 rounds.

5.56 x 45mm NATO (IMI made) was used in the M27 links.

Digital caliper used to measure. Brand new and zeroed.

DM6 Link Pics

Linking Tab end. NOTE markings

Links measured length

Links measured Length loaded

Links C2C

Links C2C lighted to show grooves match up

Link coil connectors C2C

Links C2C bullet tips

Links C2C primers

M13 links loaded with 7.62 NATO

M13 links alone

M13 Links loaded length

M13 links loaded C2C Pitch 66 TOO WIDE

M13 links loaded C2C Pitch 0.59"

M13 links C2C Bullet Tips

M13 links C2C Primers

5.56 X 45mm NATO pics

(I found with 0.470" I could place the caliper anywhere on the link pairs and get a perfect match)

M27 links loaded length

M27 links C2C left of hole

M27 Links C2C right of hole

M27 links C2C offset as fed by pawls

M27 links C2C bullet tips (seems the hardest to take for some reason)

M27 links C2C primers

M27 links C2C primers 2

Hope someone can use this info for MG47 feed lever type build.

Quote: the UK59 has a lever feed system that is real simple also. That's the Czech Gun quoted as being the concept the Isreali's took fromYou guys are exactly right. The Negev feed system is almost an exact copy of the Czech VZ59/UK59 with a short feed lever acting on the near side of the bolt carrier. They just reversed it for LHF and flipped the retainer pawl from the feed tray to the top cover. I am in the middle of building a UK59 right now and can take pics of the feed mechanism. I will just have to figure out how to post them.

The top cover/feed mech comes apart without tools. You will become intimately familiar with its workings by the time you get your MG47 working

Reinforcment rails seal the gaps between the WIDE TC skirts / receiver, and keep everything enclosed.

Have been thinking of milling the sides of the top cover and narrowing it through most of the length.

The left side can be cut back about .302" the right about the same. I will prob use a .25" endmill and cut it and then reweld. the gap then will be significantly smaller.

After looking at all the parts, I think that the ejector would have to be flipped in a standard AK receiver. The feed tray looks like it will have to almost touch the ejector rail to have the bolt lug stick far enough into the tray to strip a round. I wonder if you couldn't even get away with spot welding the ejector to the bottom of the feed tray.

One more question on gettting the feed tray set right. Cntrailrider said that he tapered the stripping lug on the bolt to fit the tray. What about the back of the carrier or does it just slide under the tray and not enter the slot?

I had to narrow the back of the carrier also but my feed tray is different than Cntrailrider's. If the bolt and bolt carrier slips between the slot in the feed tray and the open slot on the bottom of the belt link, no problem, but if it doesn't you will have to narrow it. I have a MG1 feed tray at home a romey bolt and bolt carrier and will see if what has to be modified tonight. If you don't here from me by Sunday evening, I will be in Toronto for a week on business and maybe Cntrailrider can answer your question.

[picture 404]

Locked up, ready to fire - note small clearance cuts for links, and shortened cartridge stop - tedius Dremeling. Top face of BC face sets about 1/16" or less beneath flat surface of tray. Previously mentioned - stripping lug was built up about 1/16" it would chamber hand-cycling, but not in semi/shooting, until that was built up. Bolt would slip by without stripping the round. You will encounter a few other things like this that become educational.

Enlarge your slot conservatively or they'll drop through. Takes a little tinkering till you get it right. You'll know.

[picture 404]

Remove the .308 mouse-trap spring - too strong to feed. Set-screw held weaker replacement coil spring in place, until I learned NO PRESSURE PLATE SPRING was needed - lucky find - couldn't believe it.

WARNING: The first time it consecutively feeds two rounds, you will experience a euphoric sense of light-headedness. That is normal.

A fifth screw on the bottom also holds my trunnion (and bipod) and some more could be added up top (hinge area) using spacers, if you're concerned about strength. A good front-rail-to-trunnion-fit will accomplish secure alignment, eliminating strength & saftey concerns. Cap screws = larger sockets = more torque. No reason for stream-lined buttonheads.

