Topic: Homemade black powder, once again, Valuable knowledge...

Retrieved: 11/26/2013 (30 pages)

Last Post: 02/16/2013

I've always thought that one should be able to make decent BP because, well, you simply never know when a supply of smokeless will be cut off, or when the zombies will attack. Also, it's fun and very satisfying. When loaded into traditional BP cartridges like .45-70 or .45 LC, you have the real deal - a capable cartridge of real power. None of this stuff is new... Fuzzbean had an excellent thread a while back. I do think it would be neat to compile, within a single thread, many ways of making good BP.

My goal for this new thread is to possibly present some ways to make BP at home, safely, with and without pure chemicals, and also, with and without certain equipment like a ball mill.

For those who don't know what a ball mill is, think of a big rock tumbler, filled with lead balls or other media, which grinds chemicals into a phenominally fine powder.

Materials: I have on hand very pure, pyrotechnic grade KNO3, charcoal, and sulfur. I also have on hand low-grade stuff... Stump Remover, sulfur for plant dusting, and charcoal. On the low-grade charcoal, most decent BBQ stores have compressed charcoal like Kingsford, which is pretty useless, but many also have real charcoal. If it looks like carbonized wood lumps, and is pretty light, it's charcoal. I won't go into making charcoal, but it is very possible to do at home, in a pinch.

So I will refer to a batch as either "pure" or as "Low Grade" meaning it is emergency powder from Home depot. One thing I did find that was pretty interesting is that the so-called "stump remover" from Home Depot is a GIGANTIC RIP OFF. It costs $6.00/lb, when you can buy pure KNO3 off eBay for $1.80 per pound. So if you want to mess with BP, buy 10 lb for $18 off eBay; don't buy stump remover.

I will do separate posts for the various methods I've tried... Please feel free to add your own thoughts, recipes, etc, as the idea is to create the ultimate homebrew BP thread for posterity!

Swede

Mar. 30 2008

Method number one: Green mix

Chemicals: By weight (use a GOOD scale) 15 KNO3, 3 charcoal, 2 sulfur.

Initial Prep: Separately, grind the chemicals down to at least a sugar consistency, or finer. The charcoal is hard to take from the big lumps down to a workable powder. The best way I found was to put some lumps in a heavy paper bag, and beat on them with a hammer, outside.

Procedure: My first attempt used low-grade chemicals from Home Depot, and consisted simply of combining the chemicals in a bowl, and adding enough hot water to form a dough/paste. I like mine on the thicker side, like bread dough. A thinner, runnier mix will actually work better, but is harder to mash or grind.

Use hot tap water. KNO3 is MUCH more soluble in hot water than cold, and the idea is to dissolve as much of the KNO3 as possible. That allows it to migrate nicely into the pores of the charcoal, making the wet method better than a dry mix, by far.

The chemicals are manipulated until the mix is uniform. There should be no chunks of KNO3 or sulfur. You cannot hand-grind too much. The more you work it, the better. When you feel you are done, squeeze the mash into a ball, rub the ball through a section of aluminum window screen into a pan or a piece of paper, and allow to dry.

Results: This is emergency powder, made from home depot materals. Remarkeably, it worked pretty darned well, better than my previous attempts at a green mix. A pile perhaps 1/2 inch tall burned sharply, WHOOSH, in about 1/5th of a second. In a firearm, it would definitely do the job we need.

Conclusion: Low-grade moist green mix works, but it is horribly labor intensive, and useful only when there is no other alternative. Up next: Alcohol precipitated BP.

I will get some pictures up ASAP. Oh yes, the huge clouds of BP smoke hovering next to my home... smelled good!

Swede

Mar. 30 2008

One thing I didn't mention is cost. I don't even know what a pound of commercial black powder sells for these days, but the homemade stuff can be very cheap. Charcoal is essentialy free. The KNO3, if bought pure from any number of sources, is maybe $2/pound. Sulfur, a bit more at $3.50 per pound for the good, pure stuff, perhaps $1/pound for the garden sulfur, which seemed to work OK. So it looks like you can make a pound of BP for maybe $2 to $3. That's a lot of shooting for 3 bucks.

