Thread: SMLE in 7.62x54R

TRX

09-24-2009

[this thread started off about a 54R conversion, and morphed into a .45-70

build. -TRX]

(*******************************************************)

I think another project just crawled into the queue. Right now all my funds and spare time are taken up on the current project, so this one will have to wait...

I was rummaging in the shop the other day and found a 1944 Enfield action. The barrel has a hole drilled across the front of the breech, the bolt has gigantic rust pits, and it's missing most of the rest. I'd unscrewed the barrel, then written it off as junk. The barreled action has leaned against the wall since 1993, best as I can figure.

Looking it it, it appears the whole thing was glass beaded at one time. Despite the horrendous damage to the bolt, the action appears to be just fine. And the barrel is bright and clean, despite the hole drilled in it...

Searching online:

$35 "complete" bolt assembly

$25 bolt head "not part of this complete assembly"

$15 trigger guard

$40 good used Enfield barrel

$25 magazine

-- stock set (prices vary widely)

Add it all up, and I could probably find a shooter for about the same price... but I could set the barrel back a few threads, rent a 54R chambering reamer, and have an SMLE in 7.62x54R. 54R ammo is way cheaper than .303, and it would shoot the same ammo as my Nagant.

A friend was trying to persuade me to build it in 7.62x25 with a PPsh drum magazine. He was kidding... I think.

TRX

09-25-2009

I brought the receiver in from the shop. It says:

MA

LITHGOW

S.M.L.E.

III *

1942

I had a 1945 model in the '80s, and got rid of it after determining the receiver was made out of cast iron. I was dressing a few rough spots with a file, and metal was coming off in the usual dark powder like iron does, instead of bright shavings like most steels.

This one is also a casting. It must be some pretty good stuff; I'd never heard of an SMLE failure, and I just spent some time googling as well. There are a lot of SMLEs out there around a century old, and a lot of them shot bunches of that hot Greek machine gun ammunition that was on sale everywhere in the '80s.

The cast iron part worries me because it's a rear locking lug action, and (apparently in the interest of removing weight) there's darned little metal connecting the barrel ring to the locking lugs. On the right side, there's even a slot that looks like a "don't do this" example out of any engineering textbook. The bolt looks like a pencil compared to anything bigger than a .22LR. Yet they appeared to be reliable in service, and even American commercial .303 ammunition is no joke.

Comparing a Remington 788 (a common commercial rear-locking action) and an SMLE, I get the urge to hide my eyes and make small whimpering noises.

As a bolt action the SMLE is quite unusual. Rear locking is unusual, of course. Since there are no forward locking lugs in the receiver, the lugs on the bolts cam into slots cut in the rear sidewalls. The closing cams are around 30 degrees, and about half again as long as the actual lug bearing area. Enfield really, *really* wanted you to be able to get off that next shot.

The bottom front edge of the left bolt lug rides an extraction ramp of about 30 degrees, perhaps double the width of the bolt mating surface. That's the main extraction force. The firing pin spring is quite stout, and probably provides sufficient extraction force all by itself.

The right outer locking face is, as I mentioned, just a cut in the sidewall, like some .22 or .410 bolt actions. The left side is machined into the side of the wall from the inside. I can see end mill cutter marks in there. It looks like you could reach in there with a quarter inch end mill for the basic recess, then a 3/8 or 1/2" keyseat cutter for the closing ramp.

That assumes they were actually cut; if the receiver is an investment casting, the whole cutout could be cast. Final machining could cut the right lug to match the cast left lug...

The bolt head slides through an internal reinforcing ring, like a '98 Mauser, sort of. Any extra strength couldn't hurt.

There's a big socket cast onto the back of the action, hanging down underneath at an angle, for mounting the stock. There's very little metal on the right side, no fillets or radii to prevent cracks... all the recoil goes through this offset joint. The lug under the barrel is just for mounting the forward wood.

Three 1/16" or so holes are drilled in the sidewall on the left side of the breech, approximately alongside the rim of a chambered cartridge. This makes a small slot, presumably to give gas from a ruptured case another escape path. The shape and position of the slot looks like another "don't do this" directly in the left-side load path.

("but it works", I keep repeating to myself...)

A strange thing is, if you put a .580" hole through a piece of 1-1/4" round bar, counterbored the end and cut threads with a boring bar or big tap, you could finish the rest of the machining on a mini-mill and have a tube receiver that would accept an Enfield barrel and bolt. Opening it up for the Enfield double-stack magazine would sacrifice a lot of metal... of course, you could start with a square bar.

If you wanted to build your own receiver, basing something off the SMLE would be WAY easier than trying to cut conventional raceways, though maybe no easier than some of the fat-bolt designs.

TRX

09-26-2009

Originally Posted by zteknik i wonder how hard that would be to swap to 7.62x54? the cartriges are about the same size but i wonder if the 303 enfield is large enuff to handle the 54?

I found several references to conversions online. Basically involves setting the barrel back a couple of threads, recutting the extractor, and running a 54R reamer in. Some people claimed minor bolt head mods were needed, others said it worked fine. Apparently there are no magazine problems.

Speaking of which, at least one person managed to mate a 30-round Bren mag to an Enfield. And there is at least one company out there converting them to 7.62x39, using 10 or 30 round AK mags.

Lots of comments from people who couldn't understand why someone would want to convert to 54R. Either they don't realize cheap import .303 is long gone, or the price difference between spam cans full of Commie 54R and commercially- loaded .303 is beneath their notice.

TRX

10-21-2009

I got as far as buying a bolt assembly, then gave the receiver to a friend. He'll be sending a barrel and other parts for me to finish it up in .405 Winchester, and a second barrel for 7.62x54R. I've never done a switchbarrel job before; I'll probably cheat and use a nut like the Savage-based actions.

TRX

12-03-2009

resurrection

Soo... I gave the Lithgow to a friend, as reported earlier. Then a guy here on gunco made me "an offer I couldn't refuse" on a Longbranch barreled action. And I found that Sarco has Navy Arms .45-70 Enfield barrels for $85, and... a quick phone call, and one is on the way.

Apparently (possibly?) Navy Arms used both No1 and No4 actions; different reviews said No1 and No4, anyway. Some other sources claim the tenon threads are different, some say all SMLE threads are the same... looks like I'll find out for sure soon.

Looks like two switchbarrel Enfields will be built in parallel. I have a spare barrel, so it looks like I'll be starting with .303 Epps (basically .303 Ackley Improved; I can rent the reamer for $35), 7.62x54R, and .45-70. Bob wants .410, .45-70, and 7.52x54R to start with, though I'll lean on him to pick up a spare barrel so I can chamber it for Epps while I have the reamer here.

I keep looking at the Beowulf reamer sitting by the keyboard, but that's outside the safe range for an SMLE action. On the other hand, .50-110 would be doable...

