Thread: .30-'06 conversion notes

Retrieved: 12/08/2013

The Valmet was available in .30-'06 with a standard-length receiver. So was the Saiga.

The only detailed description I've encountered was of the Saiga, done by "BattleRifleG3" on forum.saiga-12.com, Feb 2007. Pictorial Writeup: Saiga-100 in 30-06 - forum.Saiga-12.com

Basically:

* the magazine well is moved back from the standard position

* the center support is moved back

* the hammer is notched to clear the relocated center support

* the barrel is moved forward in the trunnion

* the bolt face is moved forward in relation to the locking lugs

* the .30-'06 bolt appears to be the same as the .308 Saiga bolt

* the picture in his post is small, but the bolt appears to have the third lug

like later .308s

A Saiga magazine isn't much use in a standard AK. Valmet '06 magazines appear to go for $100-ish. One of the magazines below might be adapted, perhaps with a magwell extension attached to the bottom of the receiver:

Johnson LMG 20 rd ($62 on GB)

Browning BAR 20 rd ($40 on GB)

FN-49 10 rd ($50 on GB)

The snag is "first you get a .308 Saiga bolt". Since they're basically unobtainium, the simplest solution is to adapt a standard bolt. The main difference is the Saiga bolt is longer from the locking lugs to the bolt face. This could be easily handled by cutting off a spare bolt, turning it to spigot into the original bolt. Braze or silver solder as needed. By cutting an extra bolt you would avoid having to make all the cuts for the extractor. You'd need a longer firing pin; cut and weld, or perhaps a PSL pin.

The ejector would have to be moved back. I've seen blank rails, or you could cut and weld a left rail to move the prong back.

The bolt carrier travel is more than adequate to handle all this.

The front of the trigger guard and the mag latch would need to be moved back, or just bend up a new one from scratch. The latch would depend on which magazine you picked, and whether you used a magwell extension.

reference for pressures: (Wikipedia, in CUP)

.308 Win 62,000

7.62x51 60,200

.30-06 58,700

7.62x54R 57,000

8mm Mauser 57,000

The .30-'06 should be safe with a standard AK trunnion.

1biggun

12-26-2009

AHH I WOULD NOT TRUST WIKIPEDIA. SOME OF THOSE PRESSURES YOUR POSTING ARE NOT CUP PRESSURES THERE PSI! I WAS LOOKING AT SOME CARTRIDGE SPECS THE OTHER DAY AND THEY WERE COMPLETLY WRONG

IF YOU HAD A .308 WIN MAKING 62,000 CUP AS STATED THAT WOULD BE AROUND 70,000 psi NOT GOOD. ROUNDS RATED IN CUP ARE ALMOST ALWAYS A LOWER NUMBER THAN WHEN RATED IN PSI.

AS FAR A A 30-06 IN A AK iM NOT SURE ITS WORTH IT UNLESS YOU HAVE A TON OF AMMO FOR IT. THE 308 WILL DO ALMOST THE SAME AND A TON LESS WORK AND EXPENSE. DONT GET ME WRONG WHEN i HUNT WITH A BOLT GUN ITS A 06 MOST OF THE TIME. iF YOU WANT TO LENGTHEN A BOLT TAKE A 5.45 SMALL STEM BOLT AND ADD AA SLEAVE THAT IS LONGER AND MAKE IT A SPRINGLOADED PIN WHILE YOUR AT IT. I HAVENT DONE IT YET BUT THERE IS NO REASON IT WONT WORK.

The snag is "first you get a .308 Saiga bolt". Since they're basically unobtainium, the simplest solution is to adapt a standard bolt. The main difference is the Saiga bolt is longer from the locking lugs to the bolt face. This could be easily handled by cutting off a spare bolt, turning it to spigot into the original bolt. Braze or silver solder as needed. By cutting an extra bolt you would avoid having to make all the cuts for the extractor. You'd need a longer firing pin; cut and weld, or perhaps a PSL pin.

IM NOT SURE i FOLLOW YOU BUT IF YOUR SAYING ADDING A SECTION OF BOLT FACE TO ANOTHER BOLT THATS A BAD IDEA ESPECIALY IF YOU ARE GOING TO BRAZE IT OR ANY THING THATSS GOING TO AFFECT TEMPER NOT TO MENTION THAT BOLT TAKES A BEATING. NOTING LIKE BRASS OR SOLDER IS GOING TO WORK EVEN IF ITS UNDER COMPRESION.

READ THE CHAMBER PRESSURE THREADS THERE ARE SAMMI SPECS IN THERE IN THE LINKS.

TRX

12-26-2009

AS FAR A A 30-06 IN A AK iM NOT SURE ITS WORTH IT UNLESS YOU HAVE A TON OF AMMO FOR IT. THE 308 WILL DO ALMOST THE SAME AND A TON LESS WORK AND EXPENSE.

"Just because" isn't enough? [grin]

The only additional work between the .30-06 and .308 would be the magazine and bolt, unless you found a Saiga bolt. Figuring you're starting from a flat, you just put the barrel and center support where you want.

Bypassing the whole .30-06 vs. .308 debate, the '06 is 3.34 inches long. This means you could use any cartridge up to that length, like the .270 Winchester, .25-06, .35 Whelen, 6.5x55 Arisaka, 6.5x55 Mauser, 7x57 Mauser, 7x61 Sharpe & Hart, 7.65x53 Argentine, 9.3x62 Mauser, etc., assuming the pressures were acceptable.

You could even take a .35 or .400 Whelen case, blow it out to .429 at the neck, and, oh, make a .44???? Long, with enough room to seat a long spitzer bullet, assuming you could find some suitable .429" bullets...

1biggun

12-26-2009

If you were seroius about a 06. I would buy a used 308 sagia and go from there. I bought mine for under $350 in a shop so there out there. $400 is pretty good when you figure what a kit a reciver and a unobtainable bolt cost or even using a 5.45 bolt that costs close to $60. yugo kits arent cheap and you would be smart to use a yugo bulged trunion IMOO. id be leary still of running full power loads in 30-06 on a two lug bolt.

all those rounds above have simular shorter version including the 444 marlin in a big bore. look at the 358 WIN, 7mm08, 308, 243, 250 savage, 260 rem ect.

