Topic: I think i'll make some blackpowder...,

Retrieved: 01/19/2014

Last Post: 06/09/2009

I don't know about you guys, but I find it deeply disturbing how little detailed information there is available on the internet about how to manufacture explosives in the privacy of our own homes, safe out of the reach of meddlesome government regulation. It's all fine and good that a person with proper mechanical skills can build virtually any type of gun he wants out of unregulatable raw materials in his basement without the busybodys of the nanny state even being aware of it, but precious little good those guns will do us without ammunition to fire out of them. Obviously the right to bear arms implies a right to have ammunition, and we all know the only rights that are worth a damn are the ones we are willing to seize with our own two hands.

I can't remember if I mentioned before that I once majored in chemistry at Michigan Tech many years ago. Unfortunately I flunked all my classes and ended up joining the Army after one year. Of course after my time fixing guns in the Army I also served in the National Guard long enough to go through explosives & demolition training down at Fort McCoy as a combat engineer. They really ought to be more careful about who they give these kinds of training to, and limit it to Brady Campaign contributors only. But anyway, I now feel fully qualified to blow all my fingers off in the name of science.

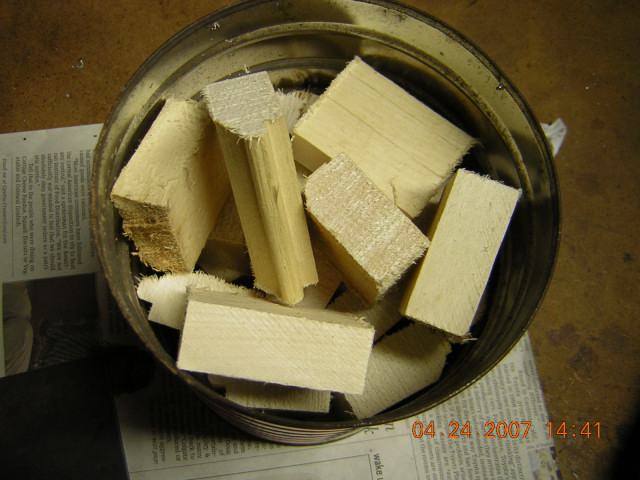

First off I need to prepare some charcoal. Ideally we want to make our charcoal out of knot-free willow wood, but I don't have any willow. I don't know what the disadvantages of using a softwood like pine would be, but I'm going on the theory that we want to use a soft hardwood. At least, I assume willow is soft. Anyway, it stands to reason that we don't want anything really hard like oak, maple, hickory, or ash. This is because the charcoal retains to some degree the characteristics of the wood it is made from. Hard dense wood is going to make charcoal that is hard to pulverize, and any powdered charcoal we do produce will probably also be dense and non-porous on a microscopic level. We want soft porous charcoal that's easy to grind up fine, and full of pores on the microscopic level so the other ingredients of the powder can enter right into the individual charcoal grains as intimately as possible.

I cut up enough scraps of knot-free poplar wood to fill this coffee can.

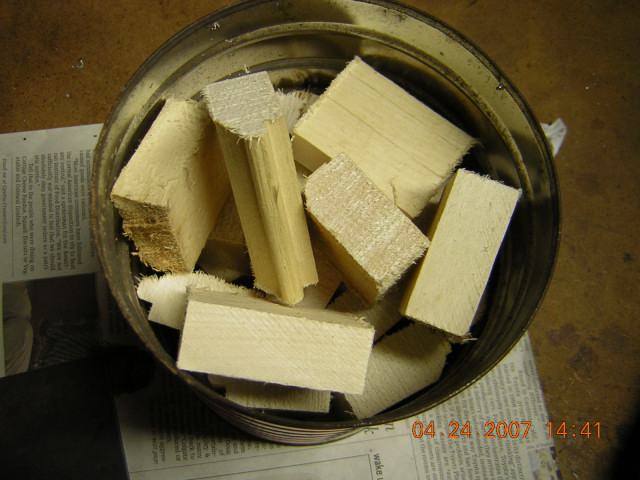

The proper scientific method here is to use a gallon paint can with maybe a .100" hole punched in the lid, but all I had was a rusty coffee can. So I wired this fine piece of sheet steel on there as a lid. The crack all around the rim is plenty to let the gaseous crap out as it is produced by the charcoalification process, without any additional holes.

Having got a good fire going in the woodstove, I toss the can in there. You could also use a gas fish boiler or grill for this, outdoors. Or use a larger steel drum and build a big bonfire around it.

Shortly we can see flames coming out of the cracks and holes. Under some circumstances the gases coming out might not burn well, and just be nasty carcinogenic smoke, but in this hot stove they burn right up. Scientifically speaking, this is all the resin and other non-black stuff breaking down and evaporating out of the wood, leaving us with the black color that is necessary for gunpowder to burn well.