The Enfield's unusual flat bolt face and generous extractor travel means it will feed various different rims without need for modification. I've even found a few reports of people who converted their SMLEs to 7mm Mauser, and there's a company out there right now doing conversions to 7.62x39.

TRX

12-04-2009

The benchrest guys seem to go with a strap wrench to remove and replace the barrels. That's what I'm planning to do. The old leverguns and Arisakas used various cams or levers to keep the barrels from wiggling around in short or interrupted threads.

.45-70 brass has gone up a lot. Believe it or not, it's more expensive than .50 Beowulf! But you can actually buy .45-70, and I've been back-ordered on Beowulf for nine months now...

There are a lot of ways to go about headspacing. The one I'm planning to do is cut the barrel back a bit so I can use a thick washer between the barrel and breech. Cut the barrel back some random distance, screw it in until it is against the no-go guage, back it off a hair, measure, and then face off the washer to the correct thickness. It would be hard to hide the washer, so I'll probably make it out of stainless steel or something and make it stand out.

Using a washer would also let me correct for thread wear, should any occur. Just make new washers as needed. Thread wear is not supposed to be an issue according to the benchrest guys, though.

TRX

2-05-2009

I always liked the Savage barrel nut system. I may use that for one of the other barrels later.

The idea of a curved x39 AK magazine hanging underneath an SMLE is almost as weird as the idea of an AK in 12 gauge...

TRX

12-10-2009

The bad thing about forums is, I get involved with a thread one day, then forget where it was a few days later. Somewhere in the multiverse I was following a thread about rebarreling Enfields, and someone said Sarco had Navy Arms .45-70 barrels for $85. I checked Sarco's web site and couldn't find them, so I called. The guy had to go look for them, but yeah, they had them. Navy / Gibbs / Parker made a couple of runs of SMLEs in .45-70 a few years ago. You can find the 3-shot magazines for the outrageous price of $75 in various places, but this was the barrel, "chambered and threaded", 22" long. Hell, yes!

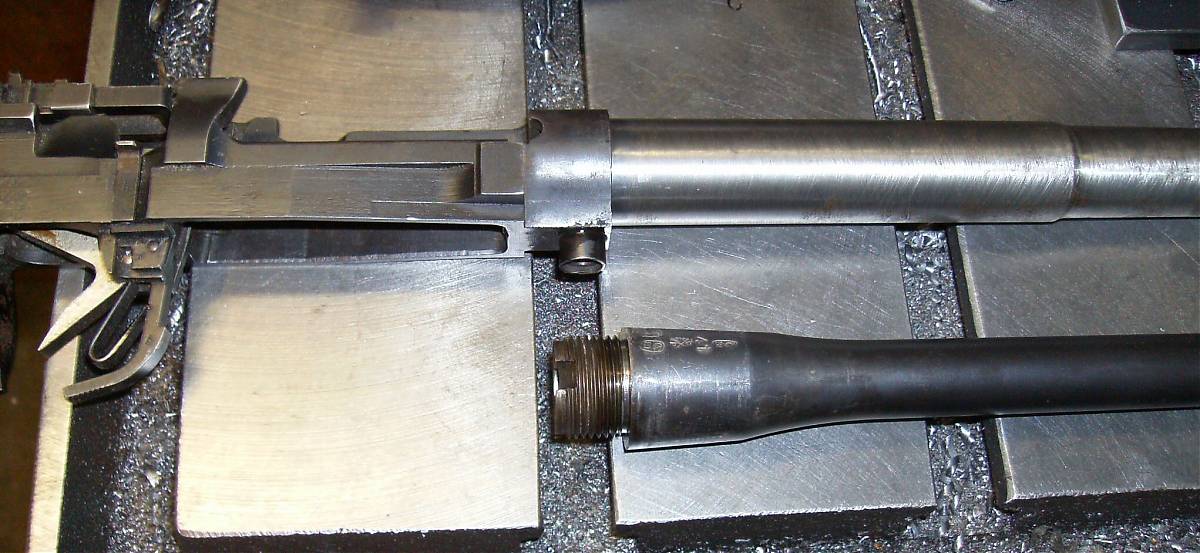

It came in today. It's 1.1" at the breech for 5", steps abruptly down to 1", and a straight taper to 3/4" at the muzzle. I didn't even notice the taper at first; my first thought was "bull barrel?" The .458 hole is impressively large. There is no extractor cut and no index mark, which is fine. It won't screw into the No.1 receiver I have handy, but the starting thread on the barrel looks munged, like it was dropped. I'll hit it with the thread file and try again. The receiver I got from Longbranch is primo, but I haven't removed the barrel yet.

This barrel is brand new, but it's from Sarco. The bore is nice and bright, but the outside had been pretty rusty. Looks like someone put it on a lathe and tried to sandpaper the rust off, but there are still pits and blotches. I was planning to Parkerize the receiver and all the barrels so everything would match, so no big deal, but if someone wanted to blue a barrel, it'd be worth telling the salesman explicitly that you wanted a nice one. Still, for $85, ($96 to my door) I'm not complaining.

TRX

01-29-2010

Okay, a member on another forum was kind enough to let me borrow his Gibbs Frontier for a while. It was a Lithgow Mk1 virtually identical to one of the receivers I have, which made the comparison much easier than it might otherwise have been.

Basically, the magic is in the magazine.

The Gibbs magazine has very short lips on the top. It's also single stack. The magazine presents the rim of the cartridge to the "thumbnail" cutouts on the underside of the receiver. These grab the rim and force the whole cartridge up into line with the breech as it moves forward for the first half inch or so.

It sounds complex, but if you look at an SMLE from the magazine well opening you can see how it works.

Where I was getting fixated was, all of the rifles and pistols I've dealt with before stripped their cartridges straight out of the magazine, which was sometimes notched for bolt clearance, or the cartridges slipped off the magazine at an angle, with the nose entering the breech and the base being levered up as the cartridge went in. I thought the Enfield did that, too. Of course I have a receiver, barrel, and bolt so far, with no magazine yet...

The .45-70 still won't fit into the .45-70 barrel screwed into the Enfield receiver; the rim wedges into the rails about 3/4 inch from the breech ring. It looks like the Gibbs people used a Dremel with a 1/2" sanding drum and reached in and took off .010 to .015" of the sharp corners at the bottom, not much more than just rounding the corners off. That's all it takes for the cartridge to slide forward.

There's a bulkhead in the receiver ring; the rim must pass through, and it's too big. Gibbs probably used a lathe to open it up. I thought the rifle's owner might not appreciate wrench marks, so I didn't pull the barrel for a look. Opening up the ring would be simple enough with a grinder if you didn't have a lathe; it's just clearance for the rim.

That's it for the receiver mods!

Like I said earlier, the magic is in the magazine. The magic consists of the short feed lips, which are 1-1/16" long, with the front edges cut back about 45 degrees.