BTW look at the leverlution ftx?? plastic tip bullets from hORNADY IN 265 AN 225 GRAIN THERE THE ANSWER TO A LONG 44. ALSO SEE MY RIMLESS 444 MARLIN POST ITS JUST A CUT 06 CASE RAN IN A 444 DIE.

Im all for the build if you can find the bolt. I have been looking at WSM reduced loads and there are gains to be had at 50,000PSI pressures but the the larger head size means more bolt thrust. but even a 45,000 PSI there are gains over a 308 not sure if its worth the cost. a 6.5 284 would be cool as would a normal 280.

hcpookie

12-28-2009

I've looked at those notes a while back, I think I even saved those pics on my computer for future reference. They basically did everything I discovered the hard way for my .308 conversion! Wish I'd have read the thread before I did mine, would have made mine easier!

They are basically doing the same thing and it may work as-is, not sure if hte longer bullet will fit the Saiga opening. If not then you need to move the center support back a little ways and weld up the holes. The big thing is going to be moving back everything starting at the back of the magazine well opening, the magazine latch (and holes), the center support, and then modifying the hammer to work with the center support's new location. In fact you may find you'll need to relocate the FCG holes back as well.

I too would start with a .308 Saiga. If US_Dragunov's contact in the Izzy plant is correct, then the 3rd locking lug is an accuracy point and not a safety point. Either way, the Saiga .308 is already going to be able to push those higher pressures out of the box and that's the reason I'd select it. Welding up those holes will be no different than doing so on a Saiga conversion with the holes for that trigger ramp. You'll be able to resell that stripped .308 barrel with no problems at all.

TRX

12-28-2009

I stripped my Romy and poked around with an '06 cartridge. I don't think you'd have to move anything back, though you'd have to shorten or modify the trigger guard and/or mag latch.

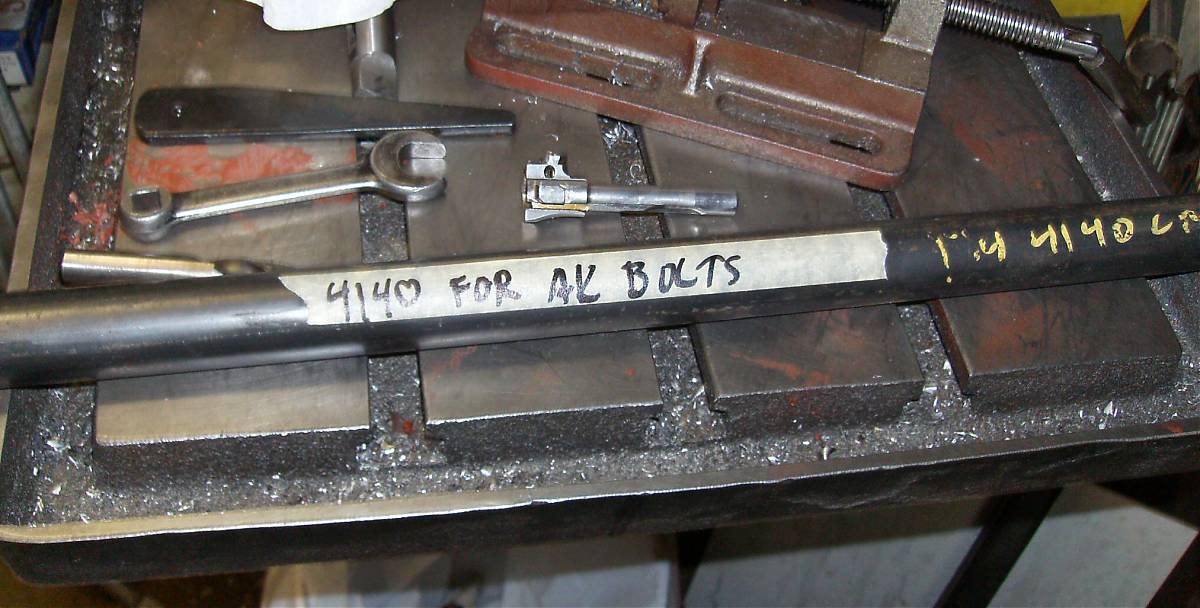

I'm a long way from getting around to my make-a-bolt project (a 4140 round bar leans against the lathe bench...), but turbothis over on theakforum has pictures of one he'd partially finished with. If he decides to sell them, he might be persuaded to make them in Saiga configuration, which would make a lot of things easier.

TRX

12-28-2009

I found this at saiga20 -

The caption is, "A comparison of the standard AK-47 bolt holding a cartridge, and the bolt of the Saiga 20 holding a shell."

Is this a two-piece head on a small stem bolt, or is it a figment of the camera?

zoom6zoom

12-28-2009

I haven't taken any measurements, but would it be worthwhile to look at a PSL as a starting point? It's already set up for the longer x54 round which is ballistically similar to the '06. It uses the bulged trunnion, and the barrel can be shortened without much fuss. Plus the recent prices have been pretty decent.

hcpookie

12-28-2009

Originally Posted by TRX

Is this a two-piece head on a small stem bolt, or is it a figment of the

camera?

Yes it is a 2-piece bolt. The "bolt face" is what holds the cartridge.

TRX

12-28-2009

Any idea what holds the pieces together?

rbthntr64

12-28-2009

A 30-06 AK variant would be interesting, but if you were going to go to all that work, why not do a short stroke gas piston system? If you were going to modify a PSL kit it would require extensive machining. Make a block that fits in the rear sight base ala sks, and make an insert that fits into the gas tube. You could even make it adjustable by using a yugo M95 gas system for referance.

rbthntr64

12-28-2009

Originally Posted by TRX

Any idea what holds the pieces together?

A short pin that wallers out after about 2500 rounds. Ask me how I know.

TRX

12-28-2009

Is the bolt face deepend to spigot the extension on?

1biggun

12-28-2009

there are some other issues with a long bolt head. As the bolt hits the bullet guide and rotates the lugs of the bolt have to be past the lugs of the trunion. so you will need to move the ramp on the bullet guide forward as well. You might have to relieave the trunion slightly as well to get the longer head in there. Your only going to really want to move the barrel a head 1/2" or so as after thaat things get more complicated

I have nevver seen a 20 Guage bolt before Interesting. I to wonder how its held together. creates some interesting possabilitys. it could be presssed into a enlarged bolt face and pinned some how. if it was a interferance fit it would likely not come out if pinned some how even a blind pin would work. Interesting thanks for posting the Photo a buddy has a saiga 20 I might be able to look at.

