Converting Berdan to Boxer Primers

Retrieved: August 21, 2016

Last Post: April 12, 2015

Yeah, Yeah I know Trenches, it's not worth the trouble but when has that ever stopped the members of this board ;D :D.

I have bunch military surplus Berdan primed .303 British. Some 1941 Radway Green and some early sixties POF.

Hating to throw away all that good brass I came up with the following method to convert the brass to boxer priming. I used small 7" bench lathes to do the work but it could be setup for a mill or drill press. It will only be efficient if you have a lot of cases to do and set up accordingly. Once the case is converted it can be reloaded normally as long as the case lasts.

Since the original Berdan flash holes remain in place, as I have converted them, the converted cases will have 5% more flash hole area than a typical boxer primed case (.082" hole). Start with caution and reduced loads to be sure the additional area is not affecting pressures. I haven't yet reloaded any of my cases.

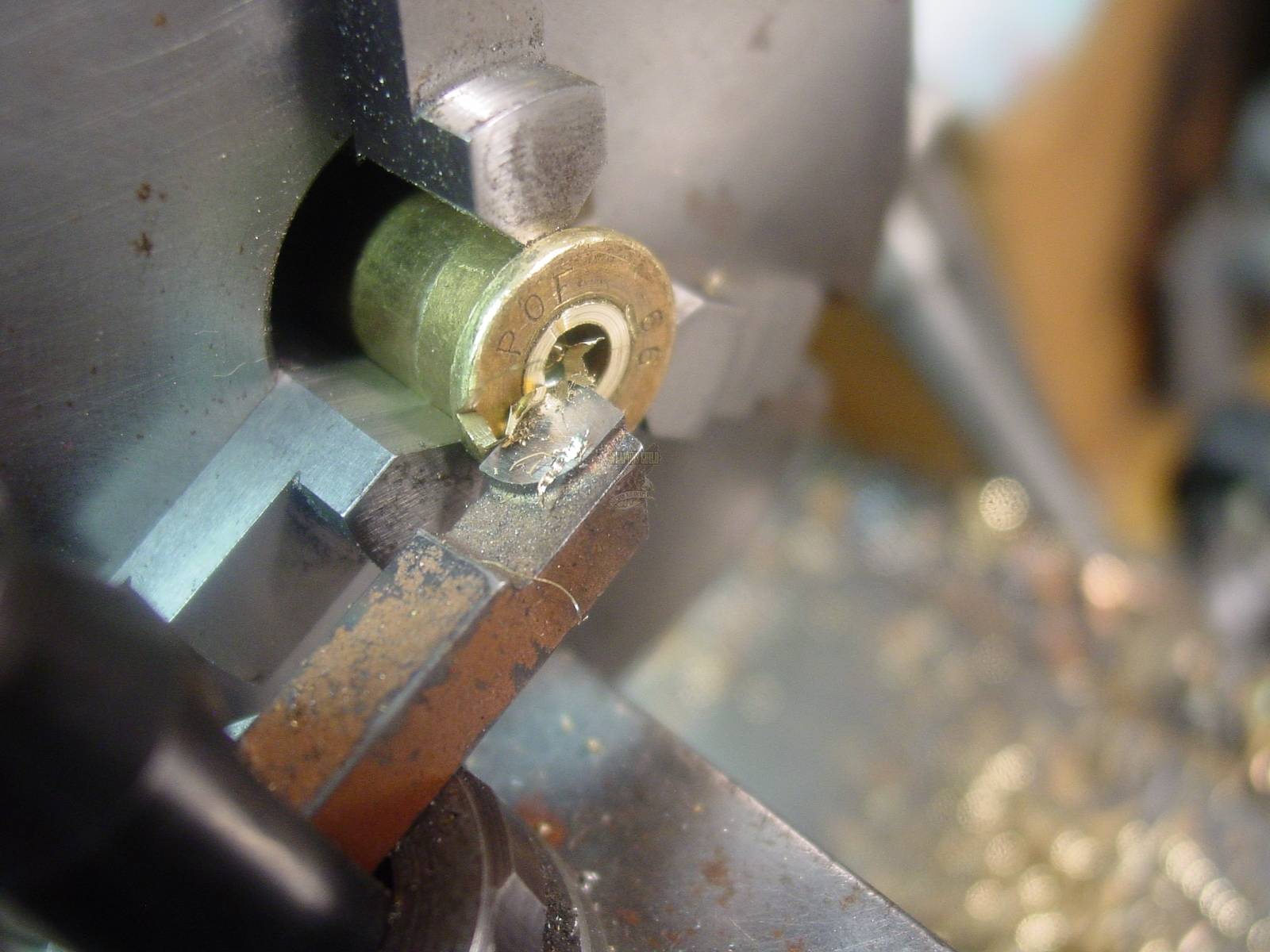

Start by drilling the new flash hole (.066") through the mouth of the case. Make a fixture for the drill so that it is centered and will only penetrate the anvil in the case and not the primer.

