Evaluations & Recommendations for Lead-Alloy Hardness Testers

Retrieved: 01/08/2015

Having participated in online discussions concerning lead hardness testers some time ago, I thought I'd post some of my comments and observations here. The threads discussed the preferred tester for black powder cartridge rifle (BPCR) shooters and the pros/cons of the four readily available units (SAECO, LBT, Cabine Tree and Lee Precision). I’ve used all four. But before discussing the individual testers, the subject of lead hardness and the Brinell Hardness Number (BHN) should be touched on.

Until recently the BHN value of 5.0 has been assigned to what bullet casters commonly refer to as 'pure' lead. Therefore, three of the four testers to be discussed are either calibrated to directly read 'pure' lead as having a BHN of 5.0 or come with a BHN conversion chart based on the same value. More recently, some well-controlled long-term testing has indicated that the correct BHN of 'pure' lead lies in the range of 4.3 to 4.5 depending on the true purity. 99% pure lead may measure 4.5 whereas 99.9999% pure lead may approach a BHN or closer to 4.0, but would be unrealistically expensive for bullet casters to purchase. I have very recently tested some 'pure' lead and essentially substantiated the above noted experiment. The lead measured a BHN of 4.2 to 4.3. But the penetration technique used by the following testers is not a highly accurate method to measure and determine the true BHN value of a lead alloy. Therefore, attempting to measure hardness to a decimal point is highly questionable. Hence, assigning a BHN value of 5.0 may be as accurate as using 4.5. Fortunately the bullet caster does not benefit from knowing the hardness to decimal point accuracy. With the above comments in mind, following are my evaluations of the four commercially available testers plus a discussion on two low-cost techniques.

The SAECO tester (http://www.redding-reloading.com/index.php?option=com_content&view=article&id=84%3Asaeco-lead-hardness- tester) has been around for many years. It certainly has a small and handy form factor, but will not test ingots and is limited to shorter bullets unless the bullet is cut shorter for testing. It's the highest priced of all and requires using a conversion chart to obtain the BHN. The chart is based on pure lead having a BHN of 5.0. Although I have not owned a SAECO, I have tried one and did not like it for soft alloy testing. It may work fine for the harder alloys typically found in hard-cast bullets, but is inaccurate when measuring pure lead or the softer alloys used by BPCR shooters.

The LBT tester (http://www.lbtmoulds.com/hardtester.shtml) has also been available for many years. It's the only tester that is directly calibrated in BHN (no conversion scale is required). It's fast and easy to use, but does not work well on ingots and is limited to shorter bullets unless the bullet is cut shorter for testing. It seems to work fine for the harder alloys typically found in hard-cast bullets, but is inaccurate when measuring pure lead or the softer alloys used by BPCR shooters. I sold my LBT tester a couple of years prior to authoring this article, so I'm unable to provide a decent photo of the unit. You'll have to go to the LBT web site listed above to see a small image of the tester.

I own the Cabine Tree Dual Purpose Tester. Cabine Tree LLC offers two tester models. The Standard Lead Tester is designed for only testing lead hardness. The Dual Purpose Tester not only measures lead hardness, but also bullet runout, case concentricity, case wall thickness and bullet roundness. The testers are extremely sturdy, very well made and versatile. They will handle just about any shape of lead, including standard bullets, thin sheets of lead and much thicker ingots. Testing is fast and repeatable. Another big plus is the ability to easily recalibrate the testers should something unforeseen happen such as knocking the unit off the loading bench on to a concrete floor. Both testers do require a cross-reference chart to obtain the BHN. The chart is based on a BHN of 5.0 for pure lead. I really like the tester due to its flexibility and ease of use and can vouch that Jim Cornaggia (owner of Cabine Tree LLC) is a great guy to buy from. He continues to support his products after the sale. The Cabine Tree tester is available from Buffalo Arms at www.buffaloarms.com/.

The Lee Precision tester is the latest lead-alloy hardness tester to be introduced for bullet casters. I'm a sucker for new technology or new apparatuses, especially when it comes to casting and reloading stuff. So when Lee Precision, Inc. introduced their very reasonably priced tester (http://leeprecision.com/bullet-casting/lead-hardness-tester/) I had to get one to try it out and to compare readings with the Cabine Tree unit. I highly recommend the Lee Hardness Tester Kit. The three components (die, microscope & 'V' block) are very well made, relatively inexpensive and simple to use. It will work on any bullet length and can be used on ingots with a simple modification to the setup.

