Thread: Timney trigger

Retrieved: 06/01/2014

I was on the Timney web site and noticed that they made a trigger group for the Enfield. I recently bought one of the AIA .308s and love it but really hate the heavy trigger. Has anyone on here used this trigger and what did you think?

Peter Laidler

05-15-2010

On a similar subject, has anyone ever tried fitting the superb No.8 trigger mechanism to a No4?

Son

05-15-2010

I think you will find that trigger fits P14 and M17 rifles, but not the No.4. I wouldn't even care to guess if it will fit the Vietnamese rifles.

Contact Timney and ask for a clarification, (I could be wrong)

No4Mk1(T)

05-15-2010

Originally Posted by Peter Laidler

On a similar subject, has anyone ever tried fitting the superb No.8 trigger

mechanism to a No.4?

I considered it but the rifle would be a single shot when you were finished. Once I realized that I didn't look into it further. It would be a great idea for a single shot target conversion.

Edward Horton

05-16-2010

If the trigger and sear arrangement are the same as a standard No.4 you can make the trigger slicker than snot on a door knob, by changing the angle of the cocking piece bent AND save a lot of $$$$$

Peter Laidler

05-16-2010

But changing the angle of the cocking piece has a downside Ed. And that is that even a slightly less angle on the C-piece decreases the trigger pressure by a disproportionate amount so that when you've got it perfect for the shooter, it fails the 6.5lbs pull-off load.

They wanted to do something like this for the L39 comp rifle so reluctantly decided that while the c-piece angle should remain, the sear spring weight would be decreased by adding another spring seating to the magazine catch.

Us Armourers who had these L39's under our wings didn't like it.

Bruce_in_Oz

05-16-2010

The Lee Enfield, being a "cock on closing" action, presents an interesting bunch of engineering issues if a "slick" trigger is required.

On cocking, the sear is engaged with a considerably greater amount of violence than, say, a Mauser 98. And that attack increases with increasing bolt manipulation speed, unlike a Mauser.

So, whatever trigger is used, it has to be able to take a pounding.

The Canadian J5550 lightweight experimental carbines used a Mauser type trigger, mainly, I suspect, because, with the butt socket chopped off and the triggerguard floating around on two pillar screws, there wasn't much else they could do.

I looked (very briefly) at building a three-lever trigger module that could be attached to a No.4 Mk2 style action. Nice paper exercise.

The standard trigger works well if you:

1. Start with quality components with the correct hardness.

2. Set the front face of the full bent of the cocking piece correctly. It

MUST:

a. Be at (or very close to) the factory angle, (86deg 10min ref. the bottom surface of the cocking piece.3. Set the engaging face of the sear for maximum contact with the full bent of the cocking piece. (Bearing blue comes in handy here).b. Be a dead flat surface and,

c. Be polished VERTICALLY, not horizontally. (The cocking piece MUST be removed from the bolt to do this properly.)

4. Polish the rear face of the lower leg of the sear, again in a vertical direction and dead flat.

5. Remove any fuzzy bits from the two "bumps" on the trigger.

"Eze-Lap" diamond hones, (several grades, decent-sized plastic handle), are ideal tools, just go easy. If too much material is removed from either the sear or the cocking piece, the safety will not function correctly.

A dab or two of moly grease and away you go.

Fitting of an over-travel screw for the trigger is a nice luxury, but not essential.

The trigger action MUST have two stages. The sear MUST return to its initial position on the cocking piece if the first pressure is relaxed. Anything else is potentially dangerous.

Very labour-intensive and not for the impatient, but much nicer than most "as delivered" triggers for target work. Out in "the weeds" the standard military trigger is safe and reliable. When snap-shooting pigs in the scrub, the last thing you will notice is your trigger. For knocking over deer at 300 yards, see items 1 to 5.

RJW NZ

05-16-2010

If you really want a good after market trigger for Lee Enfields I fitted/used and am very happy with the CanWest unit which is designed for Lee Enfields, not a general purpose one. They make a target type with no follow through that will go down to 1.5 lbs, and a hunting type with a long follow through. I used the target one, and it can be set to work like a switch, very nice on that rifle. They're listed on enfieldresource or an internet search should find them.