Later we see some gases still burning off.

But the flames disappear just a short time after that. I flipped the can over and let it go another 10 minutes, just to be sure.

After taking the can out, I let it cool plenty long before opening. The charcoal has so little mass, it can seem cool yet still have areas of high temperature which will start burning if exposed to oxygen too early.

There's the result -- nice clean charcoal. The volume was reduced about 50% compared to the wood I started with, and the weight much more than that.

We all know that charcoal has a great ability to absorb things, hence its use in charcoal filters for many purposes. In this case we want it to absorb the other components of the powder mixture, so it makes sense to use fresh charcoal that hasn't been sitting around for a long time getting all loaded up with cigarette smoke, tear gas, or whatever you have typically drifting around in your home

CStol338

April 24 2007

Fuzzbean, sometimes the information you are lookking for is in good old fashioned books like "DICKS'S Encyclopedia of Practical RECEIPTS AND PROCESSES or HOW THEY DID IT IN THE 1870'S" Page 207 article 2140. "To Make Gunpowder. pulverize seperaterly, 76 parts nitrate of potassa, 11 parts sulphur, and 13 parts freshly burned charcoal, and mix then with a little water, so as to form a cake when rolled out on a board. This is then dried on a clean sheet of paper placed in a warm situation, and afterwards crumbled in to grains. It will form unglazed gunpowder. The pulverized ingredients, thoroughly mixed, without the addition of any water, constitute what is called meal powder ; this may also be made by pulverizing grained powder very cautiously in a mortar, or with a muller. (See Porphyrization, No. 25.)"

Actually there are a couple of pages in this book on making explosives. Including a recipe for making percussion primers.

Great write up so far and I'm glad to see others endangering there lives like I do. haha

MicroGunWorks

April 24 2007

Check out back posts in rec.pyrotechnics for detailed and endless discussions about materials, proportions, and techniques. The "accepted" mixing process there is ball milling.

Fuzzbean

April 24 2007

Well here's the man for making blackpowder:

http://www.musketeer.ch/blackpowder/recipe.html Ulrich Bretscher

I forgot to check his information before I started, so maybe I overcooked my charcoal. Though I don't see any easy way to uniformly control the temperature of the process like he says is best, without a fancy oven of some kind.

His testing does show that the denser hardwoods are not as good as the porous ones, as I figured.

Well anyway, I loaded up my charcoal into my old Kenmore "BlastMaster 500" electric powder mill, and ground it on up.

I left it on the 4F speed for about 10 minutes, and got things ground down nice and fine. The whole pitcher thing was getting warm from the friction of the process.

Then I sifted it through this old brass window screen.

That Kenmore don't miss much.

Bubba45

April 24 2007

'Fuzz' I read somewhere that the best charcoal was made from willow ,aspen or birch. And the best source of salt peter was from bat guano or chicken manure leached through straw and hardwood ash.

http://www.traditionalmuzzleloadingassociation.com/

Fuzzbean

April 24 2007

As Bubba says, the really correct way to get saltpeter (potassium nitrate) is to scrape old fermented bat doo-doo out of caves. By leeching water through the bat doo-doo you get a solution that, if i remember right from college, actually contains sodium nitrate. You can make powder out of that, but it absorbs water out of the air very badly and so don't work so well. But then it's easy to leech potassium hydroxide out of wood ashes, and mix the two liquids together. All the ions start dancing around loose in solution together, and pretty soon the potassium and sodium ions get to eyeballing each other's womenz, and before you know it you end up with potassium nitrate and sodium hydroxide. These are easily separated using the same processes used in the old days. I think that one Foxfire book covers all that stuff in more detail.

Now we got bats in Upper Michigan, but unfortunately no caves. It may also be possible to substitute Army mashed potatos for the bat poop and ashes, but as a civilian I decided to wimp out and use saltpeter I bought from a drug store instead. On the right is a 6 ounce container I just bought recently for $2.29, and on the left is some older stuff I got from the Fuzzbean Saltpeter Storage Bunker.

Since various recipes for blackpowder call for mixing saltpeter, charcoal, and sulfur in ratios of from 75/15/10 to 75/12.5/12.5, this 12 ounces of saltpeter ought to give me one pound of powder.

Normally I like to grind the saltpeter into a finer flour in my BlastMaster, but the older container of saltpeter wasn't sealed and due to the damp storage conditions underground it was quite clumpy and loaded with water. This was a real headache, but finally I got it halfway ground anyway.

hammermill

April 24 2007

here at bunker 47 unfinished projects

the favorites for pyro effects is white pine not yellow

for lift charges or bursting

willow maple or grape vine are all preferred

i under stand hemp is also a high energy charcoal but my panel of independent testers keep calling for munchies and more testing.

for pulverizing a stamp mill or ball mill seem the likable result

so onward to the boom!!!!

