Thread: Measured Headspace - Now What?

Retrieved: 06/04/2014

Both of my No.4 Mk.1* rifles have failed the no-go and field guages. They both have #1 bolt heads. Am I correct that replacing the bolt heads with higher numbered ones will/might fix the problem? If so, I have a couple of questions: How can I determine which bolt head (#2 or #3) will yield correct headspace? Where am I likely to find them?

Badger

12-19-2009

Member Parashooter published a good article in the Technical Articles for Milsurp Collectors and Re-loaders:

Headspace 101 for .303's (click here)

I also had an old email reference someone sent me a very long time ago, but now I can't find it. Here's what the content said and based upon it, I did get out a whole bunch of my Enfield spare bolts I had squirrelled away, in order to measure them myself with a modern digital micrometer, just to see how true these numbers were.

I found that the results were all over the place, but I guess using a modern tool and attempting to compare with manufacturing tolerances of that time period, that's not surprising

Here's what the contents of what the email said:

It will either be marked 0, 1, 2, or 3.

The difference is the different lengths of heads.

0 .620 to .625"

1 .625 to .630"

2 .630 to .635"

3 .635 to .640"

jmoore

12-19-2009

Number three bolt heads are the hardest to find, but as mentioned above a selection of number 2 bolt heads might get you sorted. Not only do you have to find a head long enough, but it must not over-rotate.

Several good threads exist concerning this subject, complete w/ photos, in addition to Captain Laidler's article.

Here's a fairly good example:

What to do about headspace after #4 bolthead? - Military Surplus Collectors Forums

Use the search function and enter either "headspace" or "bolt head" for lots more!

tiriaq

12-19-2009

Even if you obtain No. 2 or 3 bolt heads, which fit properly, check them with a gauge, don't just assume that the headspace will be within limits.

You mention No Go and Field. You are using SAAMI gauges? Military No Go is .074".

Edward Horton

12-19-2009

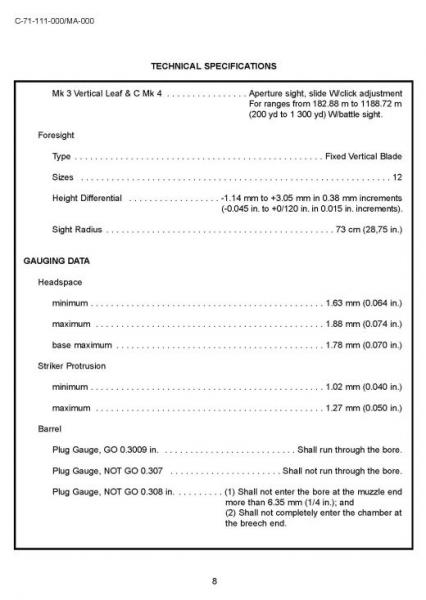

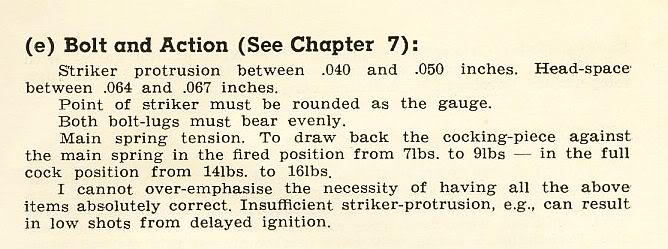

British Military head space

.064 minimum

.074 maximum

Canadian Military head space (as of 2002 for the No.4 Enfield)

.064 GO

.070 NO-GO

.074 Field

American Commercial SAAMI head space

.064 GO

.067 NO-GO

.071 Field

If you do not reload the British maximum of .074 is fine, if you reload then present day SAAMI head space settings are a better choice but not mandatory. (.064 to .067)

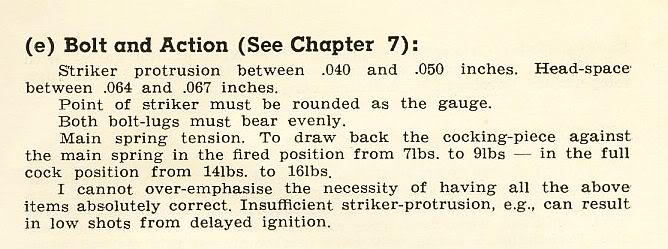

In 1946 the Australian National Champion James Sweet and Enfield author of "Competitive Rifle Shooting" recommended the following.