You then can resize and de-cap normally

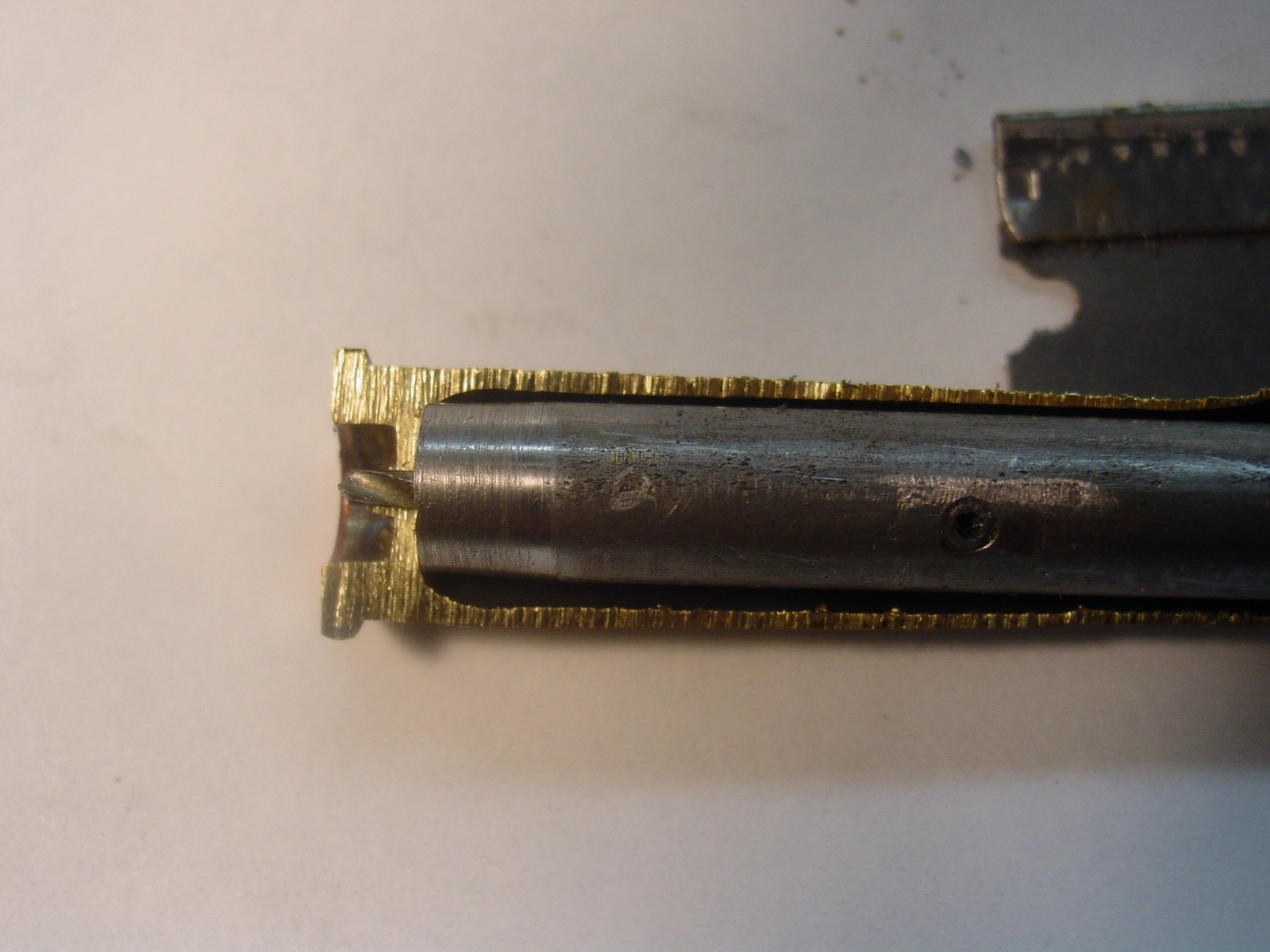

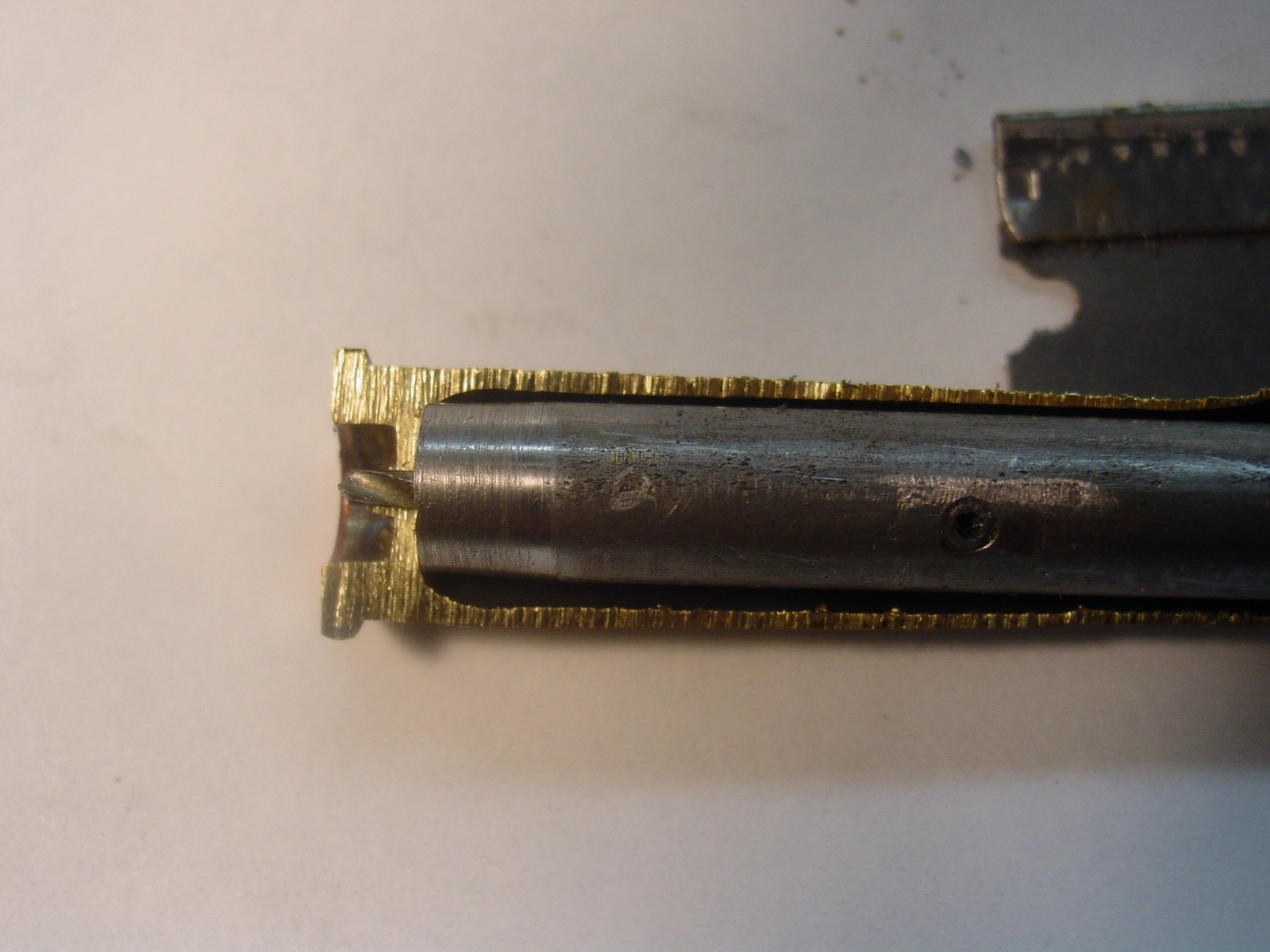

The primer pocket in the .303 British Surplus is .25". The pocket has to be bushed and reamed for the large rifle boxer primer. I cut the bushes from 1/4" .032" wall brass tubing.