The lips are so short that if you hold the magazine upside down, a cartridge will hang down at a 45 degree angle. The lips just hold the rim for long enough to get it started into the "fingernail mark" guide cuts in the receiver.

It's a single-stack magazine. There's a rib stamped into the front that guides the front of the cartridge. In back, they spot welded some L-shaped pieces of sheet metal. These are way back and close to the cartridge, and keep the rims lined up neatly. The rims can't pass forward and let the cartridges slam back and forth in the magazine, and they hold them in position to present to the fingernail marks. If the cartridge slid forward in the magazine when the bolt picked up the rim, it'd jam in the receiver rails.

I don't see any particular reason you couldn't modify a standard SMLE magazine to work the same way.

The magazine holds three rounds. As advertised, you can put four in there, but you get a big wedgie when you try to work the bolt. Five cartridges will fit, same problem.

I played with this for a couple of hours. My best guess is that A) the magazine spring is too weak and B) the follower gets tilted as the cartridges feed, letting things wedge up. I think it should be possible to tweak the magazine to feed four or five cartridges reliably, and I don't see any big reason they can't be double-stacked like the standard Enfield layout.

What it looks like is, Gibbs allocated a certain amount of time or money to the magazine work, then ran out of time (or money) and said, "to heck with it, just tell them not to put more than three in there."

Working the bolt took a bit of authority. The blunt front of the .45-70 bumps against inside bits the pointy .303 slides right past. After an evening's experimentation, I had a bunch of .45-70s with noticeably battered noses. You don't have to be abusive, but if you try to flick the bolt back and forth like you can with a .303, it's likely the cartridge will get a wedgie and you'll have to either force it or open the bolt and straighten it out.

It looks like you could safely grind clearances into the receiver to fix this. I'm guessing Gibbs didn't do it due to expense - it worked, and it was in inexpensive hunting rifle on a war-surplus action, what do you want for $299?

That would also explain the ejection problem. The Gibbs flings empty brass just fine. Trying to clear a loaded round will usually give you another wedgie.

If you look at an Enfield receiver ring, you'll see a notch up at the right side front just about the side to hold a pencil. The notch is to clear the point of a .303 bullet. The ,45-70 bullet is much bigger, and the notch needs to be bigger too. Again, opening it up should be safe and simple.

You might wonder why the cartridge wouldn't eject properly when it's short enough to slide entirely back from the breech. The cutout shouldn't be necessary. The reason is the rim gets caught on some of the edges near the back, and it gets stuck. A tiny amount of grinding or polishing might well fix the problem; it might be preferable to clearancing the ring.

I wound up clearing loaded rounds by dropping the magazine, opening the bolt, and letting the chambered round drop out.

Now, we're talking about very small amounts of interference here; with normal production tolerances, it's likely that not all the Gibbs guns do this. It's a bit quirky, but again, how much custom gunsmithing do you expect for the price?

Frankly, I don't see how they could justify the blueing job, which (in my opinion) was freakin' gorgeous. They'd done some polishing on the surplus bits, and the barrel was slick. I'm used to phosphated military stuff, and I felt like a vandal every time I put a greasy fingerprint on the Gibbs.

The bolt is a matte silver color; various articles say it's chromed, and it does indeed look like industrial matte chrome. The fit is snug and the movement is smooth. I'll probably send mine off somewhere to have it done; the couple of thousandths of plating really snugs up the fit.

TRX

08-16-2010

Hm. I couldn't find the pressure rating of the SOCOM with a quick search. The larger diameter of the SOCOM case means the case head thrust against the bolt would be proportionally higher, a=pi*r^2

Some Ishapore Enfields were proofed for 7.62x51, which is way on up there. And the Gibbs .45-70s shoot "modern" high pressure .45-70.

Find a CUP or PSI figure for the SOCOM and I can give you a better answer.

HOWEVER, looking at how the cuts inside an SMLE receiver guide the cartridge from the magazine to the breech, I'm still astonished that the .308 guns don't stovepipe cartridges. It would be worth trying to compare a .308 Enfield with a .303 to see if the receiver cuts were different; you might want to start with a .308 rifle if they are.

Even if you're set up for SOCOM, it's hard to beat a chambered and threaded .45-70 barrel for $85, though.

TRX

08-17-2010

Originally Posted by [486] brass will always be available. Plus the rifle was originally designed for the US Army .45-70.

The US Army passed on it, so James Paris Lee sold it to the British, who went for a .303 caliber cartridge. Black powder, too.

TRX

08-17-2010

Originally Posted by unclemonkey soo.. in a couple of places i found 35k as the chamber pressure rating for the .458 socom vs 45-48k for the 303 brit... so pressure won't be the deal breaker.. is there something else besides the work and $$ i am missing? That low? I kept seeing comments that the SOCOM was low pressure, but that's surprising.

In that case, I don't see any obstacles. The flat bolt face doesn't care about the case head size, and the stock .303 extractor hook has worked on 7mm Mauser conversions. If you don't have quite enough extractor travel you could use an Ishapore .308 hook.

I asked about internal machining differences between the .303 and .308 on an Enfield forum last night, but they're not technoids like here on Gunco, so I might not get a reply.

Like I said above, the only problem I foresee would be getting the cartridges to feed properly. But if it will take rimless cartridges like the .308 and 7mm Mauser, I'm sure it's no big deal. Heck, there's a guy out there who does 7.62x39 and .50 AE conversions, too... I'd forgotten about him.

Hmm... you know, I bet you could sidestep a lot of work by using the SMLE mag as a shell and inserting an AR or H&K mag inside.

Heck, go for it!

TRX

08-17-2010

You'll need a blank for a SOCOM; any take-off barrel will be in .458 Win Mag or something. An Adams & Bennett barrel from Midway might be the best deal.

You can see if reamer-rentals.com has a SOCOM reamer for rent now. There have been a couple of threads here about building an AK in .458 SOCOM, but they all foundered on the reamer. It cost me about $140 for Pacific Tool & Die to make me a not-a-Beowulf reamer, plus shipping.

TRX

08-21-2010

The barrels all screw on. However, they're clocked 180 out - the extractor cutout winds up on the wrong side when you swap a No.1 and a No.4 barrel.

However, the extractor cutouts aren't cut on the Sarco barrels, just the chambers. You can mill or Dremel to match your receiver.

Gibbs used both No.1 and No.4 receivers on their .45-70 rifles.