If you reload and fire form your cases using the rubber O-ring method of an O- ring slipped around the rim of the case the word head space becomes meaningless.

As An example I lapped a zero bolt head to a head space of .084 and fired factory loaded Prvi Partizan ammunition without any ill effects using the rubber O-ring to control headspace. Actually it is zero headspace even at .084 because the O-ring is holding the case against the bolt face.

Alan de Enfield

12-19-2009

No4 / No5 Bolt Head Survey - Results, Conclusions & Suggestions

Background: A few years ago, having always wanted a "bit of history", I purchased a Savage No.4 Mk1*, it turned out that this rifle had a No3 bolt head and whilst it 'passed' the headspace test I thought I'd better get a bigger bolt head for when I wore out the size 3, I started looking for a size 4 bolt head which are only available in the land of 'unobtanium' (In the last three years I have only ever heard of 3 examples).

During my quest I was informed by several 'old hands' that the bolt head size (number) was a guide only and in many respects was a meaningless number, Cannot be right - I thought, why put a number on it if its meaningless, and thus started my research into bolt head numbers / sizes.

I measured my (slender) supply of bolt heads and had a good response from members of another forum, which gave me a good basis for the evaluation, with the additional 'numbers' from members on Gunboards I feel the results give a good representation of the actual dimensions of bolt heads.

What Size Should The Bolt Heads Be?

It seems to be generally accepted that No.4 / No.5 bolt heads should fall in

the following range:

Size 0 = 0.620" - 0.625"

Size 1 = 0.625" - 0.630"

Size 2 = 0.630" - 0.635"

Size 3 = 0.635" - 0.640

Whilst I don't question that this information is printed somewhere, I have not been able to find the original source, the information I have found does not actually state the starting dimension, only that the sizes are incrementally larger :

a) From Parts Identification List Rifle No.4 Mk1 and Mk1* dated

1945

Bolt head 0 part number BB8584

Bolt head 1 part number BB8585

Bolt head 2 part number BB8586

Bolt head 3 part number BB8587

Number 0 to 3 increase in length by increments of 0.003 inch

b) From Canadian National Defence Manual "First Line Maintenance

Instructions Rifle No.4, all marks" dated 28th June 2002

Bolt head size 0 NSN = 1005-21-103-1143

Bolt head size 1 NSN = 1005-21-103-1144

Bolt head size 2 NSN = 1005-21-103-1145

Bolt head size 3 NSN = 1005-21-103-1146

...the sizes being progressively larger in increments of 0.08mm (0.003")

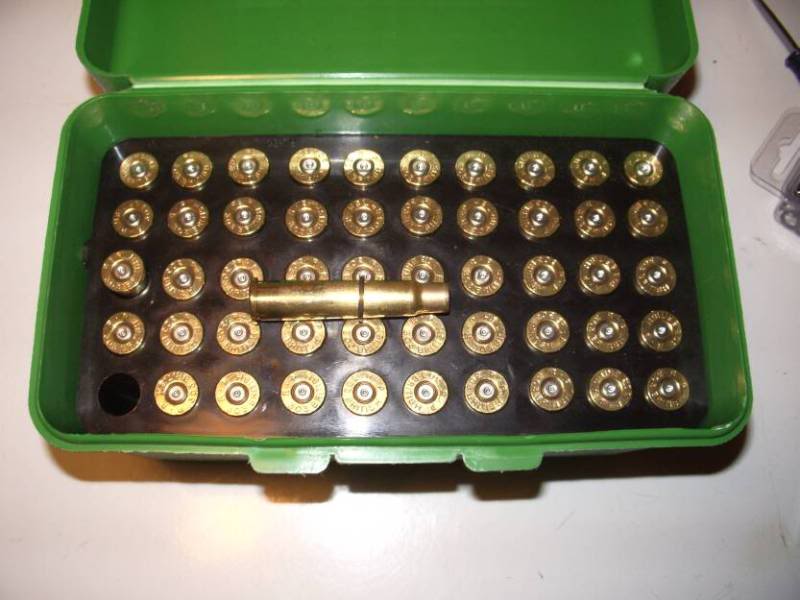

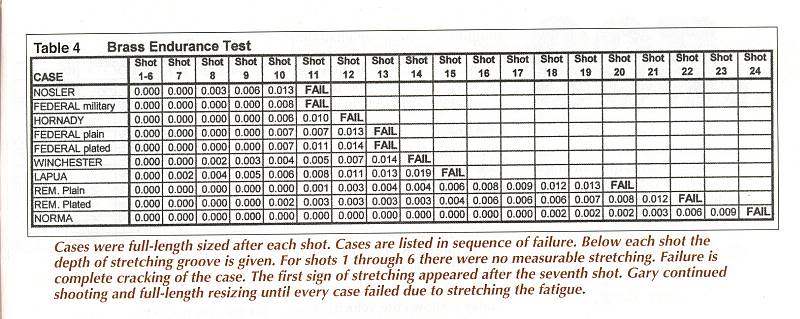

What Are The Results Of The Survey?

