Thread: NRA Safety Notice re No 4 7.62mm Conversions

Retrieved: 06/11/2014

This is the current stance of the NRA safety warning which first appeared in the Summer NRA Journal:

Safety NoticeEnfield No 4 Rifle Conversions to 7.62mm

A safety warning concerning the use of Enfield No 4 Rifle actions converted to 7.62mm was published in the Summer Journal.

After further consideration of all factors influencing safety of these conversions and consultation with the Birmingham Proof Master, the following advice must be adhered to in respect of the use of Enfield No 4 conversions:

- Owners of Enfield No 4 actioned rifles converted to 7.62mm currently proofed to 19 tons per square inch are strongly advised to have them re-proofed to the current CIP standard (requiring a minimum mean proof pressure of 5190 bar) which allows the use of CIP approved ammunition with a Maximum Average Working Pressure (MAWP) of 4150 Bar. - Conversions retaining their original Enfield barrel or a replacement barrel as manufactured by RSAF Enfield are safe to use with commercial CIP approved ammunition, which complies with a MAWP of 4150 bar, loaded with any weight of bullet, providing they carry a valid proof mark, and are still in the same condition as when submitted for proof. - Conversions fitted with any other make of barrel (such as Ferlach, Maddco, Krieger etc) should be checked by a competent gunsmith to determine the throat diameter of the chamber/barrel fitted before use. - Conversions where the throat diameter is less than the CIP specification of 0.311" but not smaller than 0.3085" must not be used with ammunition which exceeds 3650 Bar MAWP when fired in a SAAMI/CIP pressure barrel. - Conversions which have been checked and found to comply with Rule 150 may safely be used with any ammunition supplied by the NRA including the 155 grain Radway Green Cartridge, 155 grain RUAG Cartridge or any other commercial CIP Approved cartridges loaded with bullets of any weight provided that the ammunition pressure does not exceed 3650 Bar when measured in a CIP standard barrel. - Owners of Enfield No 4 actioned rifles converted to 7.62mm who are uncertain as to the proof status of the rifle should have it checked by a competent gunsmith. - Owners of Enfield No 4 actioned rifles in any calibre are strongly advised not to use them in wet weather or without removing all traces of oil from action and chamber prior to shooting. - Enfield No 4 rifles which are fitted with a barrel which has a throat diameter less than 0.3085” must not be used on Bisley Ranges. - Ammunition loaded with bullets of any weight which are of greater diameter than the throat diameter of the barrel must not under any circumstances be used on Bisley Ranges in any rifle or barrel of any manufacture.

When these conversions were made were "oiled" proof pressure rounds used or had the switch been made to the "CIP" standard of non-oiled proof test rounds?

Translation to American English and pressure standards.

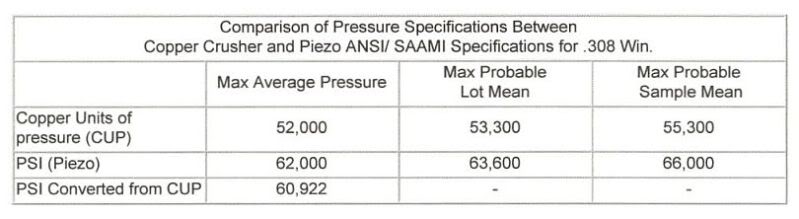

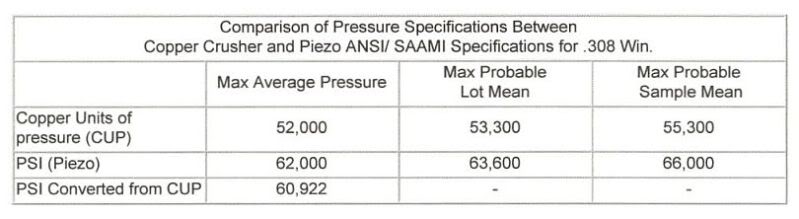

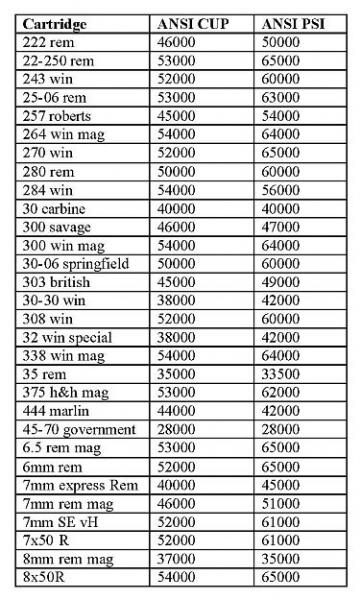

Requiring a minimum mean proof pressure of 5190 bar or 75,274 PSI transducer method.

CIP approved ammunition with a Maximum Average Working Pressure of 4150 Bar or 60,190 PSI transducer method.

19 TSI is equal to 38000 CUP or Copper Units Pressure British axial method which requires 10% to 20% to added to equal American radial method of CUP. (Between 41,800 and 45,600 CUP)

NOTE: 50,000 CUP equals 60,000 PSI transducer method.

Thunderbox

03-22-2010

Thus the UK NRA have back-tracked on just about everything. Still no attempt to present any "evidence" of an actual problem. There is also a response in the Journal which dribbles on about heeding warnings from other sources - but conspicuously fails to specify these.

"Owners of Enfield No 4 actioned rifles in any calibre are strongly advised not to use them in wet weather or without removing all traces of oil from action and chamber prior to shooting."

So, only about 120 years too late with that little gem of advice...

I think I'll continue to place my trust in the century or so of accumulated trials and testing of the Royal Arsenals, rather than internet myth merchants...

Edward Horton

03-22-2010

Ask yourselves what are the hazards of excess bolt thrust on the Enfield rifle.