Fuzzbean

April 24 2007

There it is, it's white stuff.

Fuzzbean

April 24 2007

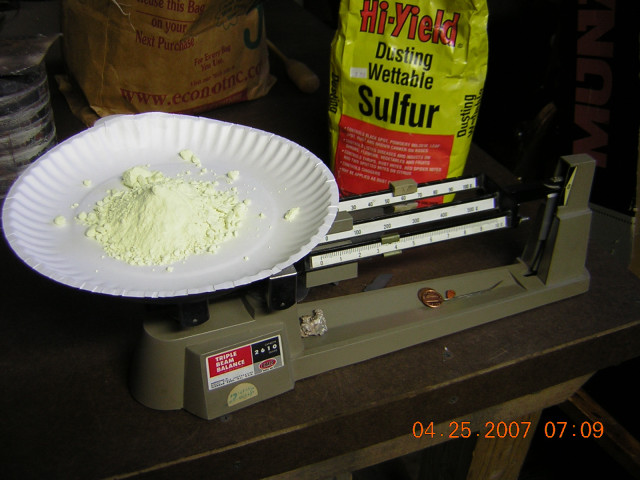

Now the sulfur. You can buy "Flowers of Sulfur" at any drug store. It's made by sort of a distillation process, and extremely pure. I read in that Foxfire book that you should not use it for powder, though why not wasn't explained. It looks like a very fine powder, and is chemically the right stuff, but possibly the condensation process in its manufacture makes the individual grains too slick, like hard little balls. I'm just guessing. In fact, I have used flowers of sulfur before, with fair results. But this time I'm going to try out this cheaper sulfur I got from a garden supply store a few years back. It's only 90% pure, but the "wettable" aspect sounds promising. Anyway, it was only $3.50 for 4 pounds -- enough to make up to 40 pounds of blackpowder. It does say "Hi-Yield" too; that's just what I want.

hammermill

April 24 2007

me thinks flowers of sulpher has a high acid content make its presence with any chlorates dangerious

Fuzzbean

April 24 2007

Here I'm weighing out 2 ounces of sulfur, allowing for the weight of the paper plate. Everybody ought to have an accurate gram scale for chemical work like this. This particular scale is an older Ohaus, which was once a very popular model across the whole political spectrum.

Next 2 ounces of charcoal. I mixed this and the sulfur together well in the BlastMaster.

Here I'm thoroughly mixing all three ingredients together dry, by stirring carefully with a wood stick. It would be very unwise to use the BlastMaster at this stage.

After mixing, I took a small sample a good long distance away and tried burning it. It was quite hard to light, and burned about the same speed as loose smokeless powder.

Here I'm starting to stir in some water.

Some say wine is better, or stale urine. I have mixed in rubbing alcohol before, but this time used water with a small amount of liquid hand soap in it. My theory is that soap or alcohol will reduce the surface tension of the water, and allow the individual grains of sulfur and charcoal to get wet easier, down deeper in the pores and whatnot.

I really got it a bit too wet now. It's easy to add too much water, if you don't stir it enough and crush every clump as you work.

It's very important to really mix it now. It won't blow up when wet, so I was pounding and smearing it energetically with a hammer handle for quite a while.

I thought about using my mom's large rock tumbler with a few stones in it, but I've already made a big enough mess without that.

I was mixing it for about 30 minutes. I'd say that's about the minimum time.

I scrounged up this chunk of flexible vinyl type stuff, and spread out the mixture into a pancake about 11 inches long and maybe 1/2" thick.

Now it needs to dry a while.

hammermill

April 24 2007

good job fuzzy remenber kids to use wieght to measure

not volume.also a little calkcium carbonate will neutralize

the acid in flowers of sulpher.

Fuzzbean

April 25 2007

Quote (Mr Fudd @ April 25 2007,01:00) This is cool. So I won't get arrested if I ask my friendly neighborhood pharmasist for some saltpeter? What is it used for that a drug store would carry it? It's funny, but drugstores never carried saltpeter when I was a kid. But about 10 or 15 years ago it started showing up. I can't imagine what other people use it for, but I keep buying it and they keep putting more on the shelf.

I think if you explain that it's necessary to keep the quills from falling out when tanning porcupine hides, nobody will suspect a thing.