Edward Horton

05-16-2010

Originally Posted by Peter Laidler

But changing the angle of the cocking piece has a downside Ed. And that is

that even a slightly less angle on the C-piece decreases the trigger pressure

by a disproportionate amount so that when you've got it perfect for the

shooter, it fails the 6.5lbs pull-off load.

Besides I prefer Air Force regulations, A.P. 3196 (Even if they are British)

Son

05-17-2010

I spent several hours playing with sears, triggers and cocking pieces yesterday, experimenting with the best way to improve what was a pretty horrible trigger feel.

I saw that when lined up on a pin, there were very slight differences in some individual bits. Several sears were identical, but there were a couple either wider or narrower spread than the norm. Some also had a bow up from the pivot to the point of the sear. Same went for triggers WRT the angle they sat at when against the stop. By changing those two parts I eliminated the free play it had at the start of pull, and reduced the total pull length. Then with a bit of stoning, I got the trigger down to a short but distinct first pull and a crisp "wineglass stem snap" release on the second pull.

A bit of work on the bent reduced the first pull down to 2.2lbs and the second at 4lbs. I did find that it was near impossible to get a "crisp" release with less than 4 lbs pull without the rifle going off with a bump on the butt with the trigger at the first pull. To be on the side of safety, I decided that would be a test.

The biggest problem this rifle had from the start was the striker was loose inside the cocking piece. When you took the trigger to the first pull, it actually pulled the front of the cocking piece down, away from the bolt body. I replaced the cocking piece first.

The entire exercise involved eight or nine sears, seven triggers and four cocking pieces. At the start I tried a few different strikers as well, before scrapping the original cocking piece and retaining the striker.

Summing up, although I have done a bit of EFD trigger work before, there are so many variables that without a lot of time and a decent supply of parts, they can be a nightmare. Often you can achieve the standard trigger weights by adjusting the front trigger guard screw bush correctly (usually in a replacement foreend) and swapping a few bits around. As you said, carefully polishing a few surfaces can sweeten a trigger, but trying for figures below spec pull weights can get expensive.

madcratebuilder

05-17-2010

I use a similar procedure as Son uses. I generally get a crisp trigger that breaks at 4.5-5lbs with a 3.5lb pull up. My problem is finding spare triggers and cocking pieces that have not been screwed with. My goal on all my mil- surps is a 4.5lb trigger. The Swiss rifles are always way below that!

Son

05-17-2010

Originally Posted by Bindi2

Having laid on the mound and having used the the correct setup out and

about as well compared to others it has no peer as an allround setup. Mind

control controlling the index finger.

Gotta say here, I don't have a Lee Enfield that is outside the specs for trigger pull. Agreeing with Bindi here 100%!

The trigger I wrote about above was on a .303/25 sporter belonging to a bloke who uses it in competition and in the field. Altering it so it suits his need was the job - he has the option of returning it if too light, but I won't go any lighter for any reason.

Madcratebuilder - you look to set all your rifles around 4.5lbs? What do the rest start at - out of interest's sake.

roughneck12

05-17-2010

Mine is one of those new Australian rifles. I have no interest in keeping it new and pristine. I just want a good shooting rifle. It has a heavy barrel that I am thinking of getting fluted and I hate the trigger. I just want a decent trigger without too much messing about.

I'm almost afraid to take the damn thing apart, but will get around to it some day.

One thing I have noticed is there is a ton of movement forward on the trigger. Is this normal on a LE? Or is there a spring missing?

Son

05-17-2010

Originally Posted by roughneck12

Mine is one of those new Australian rifles.

It's not really a Lee Enfield, more a "modernised" sporter roughly built along lines of the Lee design. Can you take a picture of the trigger assembly without the woodwork fitted? Perhaps some of the guys can come up with suggestions to help you out.

Bruce_in_Oz

05-17-2010

Good point about getting the right bits. One of the things I discovered some years ago is that there are parts and "parts".

I suspect that a lot of stuff floating around has been "rescued" from scrap bins, where it had been consigned as out-of spec.