Using Loctite 620 (green, hi temp, retaining compound), I pressed the bushes into the primer pocket.

The bushes then have to be faced to match the base of the shell.

At this point there is too much material to be removed with a primer pocket uniformer (reamer) so I remove most of the material with a 13/64" mill (UPDATE found that a number 6 drill works much better) set up with a stop fixture to limit penetration . Then the final step is the primer pocket reamer followed by a couple of twists with a hand countersink to chamfer the new pocket followed by priming as normal.

Pics below show details:

UPDATE

I fired the first batch of converted .303. I loaded a little below max. Worked fine, cycled the action properly(Bren) :-*. No signs of excessive pressure. As I decapped I found some of the bushes moved. Obviously the Loctite is not the best way to go. I made a crimping tool and crimped in the bushings. Hopefully that will solve the problem. Nevada Blue's soldering idea was right on.

NevadaBlue

February 20, 2011

Joe, thanks for this. I'm gonna save my x25 brass and try it.

I think one could solder up the original flash holes. Maybe deprime the hard way, solder the flash holes and then do the machine work?

Now that I went back and studied your writeup, I think I'll try this:

- deprime the hard way

- clean the pocket with an end mill (removing the anvil)

- solder a solid chunk of brass rod in the primer pocket (filling the existing

flash holes)

- mill out the new hole to proper size using your mill cutter setup

- drill the new flash hole using your setup, but from the primer end (saves

work)

Thanks again for this, it doesn't look so difficult, just a very tedious process. But, better than not having ammo. :-*

Lamont

February 20, 2011

This is a really nice thread. Just remember, IIRC, Berdan primers are like .002 larger in diameter than Boxer. They can loosen up over time.

And for those with rare ammo firearms, Hornday now sells the "military classic" line of ammo and brass for all those hard to find calibers... Like 9X33, 8X54R, .303, 7.65 Argie Mauser... and even some of the old Swiss Vetterli ammo.

NevadaBlue

February 20, 2011

Lamont, Joe is making a NEW primer pocket. It is sized to standard primer size. :-*

I found this reference quote on another site, and am struggling to confirm it on the SAAMI site.

From SAAMI, the depths for small pistol, small rifle, and large pistol primer pockets are .118" to .122", while large rifle primer pocket depths are .128" to .132". Small pistol and small rifle primers have the same diameter (.175") while large rifle and large pistol primers are also the same (.210").

It is recommended that primers be seated .003" to .005" below flush.

MGMike

February 20, 2011

I like the idea of plugging the base, and starting from there. It would be a no-brainer with a tailstock turret in the new lathe ;D A shouldered collet to hold the brass would help.

NevadaBlue

February 20, 2011

Yep, a turret would be the berries for this.

Now I need to look at my collets and collet block, good idea! I bet I could set up the collet holder in the mill and just step through the process. Thanks!

trenches

February 20, 2011

What I don't understand is why some enterprising outfit doesn't import Berdan primers.

MgM

February 20, 2011

Lots of work as I indicated in the other post, but I guess this is another way.

After the old Berdan primer was popped out, we crushed the anvil this closes the two bedan flash holes. We drilled through to create a new flash hole (using a 30'06 case as a guide).

Then with a drill bit, we opened the primer pocket and finished with a primer pocket reamer on a hand drill (using a 30'06 case as a guide).

Another thing to remember which always gets lost in the equation when discussing converting Berdan to Boxer is that Berdan rounds especially old brass rounds used corrosive powder and mercury filled primers. When you fire the rounds the corrosive compounds are driven into the brass and weaken it. On steel cases say old Warsaw Pact ammo, the ammo is eating through the steel and weakening the cases, as we speak.

Food for thought! like I said in the other post we only converted cases for ammo we could not get brass for.

Last I saw you can get Boxer brass for almost any type of ammo included reformed 5.45x39mm.

sprat

February 20, 2011

I'm not sure I would want to reload any of the fired steel cased ammo from the Commie Bloc countries unless I knew what was in it or cleaned them first. I don't believe mercuric primers have been used since the 30's at the latest except in very limited circumstances. Mercuric primers can affect the brass by making it brittle. The current (since the 30's) crop of corrosive primers are a potassium compound that leave a salt which is hygroscopic (attracts water) which will cause rusting in the steel barrel and cases. I've never found anything to indicate that it is harmful to brass.