1biggun

12-28-2009

That has me thinking of a possable better way to convert x39 bolts to x25 bolts as well as making 223 out of x39 bolts hmmmmmmmmmm

TRX

12-28-2009

Lichtenberg sells rings to solder/braze into your x38 bolt to adapt it down to x25. He says they work fine.

hcpookie

12-28-2009

The Saiga-12 has that same bolt-head design as well. I'm sure there are pics somewhere of a Saiga bolt disassembly process.

Originally Posted by TRX

Lichtenberg sells rings to solder/braze into your x38 bolt to adapt it down

to x25. He says they work fine.

Isn't that what caused that one bolt failure we all marvelled at a few months ago?

TRX

12-28-2009

I found a picture of a Saiga-12 bolt that looks the same as the -20 bolt. Dunno about the bolt failure; do you have a link to it?

1biggun

12-29-2009

Lichtenberg sells rings to solder/braze into your x38 bolt to adapt it down to x25.

I dont weld on bolts perticulary gas builds. There is no way to weld on a hardend bolt and not create a stress riser regardles of the size of the weld. a blow back is one thing if it fails but on a gas gun you get a failure it can be deadly.

I was thinking of boring the bolt and pressing and pinning a head like in the picture. for a X25 Ill just spend the 45-50 dollars for a 5.45 bolt and sell off the x39 bolt or use it for some thing else.

I keep saying it would be cool if some one would manufacture a 3 lug bolt with small face that can be opend up to fit the build and leave the steam long as well. make it out of the best materials that are avaliable. They would sell. I wonder what a run of 100 bolts made on CNC equipment would cost???? Guys are paying $85 dollars for 223 bolts now.

TRX

12-29-2009

Counterboring and pinning still looks practical to me. Bolts are supposed to be tough, not hard, and thus should be machineable. You can take a file to yours and check. [grin]

Turbothis' bolt thread is here: TheAK Forum :: Log in

No traffic for a while; I rattled his cage. Anyone else interested might do the same.

I can reach out and touch the CNC mill from where I'm sitting, but I haven't had the time to learn how to use the freakin' thing. Building it was trivially simple by comparison.

X2, Xylotex 4-axis kit with 425oz steppers, heavily modded CNCFusion mount and ballscrew kit, extended Y travel, dedicated XP box, Mach3, and MeshCAM. I'd add the 4th axis and a digitizer probe in a heartbeat if I knew WTH I was doing with all this stuff... and though I used to be a draftsman for a living back in the pencil-and-track-drafter days, and I'm supposed to be an IT expert now, every CAD program I've tried to learn has driven me to the point of raking my tin cup against the bars and screaming in frustration.

Theoretically, I could put an AK bolt between centers on the 4th axis, tell Mach3 to go into digitizing mode, and after a while there'd be a complete 3D mesh to use to make another one, just like a 3D Xerox machine. Gharr....

hcpookie

12-29-2009

OK - using that welded-in collar makes sense now for a BLOWBACK only. Gotcha!

I assume Mach3 is a CAD program of some sort? That would be cool! IF IT WERE ME, I'd make a raw bolt blank with a small diameter opening in the face so that I could build it into whatever sized face I need on the lathe at a later date.

Making my own bolts is on the menu. In fact it is one of the reasons I got the indexing head. I need more collets as it doesn't take the ones I have The challenge that I see is going to be drilling the small pin hole for the firing pin retainer in the hard steel. It is surely going to be a difficult task. The other things will be relatively simple tasks on the mill with a rotary table (or a lathe with a milling attachment). A slitting saw for the ejector groove. Then temper the metal to the approprate hardness for the metal in question. I have a big piece of 4340 steel but it is actually TOO BIG and I need to get a smaller piece LOL.

TRX

12-29-2009

No, Mach3 is the CNC controller software. I haven't found any CAD software worth dog spit yet.

Drilling the firing pin hole is no big deal; if you use a sprung pin the small hole is much shallower.

It's the profile of the locking lugs that stumps me. I could use the manual machines and make square lugs, but it requires a cam-operated or CNC fourth axis to cut the lugs... though I bet there are some geezers out there who could do it by eye with a file and half a plug of Red Man.

1biggun

12-29-2009

Counterboring and pinning still looks practical to me. Bolts are supposed to be tough, not hard, and thus should be machineable. You can take a file to yours and check. [grin]

Yea there machine able they have to have some flex or they would be brittle. thre not soft by any streach of the imaganation. I have opend up bolt faces on the mill, filled lugs when truing the action etc.

ALL that CNC stuff is before my time they didnt even have CNC in when I was taking classes they had some tape with holes punched in it ot some thing to control things. I should go take some classes. If i had the $$$$$ id buy a machine learn how to use it and go into bussiness. there is no reason the entire gun cant be duplicated in bettter steels. An american AK should be bassed on a 308win/ 5.56x51 IMOO and be usable for hunting and other real world situations.

Build a super 3lug trunion and bolt that will handel 70,000 PSI and we could build 300WSM and other magnum stuff. or better yet a milled magnum reciver and super bolt than we could build some classy looking stuff to.

hcpookie

12-30-2009

Originally Posted by TRX

It's the profile of the locking lugs that stumps me. I could use the manual

machines and make square lugs, but it requires a cam-operated or CNC fourth

axis to cut the lugs... though I bet there are some geezers out there who

could do it by eye with a file and half a plug of Red Man.

We discussed this a few months back on my "rotary table" thread, I think in the Tools section.

What I took away from it is that they use a precision grinder which compensates for the hardness of the tool steel, and that you need a rotary table set up to cut passes along the length of the bolt. Rotate, cut, repeat. Assume it is a tilting head rotary table, and relocate the table at a 45 degree angle to the cutting axis, use the perpendicular axis to make the 45 degree part of the lugs. A slitting saw for the ejector groove and REALLY small bits for the pin holes to finish.