By the way, having a background in optics, the one thing I always check for when purchasing an optical device is what the lenses are made of. It's especially important when cleaning the lenses as some cleaners can etch plastic. Even with the appropriate lens cleaning solutions, plastic is softer than glass and therefore more susceptible to scratching when cleaning. In the case of the Lee Precision 20X hand held microscope that comes with their hardness tester, the lenses appeared to be glass, but many low-end optical devices have plastic lenses these days. Since the instructions did not mention the lens material and did not address cleaning the lenses, I checked with Lee. Lee confirmed the lenses are made of glass. Still, as a precaution & to minimize contamination, it's a good idea to keep the microscope stored in a closed plastic bag when not in use.

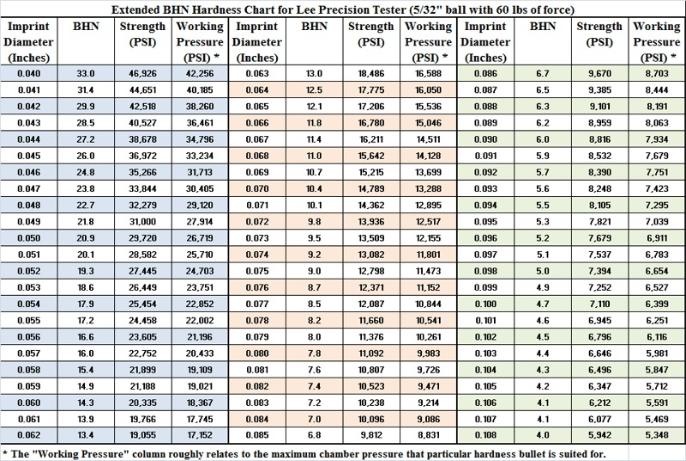

The chart that accompanied the Lee tester starts at a BHN of 8.0, which is fine if you're a hard-cast bullet shooter. Since BPCR shooters tend to use softer alloys, a chart extending the BHN value down to around 4.0 should be more applicable and can be used to test for pure lead. An extended chart is available online and has been passed around on some of the BPCR discussion forums, but it has some errors. Using the original chart provided by Lee, I worked up an MS Excel spread sheet, using it to check the accuracy of the original chart and also to extend the indent diameters and subsequent BHN values. See the chart below. Given a specific tester ball diameter and load, in this case a 5/32" ball and 60 pounds of load or force, the standard BHN formula was used. A couple of good articles on the Lee tester can be found at the following links:

http://www.castpics.net/subsite2/HowTo/Leehardnesstester.pdf

http://www.realguns.com/archives/118.htm

The Pencil Test

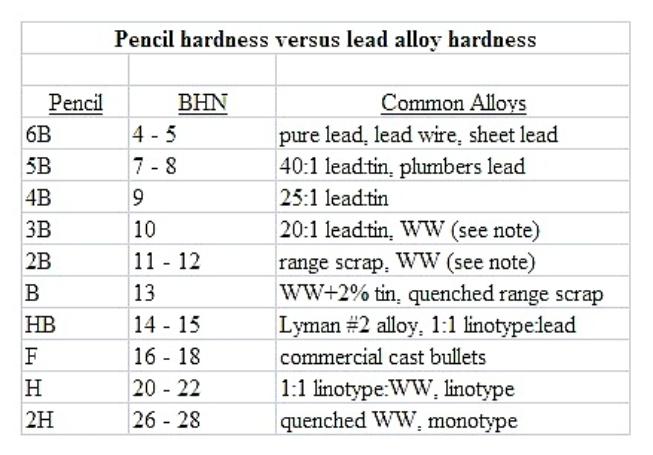

Using a set of drawing or drafting pencils of known hardness, for example, 6B, HB, H, 4H, etc., the relative hardness of lead alloy can be determined by attempting to scribe the surface using the flat tip edge of a pencil. Following is a brief overview of the technique:

Start by selecting or flattening a small section of the lead alloy surface with a file. The base of a large caliber bullet is sufficient. Prepare the pencils by peeling or removing any wood for a short distance away from the tip, leaving a short exposed section without any taper. Next, sand a flat surface on the tip with a file or 500-600 grit sandpaper, being sure to completely remove any taper. The exposed section should now be a short rod with straight sides, a flat tip with sharp 90 degree edges.