The ammo I'm converting is brass, corrosive primed, and loaded with cordite which is a type of non-corrosive smokeless powder. It's unlikely that any surplus ammo made during or after WW II will not be smokeless powder.

I'm not advocating converting Berdan to Boxer but just showing the way I've done it for my own particular purpose ;D.

Delw

February 21, 2011

Why not get a ton of brass plugs made with the correct primer hole size and step? Or make them yourself?

trenches

February 21, 2011

Mike, I bought my Berdan primers from Old Western Scrounger a long time ago. I don't think he's in business any more.

He had a very good selection of primers. I originally bought them to reload 6.5x55mm Swedish Mauser brass. I hated to throw away that beautiful brass. :D

Now I use them in 7.62x51 brass.

Joe H

April 13, 2011

I fired the first batch of converted .303. I loaded a little below max. Worked fine, cycled the action properly (Bren) :-*. No signs of excessive pressure. As I decapped I found some of the bushes moved. Obviously the Loctite is not the best way to go. I made a crimping tool and crimped in the bushings. Hopefully that will solve the problem. Nevada Blue's soldering idea was right on.

APMski

April 13, 2011

This is a topic I have been researching for a while. Some interesting discussions that I have found in other places include:

Two different versions of the "ball bearing" method for Swiss GP-11 7.5 x 55mm brass:

http://collectorguns35625.yuku.com/topic/3297/Berdan-to-Boxer-conversion-for- GP11-cases

http://users.ameritech.net/mchandler/primer.html

A similar method to Joe H's only drilled through the bottom, not the case

mouth:

http://castboolits.gunloads.com/showthread.php?t=50789

Swage the pocket with a punch and hammer method:

http://www.surplusrifleforum.com/viewtopic.php?f=112&p=600941

A method the I do not have a link for but that I find really interesting:

Using the walls of the already crimped and sealed in Berdan primer as the

primer pocket bushing. Basically set up a #4 reamer (0.2090", just right for

a 0.210" Boxer primer) with a stop collar and ream out the base of the primer

and the Berdan anvil. Then use a flash hole uniforming tool to drill out the

flash hole. And you are done.

This idea has been driving me nuts for 6 months because all my tools are

currently in storage. I finally have a garage again and in about a month or

two I should have a work bench set up. In the mean time, I'm still going nuts

:D

Somebody please try this out before I go after this free-hand with a cordless

drill. :D

Quote from: APMski on April 13, 2011

I've tried that. I was concerned that the remains of the berdan primer may not

stay in place. It will work but I never loaded and fired any. Be sure you use

some tapping fluid or case lube on the uniformer or it may spin the bushing. I

would go with a center drill, then drill the flash hole, then a drill to get

as close as possible to the primer pocket size without drilling into the web,

followed by the "primer pocket" uniformer. The uniformer cannot handle much

chip load. I made some primed cases using that method to try my Bren build.

What if you milled out the Berdan primer and anvil as stated and then soldered

what's left of the primer wall to make them permanent? That sounds like a

permanent solution with the least amount of work.

Falcon,

It may be worth a try but military primers ususally have some kind of sealer

in between the pocket and the primer. You would need to get the flux in and

have clean metal for soldering to work. That's why my Loctite didn't work, the

pockets were not clean ;D.

Would the sealer burn out with the right amount of heat? Or would that ruin

the strength of the case?

quote

quote

Also, while there are two basic Boxer sizes in four basic strengths

("brisance" in explosive-speak), there are only about eleventeen Berdan

primers now. Back decades ago the European manufacturers had a bunch of

sizes. Then the Korean, Russian, and Eastern European stuff started hitting

the market, and they pretty much use any size they feel like at the moment.