TRX

12-01-2010

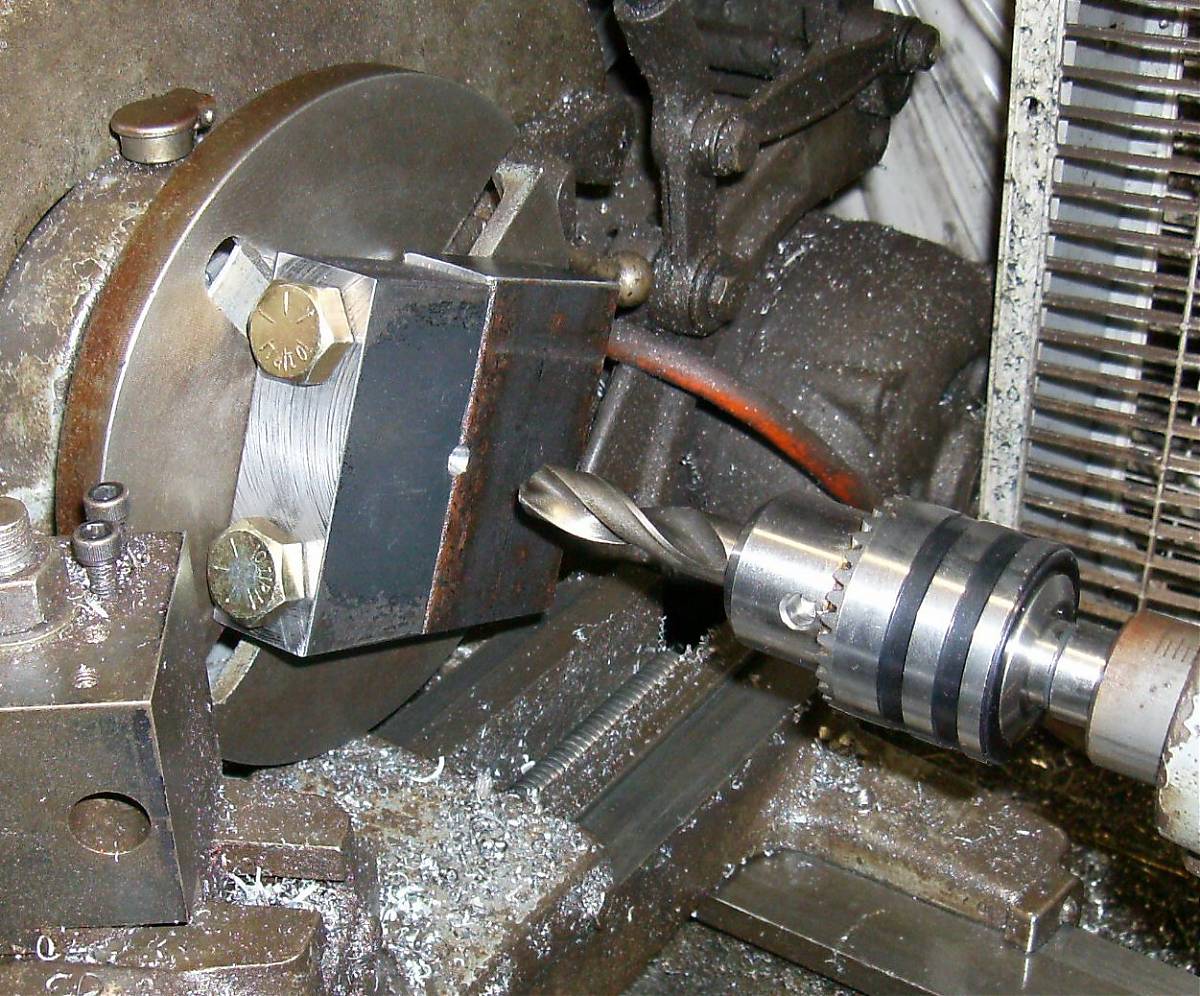

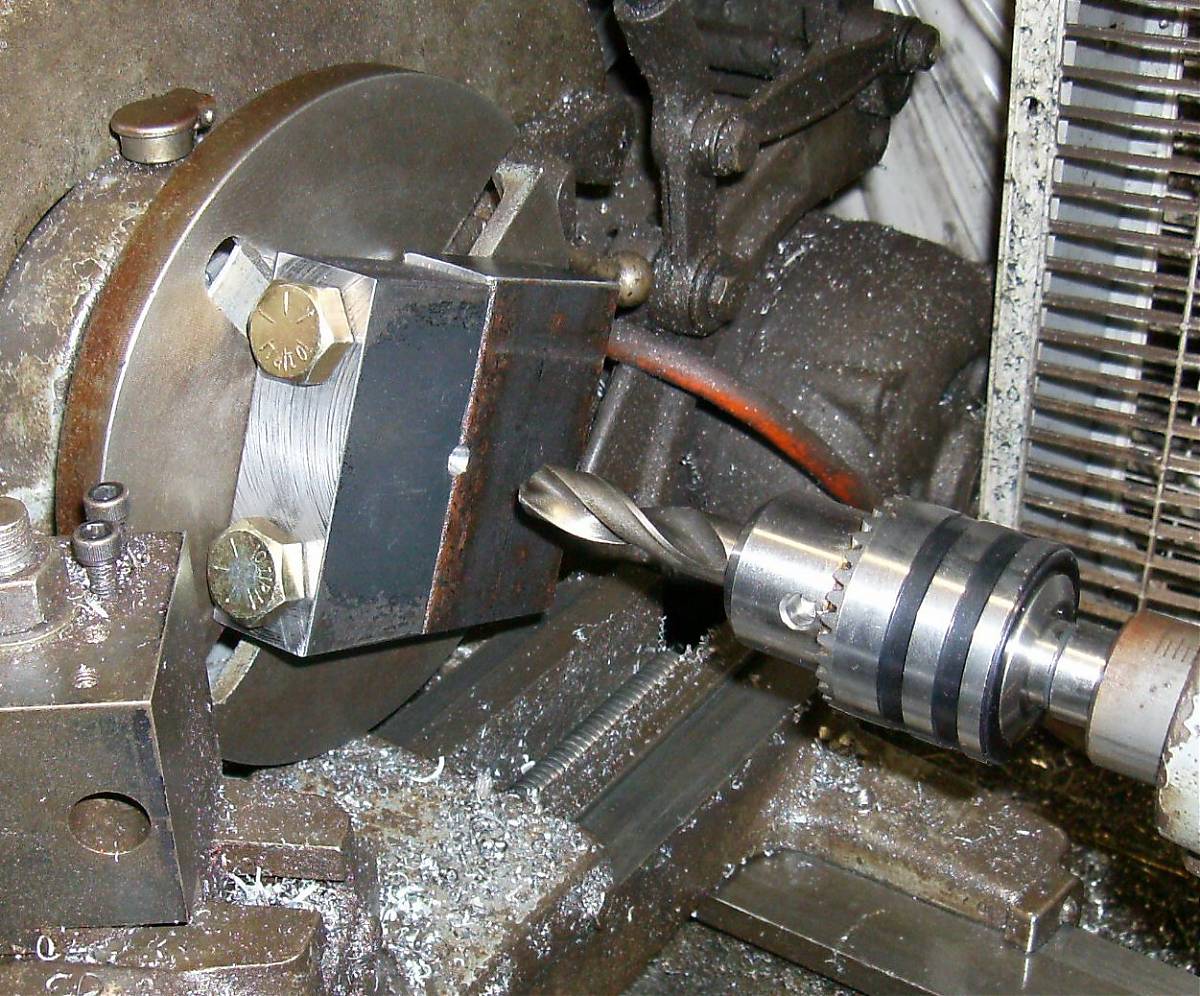

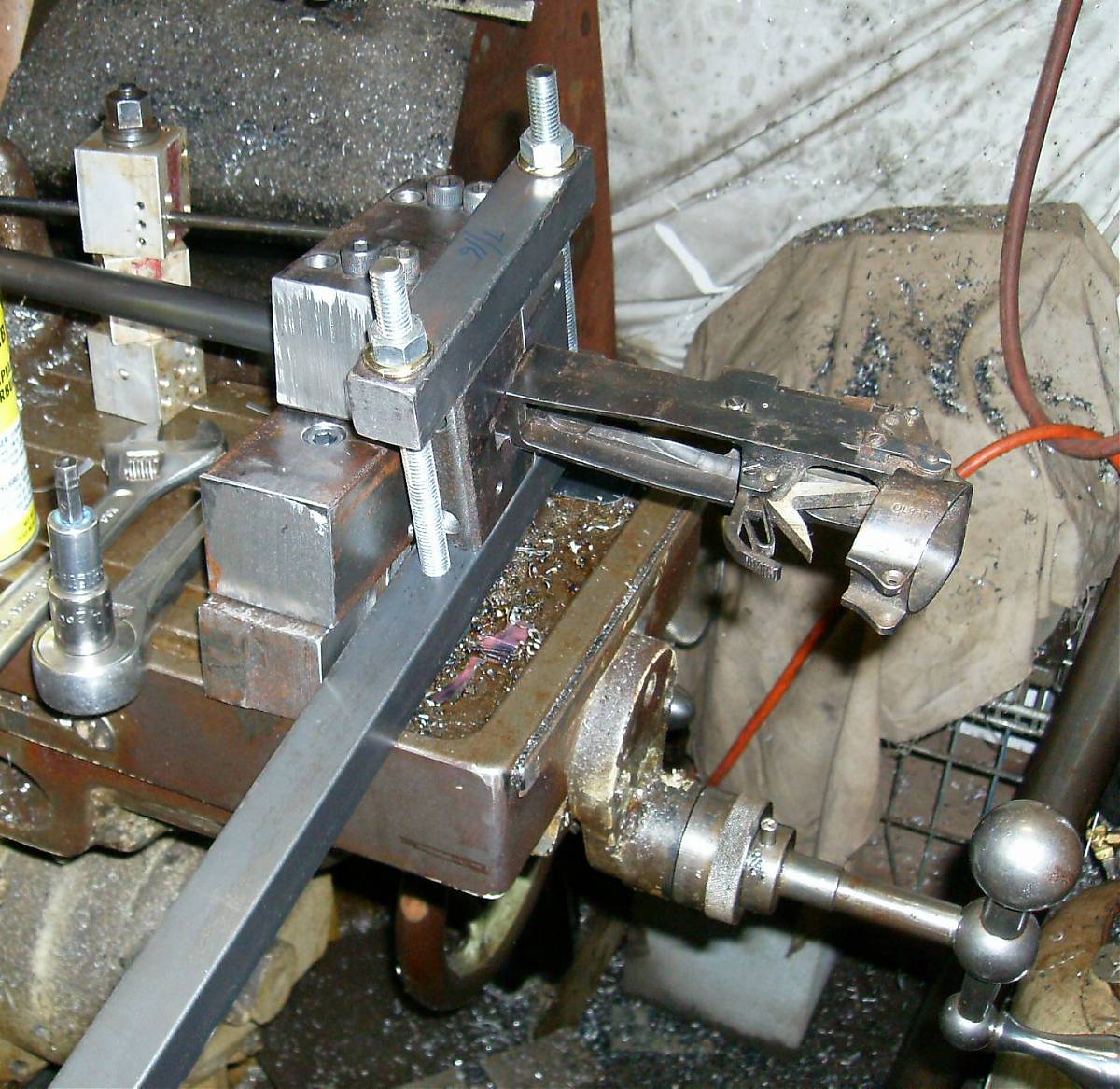

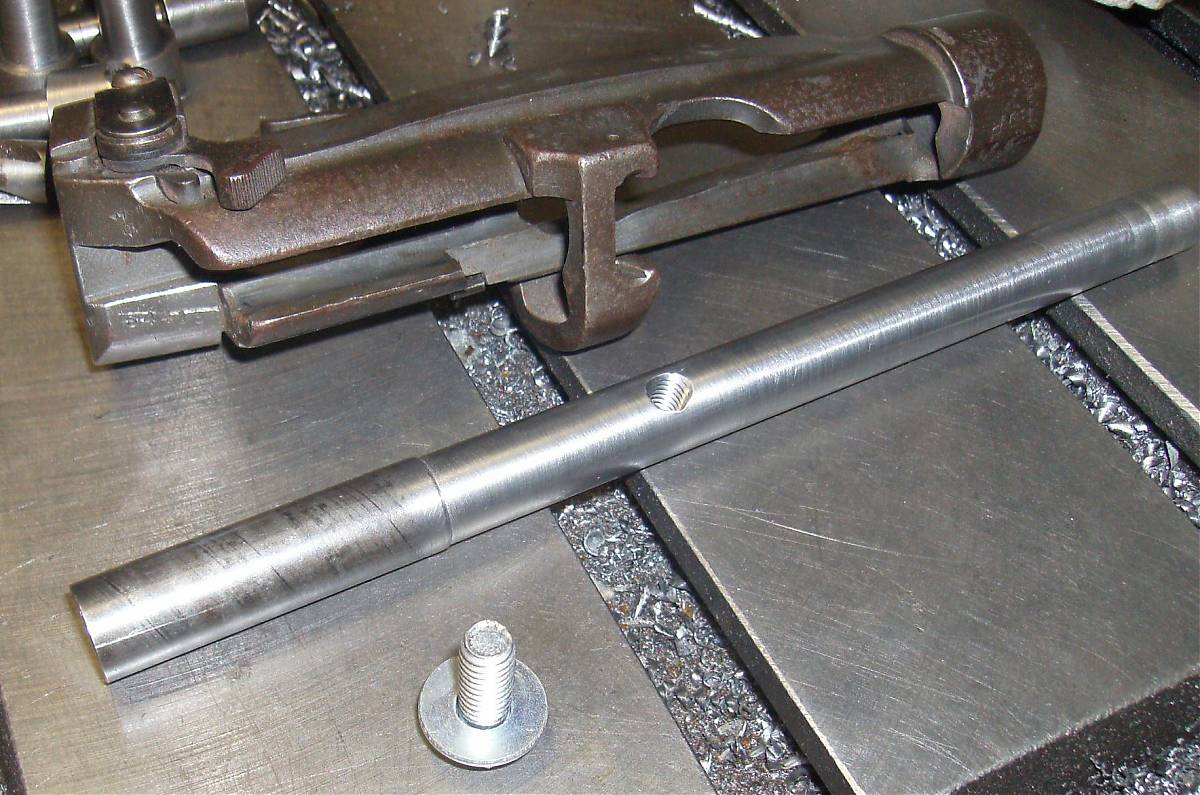

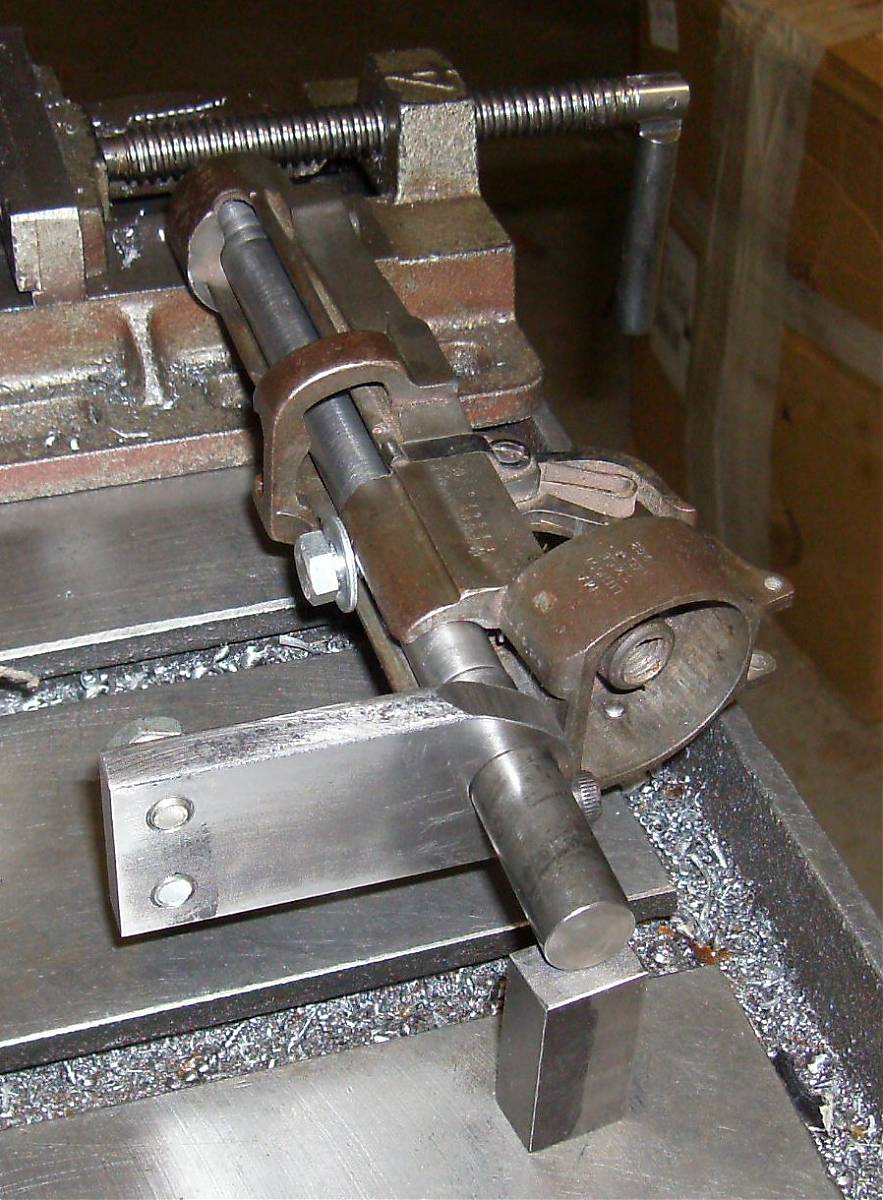

I had to make an SMLE wrench. It turns out the No.4 receiver ring is quite a bit bigger around than a No.1, and shaped differently on the bottom, too. I make it large enough for a No.4, and I'll make a split aluminum bushing for the No.1

After cutting the slot, I had to do a bunch of cutting and grinding to match it to the bottom of the receiver, which flares out into the lug, as opposed to the No.1, where the lug looks like it's just stuck on as an afterthought. You can see how that worked out in the bottom picture.

Grabbing hold of the barrel turned out to be a hassle. I wound up shortening my barrel bushing to tighten the tapered area up before I could get enough bite to hold the barrel. I've been hitting the breech area with Knock'R'Loose and PB Blaster for six months now.