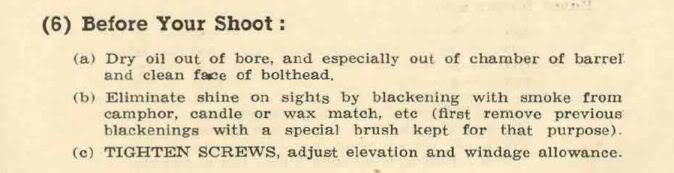

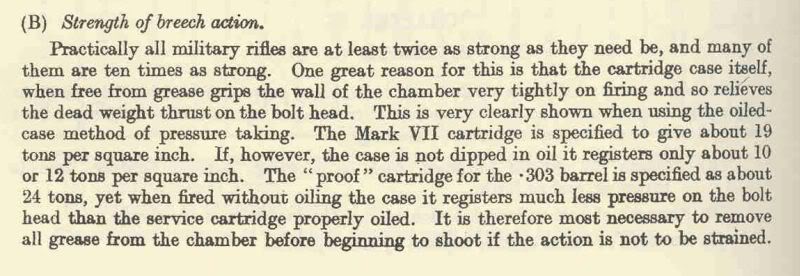

Below was written in 1946 by James Sweet a Queens Prize winner and author of "Competitive Rifle Shooting".

Strangely Brown

03-23-2010

To be honest ED I don't know whether oiled rounds were used or not; in fact I was always of the opinion that they (Proof House) used an "over loaded" round.(Can anybody else comment on that?)

Regarding CIP as a measurment, I doubt if it was in use (UK) during the period of conversions which was from circa 1969 and the last conversions I can find were around 1986.

Simon

03-23-2010

"After further consideration of all factors influencing safety of these

conversions and consultation with the Birmingham Proof Master, the following

advice must be adhered to in respect of the use of Enfield No 4

conversions".

What a surprise eh, The "Birmingham Proof Master" a private company who'll be more than happy to relieve you of your hard earned, recommends a re-proof.

Surpmil

03-23-2010

The inanities of suggesting that a No.4 in .303 is not safe in the rain, or that RSAF(E) produced barrels are safe "as long as they are in the same condition as when submitted for proof" - in other words, not used much since(!) are clear enough.

What is still not entirely clear is the reason for all this fuss and bother.

Is it legal liabilty "CYA", or did all this begin with the apparently bogus MoD "safety warning" that has been deconstructed elsewhere on this site?

If I'm not mistaken, the Lee Enfield and the No.4 are enjoying a bit of resurgence in the UK in the last few years?

So here we can see a nice convergence of government, commercial, legal (NRA?), and target rifle snob interests in attempting to discredit the No.4 (and by implication the No.1 SMLE as well of course)

What a mess, but of course if you keep throwing mud, some of it will stick in the dimmer recesses of the public mind, which is what they're counting on.

So now No.4's in 7.62mm need to be proofed to 30 Tons or MORE? Quite a jump from the 19 Tons that sufficed for the MoD for 30 odd years. Well that should blow a few up if nothing else will.

Then you'll hear some crowing.

Beerhunter

03-23-2010

I see that we all got our Journals yesterday then

When I read that load of old round things, my immediate reaction was that some one in the NRA just can't bring themselves to admit that the original statement was a load of rubbish based on no evidence and have now put this arse-covering nonsense out rather than admit it. I have read it again several times since and am now convinced that is the case.

I shall be writing again asking for clarification, and demanding that the NRA produce evidence, NOT hearsay, or that they withdraw the notice properly.

I shall also ask: how much this exercise in futility has cost us (the Members), who was responsible and their current employment status.

Thunderbox

03-23-2010

Originally Posted by Beerhunter

I shall be writing again asking for clarification, and demanding that the

NRA produce evidence, NOT hearsay, or that they withdraw the notice

properly.

Seconded.

No authority has issued any sort of warning, and the NRA cannot point to anything other than the same old hearsay.

Its noticeable that the Proof Houses have stated - reading between the lines - words to the effect "this is silly, but we are more than happy for you to recommend that everyone reproofs their rifle" (...).

My own recent feedback from one Proof House about this matter was - "hahahahaha - its all rowlocks" (sic). They declined to put that in writing, however.

BTW, .303 rifles continue to be proofed in apparently one of three ways, judging from the condition of the returned weapon: (1) filthy black bore: presumably a dry over-proof round; (2) dripping with oil but not too dirty: possibly oil proof with a normal ball round? (3) mysterious process whereby the rifle is returned bright and shiny clean... (I guess the Proof House now cleans selected rifles; I'm sure they can't possibly say "another No.1/4; haven't had one of those fail in recorded history; lets just stamp it up and send it back"...)

Ed,

James Sweet was a respected shot but, again, he never ran a ballistics laboratory, merely selectively quoted the same historical sources we all use. He omits, in quoting from the Textbook of Small Arms, to mentions that the 19 ton load of oiled ammunition was considered to be the normal service load condition and that the actual rifle proof was 24 tons.

Similarly, there is actually no tested and proved link between "straining the action" and the action fractures he mentions. A tiny, tiny number of No1 actions - out of the thousands that have been shooting for 90-odd years - do eventually warp and crack, but there has never been any military survey or trial that pointed to a finite "service life" or a correlation between service life & conditions of usage. ALL military No1s and No4s will have fired wet and/or oiled ammunition - most probably hundreds of times. More than 4 million No1 actions were mass-produced in 1914-18 so, statistically, some of those must have been borderline in terms of materials and metal hardening. The reasons for the (remarkably low) number of No1 action failures are up for supposition, until proven one way or another in laboratory conditions.

P.s. Strangely, Beerhunter, Simon, UK forum'ers: I'd be keen to hear about any case of a "stretched" rifle that is available for examination in UK, or where there is reasonable authoritative proof that this is taken place. It would be interesting to collect some real-world data. I'm not stating that it doesn't happen, but of the three rifles I've been shown so far where this is alleged to have happened, all had evidence of previous bad gunsmithing (no names, no pack drill...) - brand new bolt in one with uneven bearing, one with a bolthead over-rotating by about 90o, another with barrel shims and evidence of "improvement" in the locking surfaces.

Bindi2

03-23-2010

Q. Were not the conversions proofed for the 144gn nato round in use at that time. Therefore any heavier rounds (155gn) would not be covered by that original proof.

Beerhunter

03-23-2010

Posted to Glynn Alger

First of all you must be getting sick of these letters of complaints about the above but I can only say that you must know who in the NRA started it all and therefore you know who to talk to about their waste of everyone's time.

At the time of the original notice I, and many others to my certain knowledge, asked for references and got, in my case, complete silence.