Dogbert

April 25 2007

It's a diuretic ( Causes you to retain less water in the kidneys, and piss more.) For folks with a high sodium diet, this can aid hypertension issues.

skippy

April 25 2007

Amateur fireworks guys make the fastest black powder by ball milling the stuff for anywhere from 3 hours to a over a day. It all depends on how efficient the ball mill is. Oh and I wouldn't use any old stones in a mill, stones can make sparks. Use lead balls. Properly ball milled black powder burns very fast, with a whump sound and it leaves only a slight black residue where the powder was lit. If anyone wants to ball mill (rock tumbler) black powder, take appropriate precautions, because although it is rare, the ball mills can blow up. Commercial blackpowder operations blow up now and then, even when every precaution is taken. Sand bag around the mill or use the mill in a large tire(s), something like that. If the mill were to explode it would be something of a shrapnel bomb.

It would be really neat to see how a relatively crude black powder stacks up against a commercial powder with a chronograph.

here's a couple of excellent links

http://www.wfvisser.dds.nl/EN/ballmill_EN.html

http://www.wfvisser.dds.nl/EN/bp_making_EN.html

Jetlag

April 25 2007

Don't tell me none of you never corned your own beef before?? Saltpeter is what makes it pink. (Hot dogs too) Just tell the drug store guy you got 40 lbs of briskets in the freezer that need cornin.

hammermill

April 25 2007

purchase of potasium nitrate is legal. i have had it delivered in 55 gallon drums

two venders skylighter and firefox sell it and the sulpher both in medical grade to the pyro industry and cannon shooters.

give some looooong thought before milling in a ball mill.

lead balls are a must. i even use a wooden drum with seperate drums for the charchol nitrate mix and sulpher final mix in. flash powders are even a bigger hazard

having not heard from fuzzybean i hope its not fuzz less bean

i am waiting for the screen and testing

we have used a small golfball motor to compare.

outfixs like goex use castiron bowls with huge wheels the roll around the bowl to incoprate the powder into intensly close contact.

mjdarby

April 25 2007

i would like the throw in a helpful resource for anyone who would like to get all of the supplies and know-how in one easy place:

http://www.unitednuclear.com/ United Nuclear

they have readily ground charcoal, sulfur, potassium nitrate, gram scales, and ball mills (including lead grinding media). you can also find other helpful lab equipment for mixing etc. they even have a recipe and instructions on the creation of black powder (not that any of us need them ;)

browse around too, you'll have to look around their site for some of this stuff. you may even find some other things you weren't looking for, but always wanted!

fyi, this isn't an advertisement for their website, i just get really enthusiastic about chemistry!

jeeper1

April 26 2007

Another source of potassium nitrate is stump remover sold in nurseries and wally world and home depot. I don't know if it is pure but it is the only ingredient listed on the container. Also I have found on occasion pure hardwood charcoal at wally world. It was with the BBQ supplies.

Fuzzbean

April 26 2007

OK, OK... I'm still alive, so far.

I've only made blackpowder a couple times before, and I think then I spread the mixture out real thin on a large sheet of flexible plastic and then put it to dry in the sun. That all worked well, but then I had to pound up the dry stuff into usable powder using a mortar and pestle or something. That made pretty dusty powder, and wasn't good for my blood pressure either although I wore leather gloves and only ground like 75 grains at a time while keeping both the unground supply and the finished product in covered containers far away from where I was doing the grinding.

So this time I thought I'd make a thicker cake, and then try to catch it at just the right stage of drying to grate it into grains through my window screen. The only major problem so far is that the glob is drying really slowly. It behaves something like cornstarch, where it looks pretty dry but if you poke it with your finger a few times liquid water puddles up on the surface again. The weather just isn't warm or dry enough here now to move forward very quickly.

We're getting some interesting links here. By studying the information in those links, a person could set up a bit more and make some first-class powder. I'm just trying out this super simple way to see what happens. I expect to produce powder that's usable in percussion guns, but maybe too slow for good results in a flintlock.

It sounds like the charcoal-making and the ball-milling are the keys to better powder.

scasa

April 26 2007

Maybe you could extrude it through a garlic press . Long skinny strings would dry a lot quicker and be easier to grind up.

Swede

April 26 2007

Touching again on the "survivalist" aspects of this, that is what the original Foxfire series was all about - self-sufficiency. Even if you never do it, knowing how to do it is a good thing. Understanding (and owning) flintlocks is also a good thing, because unlike every other form of practical ignition, the ol' flinter is self-sufficient.

Of course, you can take pretty much ANY metallic cartridge and pack it completely full of BP in a basement or garage reload operation, and it'll work. Large and heavy projectiles preferred. I don't think a .223 with BP would work on anything except squirrels, but consider the .45 long Colt - a recognized manstopper, and originally it was a BP load, of course.

It'd be interesting to research non-mercury recipes for percussion/primer compound. If you can make BP, and can fabricate a boxer primer from, say, beer-can sheet metal and some dies and a press, you can create effective cartridges like .45-70 from scratch.

