Retrieved: 01/08/2015

PAN LUBING PROBLEM SOLVED

By Wayne McLerran

Updated 5/30/13

Much has been written and posted on the Internet BPCR talk forums about pan lubing techniques for BPCR bullets. I've been pan lubing for some time and have a technique that now works very well for me. The fundamental process consists of standing bullets up side-by-side in a pan and pouring melted lube into the pan until the lube covers the bullet lube grooves. Once the lube has cooled, the hardened lube cake is removed from the pan and the bullets are pushed out with thumb pressure. Since everyone seems to have their own version of pan lubing I will not cover the details here. If you need specifics, run a Google search or go to one of the BPCR talk forums. There are also several videos covering the process on YouTube. My intent here is to share my solution to a pan-lubing problem I've experienced in case others are having similar difficulties.

The problem I've had is obtaining completely filled out uniform lube in the bullet grooves when pushing the bullets out of the lube cake. Even when the grooves were filled out, some of the lube would have a tendency to roll out or slough out of the grooves. It was usually the lube in the 1st or last groove exiting the cake. This is certainly not a new problem and has been reported and discussed previously on BPCR forums. BTW, so far I've exclusively used SPG lube, which has worked very well under various shooting conditions.

The sloughing off of some of the lube in the grooves may be due to the lube age and how many times it was melted and reused. Depending on the formula, some "soft" lubes are softer than others. Lanolin can be added to soften lube, or adding beeswax can harden it. I have not tried it but understand that adding rosin plus some of the brown sticky wax used on toilet wax seals will result in a "stickier" lube.

In an attempt to eliminate the problem I experimented with preheating the bullets with a hair dryer and/or hot air gun to various temperatures prior to lubing. The lube cake and bullets were also allowed to cool to various temperatures: slightly warmer than room temp, room temp, some cooling in the refrigerator, more cooling in the refrigerator, cooling in the freezer, etc. Nothing seemed to consistently work. So I finally said the heck with it and decided to use the "cookie cutter" method.

A simple cutter was made by modifying a cartridge case of the correct caliber. See the photo below. The neck was expanded to a diameter just slightly over the bullet diameter. The primer hole was drilled out to 1/4" to allow using a dowel rod to push out the lubed bullet. A small hole was drilled completely through the case in front of the rim to allow air to escape when pushing the cutter down over the bullet with my thumb covering the drilled primer hole.

Nothing I previously tried worked near as good as this technique and variations in lube cake hardness are no longer a concern. The lube sticks tenaciously to and completely fills the grooves every time.

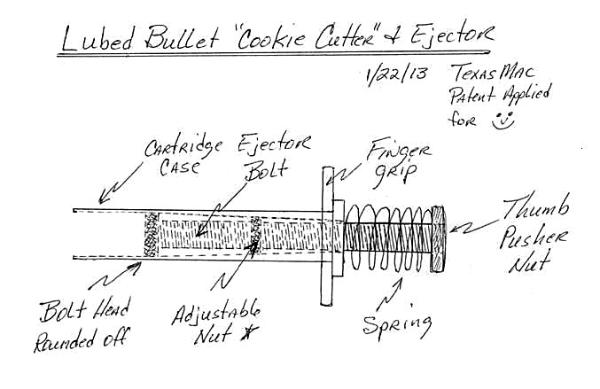

In case you'd like to make an improved version of the cutter, I worked up a quick sketch, see the illustration below. A nut was added to limit spring- back travel and, depending on bullet length, can be adjusted to expose a small part of the bullet base for ease of wiping lube off the base. Starting with a cartridge case it should be relatively easy to make. A large washer could be used for the finger grip, or forget the washer and just use the case rim as the finger grip. The adjustment nut could be eliminated and, using trial and error, round off the bolt head until the plunger stops at the correct position to allow wiping the lube off the bullet base prior to ejecting.

Update:

After using the simple cutter and prior to making the improved design above, I was referred to a commercial unit that incorporates all the needed features, see the photo below. The spring and adjustment nut is located inside the housing.

The unit is available for sale at http://www.ideadevgroup.com/waxmeister.html.

A YouTube Video displaying how it works is at http://www.youtube.com/watch?v=YdGgnfouiEI.

I ordered one of the IDG WaxMeister units with two cutters, .40cal & .45cal. It's well made, works as advertised and it can be adjusted to expose a small portion of the base for wiping the lube off prior to ejecting the bullet, which was a pleasant surprise. BTW, the cutters are standard cartridge cases that have the primer pocket drilled out and the neck ID expanded to the required dimensions. Therefore, if you'd like to save $5.95 each for additional cutters, one can be made from a fire-formed & un-resized case, or use any cartridge case assuming you have a neck expander large enough, which I did not.

If you pan lube and are having problems with lube adhering in the grooves when "punching out" bullets, then the WaxMeister is the tool for you. From my point of view, at $25.95 + $3.00 shipping, it is certainly not worth the effort to make one. Darn, it looks like my design, noted earlier, won't make it from the drawing board to production. Another missed opportunity at great wealth.