A Black Powder Burn Rate Tester

Retrieved: 12/22/2014

The quest for the ultimate, fast black powder seems to be an obsession with many pyros. In my case, I relinquished the quest after having achieved a reasonable, lift quality powder. However, after having become interested in girandolas, the consistency of my black powder emerged as the paramount concern. The concern motivated me to develop this simple electronic means of measuring black powder burn rates. It has been an interesting project and is simple enough that I thought others might be interested in the design.

The intent of this design was to produce a stand-alone timer that didn't depend on a computer or video camera to make consistent and accurate measurements of the burn times of a uniform train of black powder. A human being with a stop-watch meets the goal of stand-alone functionality, but consistency and accuracy is low because of reaction times of the nervous system. Therefore, I designed a simple circuit to control the contacts of a stop-watch start/stop button. Probably the biggest challenge of this approach is to find points on the circuit board in a common digital stop-watch from which to connect control wires . The picture shows a bottom-of-the-line stop- watch purchased from MVP for $5 US. The metal traces that connect to the switch are very small, but quite accessible. A steady hand and a fine point soldering tool are required to attach wires to these points so they can be controlled externally by a controller circuit. This stop-watch would have served the purpose very well, but I eventually opted for a $20 digital stop- watch because I liked the very large numbers it had in the liquid crystal display.

The schematic of the controller circuit will be briefly described here. All of

the parts were purchased from Radio Shack or BG Micro for less than $18 total.

The circuit uses two micros-witches to sense the start and stop times of the

burning train of black powder. The switches are held with the "normally open"

terminal connected to the "common" terminal by a single thread which is

positioned across the powder train. When the burning powder severs the thread,

the micro-switch delivers a change of state through a CMOS debounce latch to

one of the inputs of a one-shot circuit. Since the 74HC123 is a dual one-shot

device, one of them is used to detect the start time and the other is used to

detect the stop time. Both of these events cause a one-shot to put out a 1/10

of a second pulse to a DIP relay which closes the contacts of the stop watch

start/stop button. It's a very simple circuit that is relatively easy to

build.

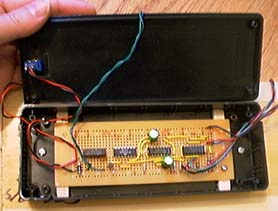

This picture shows the circuit board mounted in the enclosure box . A Radio Shack (cat. no. 276-170) proto board and project box (cat. no. 270-1808) were used at a cost of about $6 US for both. A battery pack with four AA batteries is mounted on the outside of the enclosure for easy access.

This shot shows the enclosure box with the lid in place. The battery pack and large display, digital stop-watch are shown mounted on the top of the box. An on/off switch is mounted at the end of the box beside the battery pack.

A 4 foot length of 1 inch X 1/8 inch angle is used for containing the powder train. This is mounted on a long wooden platform made from lengths of 1 X 4. Wood mounting brackets have been made with notches in them to cradle the piece of angle iron. The angle merely rests on the bracket, but is not securely attached. This facilitates easy removal of the angle for cleaning between burn tests.

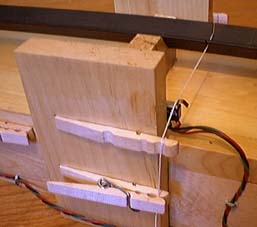

This is a close up of the place where the start thread is secured across the angle iron. For illustrative purposes, a large, white string has been used so that the placement of the thread is clearly visible. A common clothes pin secures the thread at both ends and eliminates the need to tie any knots. In actual use, a very fine, artificial fiber thread, such as fuzzy nylon, is used because it melts very quickly upon contact with the black powder flame front. A groove has been cut in the angle iron so that the thread is suspended very close to the powder train. The start thread is positioned 6 inches from the end of the angle so that the train of powder can extend beyond the start thread by about 4 inches. This gives the flame front propagation a chance to stabilize before timing of its speed begins.

The stop thread can be secured by an identical arrangement at either 45 cm or 100 cm from the start thread. The wood block which holds the stop micro-switch can easily be moved by removing the two screws which secure it to the platform. This angle shows that the micro-switch has a small restraining block glued to it which limits the travel of the switch actuator. This shortens the time for the switch to register the change in state when the thread has been severed by the flame front.

A small bolt has been installed at the start end to help secure a piece of visco under it. The visco gives the operator a chance to retire a few feet before the powder train flares.