1) Brass cases

2) Lead for molds

3) Black Powder

4) Some ability to create a crude primer

5) and of course a rifle

That'll set you up!

Fuzzbean

April 26 2007

Well it's only about 55 degrees out today, but at least the sun is shining, so I put the powder cake out to dry after breaking it up to increase surface area. Also some powder in the pan there that I grated up as a test. It was still wet enough to cling to the screen and stick back together to some degree, at that point. I don't want it to be dry and hard like concrete or anything, moist is better for safety anyway, but it can't be sticky moist.

Swede seems to be implying the matchlock system of ignition isn't practical... might have to teach that feller a lesson.

JFettig

April 26 2007

What would happen if you dried it into chunks like that then used it chuky? would it work like it would if its all crushed up?

I'm just thinking of those pyrodex pellets they sell for muzzle loaders. Could you make a mold for something similar to that and make your own?

mjdarby

April 26 2007

i'm thinking that if you were going to make pellets like that, then you would need to bind them up with something that wasn't water based. also, pyrodex is more powerful pound for pound than black powder and is less dense, so to get the same amount of umph you would have to make bigger pellets.

hammermill

April 26 2007

fuzzy cover it with a piece of clear sloping plastic sheet.. like a solar oven to speed the drying up. the slope is necessary to drain condensation off.

the pellets for pyrodex work because of a different chemical reaction to flame.

black powder will burn from the outside in in fireworks they add metals for color and call them stars.

Bubba45

April 26 2007

Watch it hammermill,you'll start a new fad ! Everyone will start making their own BP and adding glitter for effect everytime they pull the trigger

hammermill

April 26 2007

well if they did that they would be shooting stars

but seriousely they wouldnt burn fast enough to generate enough pressure to push a bullet. but the stars you see in the air from a exploding fireworks is what i am talking about.

ke6guj

April 26 2007

Quote (Fuzzbean @ April 24 2007,22:14)

I think if you explain that it's necessary to keep the quills from falling

out when tanning porcupine hides, nobody will suspect a thing.

Funny story there...

My sister's father-in-law is a hunter and has a nice collection of furs and mounts from his hunts. One item in the collection is a mounted porcupine. He said that that was the hardest thing he had ever skinned, and that the taxidermist told him, after he had it mounted, to never, ever, bring him another one

Fuzzbean

April 28 2007

My dad, oldest brother and youngest sister all graduated from Tech -- we just lived close by anyway. Keweenaw bay was still clogged with ice yesterday when we went by L'Anse and Baraga.

After some interruptions I finally finished grating up all the powder today. Fortunately the chunks had not fully dried even yet, as it becomes much more difficult to grind against the brass screen when dry. The pucker factor goes up, too. There is a point between to dry and hard on one hand, and too sticky and clingy moist on the other, where it broke up into grains pretty easy. It's much more irregular and dusty than store powder, though. I want to let it dry some more yet, but I think hot sunshine is my best bet.

I'm trying to round up something besides my flintlock to test it in now.

MicroGunWorks

April 29 2007

Quote (Fuzzbean @ April 24 2007,20:28)

Well anyway, I loaded up my charcoal into my old Kenmore "BlastMaster 500"

electric powder mill, and ground it on up.

you gonna use the ol' Blastmaster to mill the KNO3, sulfur, and the raw powder cakes too? That last one ought to make quite a photo, if'n ye got a high- speed camera with a really long lens...!

The pyro guys mill their cake powder in ball mills with non-sparking media at the end of LONG extension cords out back of the barn...

You'd probably get away with milling the sulfur and potasium nitrate (separately of course..) but I dunno about the cake powder.

nevadablue

April 29 2007

Fuzz, I wonder if a cheese grater would work better than a screen? You have a choice of sizes and sharp cutting edges instead of the round screen wires.

hammermill

April 29 2007

the grater sound like a good idea if the powder isn't too sticky.

my preferred method is to place the pressed puck between a couple sheets of canvas and then use a wooden rolling pin to break up and then run through a set of shifting screens to get the right size for the application.

i also ball mill the sulphur/charcoal mixture then use water/alcohol to mix in the potassium nitrate.

i have scrounged up most of the parts for a small roller mill but need to sort out some details before trying it out.

as a side note if you are thinking of using sewer pipe for ball mill jars make sure its hdpe pipe.

if a explosion occurs it will mushroom and not fragment in to shrapnel.cant find any look at fireworks suppliers

Swede

April 29 2007

Guys, DON'T use a microwave. It WILL torch.

How about this for a dessicant? get it as dry as possible with normal and safe methods. Then, put it in a tupperware or similar, and in the same sealed container, add some dessicant crystals like silica gel, or calcium chloride (drierite) to pull the remaining moisture. Might be worth a try.