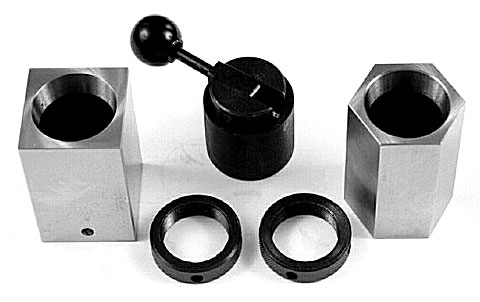

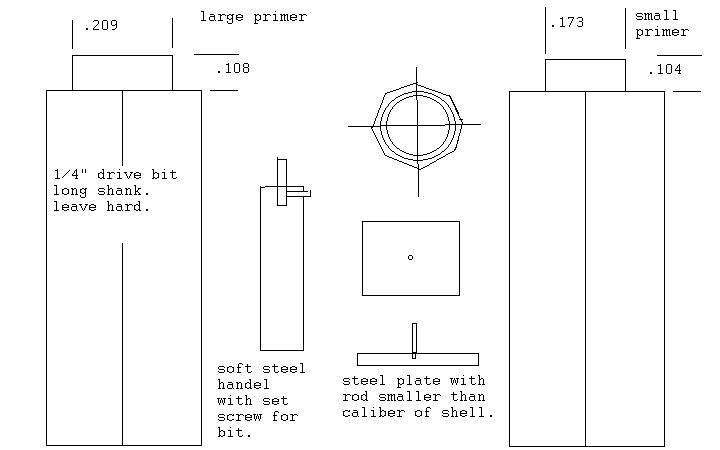

Here is a set of tools I made to convert berden into boxer primed.

This is the drawing to make your own, the two sizes large rifle and small

rifle boxer primer punchs are made from 1/4 inch Philip screwdriver tips, you

can use the two inch length. the pins were cut on a metal lathe with carbide

cutting tools and polished with a diamond knife sharping stone and emery

cloth.

The tip of the punch, cut to crush the berden primer pocket to the boxer size.

the nose is the size of the boxer and the shoulder is doing the crushing down

when the tool is hit with are large hammer.

The punch is set into a hole in a steel handle to hold it firmly and give a

good hand hold on the tool.

The pin to place a shell onto is mounted to a thick steel plate. the pin has a

small center bump to hold the shell center on the pin center.

The shell is prepped by removing the old Berdan primer cap, I use a drill just

under the size of the old primer, and I drill down to remove the Berdan bump

in the primer pocket. (I drill the primer and new vent hole in my metal lathe,

you could use a drill press and a vice with a hole in a bit of wood) and I use

a small drill the same size as my decapping pin on my die set, I think 1/16"

to drill the new hole, but the old holes are still in place and I think they

would work to help the main one and don't need to be plugged up.

I have used these tools on brass and steel shells and the steel have to be hit

harder with a BFH (big F$#&ing hammer) than the brass, but it works.

Do this on a hard concrete floor and wear hearing protection, the steel plate

the vertical pin is mounted even on a 1/8" of felt, will ring when hit hard.

I've reloaded some .303 miltary brass converted to boxer primers. I had one

case separate cleanly at the base. Had to use the broken case extractor :(.

A little research indicated that the the chambers on the military firearms i.e

the Bren and SMLE were very generously sized (not ideal for reloading). When

the case is resized the brass at the base can be cold worked and consequently

fail as happened to me. The recomendation was to keep the brass separated

relative the firearms they are used in and only neck resize when reloading.

I've got the die but so far i haven't got around to reloading any rounds.

I tried this with the 8mm Yugo brass 1950's type with no success. The casing

were not very good quality. Some had split. I did not trust reloading them. I

have not had time to work with the new surplus to see if it is worth the time.

Remember to anneal any OLD brass cases before you start messing with them.

Brass gets brittle and annealing can make them last longer.

I have never seen Berdan primers for sale, not that I have ever looked though.

The problem would be getting the old primer out with the anvil stopping you

from getting access to it through the case.

Excellent call on annealing, the older brass was never designed to be

reloaded, or stored for 60 years for that matter.

Some believe that you cannot rehabilitate Berdan cases because of the anvil

being in the way, but I use a very hard and sharp pin punch with a separate

base to punch the anvils out of the cases. I got the idea when I accidently

mixed a Berdan 9mm case in with some regular Boxer stuff. I heard a crunch

during the deprime step and investigated it. I found a case that now had

three holes through the primer pocket instead of one. I will admit that the

casing in question only lasted about three reloads before it cracked, but it

was a great experiment. I have had some cases fail to punch out the anvil,

but I'd say they were less than 30% as a guess.

A far as the concern over the corrosive salts, a simple and cheap wash of

ammonia and water will neutralize the residue and help to wash the cases prior

to tumbling.

Milling the anvil out, drilling a hole - those are easy. The size isn't.

What would be good would be if someone would manufacture brass 'cups' that

would be inserted in the oversize Berdan hole, could be soldered in place, and

would then tightly accept Boxer primers. If you look at how bullet jackets

are made, they start with a circle of copper, then use a press to form it.