Harden the steel to the appropriate temper for that metal and you can rely on the published yields for that particular hardness. Calculate bolt thrust using Gunter's forumla and you'll have a really good idea of how much it should be able to handle.

Just thinking out loud. I have birthday money and plan to get that 4" tilting rotary table from Grizzly.

TRX

12-30-2009

I guess there's no reason you can't take a dozen cuts on each cam surface.

Mount the rotary table flat on the mill table. Make a fixture to hold the bolt parallel to the table; a block of steel with a pair of perpendicular holes would do, one for the bolt, one for bolting it to the table.

Figure out your cuts on graph paper. Draw the bolt 5X or so, then use a ruler and protractor to figure how many degrees to turn the bolt before each cut. Make the cuts with the Y axis, in and out. Since the cam is a snail shape, you'll need to adjust the X (left to right) position slightly for each cut.

Index to the next lug. You could mount a disc on the tail of the bolt with some pencil marks at the correct angles and line them up with a mark on the fixture.

Use a file to dress the step at the corners of the lug where the bolt head curves downward, then dress the cam shape. Shouldn't take too many strokes to do it.

After cutting all the lugs, hit them with Dykem or felt tip, put it in the bolt carrier, and cycle it to see how it contacts the trunnion lugs. File a bit here and there as needed.

Hmm. I got so hung up on the CNC thing, it never occurred to me it could be done by hand. And for those who might boggle, Harold Brookshire showed me his camshaft prototyping setup back when he owned Ultradyne Cams. He made the master lobes for the cam grinders in that exact same way, making a bunch of cuts and smoothing them out with a polishing wheel. It was state of the art back in 1986; nowadays he doesn't touch any tools at all, he just generates the profile and emails it to one of the specialty grinders, who send the cam directly to his customer. Joe Lunati used to make his master lobes the same way.

I also got hung up on somehow measuring the precise shape of the AK bolt cam shape... but I bet "eyeball is close enough" there, too. Cut the shape slightly "fat" and keep filing until it test-cycles okay, and it doesn't matter what the precise shape is.

Hot dang, this looks doable...

1biggun

12-30-2009

what ever metal that the latest and greatest AR bolts are being made form and what ever processes there using to treat there stuff is likely what would be best. I can think of very few things that have had as much research trying to make an existing sized object stonger..

I likely cut the angles on the bolts lugs with a tool post grinder in the lathe set at the aproperiate angel and rotating the part chucked into the spindel by hand. I just need a hardend properly made 3lug bolt with square to the stem lugs thats slightly oversized. I can get the rest to fit. Id like od of the entire head a little larger to reduce the side to side play in the trunion as well

TRX

12-30-2009

I have a bar of 4140 I bought last summer. It's the same stuff the make many bolt-action bolts out of.

Anyone have access to a Rockwell tester? It would be nice to know what the surface hardness is, or even to sacrifice a bolt and check it at various depths.

1biggun

12-30-2009

some were here there was a member who did rockwell tests. what are the latest AR bolts made of?? If there is a better materail than what the current AK bolts are made from Id want to use it. a mistake with a bolt ot trunion is the one are were you can get hurt.

Ive been tempted to take some courses at the MATC college in Madision WI. I hear they have a very Gun friendly instructer there. Id like to get the 411 on proper tempering technicues and have acess to the right stuff. i could brush up on my Mill and lathe skilles as well

Viper Dude

12-30-2009

I do believe that many if not most gun bolts are machined from forgings. The forging process allows the metal grain to follow the shape and thus boosts strength vs bar stock or cast pieces, heat treat aside.

Machining a bolt was often done with either a tracer mill or horizontal production mill using form cutters to create the desired radial shapes. A table-powered dividing head placed at angles to the table axis can create the symetical bevel cam shapes.

Non-symetrical cam shapes such as are found on race car engine cams are best produced on CNC grinders these days. Exotic cam profiles date back to WW-II German technology brought home by a few GI's (Ed Iskenderian et al). The profiles necessitated new machining techniques to grind.

I believe that these small gun bolts can be turned on a lathe and then milled using formed horizontal side cutters. A tool and cutter grinder will be needed to produce the special side cutter (unless you could fudge with a home-made fly-cutter).

Unlike a Rubic Cube or a Chinese puzzle there are numerous solutions to this machining challenge usually dictated by what machinery you have at hand and the quantity of parts you wish to produce.

hcpookie

12-30-2009

Here's another time-saver thought for the Eyeball 1.0 method - who says you need anything but the bearing surfaces rounded smooth?

You could have for example a 12-sided bolt in-between the lugs themselves, as that area doesn't touch anything. It may look funny but there's no need to make it *perfectly* rounded on those non-bearing surfaces. The only bearing surfaces I can think of are of course the locking lugs themselves, the top- most unlocking lug that rides inside the mating notch on the bolt carrier, and the stem itself. All other surfaces aren't even touching anything and so don't need to be pretty.

You'll have to make them at least 1-2" longer on the back of the stem than the longest you'll need them so you'll have room to clamp in the collets. Just be sure to make them long enough for a PSL style build or perhaps a little longer, and you should be good for whatever caliber you can dream up

ETA the only cut that concerns me is the matching angled cut in the trunion. Still can't picture how that gets all done up pretty.

1biggun

12-30-2009

Yea I never bought that guys in caves an huts building these.

I think I could make the thing. Im not sure Im the guy to properly temper it. thats out side my abilitys. Id need a rotory table that can be set up flat and at a 90. ( Mine only lays flat ) a tool post grinder for my lathe. man there is a lot of steps. Id do extra long like mentioned before. Id make it large stem although there seems to be a reason all the newer bolts are small stem some thing abut the smaller being more reliable

Id never make these to resell by hand turn equipment it would cost more than a new Saiga 308. now if it can be done on a cnc deal and in multipul quanitys.

TRX

12-30-2009

You could have for example a 12-sided bolt in-between the lugs themselves, as that area doesn't touch anything. It may look funny but there's no need to make it *perfectly* rounded on those non-bearing surfaces.

Absolutely. You make as many cuts as you need until it clears the trunnion and satisfies your esthetics, then move on to the next operation.

"That's not a pentagram! That's a circle!"

"A circle *is* a pentagram, for high values of five."

- Rick Cook

ETA the only cut that concerns me is the matching angled cut in the trunion. Still can't picture how that gets all done up pretty.