The receiver was much tighter than a Chinese AK, not as tight as a Mosin. And much tighter than the No.1; I removed the barrel from the No.1 with a strap wrench!

TRX

12-21-2010

Hmm. It's time to screw in the .45-70 barrel and check the headspace. But what is the headspace supposed to be?

The SAAMI cartridge drawing shows a rim thickness of .060 to .070". It also shows a chamber with a rim recess, the recess being .070-.077.

A max rim and minimum recess would give a headspace of zero.

A minimum rim and a max recess would give a headspace of .017"!

Well, that's how things were in 1872, I guess...

I have a box of new Remington cartridges on hand. I think I'll mosey down to Blue Star next week and pick up a handful of commercial empties of as many brands as I can find, and see what modern commercial brass is closest to.

If the variation is small, I'm going to set the headspace to .001 or .002 on the thickest rim, unless someone has a better idea.

TRX

12-21-2010

net.lore says you can just run a 54R reamer into a .303 barrel, though it'll result in a funny-looking stepped case after firing. Lore also says if you set the barrel back a couple of threads you can fix this.

Ain't no way, droogies. Two threads isn't *nearly* enough to make a clean chamber, which I should have realized from looking at the drawings.

The SMLE doesn't have many threads to begin with, so setting it back more than two threads would start getting iffy. There's also the problem that on the No.1, you're moving the barrel far enough that all the "stuff" on the forend might not line up any more.

So, if all you want is something that'll shoot, just run the 54R reamer in. But there's no way to cut a correct chamber into the factory .303 barrel without shortening it too much to use.

The Mosin barrel has a finer thread than the SMLE barrel, too. I was hoping I might be able to step it on the lathe to take some of the SMLE hardware, but no go.