Firstly points for consideration:

a) Used bolt heads will be worn and should be slightly shorter than new bolt heads.

b) The measurements were taken by many individuals, with varying measuring equipment. In quality control circles this would be totally unacceptable but for the purposes of this survey it is the best we can do, and does give results that demonstrate the point of the survey.

c) There have been instances where a bolt head falls way, way outside the expected (ie a size 0 measuring 0.641") and it turns out that some enterprising individual has "peened" over the rear face of the bolt head by as much as 0.010" (10 thou) to tighten up the headspace, these measurements have been discounted from the results.

The numbers x1, x9 etc are the number of samples reported. (x1 = one sample, x2 = two samples and so on) Any further contributions will be gratefully received and the table updated periodically.

How often do we see the advert Wanted size 3 bolt head - hopefully we can now show that its not a size 3 bolt head that is needed - just a slightly longer bolt head.

Example (with sizes taken from the above survey) you have a size 2 bolt head that measures 0.630" but fails headspace by 0.003", you actually need a bolt head that is 0.633"+ and this could be anything from a size 0 to a size 3

I don't want to get into a headspace debate (there is already a sticky for that) but we need to clarify what headspace we are looking to achieve. The Enfield is a British Military rifle and it is they who set the headspace (if others want to set alternatives to achieve their own aims, then so be it). The headspace is specified at 0.064" min and 0.074" max.

So when measuring headspace ensure you use the correct gauges - the American SAMMI "field" gauge is only 0.070" (The Sporting Arms and Ammunition Manufacturer's Institute (SAAMI) .SAMMI specifications call for a Minimum of .063" and a Maximum of .070" headspace in 30 calibres.) so you could be condemning a perfectly good rifle by using the wrong gauge.

The following are notes from Peter Laidler on proper use of headspace gauges and bolt head sizes:

Now that the gauge is into the chamber and the bolt is being closed, this is where the trouble lies. It's important here to remember the often said phrase among Armourers of "DON'T OVER CHS". Here's another thing to remember during this. Because there is a camming action operating while OPENING the bolt, called "PRIMARY EXTRACTION" this action also operates when closing the bolt. And the same primary extraction forces that will enable the infantryman to force the bolt closed and unlock and extract a possibly distorted shell case, covered in wet silt and mud in the saltwater Magrove swamps of Johore in Malaya that's caused the case to stick hard to the chamber walls will also enable the butchers or bubbas to close the bolt hard against the gauge. NO-GO on the .074" gauge is when, using the lightest finger and thumb action on the knob causes a slight feel of resistance.

The next question you're going to ask is "where during the bolt closing movement is this slight feel of resistance acceptable --- Is it almost closed or, hardly closed or in between?" Good question and the answer in the bible reads thus: "with a 0, 1 or 2 bolt head, there must be resistance onto the .074" gauge prior to there being a minimum of .050" from the underside of the bolt lever to the contacting point of the body socket." Then it goes on to say "...With a #3 bolt head the left edge..." But I want you to forget this because the statement was too ambiguous. I suggest that you use my maxim of "WITH ANY SIZE OF BOLT HEAD FITTED THERE MUST BE RESISTANCE OF THE BOLT ONTO THE .074" GAUGE PRIOR TO THERE BEING A MINIMUM OF .050" FROM THE UNDERSIDE OF THE BOLT LEVER TO THE CONTACTING POINT OF THE BODY SOCKET. I want the master Masons among you to learn that by rote!

Using this criteria, if a #3 bolt head starts to resist half way closed and a #2 resists at .051" from the body side, then use the #2 bolt head. Remember DON'T OVER CHS.

There are a couple of reasons for this. Firstly, it is from a point when the underside of the bolt handle is approx .15" from the sharp curve between the top of the body and the side of the butt socket, that the bolt effectively ceases to move any further forwards and is effectively locked.