I had to remove the front end at least a dozen times until it was finished and working properly. A lot of that was due to the sleeved Chinese barrel (saving pennies here) and bringing the gas tube back to standard length. My block is off a '74 and that helped, being able to 'over-port' it with a 90 degree/vertical hole. So good thing it was screwed. I suppose it could be plug-welded hmmm when finished, if cosmetics were that great a concern. My 'upper' rails are welded.

This is the perfect project for using up those leftover spare parts laying around, rather than buying everything new. My total cost was under $300, including the more expensive MG3 topcover & tray (MG1s were sold out at the time) which I had to 'ruin' by removing the drum latch, in the end.

Just got my first TIG (Miller Econotig) so some things are getting a re-do (reinforced FCG holes (gripstick walls are thin) did a better job on the extended hammer, extended the cocking plate / added a 'slot guide'; improving the cocking handle mount is next) then it will be on to a pistol attempt. Plus I have a stack of HK flats sitting here. As one builder put it, 'It never ends, Thank God'. Also made a nice fire/safe selector which will get flourescent red nail-polish.

Thread's been pretty quiet, and I take that as a good sign - bet the grinders are running & the dust is flying - we'll soon be seeing new pics of other builds, and getting more technical build-related questions.

Just got back home to find a trunnion waiting for me.

I have all my parts except the bolt and carrier (on the way)

Need to tighten a bolt on my mill though before I can use it (its 300lbs down, around and behind everything...)

May get to cutting tomorrow!

parts:

MG1 cover

MG1 feed tray

MG1 links

RPD drums

Yugo trunnion (slab side)

finned Yugo RPK barrel (I am thinking of fluting it on the front end)

Yugo bolt and carrier

Have not decided on FCG.

Parts kit is almost ready for the build, but need to tap the trunion and of course do the BC mods. Won't do that until I have the trunion in the receiver and the BC riding on rails.

Upper and lower metal cut to 15-3/8" today on the band saw. I'm using the 1/16" tubing. Am I going to have to mill the top rails for the BC? Looks pretty thick to me!

MP43 yes it will be too thick, File or mill down.

Ctlaw -

The gas port hole can be drilled perpindicular to the barrel (if block is removed) easier/minimizes bit breakage. Can use a filament light through the port to confirm it lines up. Some folks drill them through the block, diagonally with it in place. Mine is out to .191 which seems awfully large, but accuracy has not suffered. I was concerned about that. Make your super- tight-fitting gas tube last. You can headspace as soon as you get your trunnion in and the BC sliding on the rails - that's where the simplicity of a screw build helps alot. Eventually someone will figure out rivets, using home tools. I like your idea about a self-opening dust-cover for the ejection port.

Sniper -

I cut my tube/rails with a hand grinder (no mill here) then coarse file to fit BC; underneath too, to remove the full-length burr. Are you using 1/8" wall on top?

Remember that square cut-out in the rear of SharpShooter's receiver? Feed stud. I need to unscrew mine whenever I remove the BC. That is ripe for new ideas.

Sniper

I built mine for all 1/8" tubing and I think you will have less welding problems that way. Cntrailrider used a combination (CTR correct me if I am wrong) and had some warpage issues from welding.

Either way will work.

Main reason I used 1/16 on the bottom was the RAILS - it's already the right thickness for the BC to slide on. Also easier cutting the cocking slot, ejection port & FCG holes without a mill. I used a cutting wheel, Drmmel and files.

It did warp when joined, and twisted that out when I removed the TOP of the rear (TC latch area) then went back over my less-than-perfect joining-welds and filled in the pits. Some very small pits are still visible if you look closely. The reinforcement rails remedied strength concerns, center the TC skirts firmly (full length) and close that gap.

SS's didn't need R-rails, using all 1/8", but both of his UPPER rails are full-length too. My ejector rail is a standard short one that came with a flat.

1/8" on top gives a stronger anchor for the TC hinge and latch area. It's still theory at this point, but I believe 1/16 throughout would need R-rails for sure.

Taper the stripping lug - it needs to fit through the links - and open the slot almost to where the round will fall through. Round is suspended by the belt, positioned & guided by the pressure plate.