The drawings I have for SMLE and No.4 parts show quite tight tolerances for dimensions and surface grades on working surfaces. There are definitely dodgy parts out there; I have had three cocking pieces fracture on rebuilt No.4 bolts in the last four or five years. All seemed dimensionally correct and functioned properly; internal crystal structure was like granite! Basically, they had been "over-cooked" in heat treatment.

As for the AIA rifles, they employ the hung trigger system as per a No.4 Mk2. Their trigger is straight from the drawings of the Lithgow No.1 Mk3. Yes, you can mix SMLE and No.4 triggers (with the usual caveats); also the sear spring is identical down to the part number. (As an aside, their receiver had all its critical internal dimensions lifted from an amalgamation of UK and Canadian drwaings, hence the "eclectic" array of features.)

Anyway, not having to fiddle about with the trigger guard makes setting up a lot easier. The drawback to this trigger system is that it reduces the stability of the fore-end, which, I suspect, is the main reason No.4Ts were not built on the later actions.

Edward Horton

05-17-2010

With all due respect to Mr. Laidler and what the British Armourers did to the Enfield rifle and what "WE" have to do are two completely separate and different things.

Trigger adjustments, if a British Armourer had more than .020 wood crush on the fore end below the receiver and trigger guard the fore end was replaced.

We are not going to throw away a stock for this reason so we need to learn how to adapt. If you notice the Canadians give us a "hint" about this in their No.4 manual and trigger guards that have been bent in the field to get better trigger pulls.

If you read between the lines on this you will understand, there are no more replacement fore stocks and you have to learn the work around for excess wood crush.

The manual states the Armourer might find bent trigger guards coming back from the field, and the Armourer "MAY" need to straighten the trigger guard to adjust the trigger.

If the fore stock has excess wood crush you are wasting your time trying to adjust the lobes on the trigger for the correct pull.

Here is a simple fact, if your fore stock has more than .020 wood crush and you shorten the trigger guard bushing or collar to keep the fore end tight you will need to bend the trigger guard to make up for the increased trigger guard angle.

What this means in plain English is this, if you don't bend the trigger guard you will NEVER get the sear in the proper position on the cocking piece. The problem is simple you are out of the adjustment range of the lobes on the trigger. You can work until you are blue in the face and you will NEVER get the lobes to the correct shape and hight. You will need to bend the trigger guard or go find a brand new fore stock, you pick which is easiest to do.

We don't have any fancy adjustment screws on our triggers to change any settings so you must learn to "adapt" to what you have. At the end of your first stage pull the sear should be at the bottom edge of the cocking piece and ready to "fall off the edge" when pushed by the second stage of your trigger pull.

If your sear stops too soon on the cocking piece, your second stage is going to be a "LONG" and "HARD" pull.

Step one is getting your sear as near to the edge as possible and ready to "fall off the edge" with your second stage pull. AFTER your sear is at the edge of the cocking piece you can worry about changing the angle of the cocking piece and pull weights.

madcratebuilder

05-18-2010

Madcratebuilder - you look to set all your rifles around 4.5lbs? What do the rest start at - out of interest sake

I have two 'new' No.4 Mk2's that are 5lb+/-. The rest of the No.4's ran from 3-8lbs, half had been messed with, eliminating the first stage. I hate that looong pull with no idea when it's going to break. I'm down to just two unmessed with No.4 triggers... everybody's a gunsmith!

I would say that most of my mil-surps are 6-8lb as purchased. The exception is the Swiss K-31 and Zfk. 3-3.5lbs is the norm. I played around with a bench .22 and have it at 8oz.

There are mil-surp shoots at several local ranges and they well check trigger pull on you. All use a 4.5lb minimum rule. I'm much to cheap to buy an aftermarket trigger so I make do. Todays project is a unissued M48 Yugo that has a gritty trigger, pull weight is good, just has a catch in it's get along.

Surpmil

05-18-2010

Originally Posted by Peter Laidler

On a similar subject, has anyone ever tried fitting the superb No8 trigger

mechanism to a No.4?

I'm all ears...

Originally Posted by Peter Laidler

...They wanted to do something like this for the L39 comp rifle so

reluctantly decided that while the c-piece angle should remain, the sear

spring weight would be decreased by adding another spring seating to the

magazine catch.

It was done on the ENVOYS I believe. Was it on the ENFORCERs too?