The latest notice published in the Spring Journal, has done nothing whatsoever to address those questions of fact. In fact it seems to be a thinly disguised justification of the original notice. Some of the points made are general to any firearm and just seem to be there as padding and/or, dare I say, more justification for the original notice. For example bullet point nine – I nearly fell over laughing at that obvious piece of nonsense.

As to bullet point seven. I try to keep my ammunition dry for accuracy reasons but going as far as saying that a No.4 is dangerous in the rain beggars belief. They were designed to be used as a battle rifle in all weathers. Has the author never seen newsreels of Far East troops using No4s in the Monsoon!

Finally we are all still waiting for the evidence (not hearsay) that prompted the original notice that has caused so much waste of everyone's time.

Thunderbox

03-23-2010

Originally Posted by Bindi2

Q. Were not the conversions proofed for the 144gn nato round in use at that

time. Therefore any heavier rounds (155gn) would not be covered by that

original proof.

Proof covers the chamber dimension - i.e. the case specification for the designated calibre - up to a certain upper pressure reference. Hence any round of that calibre is ok if it generates pressure under the limit.

Edward Horton

03-23-2010

Strangely Brown and Thunderbox

The proofing laws between the U.K. and the U.S. are light years apart, and our newly manufactured firearms are proofed once in their lifetime here in the U.S. An Enfield rifle being sold here in the U.S. is sold as an Antique and Curio and by law it is not required to be proofed nor have any serviceability checks or inspections done.

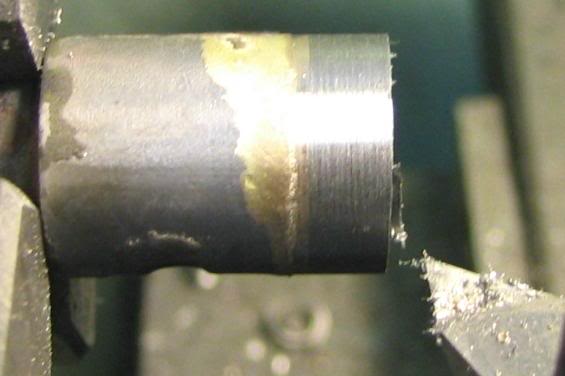

Bolt thrust does have effects on any rifle and if bolt thrust didn’t have any effects on the Enfield rifle the No.4 would not have numbered bolt heads. Below is a photo taken of a case fired in a No.4 Enfield and the backed out primer. With a rim thickness of .058 and a headspace of .074 you would have .016 head gap clearance or air gap between the bolt face and the rear of the case. The photo below shows more than twice that distance and also shows what condition an Enfield rifle can be sold here in the U.S. without any inspections.

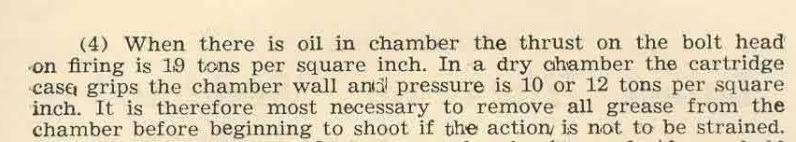

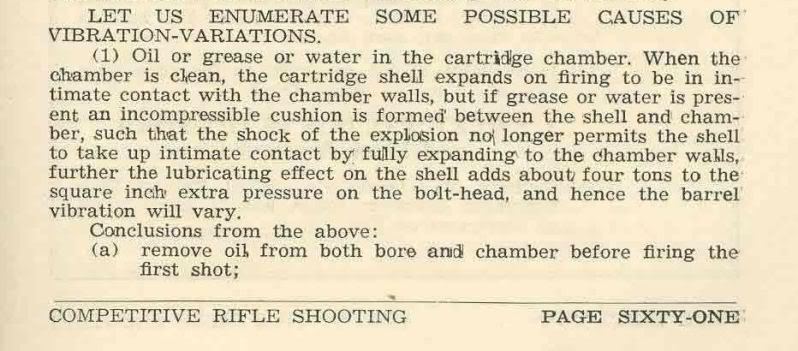

Oil, grease or water can double the amount of bolt thrust and does affect the amount of wear, headspace and the useful life expectancy of any rifle. For seven years I have been warning people about oil and grease on their ammunition and in their chambers and water or wet ammunition also comes into play on this subject of increased bolt thrust.

The person who took the photo of his backed out primers was a machinist and he made the "new" bolt head below to solve his problem.

Anyone who thinks that water, oil, grease and bolt thrust won’t have any effect on wear and headspace on their rifles needs to seriously rethink this matter.

Bolt head over rotation is caused by bolt thrust.

GREASE IS NOT THE WORD

"A series of tests at Frankford Arsenal revealed that the use of grease dangerously increased bolt thrust and chamber pressure. When a rifle is fired, the case is driven back against the bolt face with the force of the powder pressure minus the resistance generated by the friction of the expanding brass case against the chamber walls. Grease in the chamber diminishes the amount of friction significantly, and allows almost the entire rearward thrust to operate on the bolt head. With respect to pressure, a test was conducted with 1920 National Match ammunition, caliber .30-06, where the chamber pressure of dry ammunition was noted to be 51,355 pounds per square inch. When the bullet and neck were lubricated with vaseline, the pressure rose to 59,000 pounds per square inch. When the tests were repeated with the entire case being lubricated, pressure soared to 71,154 pounds per square inch, and destroyed the pressure gauge."

http://www.cruffler.com/trivia-January01.html

Amatikulu

03-23-2010

Ed, I don't think anyone is arguing about the influence of oil, grease or water on ammunition and the increased pressures. This is generally accepted by all from what I read.

This thread is about No.4 actions converted to fire 7.62 Nato ammunition. What is being asked is - " What actual evidence exists of failed No.4 actions to substantiate them being singled out by the NRA in the United Kingdom, and imposing these additional requirements on them."

Edward Horton

03-23-2010

Someone did and is proofing and testing these No.4s converted to 7.62 NATO and this would be the actual source for finding out how many Enfield rifles failed proof testing.