VZ58

The shortest simpliest path to the chamber, like a pistol-caliber conversion, increases the 'likelihood' the round will chamber. To say this is 'experimental' would be an understatement, since using a .308 feed tray already increased that distance of cartridge travel. The MG1/3 TC will not feed 7.62x39 without a few mods to the (brittle ! hardened) pressure plate as well, since the round is weaker, and a 'slicker feed path' must be created, in order to cycle. Front lip must be bobbed to clear the trunnion; rear 'lip guide' must be almost straight to reduce feed resistance, even w/o the spring. These two mods are inter-related. The cartridge stop on the feed tray must be lowered (as well shortening the 'arc stop' on the pressure plate) so the pressure plate can swing lower, to guide the smaller rd, yet not too low that it blocks the next rd-to-be-fed. It is work & thought intensive to accomplish, and I don't know a set formula that works.

Not to dim anyone's hopes, but this is by no means a simple 1st or even 5th AK project. It was a very steep learning curve, after building several other beltfeds - borrowing knowledge from every build I've ever done. I know Emory is a slightly different catagory of builder, and an exception (bonified 1919 CII guru)

Mentally approach it as a conveyor-fed mag. The rest is a scratch-built-rcvr AK. or as Doubletapme put it, "A beltfed using some AK parts."

2nd pic, post 91 is the starting point; 4th pic shows position of feed tray, where chambering was accomplished

The bolt and carrier has to be narrow enough to pass between the open bottom of the belt link. If it doesn't, it will hang up on the link and bend the crap out of the link. The bolt and carrier must be narrowed!

Does anyone know where to find the U style RPD belts that retain the cartridge at the extractor groove? All I have found is the other style. Has anyone tried 5.45 in the U style RPD belt?

Numrich has both styles, however they send you some of one kind and some of the other when you buy their RPD drum. I have some of both and will trade for mg3 links if you want.

One last question. I bought the thicker wall reciever stock and after I remove the middle section I planned on milled down the rails a tad to the bolt will slide easily on them instead of milling the bolt carrier grooves wider. Is that the way to go? Also is it OK if I mill the trunnion a little on the sides to fit it in the receiver tubing?

That's the way I did it, thinned the rails down to fit the bolt. I milled the inside of the receiver for the front trunion but with what little you have to take out, I don't see why you couldn't slightly mill the trunion if it's only around .020 per side.

Just thought about another variable that nobody's addressed, wha Distance is the trunion from the front edge of the receiver. IE: How far into the lower half does it go?

Can somebody give me a measurement from the front of the 15 3/8" receiver to the trunion screw/rivet?

Looks like SS's FT is flush with the front. I recessed the front trunnion in an effort to hide the rear sight block as much as possible, yet be able to flip the tube retaining lever. 2XTM didn't use a RSB and his also appears to be flush. Type of handguard you use (placement, retainer) will come into play when determining FT position.

Pics 1, 3 & 5 in post 91 shows my FT location - the distance between the holes = distance back, for the front hole. Be careful about 'choosing' a set receiver length - don't paint yourself into a corner, when it comes to BC extension & recoil spring length & guide/tube. It's easy to fall into the 'cosmetics & proportions' trap, and wind up with a beautiful dummy gun that won't cycle. Longer spring is easier. How SS compacted it into that short stock is beyond me.

Am dealing with a whole new set of variables on the RPD version, right now, with the shortened barrel & gas system. Can see this is gonna take awhile IF it works.

Sounds like you're on the right track. Flip-down grenade sight would be ideal for this. My port is .191 I can't offer any knowledge on the FAL FCG but the AR will work - very tight getting it low enough though, and the hammer spring is borderline strong enough to get primer ignition, even with a weighted hammer.

Here's what I used to smooth the 'step' in my gas tube.

[picture 404]

So the piston can find it's way into the TIGHT section, in front of the enlargement for the BC 'snout'/where there piston attaches. It was a pain assembling, during the build, before that 'step' inside was smoothed (drilled mine out to 5/8" for the snout)

A different approach would be to turn the snout down.