One way to test the safety of a setup is to use a bit of real powder, like Goex, that's already dry. Real BP is ready to go and as powerful as BP can be. If your drying rig won't set off a pinch of Goex, it probably won't do it to your homebrew. Just a thought.

hammermill

April 29 2007

nix the chloride from coming in contact with the powder

and dont try the microwave idea in the house. the blackpowder will be degraded by the high temperature reached and may ignite . my fear with the calcium chloride is it abilty to generate heat as it asorbs moisture.

realise there is no safe way to make black powder only processes that are less dangerous than others. if something goes wrong it will all be over faster than the flash in the pan.

SamLS

April 30 2007

With rocket making moisture was the secret. Too much moisture and the rocket would go off but wouldn't go high sometimes just clear the launch pad the next one would go out of sight. The commercial fireworks manufactures use dessicant driers the one I saw looked like a enclosed trailer retrofitted to be a dryer. A food dehydrator may work well also if the ambient air is dry. You can use a heat lamp to help the process.

geodkyt

April 30 2007

Correct me if I'm mistaken, but isn't the last step in commercial BP production, rolling the grains in graphite powder to get a little coat on the outside for safety and consistency?

hammermill

April 30 2007

the correct way to polish the powder is to roll it in the ball mill without the balls to smooth the rough edges on the grains. a little bit of graphite is added for rifle powder to improve flowabilty. these glazed powders are considered to be more difficult to light as compared to non glazed.

nevadablue

April 30 2007

this is kind of interesting and may be useful to those of you with all your fingers still

hammermill

April 30 2007

if i remember my Greek mythology,my wife says i don't, didnt some one make a unfaithful lover a suit of Greek fire impregnated goat skin then it ignited in reaction to his sweat when the sun came out.

younger fellows DO NOT MAKE FLASH POWDER WITH SULPHUR. the reaction to the chlorides in perchlorate can cause a detonation just from chemical reaction. the explosion will ruin your hands if not more.

if you see a photo of kirk Saxon you will get a good idea

NOTE he was injured trying to make primers.

also in the USA m80,s can make soap on a rope a prized Christmas gift. indeed a lot of new restrictions in the pyro field came about because of them.

if you call a pyro supply and ask about them, you will make the no sale list in a flash.

hammermill

April 30 2007

> slow match

soak cotton string, maybe even braided, rope may be better in potassiun nitrate dissloved in water and let dry. nylon will not work

talk about slow lock time!!!!! this kind of slowmatch is safe to transport

dont foreget he will be buying urine and mixing it with wood ash. and no i mean no cnc

Fuzzbean

April 30 2007

I rounded up a couple candidate guns for powder testing -- my old 1851 Navy replica, and my M1883 Reichsrevolver. Only problem now is I don't know where any of my other loading supplies or equipment are at.

I remember when I was a kid trying to make rockets out of sodium chlorate and sugar. It seemed like our steel motor housings weren't strong enough. Then I thought if the fuel was in one solid chunk it would burn more controllably, so I dumped some sodium chlorate into a pan of melted sugar. That didn't work out well either. We gave up and had lots of fun shooting an old M1903A3 barrel I'd plugged the breech of, until it finally went off on loading and tore my buddy's wrist all open. Chlorates and perchlorates are nothing to be messed with -- they are too sensitive and prone to blowing up with real violence. They probably go into true detonation mode, in some cases. Sodium chlorate was super hygroscopic, too.

The standard saltpeter/charcoal/sulfur mix is much less sensitive to impact, and is pretty safe as long as you never grind or pound more in one place than you are willing to have blow up in your face. It would be very foolish to put a pound of it in an electric blender, of course. In the old-time powder mills they really pressed the cakes hard, then had some means of chipping them up into grains without generating too much dust. That must have been the most dangerous step, though I imagine the old roller type incorporating mills could also blow up if the "dough" got caked up and dried out on the moving parts. Most powder mills were built along rivers, and the buildings had three stone walls with a fourth disposable wooden wall facing the water. When things blew up they just replaced the roof and the one wall and carried on.

Probably that graphite glazing on commercial powder makes it more resistant to both humidity and static charges, as well as helping the flow. In my experience commercial powder is useless for matchlock priming. The match just won't set it off predictably like steel sparks will. If you crush a small quantity in a mortar and pestle to break the glazing it works a hundred times better.

I've read that the correct way to make matchcord is to use a lead acetate solution. If I remember right. Plain cotton cord seems to burn OK to me as-is, but I never see it for sale locally in the United States. They have it in every hardware store in Japan. In America it says "cotton" but always has a big poly core.

hammermill

April 30 2007

lead acetate will work great if you dont mind the lead in the fumes and little balls of the stuff dropping on the ground some of us are looney enough as it is.