TRX

12-22-2010

You'd have maybe four threads left by the time you set the barrel back enough to completely clean it up. It's probably enough, but frankly, if I was going to use the original barrel, I'd just run the 54R reamer in there and call it good enough. Baud knows the .303 chambers are loose enough to start with; the extra neck that would be fireformed onto the 54R case would be no big deal. If you were shooting commercial Boxer-primed brass and reloading it, it would be one thing, but the whole point of converting an Enfield to 54R is to shoot cheap Berdan primed Commie ammo. As long as headspace is correct and the case doesn't actually rupture, who cares what it looks like when you eject it?

I guess I was just annoyed that "just set the barrel back a couple of threads and it'll fix it right up" turned out to be more Bubba Gunsmith lore. And if I'd taken the time to examine the case drawings in the loading manual, I wouldn't have been suckered.

TRX

06-12-2011

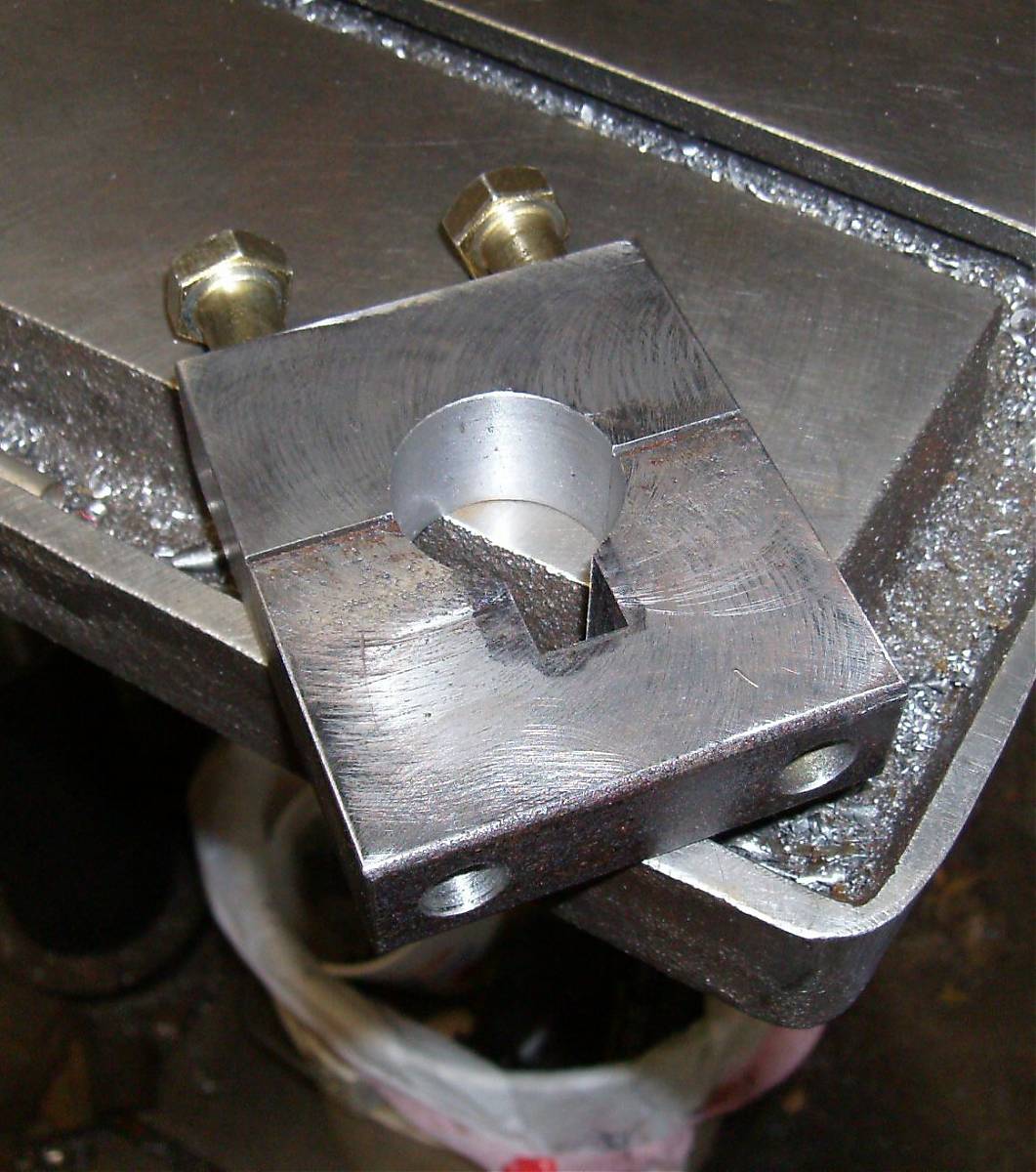

The SMLE doesn't have a straight hole back from the barrel to the bolt. It has a smaller-diameter web the bolt head pokes into, sort of like the "extra web" on a 98 Mauser.

The .45-70 rim is too big to go through the hole. It's not critical, and could probably be opened up with a Dremel, but in the interests of overkill I made a fixture to hold the receiver on the lathe. I need to make a stepped bushing to press into the front for the steady rest to ride.

The bolt keeps the receiver from turning on the shaft, and the odd metal wing is a counterweight for to balance the magwell/stock socket. I used bolts and washers to adjust the weight until it balanced.

.45-70 barrel screwed into No.4 receiver.

TRX

06-23-2012

The Enfield project is supposed to be officially parked and waiting while I finish up some other stuff, but I managed to score a No.4 forend off Gunbroker for $16 and a No.4 buttstock off eBay for $22. I've missed a couple of old sporter stock sets. "Cheap is a quality overcoming many faults", plus my dubious wood-mangling skilz are more suited to working with beat-up old milsurp bits. The barrel channel in the forend has to be opened up a *lot* for the massive .45-70 barrel.

Old Western Scrounger still shows surplus Gibbs .45-70 magazines, but they're nearly $100 to my door, with shipping. I keep gagging at that. And even milsurp .303 magazines seem to be running around $50 with shipping. I've been dragging my feet on the magazine issue. Oddly, antique Remington-Lee .45-70 magazines sometimes pop up on Gunbroker for not that much more than the Gibbs mags - $125-ish, sometimes. Sure, they're 125 years old, but they were designed to feed .45-70 through a Lee action, even though it's not quite the same action. I'd need to make an adapter of some sort. It might be worth the extra expense and trouble, but that's still down the road a bit.

TRX

06-25-2012

[reaches for Bren mag and box of .45-70]

[I might have thought of that, eventually. Maybe. Well, I might have...]

Hmm. One holds and slides out fine. Three and there's a follower tilt problem. Five and it gets a wedgie, possibly correctable by playing with the feed lips. Six won't go.

The ridge on the back of the mag would have to come off, but that would also let me push the back part together a bit more to reduce the width at the back.

Okay, that;s a possibility. Now I wonder where that PSL magazine went...