Well I'm committed. Cut the bolt handle off last night and cut open the bottom section and attempted to mill the top (new bottom) rails down to fit the carrier. I used the thicker steel. That leads me to some new questions. Milled the rails to the proper thickness and had to mill a micro amount off the side of the bolt carrier itself to slide freely into the lower section. Same for the trunion. I am noticing that once the top is opened up it has a tendency to bow out which would cause the rail dimensions to open up as well. Chocked up in the vice it is still OK, but wondering about how that gets addressed later on in the build when the top half is added.

BIG question. How critical is it that the rails are perfectly parellel? IE: equal dimensions. I am doing my best but it is a real beatch to get them perfect. Carrier slides freely and doesn't seem too loose. I know it's an AK but am not sure of how loose things can be. I am going to use stock AK rails/ejector for my new top ones so that should work right?

Please tell me I have some wiggle room. Otherwise this bottom will become the new top and I spent quite a bit of time practicing milled rails to the proper height.

If it feeds and the bolt carrier doesn't fall out, OK If you look at my receiver with the top cover open you will see that the open top of the receiver is tied together right behind the feed tray and at the rear of the receiver. CTR welded 1/2 x 1/2 x 1/8 angles to each side to stiffen up the open top of the receiver.

You can squeeze that bow out using spacers in each end, and a vise; should be fine.

Trunnion placement will be more critical than rail width - took a bit of hand/dremmel fitting before the bolt would lock/unlock easily with the trunnion SECURE & ALIGNED. Thickness of the rails determine HEIGHT of trunnion in relation to BC, I had to open up the rcvr-alignment-slots in the side of my trunnion to place it where it would work, even using 1/16" wall lower tube.

SS do you have the 'standard wiggle' in your piston-to-BC connection? That looseness gave me some play to work with, esp with the tight gas tube seal.

Yes I have a a bit of wiggle where the piston screws into the BC. I have a tight gas tube also. By the way, you were able to use the standard gas piston diameter, I recall, but made a new tight gas tube that sealed off the gas relief holes at the gas block. Or am I up in the night.

Yes stock piston, and turned a new tube to eliminate the gas relief holes, and seal much tighter. Also turned the lip on the gas block, for a deeper tube-to- gas-block interlock. It is a mallet fit. Had to open up the rear to 5/8" so the BC 'snout' could enter ONLY as deep as needed; the rear tube HG retainer is press fit; bevel & bottom lip required fitting. It would not cycle, unless the piston had adequate wiggle - the tube is THAT TIGHT. Next one will get the BC snout turned down, but there's little dia to work with, before cutting through.

I looked at your mill; old school quality, and the ticket out of dremmel world. SLC->ELP presents some logistics problems; how big a hurry are you for the space?

I am planning on milled down the rear sight block ears and top so it can fit recessed into the lower tube section. I was thinking about removing the "hinge" pin for the gas tube and perhaps using some sort of cotter pin set up. Any thoughts?Thanks for asking that question, I was wanting to remove the hinge pin also. I planned on using a bolt and grinding a flat side in the middle, running it all the way through and using an E-clip on the one end after I cut the threads off.

I would like to confirm the information, I think I have already, and fill in the following blanks on the three guns that have been built so far:

Gas port size in the barrel:

SS: .1875"

CNT: .191"

DBLTAP: ??

Gas Piston Diameter:

SS: ????

CNT: .545" std. AK

DBLTAP: ?????

Type of Recoil Spring(s):

SS: single, shortened M60

CNT: single, ????

DBLTAP: dual, ?????

Distance from gas block port, to bleed off holes in gas tube:

SS: ?????

CNT: ????

DBLTAP: ????

Any updated testing/feedback in this area? I recall that SS had solved the lack of power and then had a bit too much after sealing the gas tube. And CNT, had enough power to run the gun, but no reserve to speak of. Has DBLTAP's gun been run yet? My first piece is a bit of a departure from SS's base MG47 design, and the gas/recoil spring balance will likely be a PIA to get worked out.