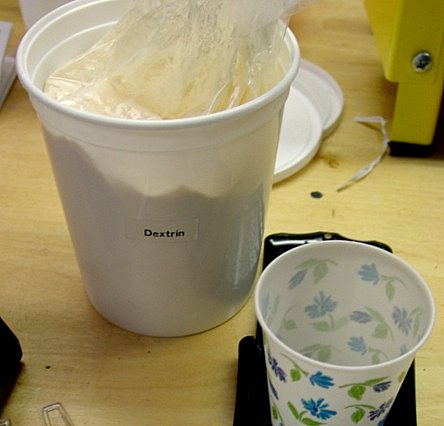

One thing I didn't mention in the second post is Dextrin. Dextrin is used as a binder. If you want your BP to be "grainy" rather than tending to devolve into dust, you can add dextrin, anywhere from 1% to 5% by weight. The more dextrin, the harder it will bind, and the more granular your BP will remain. But it will slow the burn rate a bit. I'll take that, as I dislike when homemade BP gets dusty and too fine.

Dextrin is a type of carbohydrate. You can buy it pure for $5/pound, or you can make your own for maybe $1/lb from corn starch! Spread the corn starch on a cookie sheet and bake at 400 degrees F. for several hours. You are done when the snow white corn starch becomes golden tan.

I'll also try some experiments with graphite. Graphite powder is what the commercial makers use to give their grains that nice shiny appearance and a great flow.

hammermill

Mar. 30 2008

here in the pacific northwest powders goes for around 115 to 20 a 1 pound can

the real killer is hazmat shipping fees.

a way to test preformance would be a small golf ball motor with range measured to indicate preformance

Swede

Mar. 30 2008

Quote (hammermill @ Mar. 30 2008,17:56)

Well, I finally found my battery charger, and I will describe the next method,

which is called "Alcohol Precipitation." Really easy, no equipment required

beyond the chemicals themselves, and an ELECTRIC heater. No other variety

will do! This whole thread is a "big boy" thread, and if you don't understand

the dangers involved, don't make BP! I certainly didn't invent this process.

I read about it in an excellent book, and I hesitate to post this because of

copyright, but I don't think the method itself is proprietary.

Method #2: Alcohol precipitation.

Chemicals: By weight (use a GOOD scale) 15 KNO3, 3 charcoal, 2 sulfur. Dextrin is optional - I added 1% dextrin to see what it would do.

Initial Prep: The Charcoal and the sulfur need to be very fine. You can grind them to flour in a ball mill, by hand, or with a food processor or coffee grinder. If you use one of those even once for a particular chemical, label it, and never use it again for anything else. NEVER USE A KITCHEN IMPLEMENT TO GRIND A MIXTURE LIKE BP. Boom!

The KNO3 can be lumpy because it will be totally dissolved in the process.

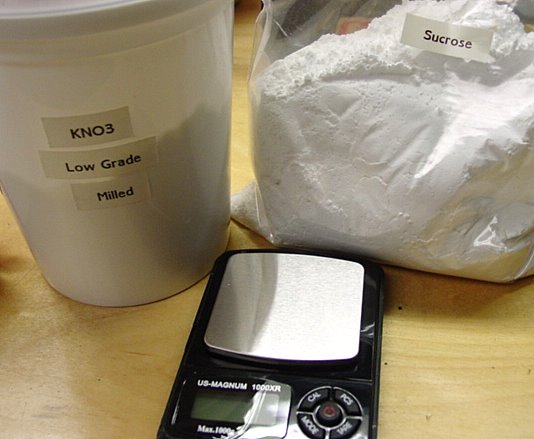

As part of my journey down the pyro path, I set aside a cabinet where I am storing raw chemicals. For the purposes of the picture, I mixed a few up, but oxidizers need to be separated from fuels, at a minimum, and BP is best stored in an ammo box away from everything else. I have a penchant for being very organized... I label everything, and try to keep things neat.

I have an old surplus lab heater which I put to work. Do this outside, or in a shed where you wouldn't mind fumes, or worse.

For this batch, I used premium chemicals from Skylighter. The recipe recommends a 500 gram batch for a first effort, and a 1 liter Pyrex beaker is perfect for this. I weighed out the chemicals, added the dextrin, then added 3/4 cup of hot water. Use a plastic spoon or a wood paddle and mix it up as much as possible. It will be pretty thick.

Put it on the heat, and slowly bring to a boil, stirring CONSTANTLY. There is little danger from the batch itself because it is damp, but spatters dry quickly and can be a hazard. Be sure to use pyrex or similar. A coffee carafe might work nicely.