Bruce_in_Oz

05-18-2010

The business of adjusting the sear spring pressure can be a problem too.

Cutting an additional notch on the mag catch seems to be the standard method. A few folk also seem to have tried grinding the spring to narrower dimensions.

All well and good, as long as the spring still has enough "grunt" to force the sear back up the front bent of the cocking piece when you relax first pressure.

If it does not do that, you have a potentially dangerous situation. Applying the safety SHOULD draw the cocking piece back clear of the sear, allowing it to reset. Still not ideal by any stretch.

I suppose if one were "hard-core" enough, there is another possibility.

After ensuring all working surfaces are close to correct spec, get an industrial shop to HARD chrome the working surfaces (only) of the cocking piece, sear and trigger. Then carefully polish with diamond tooling for a seriously slick setup. Some "restorative" dimensional build-up is also possible, however, a thick layer of chrome is quite brittle and surfaces like the sear tip could crack with too much exuberant manipulation.

jmoore

05-19-2010

Originally Posted by Bruce_in_Oz get an industrial shop to HARD chrome the working surfaces (only) of the cocking piece, sear and trigger.

It's surely not a new technique - I've a 1955 .45 ACP Hand Ejector Smith & Wesson that someone performed this mod upon. They chromed only about 1/3 of the trigger and 1/2 of the hammer. The rest is still color case hardened. Plus, most older "stainless" steel Smiths have hard chromed hammer and trigger units- they seem to hold up OK...

I'm just not sure what all the fuss is about - I LIKE a two stage trigger, so much so that I've retro-fitted most of my ARs w/Geissele FCGs, including an SSF and SSA units.

Take up crunchiness doesn't bother me, just so long as the final break is clean and repeatable.(Even if there's a "double step" in the last pull its OK, as long as it is the same every time.) I don't think I've ever had a L-E with a "too heavy" pull.

Of course, my opinion of rifle triggers may be somewhat influenced by years of shooting revolvers double action w/some degree of accuracy and speed... Still haven't mastered Mk.VI Webleys, though!

Son

05-19-2010

"Lee Enfield with a too heavy pull"? Had to sort out a sporter a few weeks ago with a single stage trigger that broke at just over 15lbs! The barrel Knox and receiver ring were sitting on top of about 1/4 inch of glass bedding, set without having any wood removed under it first. The change in the angle to the trigger guard, combined with the old Long Lee ball and socket trigger and sear, meant the ball and socket had reached the end of it's movement and was locked up at the point of release! No wonder the owner got it cheap!

Edward Horton

05-19-2010

I can remember the "good old days" when I never gave a single thought about Enfield trigger pull, if the cocking piece was going to do the wiggle, or if the steering wheel was on wrong side of the car.

bigduke6

07-01-2010

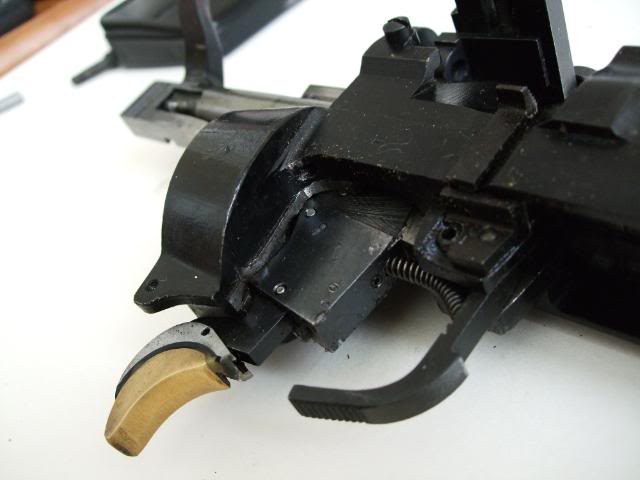

Was Looking for another thread and seen this, so thought id post pics of a Canjar trigger fitted to 7.62mm No.4 Mk2 heavy barreled action, it is pictured along side a normal No.4 Mk2 for comparison, only just noticed the barrel is Enfield marked and dated 69.

Also serial No: DD(E) 2472075SK anyone shed any light on the barrel?

Bought it to build up as a target rifle a few years ago but only got around to testing it.