I've stared at a few trunnions, looked at the marks, and I am 100% convinced the compound angles were cut freehand with a die grinder. As long as the bolt doesn't get hung up on a corner inside the trunnion, the angles appear to be noncritical.

It's stuff like that that makes me stand back and admire the genius of the AK design. Anyone can design a rifle that requires a bunch of custom tooling and precision machining; designing something that can be made with ordinary tools with few critical dimensions... that's a whole different thing.

1biggun

12-31-2009

I think the lugs on a trunion are cut with a long end mill through te bore with the trunion set up at the aproperite angle.

My guestion is if were going to make it from scratch why geep the lugs at all differant heights?? the angle I undersand I dont get the uneven lug heights from the face of the trunion.

TRX

01-01-2010

Well, well, well, my droogies... there's nothing like making a fool of yourself in public for getting a "leaning experience"...

I just looked at a Romanian and a Yugo bolt. What I had ass-umed were curved cuts on the locking lugs are just flats, with the corners rounded over, looks like hand work to me.

The left side locking lug is just a rectangle with two opposing corners clipped off.

The right side locking lug just has the back corner clipped off.

The bolt carrier lug is a parallelogram with the front corners rounded over into a curve and the others corners rounded off slightly.

The Yugo bolt is in the white. It looks like the quarter-round shape of the right locking lug was made by turning the bolt at a 45 degree or so angle and rotating it under a grinding wheel. You can see where the corners of the lugs had the leftover "fins" cut away after shaping the quarter-round.

So, there were no fancy cam operations involved in making an AK bolt. It's just straight cuts and some hand work.

Now I know I can machine this thing. The next step is to figure out a heat treat.

TRX

01-01-2010

Hmm. The cross-sectional area of the bolt seems to be fairly constant, good for deep heat treat. Google says 4140 is used for bolts from Weatherby, Smith & Wesson, and others, so it looks like a safe choice.

Heat treating ferrous metals is a huge subject, but a generic 4140 heat treat is heat to 1550-1575F, hold 3 to 4 minutes, quench in oil (agitation recommended), then draw back to the desired hardness. I found cites for 44-45 Rb and 42 Rc; there's a draw chart at Heat Treating Toolsteel - Tips - Techniques & Useful Information

TRX

01-01-2010

Originally Posted by rbthntr64

work, why not do a short stroke gas piston system?

What advantages would that give over the stock AK layout?

vz58

01-01-2010

I was told by a manufacturer that ar bolts are made of CARPENTER STEEL. I have the RC around here in an email, IIRC it was in the mid to high *EDIT* I do remember it was higher then you could reliably get with 4140

ak lugs are square.

I have used a cheap file on a victornox multi tool to EASILY round the corner of an AK bolt before.

EDIT see post on page 6 for specs.

hcpookie

01-01-2010

OK I give up, what's Carpenter Steel?

Where did you get the 4140? I have some 4340 and it is HARD STUFF out of the box.

1biggun

01-01-2010

Carpenter steel ????? maybe

Carpenter Technology | Specialty Alloys

mrtank

01-01-2010

Order Alloy Steel 4140 Round in Small Quantities at OnlineMetals.com For the 4140.

Did a little digging showing the dpms bolt head is carpenter 158 steel Carpenter No. 158® Plastic Mold Steel

Another thread I ran into

Why no improved AR bolts? - THR

TRX

01-01-2010

Carpenter is a specialty steel maker. Anything you buy that's much more exotic than plain old chicken-wire grade steel is likely to be from Carpenter.

I got my 4140 from a local steelyard. There are several online sources that will sell a foot or two. As an end user, steel looks pretty much like steel; any legitimate seller should be able to provide a "test report" showing the chemical analysis of the melt the bar came from. The test reports are generally furnished at no charge, but you have to ask for them. Not that you could tell the difference, but it increases the likelihood of the warehouse guy cutting a piece off the correct bar.

TRX

01-01-2010

Doing some net.searching...

4140: S&W rifles, Hesse .50, Weatherby rifles

4350: Surgeon, DuBiel actions

8620: M1 Garand, M14, some '03 replacements, Barrett .50, some aftermarket AR- 15

9310: some aftermarket AR-15

4140 and 4350 are deep-hardening alloys. 8620 and 9310 are case-hardenable.

1biggun

01-01-2010

Another thread I ran into Why no improved AR bolts? - THR

they sure have a lot of excusses on wy there AR15/ m16 bolts brake every thing from dry firing to heat from the round to poor design to many rounds fired BLA BLA BLA then they compare the AK bolt in a PIC and say it has three lugs when it only has two.

try to find 10 documented cases of AK bolt failure on the net its pretty hard Ive looked. more reason I think the AK can run at considerably higher pressures than the AR.

What ever the new AK super bolt is it needs to be made out of the best steel. Id like to see it handel 65,000 PSI with .500 bolt face and proof beyond that. Not sure what the m70 trunon can take but there are even less failures of trunion than AK bolts that I have found documented. If any.

hcpookie

01-01-2010

Yeah I noticed that too lol - "its just a service rifle not meant to last" is what I took away from all that

Thanks on the Carpenter reference - now I undersatnd! What are your thoughts on the 4340? I built my USA VZ-58 FCG parts from it and basically used a grinder and carbide bits for everything. Possible it could be too hard/brittle? 1 foot of .875" 4140 is only $8.00 so I may just order some because I can

Interesting that some of these steels are described as case hardening steels. I figured they'd all be "fully" hardened... is that what its called? Case hardening doesn't seem correct for this application so perhaps they mean simply that it has certain characteristics vs. fully hardened. Most interesting!

1biggun

01-02-2010

Im not the guy to specify what steels to use. I have some basic heat treating skills learned in metal shop way to long ago and some knoledge from years of racing but I would not feel comfortable doing the heat treating

If you read all she specifices in that link it says that the carpnter steel can be fully heat treated and gives draw times and this and that that are way over my head and abilitys.