What is needed is to find out the differences in proof testing between the older method and the newer CIP method. It appears that there is a proof pressure difference between the older British oiled axial proof method and the newer radial transducer CIP method. (50000 PSI is equal to 25 TSI and 75250 PSI is equal to 37.625 TSI)

NOTE: One would think the older oiled proof testing rounds would exert far more pressure and strain on the Enfield action than the newer CIP dry proof test rounds. Therefore if you can prove the difference and severity between the old and new method of proof testing the argument is over.

It is my understanding the older oiled proof round testing system was discontinued because the repeated testing in this manor was actually causing damage to the firearms. (excess bolt thrust)

Surpmil

03-23-2010

Originally Posted by Edward Horton ....It is my understanding the older oiled proof round testing system was discontinued because the repeated testing in this manor was actually causing damage to the firearms. (excess bolt thrust).... I'd hazard a guess that the oiling was introduced to enable the generation pressures that the propellants of the time may not have permitted in many case sizes, and that modern propellants have made that step unnecessary. Going back a bit in this thread, bolt head overturn is surely caused mostly by simple mechanical wear to the contact surfaces on the threads of the bolt head and bolt sleeve, together with wear to the front face of the bolt sleeve where it contacts the rear face of the bolt head. As the threads wear, they take less of the thrust, allowing the bolt sleeve face and bolt head rear face to wear against each other with more and more force, causing accelerated wear of those surfaces. I've seen a few boltheads with quite striking grooves worn in them by the front of the bolt sleeve. Now I could be wrong about this, but it seems to me it would make more sense mechanically to have the thrust taken by the far larger surface area of the threads than by the forward face of the bolt sleeve, as has been suggested here and in another thread.

Likewise the "setback" of bolt lugs and recoil lugs in the body. Is there any scientific proof that the steel in these areas is "compressed" or displaced? Surely the loss of dimension on those surfaces is caused almost entirely by simple mechanical wear as the surfaces rub against each other every time the bolt is opened and closed?

But perhaps I'm just misunderstanding...

Amatikulu

03-23-2010

If I recall correctly, the United Kingdom adopted the metric system in the late 60's. That makes me think that a L42A1 with a 19 ton per square inch proof stamp needs to be converted to pounds by multiplying it by 2240 lbs in an Imperial Ton.

That gives me 19 ton = 42,560 psi as a proof by whatever method was in use at that time.

Assuming the 19 tons referred to the maximum average working pressure and not the proof pressure, that means in simple terms that the rifle would need to be re-proofed > 41.42% higher!

It seems unlikely to me that even with different test methods, 19 tons proof will not be equal to 26.87 tons proof.

The conclusion is that the NRA (UK) wants all the No.4 rifles used under its auspices to be re-proofed to this newer standard.

DanL96a1

03-23-2010

Today I received the NRA Journal (Spring 2010), from the NRA of the UK. This had information on the Lee Enfields "being unsafe." I know this has caused much debate in previous posts. I have found that the article on page 57 by Dr E Blakely very interesting. I don't know if they have published this yet but I enclosed a link to the journal for you to look at: -

http://www.nra.org.uk/common/asp/general/journals.asp?site=NRA

Edward Horton

03-23-2010

The British used the axial method of proof testing with the copper pellet at the very rear of the case and also oiled the case.

The 19 ton = 42,560 axial psi figure must have 10 to 20 percent added to get the equivalent of our American radial method of measuring chamber pressure.

The 19 tsi figure must be "recaliberated" as follows:

19 ton = 42,560 + 20% = 51,072 CUP or "Normal operating pressure."

(52,000 CUP is approximately 62,000 PSI transducer method)

We need to find out what the exact number of tsi proof pressure cartridge that was used and convert to a more modern reading. If the oiled axial proof test round was approximately 37,625 tsi = 75250 PSI trandsducer method, then the converted 7.62 Enfield rifles had twice the bolt thrust applied to them during proof testing than a dry modern CIP proof test round that the British NRA want them retested to now.

We need to find the actual older oiled tsi proof testing pressure figure and not the 19 tsi figure that is the normal operating pressure of the 7.62 NATO. (50,000 CUP or 60,000 PSI)

It is also my understanding that possibly two military proof rounds were fired, I have read that one dry and one oiled proof round was fired. The dry round to "proof" the barrel and the oiled proof round to test the action.

Correlating PSI and CUP

(Under the British base crusher standards described below, proof loads ran 30 to 45% above normal. To maximize breech thrust, proof cartridges were oiled before firing.)

In Britain, a third set of crusher standards were developed, using a "base" crusher. The crusher was a short, thick tube placed behind a piston at the base of the cartridge, and the firing pin passed through the center. The cartridge case was well oiled before firing, to minimize cling to the chamber walls (if not oiled, the indicated pressures were about 25% lower). To prevent case rupture on set back of the base, the crusher was first deformed in a press to a pressure a bit lower than that expected in firing. The units were generally stated in British long tons per square inch, or tsi. Pressures indicated by this method run 10 to 20% below those indicated by radial crushers. Kynamco in England still rates their production cartridges with this method.

PrinzEugen

03-23-2010

Getting back to the issue of the NRA warning - isn't then a case of 'as you were chaps' unless I'm reading it wrong? An enforcer, l39 etc is effectively cleared as completely safe?

As people have mentioned - not too much of a shock for a proof house to suggest people get their guns proofed. Next thing, Kwik Fit will be suggesting people get their brakes checked.

ireload2

03-23-2010

Is there any scientific proof that the steel in these areas is "compressed" or displaced?

The bolt is compressed momentarily and the receiver is stretched momentarily. The members of a rear locking action under load are longer and deform momentarily more than the shorter members of a front locking action.

This will be the case until the laws of physics are repeals.

Tis a fact of life. Engineering books are full of the information.

Steel is indeed elastic. Ask Mark Knopfler. He is extremely familiar with the elastic properties of steel and has made millions with his abilities. He even lives in the UK.

Edward Horton

03-23-2010

1. Even today British military proof testing of small arms is done with oiled proof test cartridges, the oiled proof round exerts twice the force that a combat military rifle will ever see in actual combat conditions. (Firing in the rain)

2. If you have bolt head over turn past the 20 degree mark the threads get "hammered" when the rifle is fired. Under normal conditions and minimal bolt head overturn or rotation the mating surfaces of the bolt head and bolt body take the force of firing. You do NOT want the threads to take the force of firing a cartridge, you will screw up the threads and jam the bolt head.