Same principle could be applied. It would be nice, even, if someone made a

whole kit - the anvil mill, proper drill (including a guide bushing) and a cup

forming die, and a seating punch. I wouldn't see this as a huge sales item,

but it might be enough to be profitable for a small operation.

What a great idea! Possibly a person could make cups from old primers, swage

them to size. Might work, good way to waste some time, I'm good at that.

(wasting time that is)

My experience in converting Berdan to Boxer has been with .303 British. As I

detailed on the first page of this thread I drilled a .060” hole from the

bullet end through the dimple and stopped short of the primer. The case can

then be de-capped with regular reloading dies.

The .303 British pocket is .25�". The boxer large rifle primer is .216". I

used 1/4" brass tube (.032" wall) for the bushes. The fit is not tight

enough to lock the bush in the case.

I tried Loctite to lock in the bushes and this failed for the same reason as

the soldering would probably fail. Unless the pocket is cleaned thoroughly

before Loctite or soldering the joint will not hold. The military primers I

have seen usually have a sealer. I found it was much easier to make a crimping

tool and just crimp the bushes in.

Nevada Blue certainly makes a good point about the brass needing to be

annealed, particularly after a couple of re-loadings. Military chambers

especially the .303 British are notoriously oversized. They weren't worried

about reloading. A number of full-case re-sizings can cold work the brass

right at the top of the base. The base diameter stays the same but the thin

section of the case bulges out causing stress at the top of the base. I had

one reload separate cleanly at the base. Conventional wisdom is the just to

neck size the brass and keep the reloads separate for use in each particular

rifle to eliminate the full length resizing.

would this be better than soldering?

Wow that looks like a lot of work for each case. I wonder if someone might

start manufacturing custom Berdan primers with anvils built in. Then you

would just have to drill out the anvil pocket the first time and then use the

custom primers. Either way I'm just stashing my berdan brass cases away until

there's a good option out there.

I've been converting 7.62x25 Berdan cases to take Boxer large pistol primers

for some time now. I drill out the anvil through the case mouth as previously

described then drill out the berdan primer and finish the pocket to depth with

a modified #4 drill bit. The drill bit is modified by grinding to a flat

point. I also anneal the case mouths.

When you drill it out do you end up leaving part of the Berdan primer to make

it the right size for the Boxer primers?

When you drill the 7.62 x 25 with the #4 drill, it removes the smaller Berdan

pistol primer entirely. You just have to chamfer the new lg pistol pocket,

anneal the case and go.

I wonder what that means for 7.62x39 brass/berdan cases. Would a larger rifle

primer do the job?

I got some .25" OD brass tube to make the fillers with and used swiff solder

paste to keep them in place. Old brass lives again

Here are some pictures of some 303 british I did a while back. Some of those

cases have have survived 9 loads.

Did you use the tubing for a liner and use the original bottom of the hole and

mill it out. Just soldered in a little bit of tubing and formed? ???

here's a step by step of the way I do it

1) get the old primer out using the water method. I do dig some out with a

spike if the water fails to remove them

Would it be easier to a Vix (brand name) bit for drilling out the flash hole?

I use this type of bit in the finish carpentry field, they are available in

different sizes to center up in a hole like a door hinge. I just might try

this on some to see if it works. I never thought about it until I saw the

drill rig above.

No matter which way you convert the case there are a few issues regarding

reusing the the brass, particularly the .303 British if used in the military

rifles and MGs.

I've never annealed the brass but from what I've read it does prolong case

life and only should be done to the necks of bottleneck cartridges. The base

should stay hard for strength. So don't overheat if you are soldering in the

bush.

This is where I found the problem. The British military guns particulary the

Bren have very large chambers. They really wern't concerned about reloading,

only about extracting and firing the next round. Using the method I described

in the begining of this thread I converted to boxer & reloaded. I quickly

experienced a case separation right at the begining of the solid base. A

little reseach quickly indicated that the oversized chamber and full length

resizing were responsible for the problem. The reworking of the brass was a

result of resizing the large chamber dimension just at the base. You can

easily see the case expansion just at the base in a fired case. It was work

hardeneding the brass when it was resized causing the premature separation.

The solution was to just neck resize and use the reloads in the same gun to

assure proper fit.

Joe

Some good ideas here for converting brass. Some are a lot of work ! But,if you

want to load for tough to find stuff,that's one way to go.