Stirring is important - it distributes the heat, and prevents hot spots that could dry out in the beaker. As it heats, all of the KNO3 dissolves, and the mix becomes about as thick as tomato soup. Oddly, the batch expands a bit, perhaps due to trapped air, and if you stop stirring, one of those weird "skins" will form on the top, so keep stirring! It took maybe 15 minutes to bring to a boil. Once it has boiled for a minute or two, remove from the heat.

The next step - do this OUTSIDE, with a FACE SHIELD! Wait a minute or two, then you slowly add 1/2 cup of denatured alcohol to the mix, stirring furiously. The alcohol will flash to a boil. Be careful, add it slowly! Immediately, you'll see an interesting change, as the soupy mix becomes more granular. It took 5 minutes to add al the alcohol, and at the end, the mix had cooled off considerably, and was a texture like oatmeal.

This is then spooned into a square of t-shirt material, and with gloves, you wrap it up tight and form a ball. Twist the t-shirt so it compresses as much liquid as possible from the ball. For a 500g batch, I think maybe a tablespoon of liquid came out.

This ball is then screened. I made a frame of window screen that would fit a teflon-coated paint tray, which became my BP tray. Screen it while its wet, and it'll go through as fluffy nuggets or BP flakes.

Let it dry away from ignition sources.

I used a newspaper to transfer the dried BP to a tub. I'll be completely honest... this big pile of BP scared me a bit. i was glad to see it safely in its container.

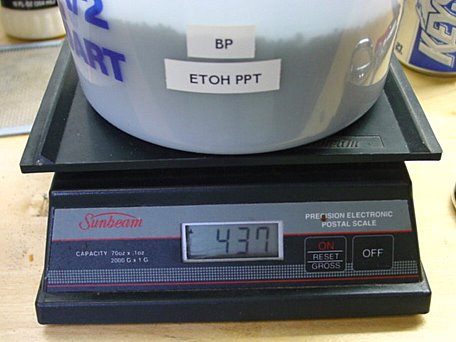

Yield: 437 grams. I probably had closer to 460 grams, as I had already burned some testing.

How'd it work? You be the judge! Here's a movie showing the burn rates of green mix, vs. the BP made using this procedure. Please don't laugh at my sandals... it was actually kind of hot today.

The first sample, to the left, is crude green mix as one might make with dry ingredients. The sample to the right is the alcohol ppt sample.

I'd say if you don't have a ball mill, this is probably the best BP you can make. The next process is going to be ball-milled BP, and is supposed to be the gold-standard for homemade BP.

hammermill

Mar. 30 2008

i press mine into pucks and the after it dries crush it and screen it to get the corser granulation then into a ballmill to polish of the rough edges

the first time 50 lbs shows up in a box of 5 ten pound bags i was more then nervious

remenber the alachol is combustable so do this outside to be safe

MADJACK

Mar. 30 2008

Excellent writeup Swede!

I do have one question, I thought plastic was verboten with BP because of the static I suppose. Any input?

Fuzzbean

Mar. 31 2008

I'll have to dig up some of my powder and make a video. I think it was like your "green" stuff, or just slightly better.

I have a golf ball mortar we can pass around as our official test device. Even with commercial powder it only shot about 20 feet -- must be too short or something.

That second batch of powder looks very impressive.

Swede

Mar. 31 2008

Quote (MADJACK @ Mar. 30 2008,23:07)

I thought plastic was verboten with BP because of the static

This is just the sort of info I am looking for, the "do's and don't" of doing this safely. Didn't we have a thread here once (the electronically-ignited BP thread) that showed a small pile of BP utterly ignore a shower of electric sparks?

I'm thinking there are two sorts of sparks. Sparks from a grinding wheel or a flintlock literally throw small pieces of burning metal into the BP and it'll ignite, but electrical sparks? Certainly I'd want to avoid them, regardless.

Hammermill, how did you press your BP into pucks? You are the expert here, anything you can share would be very useful. Thanks!

Postscript to the alcohol precipitation recipe...

After I had slept on it, I realized the amount of liquid I had wrung out of the ball in the t-shirt was really more than 1 tablespoon. I wish I had saved the liquid, because if it was water, it could have carried off significant amounts of KNO3. If it was alcohol, almost no KNO3 would be dissolved in it. So the next time I do this, I'll figure out if it's water, or alcohol.

If it is in fact water, it may be prudent to add a bit more KNO3 at the start, to make up for the inevitable loss when you wring the ball of BP.