From the chart below, select a pencil that you believe to be softer than the alloy. Hold the pencil at 45 degrees to the lead alloy surface and press firmly forward along the axis of the pencil with the sharp edge. If the pencil skids over the alloy surface, even if it leaves a slight scratch, it’ s softer than the lead alloy. Work your way up to progressively harder pencils until you get to one where the sharp edge digs into the surface, pushing up a curl or mound of alloy in front of it. Using the largely subjective cross reference chart below, the hardest pencil that will NOT dig into the alloy is used to determine of the hardness of the alloy in question.

Following is a tabulation of subjective experimental data, some of which was reported in a long thread on the Cast Boolits forum with the understanding that it was accumulated by different untrained people, using different brands of pencils and on alloys of unknown age-hardening/softening. At least it provides a rough idea of lead hardness. As a 'coarse' reference, I included lead alloy Brinell Hardness Numbers (BHNs) from other sources based on the type of alloy tested.

Notes:

1) HB is the same as a common #2 pencil

2) WW (wheel weights) – Depending on the manufacturer, wheel weights can vary in hardness from 8 to 13 BHN.

3) An excellent high-quality set of drawing/drafting pencils is the Mars Lumograph set made by Staedtler Mars GmbH & Co. ($10 to $15 at office supply stores). Ranging in hardness from 6B to 4H, the set comes in a nice thin aluminum box, which is easy to take along when searching for scrap lead. But other brands of good quality pencils can be used including mechanical pencils with replaceable cores of known hardness.

4) For lengthy discussion on the pencil test go to the following link: http://castboolits.gunloads.com/showthread.php?t=75455

Simple low-cost hardness tester

Finally, if price is the overriding factor, you can make a simple low-cost tester with a single ball bearing and a vice, as long as you have access to a small amount of lead or lead alloy of known hardness. Knowing the hardness of the reference material is the key to this technique. The results will be at least as accurate as using one of the commercially available testers noted above.

You'll need two bottle caps, a vise, a 1/4" to 3/8" diameter ball bearing and a sample of lead or lead alloy of known hardness for the reference material. Pure lead is an excellent reference material since it has a known hardness. You'll also need a vernier caliper for measurements.

1. Start with two steel bottle caps. Set the caps on a brick and heat with a propane torch to burn out the plastic inner seals. Let the caps cool and dump out any burnt residue.

2. Melt enough lead to completely fill one bottle cap with the unknown sample, and the other with the known hardness reference lead. The surfaces should be as smooth and flat as possible when the lead hardens and cools. You may have to skim off some crud or oxides and re-melt the samples a couple of times to obtain good surfaces. Allow the samples to cool by themselves (do not quench with water to speed the cooling).

3. When the samples are cold, put the ball bearing between the two lead surfaces and squeeze the "sandwich" in the vise until the ball bearing is driven partly into both surfaces (just enough to make fair size indentations, but definitely not past the middle of the ball).

4. Remove the sandwich and, using the vernier caliper, measure the indentation diameters as accurately as possible. Using the following formula, calculate the hardness of the unknown sample.

Hu = Hr(Dr)(Dr)/(Du)(Du)

...where

Hu is the Brinell Hardness Number (BHN) of the unknown sample

Dr is the diameter of the indentation formed in the reference sample

Du is the diameter of the indentation in the unknown hardness sample

and Hr is the BHN of the reference sample

Assuming you know the hardness of the reference sample, this method is as accurate as your ability to measure the indentation diameters. A relatively smooth surface is necessary to provide a "clean" diameter to measure. A rough surface will throw off the answer because you may not get a true diameter to measure. As noted in the beginning of this article, the BHN value for 'pure' lead can vary. If you're using pure lead as the reference sample, you'll have to decide on the BHN value to use.

The measurements should be taken shortly after the samples have cooled as lead/tin alloys will age soften and lead alloys such as wheel weights with antimony will age harden.