The heat treating is what has stoped me from compleating my 50 BMG build. Im not going to but my or anyone elses life on the line based on my heat treating knowledge. heat untill a magnet dont stic and quench in oil while stiring and then re heat untill it turns purple if you want to then soften it is all I really know. dipping hot metal into carbon powder is how you case harden as I recall

TRX

01-02-2010

Generally, steels are either hard or tough. You need hardness to reduce wear, you need tough to handle shock loads. Sometimes you want both, so you case- harden a part on the outside, while leaving the inside softer, so it can flex a bit under load, but not enough that the hard outer layer will crack.

Working with a rifle bolt, I'd start soft, watch for lug setback in use, and then try another bolt at a harder treatment, etc. until I didn't see signs of wear. It's not like you can open up an engineering book and find "heat treatment for locking lugs" in the index.

Bradrock

01-02-2010

So... Can your basic Rockwell hardness tester tell the difference between case/surface hardening & deep heat treat?

TRX

01-02-2010

Saiga bolt discussion and pictures:

http://www.gunco.net/forums/f277/bolt-stem-diameter-saiga-308-a-43637/

more Saiga bolt stuff:

(I had wondered about the corner on the back of the third lug, and how it

might dig into the shoulder of the case as the bolt moved back...)

3rd lug Saiga vs PSL Bolt. - forum.Saiga-12.com

round gouging on 308 - forum.Saiga-12.com

Have a weird jamming problem. - forum.Saiga-12.com - Page 2

BTW, looking at my Yugo trunnion and bolt, if you make the cartridge ramp into a third lug, only the left side engages the mating lug on the trunnion. It's about as much area as the regular top lug, though.

(more searching on saiga-12.com...) looks like there were quite a few variants of .308 Saiga bolts. On some, the third lug was a big square block, that sometimes smashed the shoulder of a cartridge as it slid back. Later ones were beveled a bit at the back. Still others have a small bevel on the left, where it contacts the trunnion, while the right side is ground down into a ramp similar to a standard AKM bolt.

I also note the extractor is different on the Saiga bolt; it fits into a slot instead of a hole.

1biggun

01-02-2010

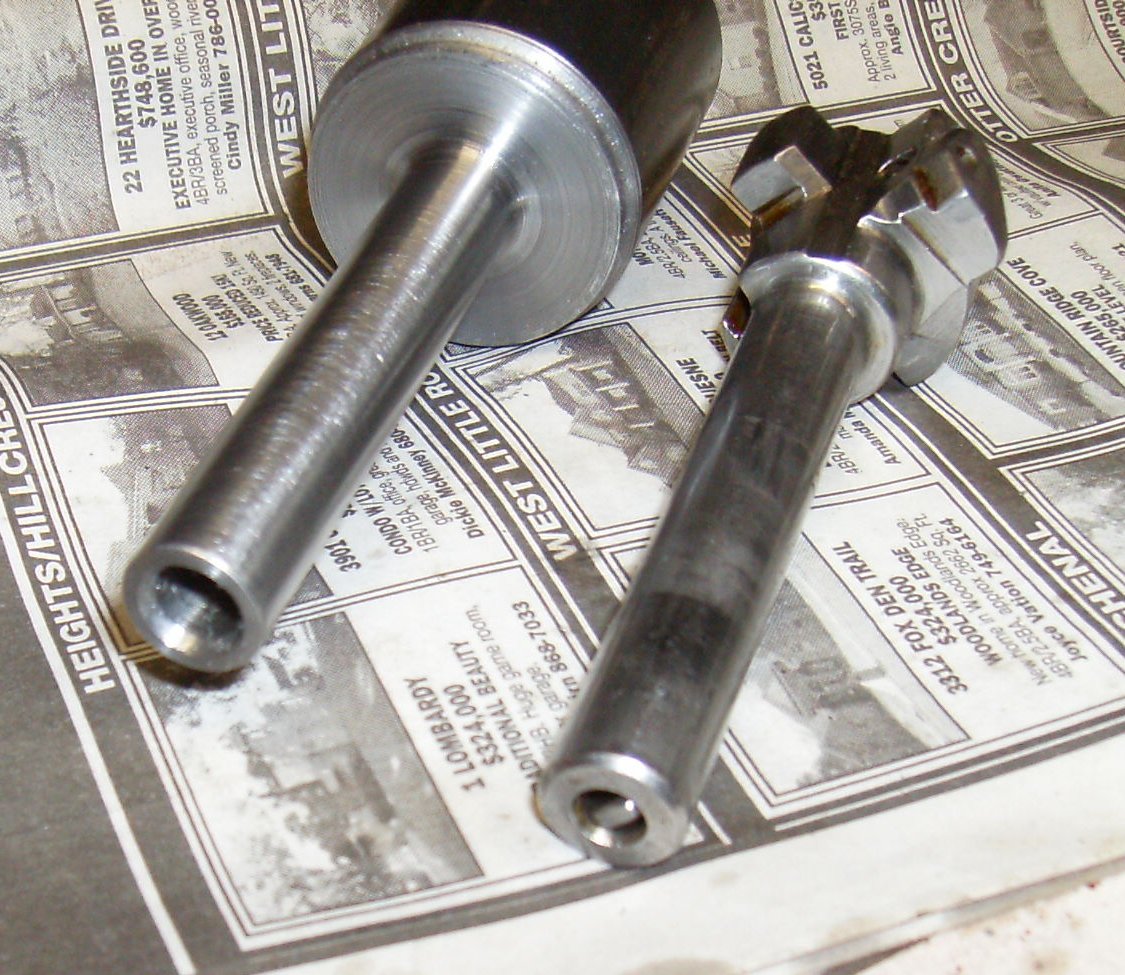

here is mine

1biggun

01-02-2010

wouldent be easier to just make a trunion and bolt with bigger lugs and then not need all this third lug BS. I really need to get mine out and shoot it, IMOO its a POS from the factory the carrier hits the RSB and it james up tight right at bolt lock up. there aare somany sharp eges on it I have cut my hans twice on differant parts the mag catch does not work properly and the trigger is joke, wost of aany fire arm Ive ever owned my kids red ryder is better. I honestly dont know why people buy these aside from there a AK varaint. the gun is horraable in its current form. to me its a bunch of parts right out of the box.

TRX

01-02-2010

Originally Posted by Bradrock

So... Can your basic Rockwell hardness tester tell the difference between

case/surface hardening & deep heat treat?

No, the Rockwell probe only measures the hardness at the point it contacts the part, which is the surface unless you grind or drill the contact point.