3. In the Text Book of Small Arms after the proof round was fired the Enfield was checked with a .067 headspace gauge and if the bolt closed on this gauge the Enfield failed proof testing due to excessive bolt setback. It does not state this in the book but I assume the headspace was set as close to .064 as possible before testing. An oiled cartridge exerts twice the force on the bolt and lugs than a dry cartridge does, therefore it causes twice the wear and the effects of excess bolt thrust over time are accumulative. (If you keep letting someone hit you over the head with a baseball bat your going to get a headache and the guy with the bat is going to leave an impression on your mind).

Surpmil

03-24-2010

Steel is indeed elastic. Ask Mark Knopfler.

Yes, the stretching and flexing part I knew about. I had the (mistaken?) impression it was being asserted that this was a permanent change.

Mr. White (was it?) thinks the body of his No.1 MkV has "stretched" according to his reply to Alan d'Enfield's letter. I wonder how he 'knows' it has done so, rather than just worn at the bearing surfaces?

Mk VII

03-24-2010

You will never get the NRA to admit they are wrong. They would rather maintain their position than lose face.

coppertales

03-24-2010

This whole deal falls under the "FOLLOW THE MONEY" sniff test. It seems the British are looking at another way to remove servicable rifles from use in that country by making the inspection process impossible to follow. On the other hand, just buy an Indian 2A or 2A1 and be done with it. They were built to shoot 762x51 ammo.

This whole exercise is a bit after the fact. Enfield 303 rifles have been around for over 100 years. If the British followed today's claims, they would have lost two world wars...

Alan de Enfield

03-24-2010

Enforcers, Envoys, L39, L42 etc were all 'built' to shoot 7.62 x 51.

The argument from the NRA is that they are (were) not strong enough to use the 'hot', heavy bullet, ammo that the NRA is issuing for their competitions.

The NRA accepts (I think) that the No.4 action is stronger than the No.1 action, so I dread to think what they would make of a 7.62 No.1 based rifle.

Patrick Chadwick

03-24-2010

If any of you are NRA members, could you please get the message across to them that the following information "throat diameter is less than the CIP specification of 0.311" but not smaller than 0.3085" is just WRONG and, in fact, DANGEROUS as it implies that some rifles may have thoats as tight as 0.3085, and that would be OK.

(Sorry lads, but sometimes one does have to shout!)

All CIP linear dimensions are in mm. Perhaps one of you could donate a cheap pocket calculator to the NRA, as they are apparently unable to convert millimeters into inches.

Please see my comprensive posting on the "bad publicity for Enfields" thread.

A 308 WIN chambering with a throat (CIP term: "Commencement of Rifling") diameter less than 0.3098" is BELOW the minimum value. That will, of course, raise pressure with any type of ammo. It does not matter whether the rifle is an Enfield, Swing, Tanner, Grünig and Elmiger or whatever. So why pick on the No.4?

Bindi2

03-24-2010

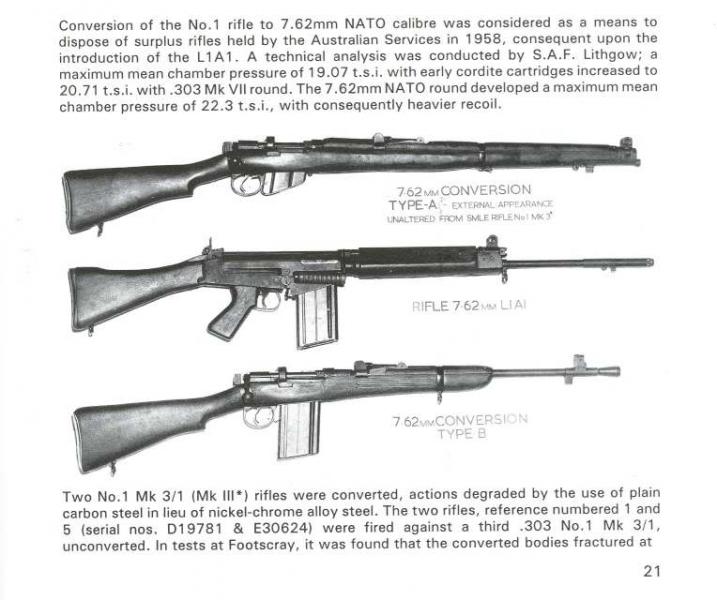

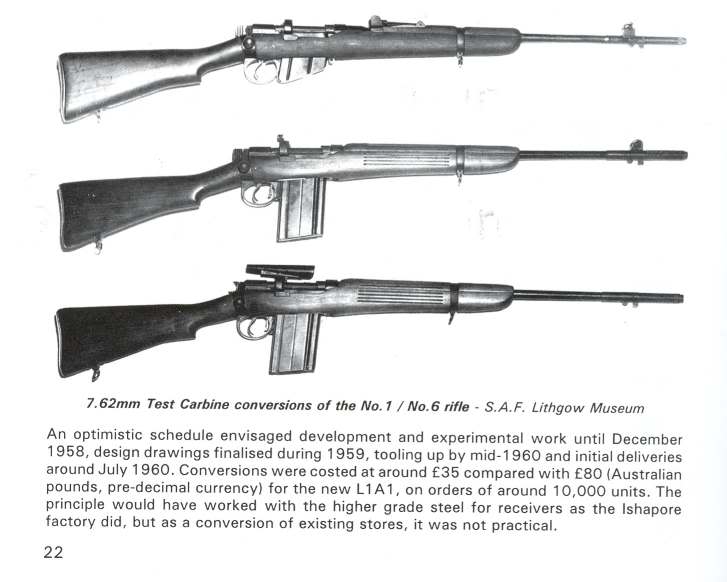

The Aussies converted some No.1,No.6 actions to 7.62. They all failed which was the end to that trial only No.4s survived and were convereted en masse.

Surpmil

03-25-2010

AFAIK, the only thing that separates a No.4 Mk2 from an Enforcer, Envoy, L39 etc. is the hammer-forged RSAF(E) barrel and the extractor & mag. In fact, a bit of 'meat' is milled out of the mag wells for those conversions (at least the first two) so those bodies must in fact be very slightly more 'stretchy' than their .303 equivalents!