Converted some old 42 Russian Berdan cases many years ago to take 209 shotgun

primers.

Only using them for light black powder loads with a round ball.

Used some unfired cases with dud primers. These were primed corrosive, mercuric

so unfired cases best.

Removed primer then drilled out a hole to press fit a 209 primer. Countersunk

it so the primer would sit flush. Annealed case mouth. Got 2-3 reloads out of

cases.

Did not need to size them, just deprime, reprime, powder, grease wad and a ball

one top.

Of the bunch of .303 British cases I did back in 2012 I still have a few in the

brass pile. they have been reloaded over 10 times and possibly 15 times. I

never lost a case from a failure of the head due to soldering or primer

pocket. They all failed over time the same way the Boxer brass did.

I am getting set up to do another big batch of .250 Berdan primed 303 British

brass. I have a different idea that I will try out. I will flare the .250

primer pocket so its larger in the bottom and then when I put the brass collar

in there and swage it in with the primer pocket swaging tool it should spread

the collar and lock it in place.

I will do a few test cases and see how they perform before doing the big

pile<.P>

here is a link to the torture test I did on a group of converted cases

http://www.weaponsguild.com/forum/index.php?topic=55112.msg749820#msg749820

For some time now I have been wanting to convert 7.62 x 39 Berdan primed cases

to Boxer primed, and thanks to NevadaBlue (for the collet idea) I finally made

a fixture to successfully do just that.

Here's what I did to make the fixture:

1 - Pulled out an old 5C collet closer I had laying around

Here's a picture of what I have so far

When I get a little more time, I'll post a video on the process...

How are you going to stop the ring from the old primer from coming out next

time you deprime the case?

After cutting the base of the primer with the 5mm end mill, you then swage the

remainder of the primer (the outer part of the primer cup) with the RCBS swage

tool. I have loaded these cases four times and have not yet lost a primer.

These cases deprime as normal Boxer primed cases. Hope this helps...

Joe H

April 13, 2011

Somebody please try this out before I go after this free-hand with a

cordless drill.

falcon62

April 13, 2011

Joe H

April 13, 2011

falcon62

April 13, 2011

TRX

May 21, 2011

What I don't understand is why some enterprising outfit doesn't import Berdan

primers.

The people who have the paperwork to import ammo probably have the idea it

would cut into their ammo sales.

padkychas

August 24, 2011

Joe H

September 02, 2011

Stinkyboy

September 02, 2011

NevadaBlue

September 04, 2011

rduckey

September 23, 2011

dr moe

September 23, 2011

elmacgyver0

September 23, 2011

Joe H

September 26, 2011

Joe

muttman

October 24, 2011

falcon62

October 24, 2011

TradeGun

November 12, 2011

falcon62

November 12, 2011

TradeGun

January 15, 2012

falcon62

January 15, 2012

sub-sonic

January 22, 2012

sub-sonic

August 01, 2012

NevadaBlue

August 01, 2012

sub-sonic

August 01, 2012

3) clean out the primer pocket with a wire brush on the dremil

4) anneal the case to half way down (get all the wet jobs done first)

5) mash the anvil down

6) ream the pocket to depth removing the anvil stump

7) apply solder paste and press in collar thats made from brass tube with an

od of .25 and an ID of .206

8 ) heat with a propane point torch to solder the collar to the case

9) turn the collar down flush with the base of the case and drill the flash

hole (lathe)

10) use a primer pocket swaging set up to form the primer pocket

11) resize and trim the case to length

12) wash cases in hot water and dish detergent and rinse clean in hot water

then dry and stick them in the tumbler

13) load

Bozoni

August 15, 2012

Joe H

August 16, 2012

Ivan Ivanovich

October 30, 2012

sub-sonic

January 15, 2016

John_Steven

April 11, 2016

2 - Bought a 5C emergency collet

3 - Ran an '06 chamber reamer partially into it (until a fired case just fit)

4 - Made a stop (that screws into the collet) that uses the neck of the case

for a pilot

5 - Made a centering spud to align the jig on the mill or drill press

6 - Used a long #2 center drill with a drill stop to drill out the Berdan anvil

7 - Used a 5mm end mill to remove most of the primer shell

8 - Set up my Rock Chucker with an RCBS primer pocket swager and swaged the

remainder of the primer shell for a nice fit of a Large Boxer Primer.

sub-sonic

April 11, 2016

John_Steven

April 12, 2016