Thread: No4Mk1 Washers and Bushing

Retrieved: 06/08/2014

I've got a 1943 BSA No.4 Mk1, which has been converted into a repro sniper, complete with No.32 scope. Accuracy started off great after it came back from the smith, but has degraded noticeably of late.

Deciding the accuracy was no longer a shooter problem and had to be something going on with the rifle, I pulled it down over the weekend. I found a few things, including a buttstock fit to the wrist that was rather loose; I suspect this is the core issue. I've subsequently gone and bought a bottle of linseed oil from a local art store (as recommended on here), and have begun re-oiling the stock and will build up the buttstock with paper shims to get a better fit soon. What I have noticed however is that some parts that should be there (according to a No.4 schematic) don't appear to exist.

These parts are:

Front Guard Screw Lock Washer

Front Guard Screw Bushing

Buttstock Bolt Leather Washer

Buttstock Bolt Lock Washer

Now; the first three I'm certain aren't there, the Buttstock Lock Washer, I need to do some investigation to make sure it isn't embedded into the stock, but from first examination, I can't see it.

My question for the gurus here; are 'Front Guard Screw Bushings' on all No.4 Mk1's? I notice varying schematics, some show it, others don't. So I'm a bit confused. Below are two schematics, both for No.4 Mk1's, one shows the bushing the other doesn't. I guess the other question is; are these important in terms of accuracy? My instincts for accuracy is that if the bolt has more surface area laterally on the lower for-end, it's gotta help, but I could be wrong.

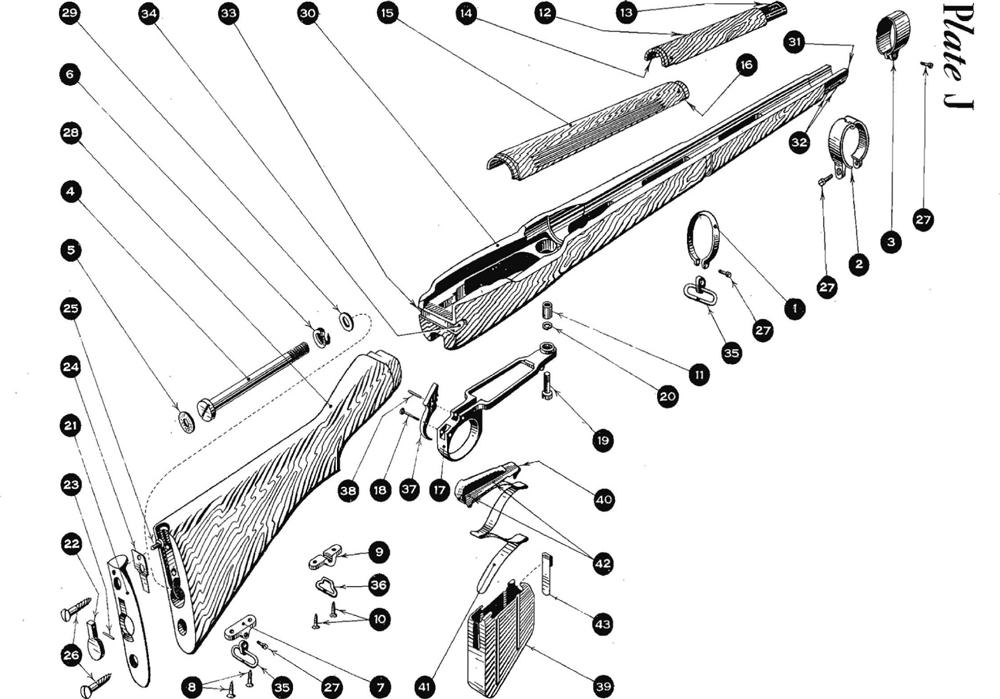

This one shows bushing:

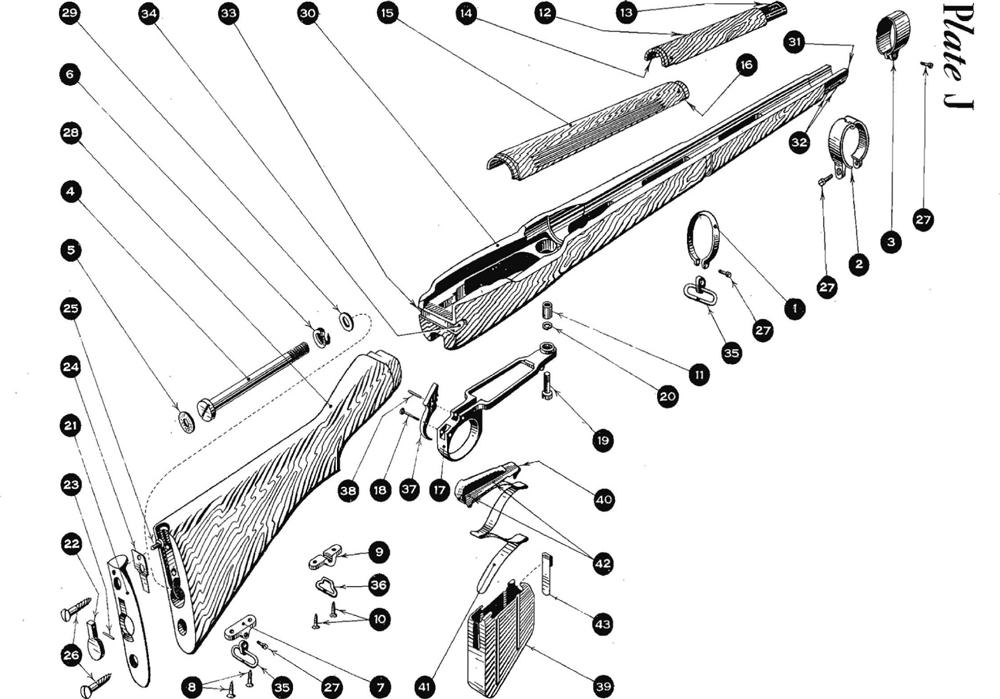

This one doesn't:

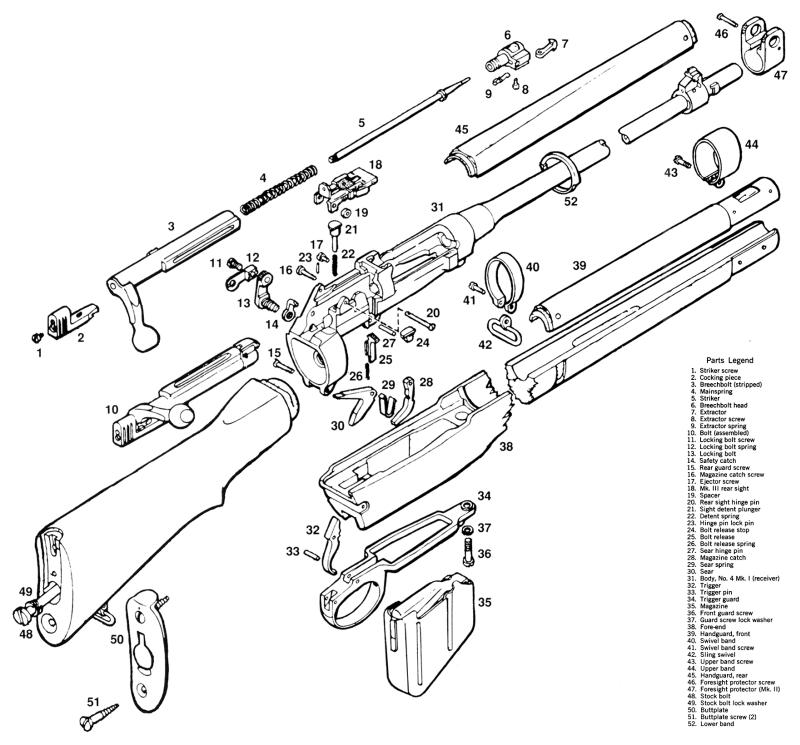

And here's my toy:

Bruce_in_Oz

04-29-2014

Your butt may have shrunk!

Doesn't happen to a lot of folk as they get older, but it does with these rifles.

Try standing the errant butt front down in a container of linseed oil for a few weeks. At factory level, butts were STORED in linseed whilst waiting to be fitted. If yours hasn't seen oil for fifty years, it may be a bit thirsty.

If you live in the drier parts of Oz, (almost anywhere but Tully or Tasmania), your woodwork may shrink unless oiled from time to time. Ask the natives of Nevada, Arizona, etc what happens to stocks that are made from insufficiently cured / oiled timber.

Paper shims are at best a temporary fix.

If the rifle has been extensively fired / "square-bashed" with a loose(ish) butt, it may be better to hunt down a newer one, do the oil pre-treat and carry on. If your current one is numbered to the rifle and covered with nice, original markings, try the linseed bath first. If that is not satisfactory, you may need to get some creative "carpentry" done to beef up the offending area where the sun rarely shines.