Swede

May 01 2007

BP is legal to make, and is relatively safe stuff. For a confidence boost, like I mentioned before, get a 1/4 teaspoon little pile of GOEX commercial powder, and try to make it go off without flame. You can beat on it with a hammer all day. Remember, right here on this site, we had those videos of 20,000 volts of electricity arcing through a pile of BP. It didn't go.

The military used it for hundreds of years, transported tons in primitive ships, wagons, etc. There was an occasional accident, but it is nothing like the flash powder in that .PDF, or any other primer compound. So a little common sense and basic safety precautions will work.

As a kid, we used to take those "wasp" gun caps, the little red plastic cones, and empty thousands of them to create a pile of reddish powder, which made a fantastic M-80 type of charge. To make a quality bomb, we'd compress it like crazy, wrap it in hundreds of winds of duct tape, use cannon fuse, and to top it off, we'd layer it in clay, to make it look like a Wile E. Coyote or Snidely Whiplash cartoon bomb. It'd be waterproof, too.

One day, we took our two bombs into the woods. My buddy found a huge pile of dog crap, and decided to blow it up. We had to be fifty yards away, but even there, a huge chunk of fresh green dog doo impacted SMACK onto my face. I don't think we have ever laughed so hard, before or since, as I chased my buddy around, trying to wipe the dog doo on his sorry carcass.

Only now in retrospect do I realize that the powder that came out of those caps was friction sensitive and had sand in it to help it POP when the hammer fell. We were MASHING a dangerous quantity of that stuff with our hands. Stupid...

We also had a kid with a cool hook instead of a hand. He had made a pipe bomb. You know the rest. I suspect he didn't think it was too cool.

geodkyt

May 01 2007

Hemp cord makes good match, too. Check out re-enactor fabirc suppliers -- they sell it.

geodkyt

May 02 2007

Another poster has pointed out that, while glazing is normally done in commercial smokeless powder production, it is actually disadvantageous to do so with blackpowder.

hammermill

May 02 2007

it would be a lot of work graphite powder is available as a lock lubricant and i even bought some 5 gallon drums at a feed store, seems it was added to grain to help it slide down shutes and legs. it will slightly inhibit blackpowder ignition but a little goes a long way.

MicroGunWorks

May 02 2007

Marmaloon --

Sounds like a great idea, huh. So if this goes through, in Canada, it will be illegal to do the following:

Corn your own beef or make sausage, bacon, or hams(nitrates)

Etch silver (concentrated HN03)

Refine gold (HNO3 again)

Melt gold with a refining flux (chorates)

Make a pickling solution to remove copper flash from brass and silver after brazing (30% peroxide)

Make a "bright dip" solution for silver and gold (HNO3)

Bleach hair (30% peroxide)

Run a fuel dragster or model airplane (nitromethane)

Fertilize your fields with inexpensive nitrogen (AN)

But, you will say, of course you can -- you just have to be a permitted user, and (the part I like best), I'd have to check my liter bottle of HN03 weekly to see nobody stole any of it to make explosives!

Fuzzbean

May 04 2007

Quote (defender of liberty @ May 04 2007,08:35)

I got a roll of cotton twine at Wal-Mart for about a buck.

Twine sounds kinda thin... what diameter is that?

The 6mm cord I get in Japan is nice, but all the 1/4" clothesline I find in stores here has a poly core.

hammermill

May 04 2007

take several strands of the cotton cord and braid or twist together make what ever final size you want

i have been to take 6 strands for a core and then 4 strands woven to make the fuse but then again i enjoy tying my own crab rings. throw nets and stuff.

when i am making prop fuse i use black powder fines,

white glue,aluminum fines or magnesium, all mixed in a slurry and the fuse string pulled through the slurry.

if after drying water proof is a factor i coat it with nitrocellulose lacquer.

Bubba45

May 04 2007

What about all cotton yarn at a fabric shop,walmart has a fabric section.

Jaymo

May 05 2007

Where do you ger the nitrocellulose laquer?

hammermill

May 05 2007

skylighter and fire-fox both carry it its pricey at about 32.00 a quart

it is usually around 32 percent nitrocellose 58 perscent accetone and 10 perscent prolene i add some industrial dye for color

i also see it sold as a musical instrument finish at about 1/2 the cost above

MicroGunWorks

May 05 2007

For nitrocellulose lacquer, you can also just dissolve some double-base powder in acetone or lacquer thinner. That's what a lot of the pyro guys use.