The second is that prior to the point of fully locking, a feature called "mechanical safety" comes into operation and (it's getting technical now...) the stud on the cocking piece will strike the stud between the short and long cam groove at the rear of the bolt causing a diminished force of blow to the striker, resulting in a miss-fire! Phew!

You will understand that this is a highly condensed precis of events taking in months of learning, investigating and examining undertaken by apprentices and I'm trying to cram it into a 40 minute lesson!

This brings me to another point... It's very basically this. If you cannot get headspace, even using the very relaxed criteria I have discussed here by using a new bolt and a #3 bolt head, then I'm afraid that it means your body is knackered. This quaint old Armourers technical term indicates that it's seen better days... it's xxxxed! You COULD allow yourself up to, say, .078" headspace but the technical opinion reached during research into this during the 50s is that it's a palliative and not a true cure.

Very few of us will have a bucket-full of bolt heads to work with so we need to have an idea of what bolt head size we need to overcome the headspace problem, headspace gauges will tell us it fails but not by how much.

A simple way, that gives a close approximation is by using a case and a primer:

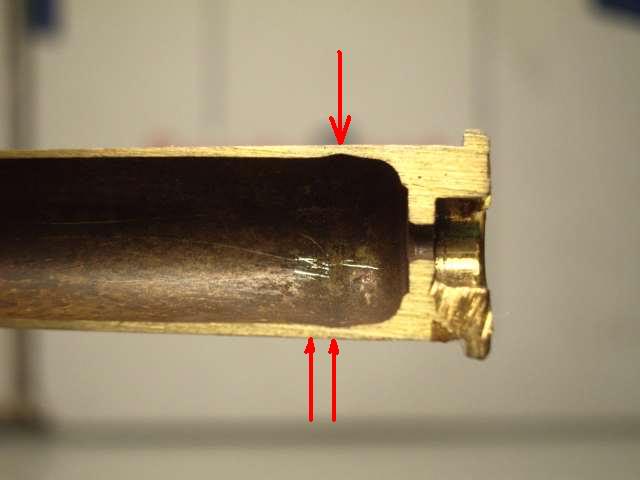

Since the 303 headspaces on the rim, its headspace is the distance from the

front of the rim of a seated case to the face of the bolt. To determine that

distance we:

* Measure the rim thickness of a new case. A fired case will have expanded and

closed the headspace. You must use a new, i.e., unfired case. Measure around

the rim and use the highest value obtained. For an example, we'll say it

measures .062".

* Take a fired primer and start it into the unfired case's primer pocket. Seat

it just enough that it doesn't fall out.

* Hand chamber the new case, and slam home the bolt, seating the fired primer

with the bolt.

* Remove the case from the rifle's chamber, and measure the distance the

primer protrudes from the case head. For an example, we'll say it protrudes

.014".

* Add the rim thickness measurement to the primer protrusion measurement and

you have your rifle's headspace, at least you have a close approximation of

its headspace.

In our example, 0.062" + 0.014" = 0.076"

Thus if your headspace comes out at 0.076" and your bolt head is currently 0.630" then you'll need a bolt head a minimum of 0.002" (two thou) longer but ideally somewhere between 0.002" (to give the 0.074" max) and 0.012" (to give the 0.064" min).

Instead of specifying I want a #3 bolt head you can now look for a bolt head between 0.632" and 0.642"

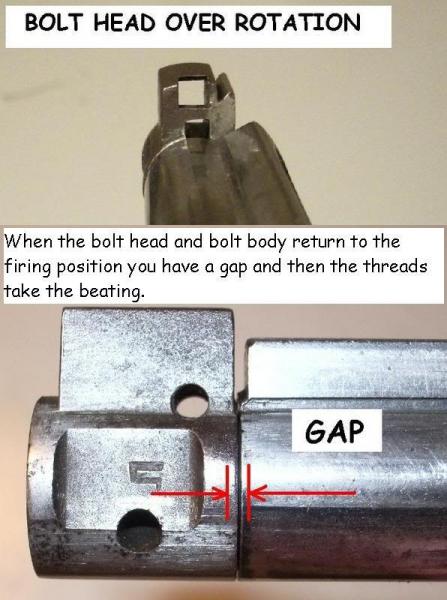

Finally when changing over bolt heads consider bolt head over- rotation.