Note that the front end of the butt is TAPERED to match the taper inside the "socket". At the factory, they had a serious machine that pressed the oversized, oiled butt into that tapered socket; it was not just lined up and the screw tightened.

Not only that, but the "shoulder" should NEVER contact the rear face of said socket. The front end of the butt, where the stock bolt thread protrudes, seats FIRMLY on the inner face of the "socket". If there is not a SMALL gap between the shoulder of the wrist of the butt and the very rear outer circumference of the "socket", the butt will start shedding chips in short order.

Finally, NEVER, EVER store your fine collectibles (or precision shooters) in a small, airtight safe that has a serious "dehumidifier". Your metalwork may not rust, but evil things will happen to your woodwork.

Keep us posted.

Berg83

04-29-2014

I did download a good little PDF from this site a while ago about the buttstock / forend fit for the wrist. Was rather interesting in regards to a gap at the rear of the wrist and none at the front.

Do you have any clues in regards to the front bolt bushing? And any ideas on who's good to get parts for these old girls here in Australia?

Beerhunter

04-29-2014

Those two parts are ESSENTIAL on a Mk.1 for a good trigger pull and proper fitting of the fore-end. Did your "smith" leave them out perhaps? Can't help with Australia but in UK, they are both easily obtainable. If you get stuck, I can give you a UK dealer's name.

I am sure that a certain ex-REME bloke has written how to fit them many times. Try a search.

Bruce_in_Oz

04-29-2014

In Oz, the best source I know is Alan at Kingaroy Firearms.

Most of his parts seem to be in perfect condition and come out of their original packets and boxes.

He mainly works with No1 (SMLE) types but has some parts for No.4s.

That "collar" for the "screw, trigger guard, front" is fairly common. As Peter will insist, it is not just a drop-in item, but must be "adjusted" as per the instructions he has posted elsewhere on a page close to this one. As this collar is an "adjustable" part, I understand it was one of the few parts common to the SMLE and No.4 series rifles.

Alan de Enfield

04-29-2014

Short extract from Peter's article :

Now it's time to fit the trigger guard and Screw, Rear, Tie, Fore-end if you have a Mk.1/2 or 1/3. There's a good chance that the rear of the trigger guard will foul due to the height of the new wood. If that's the case, then simply scrape away the wood inside its seating to allow it to seat correctly all the way to the front. The trigger guard should not spring at the rear or front... NO it shouldn't! If it was meant to, it'd be made of spring steel! Now for a little tip.

The COLLAR. You MUST have a collar and spring washer.

This is what WE used to do. Put the front trigger guard screw into the trigger guard and body WITHOUT the washer or collar. Reverse it (that's anti- clockwise...) until you hear it click over the start thread and tighten it BUT COUNT THE TURNS UNTIL IT TIGHTENS AND LOCKS. Say, that it's 7 ¼ turns to lock. Now do this with the collar fitted if it's now, say 6 ½ turns, shorten the collar, a smidgin at a time, until the screw tightens up at exactly 7 ¼ turns.

That way, you KNOW that the screw is tight, the fore-end is tight between the trigger guard and the screw and you are not crushing the living daylights out of the fore-end. And if it feels a little loose in a years time, then you can safely turn a few thou off the collar.

Brit plumber

04-29-2014

Ref. the diagrams, the first one looks like the correct diagram from the parts list but the second looks like a commercial drawing found in a number of firearm books. I may be wrong but that's the only place I've seen the second image.

Berg83

04-29-2014

Looks like its time to track down some components while the buttstock wrist end sits in linseed oil

ssj

04-29-2014

Front Guard Screw Lock Washer

Front Guard Screw Bushing

If the bush is missing the trigger guard will have no limit of the squash it can have on the foreend wood (It also may help with absorbing/dispating the forces going on). Over a bit of time I wouldnt be surprised if things started to move about. If the gun is stringing vertically this points to the main screw being the issue.

Both these can be picked up readily via ebay, often as a "kit" for about $20. You then have to fit it but thats covered off elsewhere here. You may also have other issues like loose draws that will need addressing as well.

If I had a gun come back like this from a gunsmith missing such parts I'd never use them again.

Berg83

04-29-2014

Thanks SSJ; and way ahead of you on the gunsmith front mate. To say I'm disappointed is a mild understatement.

For what its worth, the outfit in question was "Island Accuracy" out of Tasmania: Island Accuracy - Home

I'll have a look on eBay as well, I was going to grab everything from Numrich, but given the freight and export cert cost significantly more than the parts combined, it'll be a second choice.