M60 spring, braided or single strand (both work) about 14 - 14.5" long. 1/2" makes a BIG difference using a stock piston. Too LITTLE spring, and the bolt won't strip & lock closed. Receiver rails are 'friction free' to where BC can be slid with pinky. Start with long spring and trim. Hand cycling will help break it in and locate resistance spots to smooth out

No gas tube relief holes, yet no pressure to spare. Delicate balance between spring length & being able to cycle, using stock piston w/ concaved head, 2- ring seal. I should try a third seal cut in the piston head and see if it changes anything. There is enough space to cram another cut in there.

My gas tube is made out of a 12 ga. barrel section, about .729" in diameter. My gas relief port is 1/2' forward of the rear most travel of the gas pistion head. It is 1/8" in diameter.

Well I got an RPD cover and tray and was looking it over tonight. From what I can tell the origonal receiver would have been about 1 1/4" (+/-).

Would it be possible to use a 1 1/4" square tube or even a 1 1/4" x 1 1/2"?

Never mind about the 1 1/4" question, I just looked at the MG47 Pistol thread and I think the pics answered my question.

Emory,

I can't wait to see what you come up with. Sorry it took so long to post those dimensions.

gas port .185"

gas piston diam. .648"

recoil springs and guides = standard AK

the springs were cut and stretched

gas port to bleed holes 4.5"

My rifle is running good except I have an occasional empty case not clear the ejection port. I am fairly sure the cases are hitting the upper edge of the ejection port as they exit and sometimes bounce back. I am going to open that area a little so they eject clean. I still need to put it on paper and see how acurate it is too.

How did you guys "lock" the trunion in the lower half? There are no rivet holes down there so I didn't know whether it's held in place only after welding the 2 halves together or if there were other ways of keeping it in the lower part before welding.The trunion only attaches to the upper half after the 2 pieces are welded together. I believe though, that Cntrailrider threaded a screw into the sight block from the lower half. Not a bad idea, just helps to tie the trunion in better. I think if you do that you should do it after the two halves of the receiver are at least tack welded together.

I spent a few hours on this this weekend and made some good progress. I need to add the filler under the feed cover on the left side next, then correct the cover latch in the rear. I am planning on installing the ejector on the bottom of the feed tray.

Originally Posted by vz58 HCpookie you are right as this is ever evolving , I am working on a downward eject but am limited on time for the next 2 weeks. I have something worked out, except I would like to keep the rpd drum, which gets in the way of the drum.Yeah there isn't much room down there is there? The trick, I think, would be to mount the drum to the side like with an MG42 saddle drum. The MG3 tray would work with the plastic MG3 drums, so that should be no problem for a single 50-round belt.

Getting 100 rounds would be a different story, but then again I'm not sure that that is a necessity. 50 rounds for "mobile" patrols, and 100+ rounds in a box on the tripod for "fixed emplacements"

The Russian PKM design puts the ejection port behind the drum area, but it is a slightly different design since it is a "puller" vs. a "pusher" feed mechanism. That would mean relocating the ejector way back behind the feed mechanism, which would work as long as the receiver goes back that far.

Quote: Originally Posted by glock cool i'm a lefty you offering a belt fed kit ? :xIt would not be a stretch to put an AK together that looks like a Bren, with a magazine on TOP of the receiver, for lefties. Or for this "low power" round, you could probably cut the notch in the bolt on the other side. I plan to do something like that for my wife. Maybe. If ever I get around to it.

I made a 50 round drum magazine that mounts from the feed tray like a MG42. Made it out of a 4" dia. backpacking cooking pot with a intergal hinged and lid latch. Will post pictures as soon as I find where I hid them on my computor. Sits well above the side ejection port and the rounds never touch it.

Hcpookie, yes you can eject down after the drum, looked into that but that is where the FCG is.

Well I had another fun experience of trying to hillbilly an MG47 together with the smallest number of tools possible... Today I cut the upper tubing section for the receiver. I used my small band saw to cut off one side of the 1/8" thick tubing so it's now a U channel. Just going by eye, I was pretty surprised how it came out. It needed miminal cleanup with the grinder and files.