Check the bolt head to ensure it does not overturn by more than 20 degrees when assembled to the bolt.

The 20 degrees may be measured as 4.76mm (3/16") from the left corner of the bolt head lug to the left corner of the bolt column.

An over-rotating bolt head allows all the recoil to be taken on the threads, with in few rounds your headspace will be back to where it was.

A picture speaks a thousand words :

Edward Horton

12-19-2009

Quote:

The Enfield is a British Military rifle and it is they who set the

headspace

The Enfield rifle is a British and Commonwealth rifle.

And Canadian head space is different than British head space.

Fultons of Bisley set the head space on some Enfields to where the bolt face was just kissing the rear of the cartridge case for the utmost in accuracy to minimize action flexing.

I have two bolt heads fitted for the Mk2 Enfield pictured below, one is just under .067 and the other is below minimum head space of .064 and it is set at .062. Our American made cases have thin rims and small base diameters and even at .062 I still have .004 head gap clearance.

My bolt is resting on the .064 head space gauge, it fired hundreds of rounds and never had any misfires or problems.

You have the right way, the wrong way, and the Army way of doing things.

miketuite

12-19-2009

Wow! Thank you for all the information, gentlemen. It's very much appreciated. For what it's worth, my no-go guage is the Yankee Engineers coin-type. THe package says it's mil spec. The field guage is a Forster. According to the Brownell's site, it is SAAMI.

Steve H. in N.Y.

12-19-2009

I think we obsess about headspace because it's possible to tinker with it. I don't hear Mauser collectors talk much about it.

Edward Horton

12-19-2009

1. Do you reload?

2. Do you have a micrometer or vernier calipers to measure your coin gauge to

confirm thickness?

NOTE: Yankee Gauge size identification (how many notches on your gauge?)

Go Gauge - Identified by 1 notch inside the gauge firing pin clearance hole.

No-Go Gauge - Identified by 2 notches inside the gauge firing pin clearance hole.

Field Gauge - Identified by 3 notches inside the gauge firing pin clearance hole.

My gauges and sizes are easy to read.

Edward Horton

12-20-2009

American SAAMI commercial ammunition was never designed to shoot in large diameter, long head spaced military rifles like the British Enfield. And American military ammunition is thicker in the base web area and was designed to shoot in military chambers.

As long as American SAAMI commercial ammunition stretches and thins in the base web area over .009 (nine thousandths) when fired in an Enfield with the head space set at .067 I’m going to keep bugging you.

As long as American SAAMI commercial ammunition doesn't stake or crimp their primers like military ammunition does, I'm going to keep bugging you.

As long as people with a head space sticky tell everyone to grease or oil their cartridge cases when they fire their ammo, I'm going to keep bugging you.

As long as the ammunition manufactures, firearms manufactures and reloading manufactures tell you to keep your ammunition and chambers grease and oil free, I'm going to keep bugging you.

As long as Son the Australian over at Gunboards tells people that .074 is good enough when he is reloading military Greek HXP ammunition, I'm going to keep bugging you.

And last but not least as long as the Australian National Shooting Champion James Sweet tells you to set your head space between .064 and .067 AND the Australians Ian Skinnerton and Brian Labudda tell you to set your head space .003 (three thousandths) over your rim thickness I'm going to keep bugging you.

Brian Dick

12-20-2009

Ed, are those Arrowmark gauges from Australia? If so gents, those are the ONLY ones to purchase. They are correct British and Commonwealth MILITARY specification and NOT SAAMI which cause more problems than good.

Bolt heads need to be select fitted. Purchasing one and just screwing it in is a crap shoot. You might get lucky but... factories and armourers had bins with hundreds from which to select fit.

Peter Laidler

12-20-2009

You are SO right Brian. A monkey can unscrew a bolt head and screw another on but the bolt head is interrelated with and controls other things too such as firing pin protrusion, cocking piece lift. I could go on. Don't change it if it ain't broke.

Edward Horton

12-20-2009

I bought all three head space gauges for $35.00 (yes I'm a cheap bastard) and I didn't ask where they were made.

And Enfield head space gauges come in many diffrent sizes for very good reasons.

gravityfan

12-20-2009

I am intrigued. I have been reloading .303 for a while, but I've not heard of this O-ring thing. Please tell me/us more; size, type, source, etc. Or would anyone like me to make a separate thread of this?

Brian Dick

12-20-2009

They certainly look like Arrowmark gauges. If so, you stole them for sure @ $35 as they retail for close to $100 now! Good on ya.