This is the complete unit from a distance. Data gathered from using it to test various aspects of the black powder manufacturing process and the effect of different kinds of charcoals will be posted below as it is taken. If there is sufficient interest in the timer circuit, it may be worth the effort to draft up a circuit board that would greatly reduce the effort to construct it. If you have an interest in obtaining one of these circuit boards, let me know.

Here is a nice picture of the tester during a burn test. It's amazing how much fire and smoke a little train of black powder can make. The burn time of the test is so brief that I barely caught it before the flame front reached the stop thread. Below is a table containing the results of my first burn rate tests. All of my powder samples were manufactured by me with 3 hours of ball milling. I used home-made charcoal made from local weeping willow. Most of the tests were conducted during a warm sunny afternoon in the shade of my garage where the air movement is kept quite still. NOTE: Tests marked with an asterisk were taken at about 8pm after the ambient temperature had cooled to about 70 degrees F. from a high of 82 degrees F. Even with this small number of data samples, it appears that test result dependence on ambient temperature is significant.

Test Grain Size Burn Time (sec) Burn Speed (cm/sec)

1 -20+40 0.72 138.9

2 -20+40 0.70 142.9

3* -20+40 0.77 129.9

average average

0.73 137

Test Grain Size Burn Time (sec) Burn Speed (cm/sec)

1 -10+20 0.73 137

2 -10+20 0.76 131.6

3* -10+20 0.85 117.6

average average

0.78 128.2

Test Grain Size Burn Time (sec) Burn Speed (cm/sec)

1 -4+10 0.58 172.4

2 -4+10 0.60 166.7

3 -4+10 0.59 169.5

average average

0.59 169.5

More tests were done on Aug. 11, 2001 to look at the effects of different

kinds of charcoal.

Weeping Willow-Branch

Test Grain Size Burn Time (sec) Burn Speed (cm/sec)

1 -10+20 0.57 175

2 -10+20 0.59 169

average average

0.58 172

Poplar from Phil Hurley

Test Grain Size Burn Time (sec) Burn Speed (cm/sec)

1 -10+20 0.67 149

2 -10+20 0.64 156

average average

0.655 153

Black Willow-Trunk

Test Grain Size Burn Time (sec) Burn Speed (cm/sec)

1 -10+20 0.59 169

2 -10+20 0.57 175

average average

0.58 172

Black Willow-Branch

Test Grain Size Burn Time (sec) Burn Speed (cm/sec)

1 -10+20 0.53 189

2 -10+20 0.55 181

average average

0.54 185

Comments and suggestions from visitor feedback:A great idea has been submitted by "mike.j" for building the tester without the need for an electronic controller. A drawing of the concept can be found here. It uses three micro-switches instead of two. The first and third ones are at the start and stop points as they were in the original tester. The second switch, and its accompanying thread, may be placed anywhere between the original two. The ingenious idea is that the first switch, when its thread is burned, will close the stopwatch contacts by completing the circuit through the closed second switch. This causes the stopwatch to start counting. When the thread for the second switch breaks, the second switch opens the circuit. The third switch can then close the contacts again to stop the counting.

[subpage for circuit]

Schematic and Parts List Page

Just a few additional details... R15 in the schematic is listed as 33K ohms, but it is not a critical value. Another 47K resistor would work fine. The stop watch I ended up using is called a Cronus Pro Survivor which I bought for $19.99 US. The $5 stop watch in the picture is a Synchrotimer X-1000.

Parts list from BG Micro

(2) SWT1023 - Lever Mini Switch.................$2.50

(1) BAT1016 - 4 "AA" Battery Holder..........$0.79

(2) CAP1019 - Electrolytic 1 uf/100Vdc.........$0.78

(1) REL1006 - 5/6V Dip Relay.......................$0.99

(1) ICSHC123 - 74HC123...............................$0.35

(1) ICSHC00 - 74HC00...................................$0.25

(1) ICSHC02 - 74HC02...................................$0.25

Parts list from Radio Shack

(1) 270-1808 - Project box...............................$2.98

(1) 276-170 - perforated proto board...............$2.98

(1) 276-1114 - silicon diode, 1Kv, 2.5A ..........$0.49

(1) 275-612 - toggle switch..............................$1.49

(1) 271-1347 - 1/4 watt 100K ohm res. 5 for...$0.49

(1) 271-1342 - 1/4 watt 47K ohm res. .. 5 for..$0.49

(1) 276-2058 - 2N4401 transistor....................$0.49

(4) -------- AA alkaline battery................$1.99