Swede

Mar. 31 2008

One more thought - I was visiting a pyro site, and they were talking charcoal. Charcoal is the most important part of the BP, and to get really high-grade BP you need good willow charcoal. Even the stuff the pyro suppliers sell is not willow, but rather mixed hardwoods.

There is a guy that sells real willow charcoal here. For fireworks or casual use, the mixed hardwoods might be OK, but I'm thinking if you want serious BP, willow may be the way to go. I'll order some willow. I'd make it, but there are no willow trees nearby here in TX. If you are going to go to the trouble to make BP, you may as well use the best ingredients if they are available.

Cobbler

Mar. 31 2008

The last few pounds of BP I purchases were Graff & Sons and it came in a plastic container... Wonder if it has something to do with the composition of the plastic, maybe some are more "staticky" than others

.22shooter - second acct for JackfromOz

Mar. 31 2008

Maybe we have a lot more willow here because of the cricket, bats and stumps are traditionally willow wood and often line creeks and water ways here.

I read in a book it had to do with the cellulose content and space of the fibre that was important and in the book the gent theorised about Papyrus as it had both a very high cellulose and space per fibre but he had not tryed it at that stage.

MADJACK

Mar. 31 2008

I have noticed that the powder measures for BP are metal. My GOEX came in a metal can. I'll see if a search on BP safety turns anything up.

here we go

MSDS for BP

Download attachment [ PDF Document ]

Number of downloads: 327

MSDS for potassium nitrate

Download attachment [ PDF Document ]

Number of downloads: 186

general BP safety

Download attachment [ PDF Document ]

post-101-78988-BP_safety.pdf

geodkyt

Mar. 31 2008

"Keep away from static electricity".

You probably have MORE risk from static sparks from the homemade stuff than commercial.

Commercial stuff is EXTREMELY well graded, and is nearly always (always, in my experience) graphite coated. All you need top start the fire chain is for one teeny-tiny particle to catch, which spreads to a slightly larger neighbor, etc -- until it is lighting off the big chunks.

Swede

Mar. 31 2008

Safety is important, and thank you all for excellent tips. One of the books I am reading is "Rocket motor construction" using BP. The author is a highly respected guy, and he claims in 20+ years of loading his own BP rockets, he had never heard of an accidental detonation when only BP is used in ramming up rocket motors with a hydraulic press. When you hear of accidents in fireworks, or this sort of activity, it is almost always from messing with powdered metals, chlorates, and perchlorates. BP is reasonably safe stuff, but exercising care is normal.

I wish I had saved my plastic powder cans that I had used over the years. I'll bet they would have been safe with BP. At a minimum, I need some good, large ammo cans to store the stuff. Because they seal perfectly, they add a layer of safety. Some accidents have happened when some guy is using acetone or other super-flammable liquid, the vapors migrate to an ignition source (like the sparks of a ball mill motor) and the flash of vapor then ignites some big exposed pile of BP. Keeping the stuff sealed and secured is a big plus.

Today, I cut two precious 3/4" bars of brass to create spark-free tumbling media. I am going to execute a straight ball-milling on a very small scale... dry! Wish me luck! We'll see if you can simply dump your ingredients dry into a ball mill, and produce good BP. I'm guessing it's going to come out as dust, so I'll subsequently need to wet it with some dextrin, press it, and then screen it.

hammermill

Mar. 31 2008

static seems to have a hard time igniting black powder

i took a sample outside and used ataser type device to see if i could get it to go

no luck seems a lot of sparks dont have the heat energy

to start ignition

i press my powder using a device like a expresso press with a pressure gauge

i got into this because course powder is hard to come by as is concussion powder in the 6 to 8 f range

graphite coating does slow down ignition

also the powders burn differiently under compression

hence the use of golf ball motors,or devices that lift a weight up thru a set of ratchets to measure preformance.

the ratchet hold the wieght at its highest point of travel for each shot

another thing

DO NOT MIX UP POTASSIUM NITRATE WITH CHLORATE

this is how you can loose fingers

the main reason to ball mill the sulpher is to get the two compounds in intimate contacts with each other

the discussion of charchol leads to some interiesting facts

goex powder is mads from maple charchol

for willow on the east coast use black willow

in the west pacific willow is a good choice

for cotton wood pick narrow leaf it was used during the civil was after willow supplies ran out

oak is said to be used in britan and au land althougt no menyion of species is made

making charchol by the retort method produces the best results expecially if you keep the temperatue on yhe cool side

suggested reading black powder manf isbn 0-929931=21-1

skylighter web site

chemistery of powder and explosives isbn 0913022-00-4

gunpowder by jack kelly adds some interiesting stories

these often show up used at amazon.com

Bubba45

Mar. 31 2008

I wonder how aspen charcoal would work? It's a really soft wood.