To measure the hardness through a bolt would require destroying a sample bolt.

TRX

01-07-2010

I just found out some Valmets and .308 Galils used a bolt with a slot for the extractor instead of the drilled hole most AKMs use. The extractors look identical to Saiga extractors, at least in the pictures.

These are supposed to be a Romanian 7.63x39, a .223 Galil, and a .308 Galil. I found the picture somewhere online.

TRX

01-07-2010

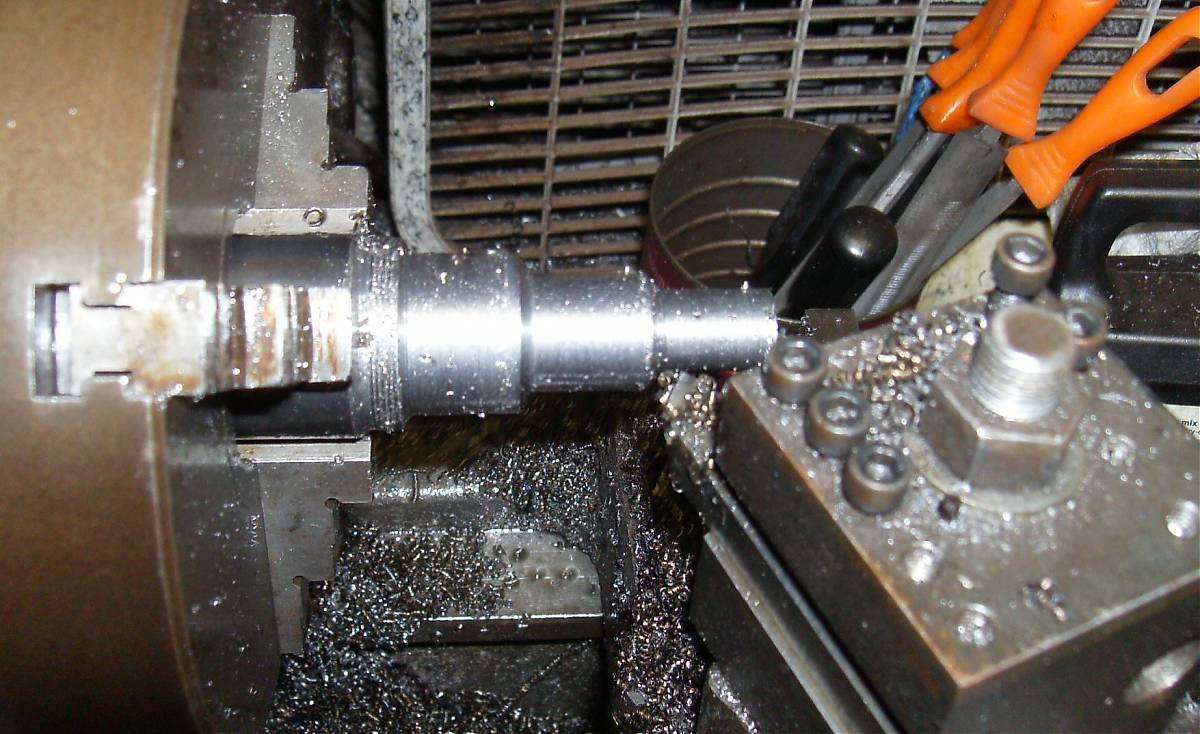

I managed to steal a few hours in the shop today. The G diameter counterbore fits the spring on the Polytech sprung firing pin I have, and there's a #14 hole to the correct depth. It took the full length of the drill bit to make it. The firing pin hole will come in from the other side.

The Polytech pin won't actually work with a long nose bolt since it's too short, but I can use it as a pattern to make another.

I used a sharp-pointed tool for most of the metal removal, and a large radius for the last .005. Not as much trouble with tearing or smearing as some of the online sources made out. Drilled okay, too. 4140 makes small chips, more like cast iron than stringy 1018 steel. I polished the stem with emery cloth and steel wool after cutting to size.

vz58

01-08-2010

Nice, sorry I posted and ran about the carpenter steel, I should have said it was a company. Here is the email:

Hello,

EXTENSION - 15-89-91 (CONVERTED WOULD BE RC 57-62), MATERIAL 8620 STEEL.

BOLT - 15N-89-90.5 (CONVERTED WOULD BE RC 57-60.5), MATERIAL 158 CARPENTER

STEEL.

Thank you,

Jim Eden

Technical Support

Bushmaster Firearms International, LLC

Office: 1-800-883-6229 ext. 277

Fax: 207-892-8068

I meant to come back and post it. sorry.

1biggun

01-08-2010

Good luck on the bolt I hope you pull it off.

TRX

01-08-2010

It would be nice if I could borrow a Saiga bolt from somewhere to measure. I guess it doesn't matter for a one-off, though.

TRX

01-11-2010

Does anyone have a picture of a Saiga .308 trunnion? Down from the top so I can see the relationship of the locking lugs to the magazine notch?

1biggun

01-11-2010

here are some if you need more let me know

1biggun

01-11-2010

more pictures I need to get differant lighting and back ground for this stuff.

TRX

01-11-2010

Thanks! That should be pretty much all for the bolt.

While you have the top cover off, could you take a few shots of the visible parts of the trunnion?

1biggun

01-11-2010

here is the trunion

Bradrock

01-11-2010

Geeze! I do a better job on the rivits! Heh....Heh

TRX

01-11-2010

1biggun: thanks!

Brad: I think the "rivet" you're looking at is supposed to do the same thing as the ramp on the left corner of a regular AK bullet guide; that is, let the trunnion turn the bolt, as well as the lug going into the bolt carrier. I have a 1905 Ross straight-pull receiver that has a chamfered screw through the side that does the same thing.

Okay, I got to see what I was wondering about. The Saiga trunnion doesn't have the "tie bar" underneath that ties the left and right sides together at the magazine lug cutout. The bullet guide stuff is presumably taken care of by the Saiga magazine.

Valmet made both milled and stamped receivers, but almost all the Hunters were milled. I guess they'd've just machined them to whatever layout they wanted. I'd give a lot to see a Saiga trunnion out of the receiver, though.