It may not be strictly "nitrocellulose lacquer" but it seems to work fine.

hammermill

May 05 2007

i would be more inclined to use single base powders but for my uses it has never been necessary

i use lots of greendot in flame projectors

geodkyt

May 10 2007

Quote (Bubba45 @ May 04 2007,18:51) What about all cotton yarn at a fabric shop,walmart has a fabric section. The denser the weave, the slower (and more reliable) the burn. The thicker the cord, the better ignition.

Fuzzbean

May 13 2007

OK, I was down in Chicago for a while, but I'm back in the woods now so I started testing my powder. I dug out this old M1851 Colt Navy replica, which I've owned since I was about 15 years old:

Here's a couple "control" shots I took into a piece of oak firewood, using about 26 grains of 2F factory powder. That was close to a full load for the chambers of my revolver. I split the wood with an axe after firing the shots, to reveal the penetration.

I had some old Crisco I smear over the bullets, but after 15 years of sitting up in a hot attic that Crisco turned very strange, like some kind rubberized tar. A piece of it actually came out the barrel whole and hit the target and stuck there.

Here's a shot with the home-made powder. The recoil of the gun seemed very noticeably less sharp, but everything else seemed normal. The home-made powder is less dense, so the cylinder chambers only held about 20 grains. The bullets seated considerably deeper as they compressed the powder charge.

Another shot with the home-made powder.

Another one. Remarkably, this shot appears about equal to the factory powder in penetration. Variations in the wood, I guess.

I'll do some other form of testing later on.

Here's what the chambers looked like after firing 8 shots of the home-made powder, plus 5 with commercial powder before that. I think it was dirtier than normal, but nothing to interfere with normal shooting at this point.

Fuzzbean

May 23 2007

OK, having made gunpowder out of scraps of wood, and

http://www.homegunsmith.com/cgi-bin/ib3/ikonboard.cgi?act=ST;f=101;t=18148

percussion caps out of a pop can, there was only one proper thing to do -- recall my infamous

http://www.homegunsmith.com/cgi-bin/ib3/ikonboard.cgi?act=ST;f=30;t=15656;st=0

Yooper Assault Rifle

back to active duty.

I brought along a few plastic type caps for comparison.

The caps fit OK.

I had a scoop that would throw about 50 grains of commercial FFg powder. I didn't check the actual charge weight with my fluffy powder, but maybe 30 grains or so. I had to put my thumb over the grease fitting/nipple as I rammed the bullets, to keep the dusty type powder from all blowing out of the gun due to the large hole in this nipple.

I was shooting commercial .530" balls I got on sale at Wal-Mart years ago, somewhat loosely patched.

Here's the accuracy results for 10 shots at 25 yards. Every shot did hit the cardboard box at least, though one bounced off the ground first.

This burst of fire shows excellent dispersion.

This 1/2" ballistic-grade plywood was easily penetrated by my armor-piercing projectiles.

In another test, using a scoop and a half of powder, this exceptionally well- seasoned hardwood, nearly 3.5" thick, was also easily penetrated. There is nowhere to hide.

This piece of steel was originally en route to become the frontal armor of a Nazi German Sd. Kfz. 182 King Tiger battle tank, when the production lines stopped at the end of WW2. It was later formed into the bottom of a steel drum that I chiseled off to make my dad a burn barrel.

The awesome power of the Yooper Assault Weapon easily put a small dent into this incredibly tenacious material.

So much raw power was released in that last shot, that the bullet began to crack apart from the force.

I also fired one test shot with one and a half scoops of powder and a scoop of birdshot I scraped up off my dad's reloading bench. I used newspaper for wadding.

A couple pellets actually penetrated this heavy-duty hash can at 5 yards.

The overspray sunk deeply into this hapless ballistic plywood.

Thoughout this extensive 16-round torture test, I experienced absolutely NO failures of any kind. Except maybe the one shot I took with them plastic caps, the darn plastic got left stuck on the nipple afterwards like a ring. The pop- can caps just disappeared without a trace on every shot.

I think my home-made powder is much easier to ignite than glazed commercial powders, anyway.

Bismarck

June 09 2007

Hey mr. Fuzzbean I have a question about your BP. Did the grains come out a little "fluffier" (less dense) than commercial powder? If so, isn't there going to be a problem when pressing a patched ball against it turning it into FFFFFFFFG?

I wonder if there's anything we can add to the mixture or if there's any process that would make the grains a little "crispier".

By the way I used a mortar and pestle instead of the electric tornado blender of yours, that might be making a difference. What a messy propelant to make though

PS. I absolutely love your projects, especially that awesome playground- material assault musket of yours.

Fuzzbean

June 09 2007

I'm not too worried about the granulation. Putting some of my powder in a pile and igniting it, it burns more like you'd expect smokeless to burn, rather than the instant "poof" of factory black powder. I think better charcoal and more thorough grinding together of the ingredients would be big improvements.

But as long as it shoots, I'm calling it good.