[edit] Okay, a G3 mag will hold five, but gets into a follower problem again. Same with the PSL mag. The PSL also doesn't want to release the cartridges at all; I finally had to use a knife to push the follower down and work the cartridges out. ("Brass checks in, but it doesn't check out!")

It looks like an ideal lip setup would hold both the rim and front of the cartridge, and then have a cutaway section to let the rim pop up after the nose has lifted toward the chamber. I also have an M-14 mag around somewhere I can check...

A Saiga .410 mag won't work. The .45-70 rim is too big, and the plastic Saiga mag doesn't come apart to allow grinding inside.

There are some guys who have evaded opening up the receiver ring by turning down the rim on the .45-70 some. This means they have to stay with their modified brass... but it might also let them use Saiga, Savage, or Mossberg .410 box mags.

TRX

06-30-2012

The Gibbs magazine lets the .45-70s flop around - if you turned the mag upside down, the top cartridge would hang down at more than a 45 degree angle. The Gibbs also requires that you cycle the bolt with some authority or the cartridges do odd things, like slamming into the breech ring instead of going into the barrel.

I don't have an SMLE magazine or I'd screw the old barrel back on and watch how it feeds. I don't have all the magazine bits for the Ross, and I don't have the barrel done yet anyway. The only complete rifle I have on hand that handles a rimmed cartridge is a 91/30, and I now understand what the "interruptor" blade on the side is for. Ingenious... except there have been plenty of rifles that didn't need such a thing to handle a rimmed cartridge. I just need to figure out how they did it...

TRX

07-03-2012

The buttstock and forend showed up last week. There's no hardware with either, no big deal. I think I'm going to go with a rubber butt pad on the buttstock since I don't have a proper metal buttplate for it, and frankly, in my advancing years my shoulder is getting tender.

I still don't know what the difference between a No.1 and No.4 buttstock is; I can't tell them apart by eye, and a No.1 will hammer into the No.4 receiver.

The forends are *much* different. The No.4 receiver is much more squared off, and the recoil lug is different. Looking at the impressions, I was struck once again by now few places the action and forend touch. Of course, the socketed buttstock takes all the recoil, and the forend just provides a place to hang on to. Just another example of James Paris Lee's brilliant engineering.

A *lot* of wood has to come out of the forend for the pipe-ular .45-70 barrel to snuggle in. What I need is a big half-round rasp with the right radius and an offset handle. So far I haven't found exactly what I'm thinking about at Brownells or any woodworking site. The other thing would be a round scraper. I'm thinking of a beveled disc of the right diameter, mounted on a handle. I think I saw something like that somewhere, but it would be easy enough to make.

Somewhere along the way I have to decide what I'm going to do for the front weight. The No.4 has an excellent peep sight on the receiver already.

Somewhere along the way the Voices have persuaded me to load the .45-70 cases with black powder. The ball mill is about half finished. The Voices have been suggesting that a nice muzzle brake would make the SMLE a true "smelly" if I wanted to be obnoxious to any hip-hop assault rifle yuppies at the range...

TRX

10-31-2012

The SMLE extractor has a very long stroke; up in Canada people have done 7mm Mauser conversions and claim the unmodified extractor works find with the rimless case.

The extractor is *supposed* to be able to push the case to the left. That preloads the case against the left side of the chamber for consistency, sort of like a the ejector pin on an AR or a Savage. And it keeps the case pushed to the left side of the receiver, so it will slide across the bolt face a bit as the bolt strokes back, so it can hit the ejector screw.

The left sidewall is actually scooped out a bit to let the case slide over; that's one reason the bolt feels loosey-goosey.

How's your headspace? You might be able to take a little off the bolt head face to get more extractor bite.

I never did get any feedback on the varying rim thicknesses of .45-70 brass on any of the boards where I asked, and the only local place that had used brass went out of business.

I'm tempted to set my rifle up tight on an .062" rim, and face off the front of any thick rims on the lathe to .062". Just reaching in with a parting tool should do it. You can't take of off the back of the case without making the primer pocket shallower.

In my case, I'll probably just "adjust" forty or sixty cases, which will probably last me the rest of my life... I'm not worried if it won't handle all commercial ammunition. Though, really, the change in headspace doesn't seem to be an issue with .45-70 guns in general, and if there's any platform that has proven it can handle excessive headspace, it's the SMLE!

TRX

45-70 No.4 Enfield

Mon May 25, 2015 8:56 am

I'm not finished with mine yet, but here's how I'm doing it:

I picked up a leftover Gibbs barrel from Sarco; it was already threaded, profiled, and chambered, but didn't have the extractor groove cut. If they're out of stock you'll have to thread your own barrel.

The extractor on my bolt fit the .45-70 rim without modification.

There are a number of "fingernail cuts" in the magazine well, intended to guide the cartridges into the breech. I had a couple of receivers to play with; some would pass the .45-70 rim freely, some needed a bit of clearancing.

The Enfield has an internal bulkhead in the receiver ring. I think they had it before the 98 Mauser. The .45-70 rim will not clear the bulkhead. Because I am stupid, I made an elaborate lathe fixture to hold the receiver so I could bore the bulkhead ID larger. Just use a die grinder and a little care and you'll do fine. Note: some people have made up "semi-wildcat" .45-70 brass, turning the rims down so they'll feed through the bulkhead. This also eliminates clearance problems in the feed track. If you reload it will save your some aggravation.

There's a notch cut in the right side of the receiver ring to clear the tip of a loaded .303 round. It won't clear a loaded 405 grain .45-70, and it's nowhere close for the 500 grain rounds. Gibbs didn't bother to alter this; you have to wigge the round out. You can open the notch up carefully with the grinder. Since you're not changing the depth you're not weakening the receiver ring.

The .45-70 barrel is much larger in diameter than the .303. Be prepared to spend lots of quality time with the chisels opening up the forend.

You'll have to find a front sight of the proper height and fix it to the barrel. I can't help you there since I haven't gotten to that point yet.

The Gibbs magazines were, in my opinion, junk. I've read that some people have managed to modify Enfield magazines to work. If you have one on hand it's worth a try.

I observed that the SMLE/No.4 was a descendant of the Remington-Lee, which came in .45-70 to start with. I ordered a Remington-Lee magazine and... it snicked right into the No.4 and fed all five cartridges into the chamber. Wa- hoo! The magazine is single stack and narrower than the .303 mag, so I still need to make some filler pieces to keep it from wobbling in the bottom metal.

I've also found that the Saiga .410 shotgun magazine works fine with .444 Marlin and .405 Winchester ammunition. Full-size .45-70 rims are too large to fit inside. The Saiga mag is wider than the Enfield one at the front; you can probably bend one of the sheet metal trigger guards to clear the magazine. You can *almost* grind enough out of a cast trigger guard; you might be able to shave some of the plastic off the front of the magazine instead, but you'll have to scout that out for yourself.