The No.4 Mk2 bodies and bolts that were used to build the Enforcers and Envoys etc. are otherwise identical to the .303 pattern they were originally built as, as of course we all know.

Since when has bullet weight been an issue in proofing? .303 MkVII has been loaded with everything from what, 150 grains to 215, and with never a safety issue AFAIK. So now 15 grains more bullet in 7.62mm is suddenly grounds for re-proofing and all kinds of hoopla?

Surely bullet diameter is the significant issue in relation to pressure?

As for the 7.62mm SMLE, I wonder if they've sent an urgent "safety warning" to the Indians yet?

Patrick Chadwick

03-25-2010

Perhaps someone could get hold of a couple of rounds of the questionable NRA ammo that seems to be the source of the problem?

Then measure neck width and bullet diameter with a bench micrometer that is really good for 1/100 mm or better (I actually have a measuring head that measures to a micron, but I realize not everybody has such an item).

Then compare the measurements with the maximum cartridge dimensions from CIP - which are in mm, not inches. Avoid converted tables - they may well be erroneous.

There might be a surprise.

Then have this ammo proof fired in a CIP test barrel, to determine the pressure that is developed by this problem ammo. Over here, the DEVA test house will conduct such tests for considerably less than the cost of rechambering/rebarrelling/reproofing/junking a No. 4 (which is apparently what certain parties in the UK would like you to do).

That may produce further surprises.

ireload2

03-30-2010

So why pick on the No. 4?

This issue seems to be more of a barrel problem. While the #4 is a little springy the normal pressure levels only result in about 11,000 PSI loading on the action rails, far below the amount to cause any permanent deformation.

jmoore

03-30-2010

Why, yes, do please. I can think of several localized areas off hand that are subjected to MUCH higher pressures. Plus, the assymetric nature of the action body itself makes an "average" pressure meaningless.

ireload2

04-04-2010

If you divide the breech thrust by the total cross section area of the receiver rails you get about 11,000 PSI. Try it.

Naturally the smaller right rail will be stressed more than the left rail. You can determine the relative stress in each rail based on their proportion of the total area. They are after all the sum total of the members in the receiver resisting the bolt thrust.

You can check my numbers if you like.

Area of the right rail R .158 sq in.

Area of the left rail L .284 sq in.

Total area of both rails (L+R) = .158+.284 = .442 sq in.

How did I get these numbers? I actually measured my #4 with dial calipers.

Where the shape is too odd to measure directly it was resolved into small triangles and rectangles.

Each of the little rectangular or triangular areas was measured. Then the areas of each were totaled to give the area of each rail.

If you disagree with my method you can propose an alternate method.

If you think the area is smaller that is ok the stress is slightly higher.

No matter what you do the breech thrust has to be restrained by the receiver rails. Use whatever strength you want for steel but you will see that it is always far stronger than the load applied.

With this loading you can treat the receiver and bolt like a pair of springs and calculate their momentary deformation using Hook's Law. The bolt is a compression spring and the receiver is and extension spring.

Use the Young modulus for steel. Since the steel in not being permanently deformed Young modulus for all steels is a similar number.

Edward Horton

04-04-2010

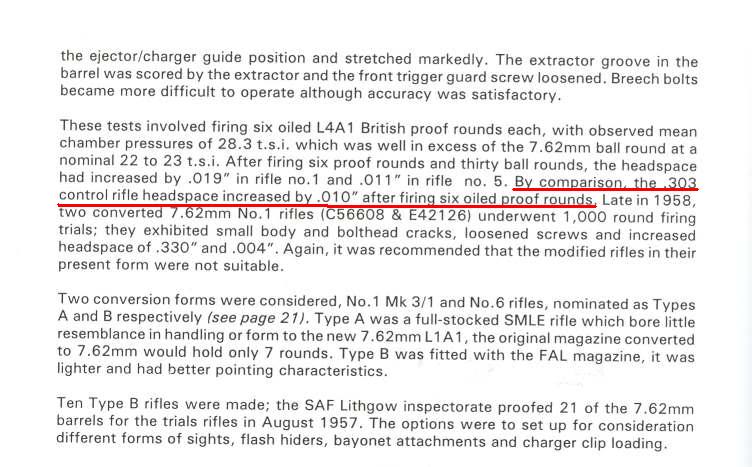

There is calculated theoretical bolt thrust and actual bolt thrust measured with pressure and strain gauges. What do you call it when six oiled proof test cartridges increase head space by .010?

If you do not know the exact pressure being exerted on the bolt face theoretical bolt thrust calculations mean nothing.

On a bolt wet torque is 25% less than dry torque (oil on threads vs dry threads)

I haven't seen any figures for "dry" bolt thrust or "wet" bolt thrust or something as simple as a dry cartridge case gripping the chamber walls vs a oiled cartridge case delivering the total chamber pressure to the bolt face. (force-area-pressure)

So is 11,000 PSI dry or wet bolt thrust and how do you know the exact "force" without the proper test equipment.

You have to input the correct "data" to Mr. Hook and Mr. Young to get the "correct answer". Head space can change the amount of bolt thrust with the same pressure cartridges. The cases themselves absorbing part of the thrust as the case stretches to meet the bolt face.

"Hooke's law of elasticity is an approximation that states that the extension of a spring is in direct proportion with the load added to it as long as this load does not exceed the elastic limit."

Don't tell me Hooks law doesn't apply to stretching brass.

Dimitri

04-06-2010

Bottom line is I figure shooting 168gr SMKs I should be fine as long as not a max loads correct?

jmoore

04-07-2010

Originally Posted by ireload2

Use whatever strength you want for steel but you will see that it is always

far stronger than the load applied.

Working backwards, it seems that your bolt thrust value is 4862 pounds. I can live w/ that, assuming a well adhered case to the chamber wall w/ no localized thinning of the case.

If you assume equal loading on the bolt lugs (due to unequal receiver deflecton this ISN'T really valid, but there's some other compensating torque loads etc. that make this possibly not TOO far off), and accurate cross- sectional areas, the right hand reciever wall would see 15,386psi.

In the case of the RH lug taking all the load (not unheard of, esp w/ replacement bolts) loading w/ your parameters is 30,772psi.