Edward Horton

12-20-2009

Originally Posted by Brian Dick

As a reloader I will never loose my preference for tight chambers and tight

head space, having said this, good brass and the o-ring method of fire forming

Enfield cases is the only way to go with the .303 Enfield rifle.

BUT the L-42 7.62 Enfield has tighter head space standards than the American

commercial SAAMI for the .308. (I read about this tight head space in a little

green book)

trooper554877

12-20-2009

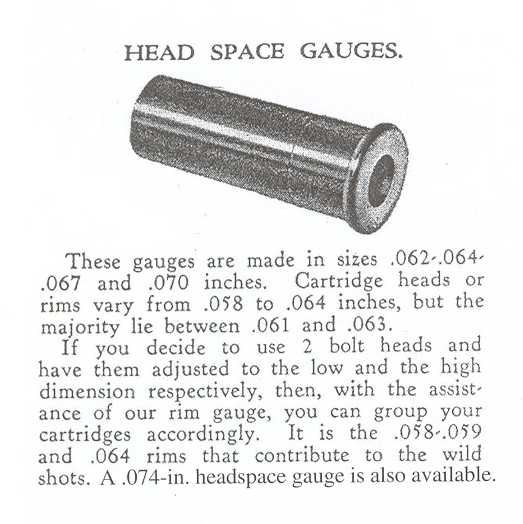

Before this gets out of hand again, a quick word on the rim thickness gauges and 2 boltheads.

When these where in vogue the ammo was ALL factory stuff or as you Yanks call it ex milsurp. Each rifle club would submit a forecast as to how many rounds where going to be needed for the years shooting. This was mostly over exaggerated as you would do and then it was railed to the club, picked up at the local rail siding. The club captain would issue the ammo to the shooters as needed and THEN the shooter would check the rim thickness and batch them to as close as possible to his rifle.

The 2 bolt heads where used if the batch of ammo was of a different size. remember this was all ex WW2 and later mil ammo so all factory spec length but with varying rim thickness due to manufacturing tolerences.As we can research and know that when we use reloaded ammo we fire form the cases to our own rifle after the first firing and if only neck sized then the headspace and overall length of the case is tailor fitted to each individual rifle, negating the need for the rim thickness gauge and batching ammo due to rim thickness.

A common theme today is rimfire competition shooters do the same batching of thier favourite ammo for each rifle, they need to achieve the same thing as the old target rifle shooters using factory ammo.

Parashooter

12-20-2009

Originally Posted by gravityfan

I am intrigued. I have been reloading .303 for a while, but I've not heard

of this O-ring thing. Please tell me/us more; size, type, source, etc.

If you handload for a .303 with generous headspace, there's often no need to

mess with bolt heads - changing the rifle's clearances to yield longer case

life. You can control cartridge end-play simply by changing technique.

When you fire a new case for the first time, use an improvised spacer ahead of the rim - anything from a precision metal washer to dental floss can work to hold the the cartridge head firmly against the bolt face and eliminate or reduce stretch even if end-play without the spacer would be significant. Another way of accomplishing the same end is to use a bullet seated out far enough to jam into the lands, "headspacing" on the bullet instead of the case. Such techniques are useful only if the rifle has excess headspace (or cartridges have abnormally thin rims). With normal headspace and cartridges, initial stretch isn't enough to worry much about.

O-rings are a slightly more costly spacer material preferred by some.

After you've fire-formed your new cases they will fill the chamber fully, stopping on the shoulder just like a rimless cartridge. If you neck size, you'll have zero "headspace". If you have to full length size, adjust the die so the cases chamber with just a bit of resistance in the last few degrees of bolt rotation. The result, if combined with reasonable-pressure loads, can be extended case life despite generous headspace.

Edward Horton

12-20-2009

Your forgetting the American SAAMI rim thickness standards are .064 to .054 for American commercial ammunition, and I have measured rim thicknesses from .062 to .057.

Then to add insult to injury the American SAAMI chamber standards are NOT the same as British military chamber standards.

On top of this you have .303 ammunition made all over the world to their countries standards or tolerances.

Are you going to tell me the base diameter on the HXP ammunition is the same diameter as the Prvi below or that the Prvi isn’t .010 thicker in the base web area and has a thicker rim.

So before this gets out of hand, don't tell me I can't read a gauge.

Don't tell me all brass cases are made from the same grade brass.