[picture 404]

I lightly trimmed the right side "ear" of the trunion and it now fits in the lower section without pushing it out. It was a neat feeling when the top fit down over the trunion on top of the lower piece.

[picture 404]

Have one trunion hole located and drilled so only 3 more to go. So now I'm just about ready to fit my feed tray.

[picture 404]

Sniper -

Nice job on your trunnion fit; middle pic illustrates it well. You're on the right track.

When you join/weld top & bottom together, the outside will want to contract, creating an 'hourglass-like' cross-section, because it's welded only on the outside. Inside rail width may become to narrow for the BC to slide on. Outside of your rcvr may be slightly concave, full length.

2XTM may jump in here and share how he did his without warping.

I plan to do my smaller version clamping the top side-to-side so it doesn't bow out, and a full length spacer inside, extra long & hanging out the rear (something to grap onto for removal after the welds cool; it will get tight). Mine got work intensive, going back and making the BC fit again, because of warpage, after it had been sliding so nicely. Hands got tore up filing the rails. Very tight in there, especially after the 'upper' rails were in. Ejector spur and rear corners of the rails are SHARP. Might want to smooth up those corners with a wire wheel.

Short welds, alternating sides, will help keep the rcvr from getting too hot, causing end-to-end twist. I believe the shorter the beads, the less problems. If you have a steel welding table to can clamp it to, so much the better

An ejection chute may be a better idea. A "chute" could be as simple as a sheet metal wedge.

I'm using an ejection chute made from a piece of scrap sheet metal. The spent cases are deflected straight down and are not in the way at all. I have a bracket on the chute to mount my SAW ammo bag. I did have several spent cases not eject clean but I am sure it is due to the cases hitting the upper edge of the ejection port. I will get the port opened and post a range report soon.

[picture 404]

I've mounted my fed tray as per post 247 picture /Yugo trunnion bulged/milled to fit in the 1/16 lower. Post 286, 2nd picture, you took out the mouse trap spring (mine is out) and you show the piece flipped up and I think we are looking at the bottom of that piece. On mine there is another piece that keeps it from going up like yours is in the picture. I don't know what you call that (pressure plate?) but in my top cover I will need to shortened the piece to make it fit smoothly with the feed ramp. Is that correct or did you have a different top cover?

I can get it to feed one round, but I think I need to mount the top cover to get that guide piece to guide the rounds nose down and off the belt?

I took out the mouse trap spring and replaced it with a much lighter and bent AR-15 trigger spring and shortened the nose on the pressure plate so you could just close the top cover and the nose of the pressure plate would just slide under the feed ramp. Steve's is slightlly different. He has no pressure plate spring what so ever but his still works. He also used a MG3 or MG1 not sure which feed tray. Mine is homemade. Both methods seem to work. Don't know what DTM has done.

Been busy in the basement lately. I apoligize in advance for no photos yet.

Got my tubing .120 wall tubing cut, ground and milled and fit the trunion. I had to mill a lot out of the lower and the top tubing to get the trunion to fit inside and it really doesn't sit on the rail groves of the trunion as I had to mill the sides of the tunion down as well to fit. It does not look like the setups I see here and am kind of perplexed. Could the trunion be oversized? (width) It is an RPK trunion from an IO kit (which the barrel has still not arrived yet. I had the top and bottom tubes welded together today by a shop friend. Pretty rough but he said finish the build up and hell fill in the gaps and sand/gind the sides smooth.

New question is with the top welded on how do you go about cutting off the cented for the feed tray? I mean specifically how low do you go from the top? What is the height from the top of the bottom rail? The one that is integral from the bottom half of the tubing cut? As I do not have any "new" upper rails installed all I can measure up from are the rails from the bottom tube. Any sugestions and help would be greatly appreciated. I plan on fixing the trunion in place in the next few nights, (need to tap it) and once located then begin to cut the top to set the feed tray.

A few random questions to help get answers so I can sleep at night...

1.) If using an MG42 grip with AR fire controls, is it a custom hammer which is extended, or does it reach the firing pin OK as is?

2.) what is the proper thread pitch and length of screws/tap I should get to tap and affix my trunion?