In the case of a "lubed" or otherwise "unstuck" case w/ a working ID of 0.400" at 60,000 actual psi chamber pressure, the thrust load is 7542 lb. So,

Equal bearing lugs : 23,867 psi on the RH receiver wall

RH lug bearing alone: 47734 psi.

Case head failure (certainly not unheard of!) i.e. the base separates from the body, the maximum diameter to work against is 0.473". This drives the thrust load up to 10,543 lb. So,

EBL: 33,367 psi

RHL: 66,728 psi

(Worst case scenario- cartridge case would have to have previously been thinned at the "bright ring" area.) Other factors to consider, the front of the bolt body isn't very constrained, so as the RH receiver wall deflects more than the LH, it will allow a limited amount of rotation of the bolt in a clockwise direction, introducing a further unbalance in the rearward thrust vector. Also the RH receiver wall experiences some torque due to the bolt lug bearing on the upward projection of the structure. The sharp edges of the mag well are likely locations for "fatigue" failure cracks to originate.

Again, however, the best evidence of the lack of drama is the long history of this structure operating w/o failure over many cycles and in harsh environments. How bullet weight figures in is STILL a mystery!

Anybody got a spare No.4 barrel (Bubba-ized is fine) that i can chamber to 300 Win Mag? (OK ,"303" Win Mag)

NB: The above was "ciphered out" on one piece of scrap paper, whilst doing other stuff, so errors in math ARE an option!

ireload2

04-07-2010

There is calculated theoretical bolt thrust and actual bolt thrust measured with pressure and strain gauges. What do you call it when six oiled proof test cartridges increase head space by .010?

My calculations were made using zero friction between the case and the chamber. Any friction just means the load on the receiver is less than stated. Both the 7.62 and .303 oiled rounds damaged the rifles. What does it prove? Would either rifle have been totally undamaged by firing 6 dry proof loads?

Don't tell me Hooks law doesn't apply to stretching brass.

It sure does. Try it. It only requires first year HS algebra.

ireload2

04-07-2010

The above was "ciphered out" on one piece of scrap paper

Even if you had an error you have the general gist of what is going on simply by using the area of the receiver rails, the chamber pressure and the diameter of the case head. Not much of a mystery is it? After these calculations you realize how unbalanced the reaction of the receiver can be.

Young's modulus allows you to predict how much compression of the bolt and extension of the receiver occurs. The only other number required is average cross section of the bolt.

Edward Horton

04-07-2010

Theoretical calculations for bolt thrust are not the same as real world figures using pressure measuring equipment and strain gauges. You have dry bolt thrust and wet bolt thrust, which amounts to a 50% to 60% increase for wet or oiled cases.

From the British "Textbook of Small Arms."

slamfire1

04-08-2010

Theoretical calculations for bolt thrust are not the same as real world figures using pressure measuring equipment and strain gauges. You have dry bolt thrust and wet bolt thrust, which amounts to a 50% to 60% increase for wet or oiled cases.

So, how did they design the things? How do they design things now days?

What amount of cartridge friction do designers assume in designing their actions?

Pick a number from 0 %, which means frictionless case, to 100 %, which means the case takes the entire load.

What % cartridge friction should a designer use in designing the size of the locking lugs and the receiver recesses?

Edward Horton

04-08-2010

Originally Posted by slamfire1

So, how did they design the things? How do they design things now

days?

The firearms manufactures don't guess at it or argue about bolt thrust in forums they know from actual firearms testing.

The designers want 40% to 50% LESS bolt thrust than a oiled or greased cartridge delivers. (do the math from the above warning) That is why you see all the warnings to NOT lube your ammo, you can end up decreasing the life expedience of your rifle by as much as 50% by lubing your ammo.

On top of this the American SAAMI and the European CIP use "DRY" proof cartridges to test firearms.

If six oiled .303 proof rounds increased the head space of the control .303 Enfield during testing by .010, how many normal standard pressure oiled cartridges would it take to increase the head space by .010, 100, 200, 300???

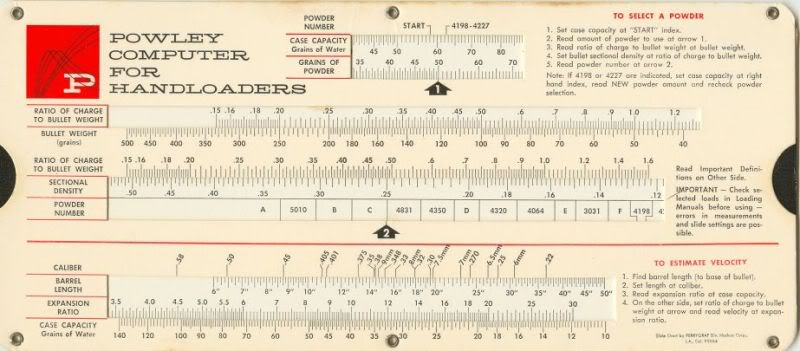

Below is a Powley pocket computer, it is from the early 1960s and is used to compute the best powder charge weight and powder type using DuPont IMR series of powders.

What it tells me is the theoretical "best load" for a .303 British and a 150 grain bullet is IMR-4064 powder and for the 180 grain bullet IMR-4350 is best.

This information is nothing more than a theoretical WAG (wild A$$ guess) based on loading density and case capacity. The real answers come through testing with a chronograph and checking standard deviation and your group size.

The "proof" is in the actual testing.

ireload2

04-08-2010

Theoretical calculations for bolt thrust are not the same as real world figures using pressure measuring equipment and strain gauges. You have dry bolt thrust and wet bolt thrust, which amounts to a 50% to 60% increase for wet or oiled cases.

No that is not correct logic if the calculations are made treating the case as having zero friction. You need to reverse your train of thought.

When calculations are made that treat the case as though it has zero friction the bolt thrust is greater than even an oiled case.

The answers are all right here.

PICTURE 404

Dimitri

04-08-2010

Originally Posted by slamfire1

What % cartridge friction should a designer use in designing the size of

the locking lugs and the receiver recesses?