And don't tell me every manufacture makes the same quality cartridge cases and they are the same thickness in the base web area.

The "Enfield inch" story covers more than the Lithgow factory or how many grains of corn or barley make up an inch in Australia or the U.S. of A.

Or are you going to tell me the Australian Shooting Champion James Sweet didn't know what he was talking about when he said this in 1946.

trooper554877

12-20-2009

Ed, I was only making observation to the rim gauge. the only constant in the ammo was that they where given it. Of course there where differences in rim thickness, case length etc, thats why the chambers are so generous, to accommodate for any ammo supplied from any factory in the world.

The target shooters like Jim Sweet had only one way to control the quality of ammo they feed into their rigs and that was to measure rim thickness. they knew what shot good in their rifles and procured ammo that fitted. they had no control over any of the loading procedures etc that you mention. It was new off the shelve stuff, fired once and discarded.

Parashooter

12-21-2009

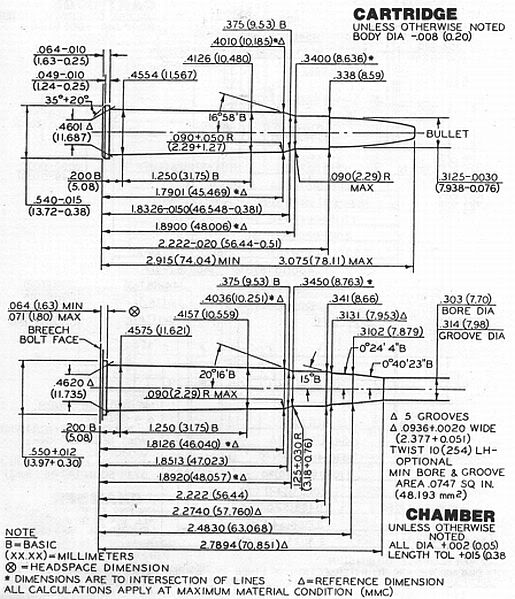

303saamicommongif-1.jpg">

Lower (British) drawing courtesy of Mr. Horton. Upper from SAAMI.

From what I can see, base diameter (.462"), shoulder diameter (.4036", .4045"), neck diameter (.345" at shoulder, .341" at mouth), leade (~.313 > .3102) and length to mouth (2.158"+.064"=2.222") are virtually identical, shoulder position and radii very much the same, and there is no practical difference if one remembers to add the .064" rim clearance to the British length figures (to adjust for the SAAMI lengths being measured from the bolt face instead of the barrel face).

Edward Horton

12-21-2009

Parashooter, your entire premise for your original "Headspace 101" was oiling and greasing your cartridge cases to keep the cases from stretching and thinning in the web area. When someone made your method "controversial" you edited your "Headspace 101" to eliminate the words oil and grease.

The problem I have with your comments here is you admitted that you still oil your cases to fire form them, you read about the rubber o-rings like I did at Jouster and yet you are here writing about fishing line and dental floss as if you use it every day or at least after every meal.

Parashooter the o-ring method came from a Canadian at Jouster, the rubber O- ring centers the case in the chamber and fishing line and dental floss will not. I will say it again Parashooter you can't have it both ways.

Oiling your cases doubles your bolt thrust and shortens the Enfield's life expectancy by half and your "Headspace 101" told everyone to oil and grease their cases for over seven years.

Mr. Laidler told us during an Enfield FTR/overhaul an oiled proof round was fired and if the bolt was hard to open the action was scraped. This was because the surface hardness in the lug recesses had worn through.

It's a little late for fishing line and dental floss and changing horses in midstream on a Enfield battered by excessive bolt thrust caused by oiled cases.

Amatikulu

12-21-2009

Both of my No.4 Mk.1* rifles have failed the no-go and field guages. They both have #1 bolt heads. Am I correct that replacing the bolt heads with higher numbered ones will/might fix the problem? If so, I have a couple of questions: How can I determine which bolt head (#2 or #3) will yield correct headspace? Where am I likely to find them?

Thank you for your help.

Mike

Above is the initial post on this thread. I think the question has been

answered.

Badger

12-21-2009

Ok, enough folks...

Thread is now locked.

This subject has been beat to death a hundred times on every Enfield gun forum on the Internet in the past 10 years.

It always results in the same arguments, often by the same folks.

As Amatikulu pointed out, I think it's safe to say that the original poster got his answer by now.