Thread: Glass bedding on my No 1

Retrieved: 06/08/2014

This being said, hi all. 2 years ago I decided to make my own woodset for my No 1. All went well, but 2 years later, having changed the action for a 1918, I decided to give it a little more precision if I could. I also make stocks, and I want to offer glass bedding to my clients, so I needed to practise a bit.

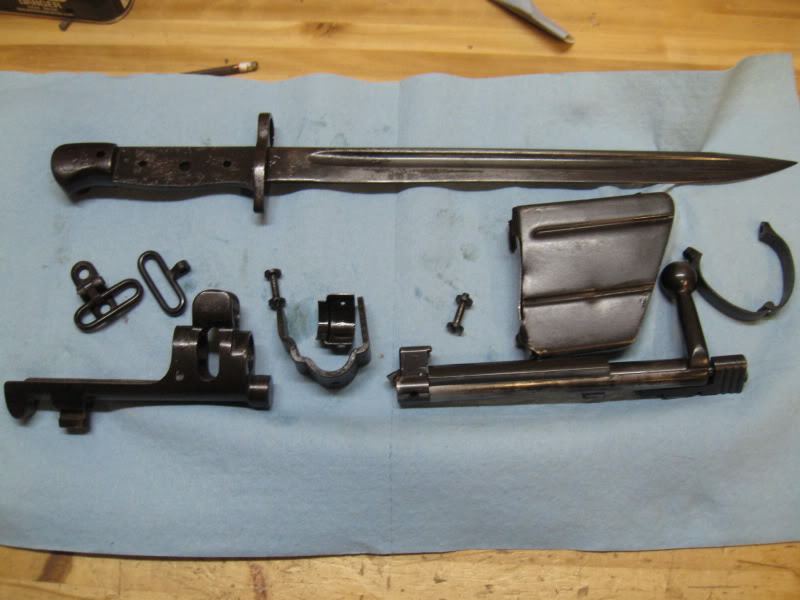

Took it apart.

It was my first stock making, so I did everything by hand back then. Now I use a router for most of the work

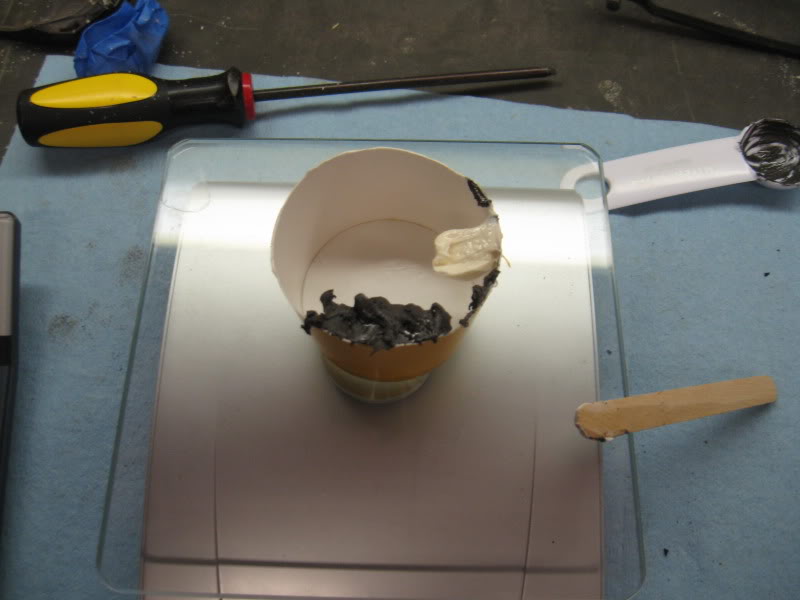

Preparation for the bedding (using Devcon steel putty)

I needed a way to make sure no Devcon would go in the kingscrew hole, so I melted wax from a candle. Worked all good, only had to melt it out after the bedding.

Devcon mix, and application

The next morning I took it out. Funny how the small punches around the chamber got into the bedding.

My barrel was free floated when I bedded the action so I could bed the tip later.

I had to find a way to give it proper upward pressure. I made a hole and I installed a screw. With the action screwed to the wood, I was able to give a bit of pressure to my barrel.

Preparation for the bedding. KIWI shoe polish was used as a releasing agent.

Next morning the barrel was properly bedded.

I also took the time to redo the grips of my bayonet. The original were ugly, and I had walnut laying around the shop.

I also re-blued the bayonet and a couple of parts

Sanding of the wood. When I made the stock 2 years ago there was some sort of "bulge" in the front. I had made it from pictures on the net, so I decided to make the forward portion a bit more pleasing.

Ready for re-assembly.

Here is a pic from 2 years ago, showing the front shape.

And here is my No 1 right now

stevebc

01-27-2012

Bob, I too have a No.1 I'd like to bed, and I have a couple of questions, never having bedded any rifle before:

a) I see where you had the receiver taped into the stock, but did you also have the trigger guard installed at that time, and if so, how tightly did you screw down the front trigger guard screw?

b) if you don't put the trigger guard in at this point, how will doing so after the fact affect the way the receiver sits in the bedding?

c) my stock was sportered, and is cut off about an inch in front of the inner band. Should I try to bed the barrel at the inner band point at the same time, or should that be done later? In either case, any recommendations on how much up pressure should be on the barrel here?

I guess I'm asking whether or not a rifle that is bedded everywhere it needs it, all at once, with everything screwed down tight as it would be in actual use, would give a better result than doing it otherwise.

bobfortier

01-27-2012

I did not put the trigger guard during the bedding, I made sure that it would fit good after however.

As for bedding a sporterized stock, I think it could be a good idea to bed the tip, similar to a no 5. I'll do my brother's sporerized no 1 in a couple of weeks.

bobfortier

02-26-2012

Started the bedding on the sporterized no 1. I removed material (no pics, sorry), prepared the action with shoe polish, and I mixed about 100 gr of Devcon.

LeeSimon001001.jpg">

LeeSimon001002.jpg">

LeeSimon001003.jpg">

Tomorrow I'll remove it from the wood, clean it, and I'll bed the tip with a little upward pressure.

Cdn303

03-07-2013

Hey look at that, the search function finally worked for me.

I've got a sporteded No4 that I plan on doing. I have a couple of questions for you bob, or anyone else who can answer them.

1. How much wood did you remove from the stock?

2. How thick did you have the devcon around the various areas?

3. Will the devcon adhere to a stock that is oiled? Or do I need to strip as much oil off of the bedding areas first?

4. Before taping the parts together, you did a dry fitting of the trigger guard to make sure the rear trigger guard screw would fit correct?

I was thinking of installing the trigger guard and tightening both screws down, and skipping the "clamping" step. Has anyone tried this with good results?

Oh man, my fingers smell like cosmoline.

bobfortier

03-10-2013

I did not removed much, about 1/16 or a bit more, leaving a couple of spots so I do not loose the reference. Devcon thickness is about the same as the removed wood. It is better to try to remove as much as oily wood as possible. I made a couple of small holes all over the place so the DEvcon was able to get there and hold better.

As far as the trigger guard, I melted some candle wax in the king-screw hole, I bedded the rifle with a clamp, and I re-adjusted the trigger guard once done. Anyway with the reference point kept, it fell at the right height. To remove the wax, just heat with the same candle, wax will melt.