0% as you cannot guaranty the friction co-efficient without testing and the moment you go from a chrome to plain bore in war time or from a plain to stainless you change that co-efficient so its considered good practice to apply the entire load.

ireload2

04-08-2010

it's considered good practice to apply the entire load.

In ASME pressure vessel manufacturing the pressure vessel is hydrotested to 1.5 times its designed operating pressure.

Dimitri

04-08-2010

I was referring to the action of friction on the bolt through the possibility that it will reduce a percentage of thrust. A safety factor of 1.5 is quite common, cars, and aerospace applications are built to that.Aircraft must be able to be loaded 125% without failer of any components however at 150% rated loading it is allowed to catastrophically fail and that is ok.

But for a starting load a frictionless case situation is better then assuming friction a d the friction co-efficient changing.

Thunderbox

04-09-2010

A lot of the assumptions in this discussion are highly speculative in any case, as no-one has ever precisely observed/measured what actually happens when a case - oiled or not - undergoes the firing sequence in the chamber.

The British arsenals, which fired millions of rounds in testing of one sort or another, came to the conclusion that, depending upon the type of propellant/primer combination, the case first expanded to the chamber wall at an initial circumferential point (the shiny "ring" on a .303" case), from where it rolled forwards and backwards according to a complex relationship with the propellant burn & gas expansion. The observation included that (a) case expansion due to gas pressure was not uniform for much of the firing sequence (b) most oil/water between case and chamber was simply expelled forwards or backwards by the differential expansion of the case. Point (b) becomes fairly obvious, if you shoot some of the waxed MkVIIIz ammo - the case go in sticky and come out dry...

The pointlessness of the whole "oiled case" scare is there in black and white in the ToSA quote above. The intended service load for MkVII was 19T using lubricated or oilcloth-wiped cases (which has been a standard battle preparation for ammunition since Snider days), and "dry" ammo was the non- standard situation.

Amatikulu

04-09-2010

The topic of this thread is "NRA Safety Notice re. No 4 Rifle Conversions to 7.62mm"

We seem to be getting off topic and moving back into a subject that has been already flogged to death without any resolution.

If the members who are posting on this thread are trying to develop factual information to send to the NRA with the hope of changing their minds, you might like to read the thread again and evaluate if your contribution to this thread is achieving that purpose.

Then again, maybe that's not your intent

slamfire1

04-09-2010

We seem to be getting off topic and moving back into a subject that has been already flogged to death without any resolution. Are you going to close down another thread because a view contrary to this posting

I don't think anyone is arguing about the influence of oil, grease or water on ammunition and the increased pressures. This is generally accepted by all from what I read. is being supported too strongly?

The whole issue of what loads actions are designed to support is 100% relevant to this discussion.

If actions are designed without consideration of cartridge case friction, then shooting in wet weather is a total safe practice.

If actions are designed assuming a certain level of case friction, then shooting an action in wet weather is dangerous because of the potential of increased loads from reduced case friction.

In which case the warning from the NRA not to shoot No 4 conversions in the rain is correct.

Edward Horton

04-09-2010

What Amatikulu is saying is a bunch of Americans arguing about oil or grease on cartridges isn't going to solve a British problem.

The bolt thrust differences between wet and dry were published in the "Textbook of Small Arms" at the turn of the century.

The Enfield rifle is not going to explode if fired in the rain or if you grease or oil your ammunition. The "Textbook of Small Arms" says "if the action is not to be strained".

What is going to increase strain and head space faster, a wet or dry cartridge case, and WHY do you think there are so many warnings about not doing this.

What our British and Commonwealth forum members need to do is inform the writers of the critical articles that the Enfield rifle was tested with an oil proof cartridge to simulate a wet conditions and the Enfield rifle survived 100 years of shooting. (its the bolt body, bolt head and lug recesses that are "strained" with the resulting increase in head space)

Surpmil

04-10-2010

I wonder how many millions of rounds were fired from soaking wet SMLEs between

1914 and 1918? I'm sure thousands of them fired thousands of rounds of wet

ammo. Sometimes not only wet, but with slippery Flanders mud applied as

well.

Were they found to be damaged in any way due to this? Was there a wholesale scrapping of rifles post-WWI for this reason? Were they "stretched" as a result? Did they all need new boltheads fitted?

I think we all know the answers don't we?

Time to tuck this one in, give it kiss and send it on it's way to never-never land.

The No.4 is stronger than the No1, ergo we surely don't need to go over all that again?

JMoore, it's going to get expensive trying to recreate 60+ years of firing all kinds of .303 ammo, not to mention the 7.62m out of all kinds of actions and barrels in all kinds of conditions. There really is no test worth a hill of beans compared to THAT test.

Edward Horton

04-10-2010

The answers would come from WWI Armourers, the repair depots, the number of Enfields put through FTR and from scraped Enfields we never saw and don't have.

Where are all the Enfields that these used bolt heads came off of?

Your question you would need to know the total number of Enfield rifles produced and the amount surviving to this day.

What lasts longer, a well cared for engine in your car or the engine from a formula 1 race car that pushes the engine to the limits the entire race.

The person writing this post worked 38 years at a military overhaul and repair depot and sees the world from a different set of eyes. In the U.S. Military condition code "H" is beyond economical repair and is scrap metal you never see in your local gun stores.

ireload2

04-12-2010

In regard to firing wet rifles some of the engineering testing of the M-1 Garand involved just that. The rifle was mounted in a firing fixture and was fired with 2 fire hoses trained on it. It eventually was made to misfire. This was attributed to loss of lubricant on the hammer cocking face. Two things were done to deal with it. The angle on the hammer nose was changed slightly on the engineering drawing and they also issued little containers of lithium grease to apply to the hammer nose. If concern about firing the M1 wet was a big issue they didn't mention it. The preceding came from an American Rifleman magazine about 40 years ago.

I am sure that one could find a way to hurt himself greasing things up just like he could hurt himself handloading. A newbie might not be able to tell the difference between damage due to lubricant and an over charge.

Surpmil

04-13-2010

Originally Posted by jmoore

Ummm, plus at some point this dicussion was about 7.62x51 variations. Only

about 20-28 years of in service experience w/ those...

Doesn't seem long compared to the lifespan of .303, which still soldiers on, but its as long as the projected life span of a lot of weapons systems these days. And of course, it still goes on...