If you ground out the mag lug recess and thinned the tiebar to give maximum forward length for the cartridge, and drilled your axis pin holes 1/4 to 3/8 inch further back, and maybe did some innovative shaping with the hammer and center support, you can fit a .30-06 in without cutting the AKM tiebar completely out, as I've verified with my Romy. But that doesn't take into account the room needed for the magazine, which could be as much as another quarter inch.

You could move all the bits further back in the receiver, but then you'd have to worry about finding a recoil spring stout enough to keep the bolt carrier from beating up the rear trunnion. The PSL kept the standard front trunnion geometry and just shifted everything back.

With a standard-length receiver it looks like you need a Saiga trunnion or you need to cut the bullet guide and tie bar out of the stock trunnion. The first thing that comes to mind is that the "wings" on the trunnion might spread out and let the bolt pop out of battery, which could be embarrassing. A Yugo trunnion has more metal in the sides than an AKM, though.

1biggun

01-11-2010

Brad:

I think the "rivet" you're looking at is supposed to do the same thing as

the ramp on the left corner of a regular AK bullet guide;

correct, that bullet guide needs to be right on the money and its critical that it perfect to get optimum bolt rotation. I have seen some of these guns that could use more rotation IMOO. not sure what good three lugs do if they only rotate in 80% of what they could. I seen a few worn regular AKs that are the same with a bullet guide. ON my 223 were you grind the ramp on the virgin bolt this is critical.

If you ground out the mag lug recess and thinned the tiebar to give maximum forward length for the cartridge, and drilled your axis pin holes 1/4 to 3/8 inch further back, and maybe did some innovative shaping with the hammer and center support, you can fit a .30-06 in without cutting the AKM tiebar completely out, as I've verified with my Romy. But that doesn't take into account the room needed for the magazine, which could be as much as another quarter inch.

I agree about cuttin to much away.

Id be carefull making the cut out to deep, that will allow more side flexing of the lugs IMOO with angled lugs there is a fair amount of side load Im thhinking.

The bullet guide stuff is presumably taken care of by the Saiga magazine.

correct. the bullet guide is in the mag and Im doing the same on my current planned switch barrel builds with G3 mags. that way I can tune the mag that costs $2 to feed any calibur and type of round I want with out having to replace a bullet guide.

TRX

01-12-2010

I think I'm in it deep now

Bearing in mind this whole thread is supposed to be merely informational in nature, and I have no intention of actually starting a .30-06 project, I find it hard to explain why I ordered an AK kit, an expensive chunk of 4140 square bar stock, and various milling cutters.

"Nothing to see here. Move along. These aren't the parts you're looking for."

vz58

01-12-2010

TRX I had some 4140 I could have sent you. What else might you need?

TRX

01-12-2010

Jeez, now you tell me...

Hang loose and let's see how deep of a hole I can dig for myself.

tylergnut

01-21-2010

The .30-'06 should be safe with a standard AK trunnion.

TRX

03-31-2010

I came across a slow motion video of an AK firing without the top cover. I'm assuming all the ammunition in the magazine was from the same box.

The interesting thing was the difference in bolt carrier travel. Sometimes it stroked just far enough to pick up the next cartridge, a couple of times it looked like it hit the rear trunnion.

It could have been an extreme example of bad ammo, but it was a dramatic example of why the AK has more bolt carrier travel than it needs to actually function. It gives "headroom" for variations in ammunition from lot to lot, country to country, subzero to desert temperatures. And temperature makes a *big* difference in pressure, according to several of the powder manufacturers.

Izhmash built some civilian-market Saigas with standard-length receivers in 54R, but the military PSL had a lengthened receiver. I suspect this was to guarantee reliability under military conditions.

allesennogwat

04-02-2010

Years ago I collected Valmets and I had a 30-06 Hunter. I never fired it. I only bought it for my collection and it had no import stamps that I could find on it. I seem to remember the receiver and bolt/bolt carrier being slightly longer than a 308 Hunter. maybe not but it seemed that way. Maybe it was just the longer magazine that made it look like that. I think the 308 Galil magazine is moved back slightly, unlike the 308 Valmet and 308 Yugo AK which I think have magazines in standard AK position. The difference in the 308 Galil is not much though. The 30-06 Saiga has the most mods.

TRX

04-02-2010

Originally Posted by allesennogwat

Years ago I collected Valmets and I had a 30-06 Hunter.

Didn't you mention that on valmet.org? If it wasn't you, then someone else got one like that too.

After reading about the full-auto Norincos and three-hole Romanians that made it through, an unmarked Valmet or two isn't surprising.

allesennogwat

04-10-2010

It may have been me. I really don't remember. I don't think the 30-06 Hunters were imported through the standard Valmet importer who was for most of the time was Interarms. The story I got was some collector had them imported but without any import markings it's hard to check.

1biggun

04-11-2010

If I were going to do a 30-06 length round id move the FCG back some and move the barrel forward some in the trunion and then use a lengthend bolt or at least a 308 SAIGA bolt with the longer head.

there is not really any cheap 30-06 ammo so its really not that practical of a build especialy with the 308 being so close in performance and generaly givving better accuracy.

it would be real easy to just make a longer reciver and use a extended bolt as well.

jreifsch80

07-18-2010

if a guy wanted to go the longer receiver route i have some usefull info.

I was comparing an fn d 8mm bar mag to my m76 mags and they are almost the same length, the 8mm bar mag is litterally only about 1mm longer than my m76 mags. as far as it seems to me 8mm bar mags are the same dimensions as regular bar mags except they have the spacer plate riveted (or spot welded) in the back to make up for 8x57 being a little shorter than 30-06. with using bar mags even without moving the mag forward a guy could use an m76 length receiver bolt and carrier (psl is same length receiver bolt and carrier too just a longer gas piston than m76) so i think an 06 wouldn't be too hard also seeing that standard 06 loads are running pressures in the same range as standard 8x57 (not wimpy american factory loads) they i suppose they would have similar bolt thrust.

i don't want to get into a discussion and debate on if the 2 lug bolt can really handle the bolt thrust. my philosophy is if the yugoslavians and the romanians trust it (m76, m77, m91 and psl) than i trust it (though i wouldn't use hot loads on my 76 that i would use in my mauser, just european factory loads and surplus) some ideas for you all