hammermill

Mar. 31 2008

my guess is it would do well if retorted right it is related to willow

you would think willow and cottonwood are in abundance in your part of the state

CStol338

Mar. 31 2008

When it comes to storage don't commercial manufacturer displace the oxygen with ether before sealing the can?

Swede

April 01 2008

C, I'm not sure. Are you thinking about smokeless powder? I've noticed that smell too when I open a can of smokeless. Ether + BP would be a scary combo due to the flammability.

The next test is underway! This one is going to be a dry ball-milling with brass media. Ball mills are pretty simple, just a motor drving a shaft through pulley(s) that gives the shaft torque. A non-sparking container rotates and grinds the chemicals into intimate contact, resulting in supposedly some kick-butt powder that will be as fine as flour.

I decided to do a 200 gram batch for my first, using the standard 75:15:10 KNO3, C, S.

This little scale I got off eBay and is the best 0.1g capable scale I have except for a reloading scale. I think these are marketed to drug dealers based upon the description off of eBay. Anyway, good electronic balances have gotten really cheap. Here's a nice one. I think a good basic pyro balance needs tenths of a gram, and a high end of a kilo or more is nice too.

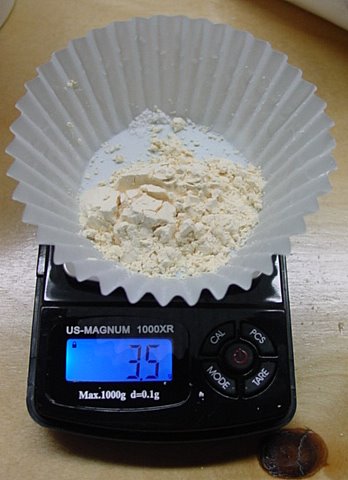

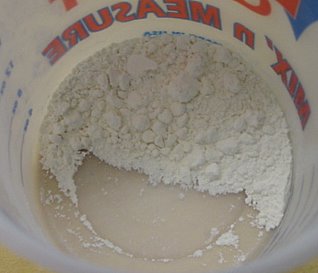

For this batch, I am going with the primo ingredients. First the KNO3...

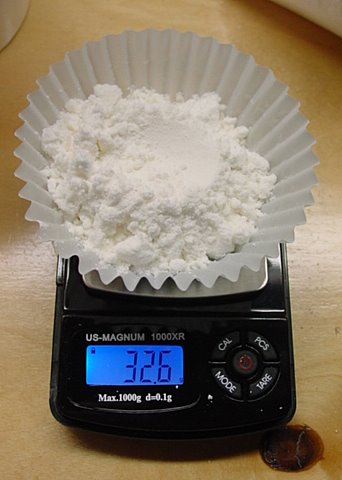

I am using muffin papers or disposable dixie cups as receptacles. Since this little scale doesn't go past 120g, I need to do two weighings, to get 150g of KNO3.

Into the ball mill drum, right on top of the brass media...

This drum is from one of the really cheapo rock tumblers that Harbor Freight sells. I foolishly bought one. The quality is very low. I think if one wants to be serious with this stuff, a much heavier duty ball mill is needed. There's a guy on eBay who sells nice ones. Something like this would be very easy to make, but I have elected to go with the commercial unit to save a bit of time. Here's the guy who sells them...

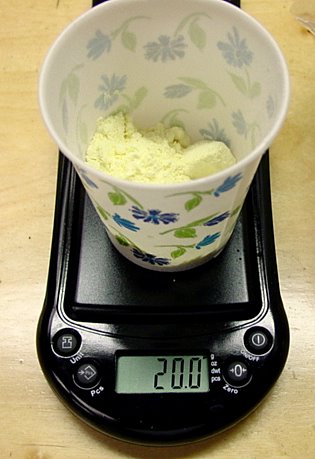

On to the sulfur, 20 grams, which is 10% of 200 grams...

Finally, the charcoal. I have read on various other forums that this charcoal, sold by Skylighter is not the best quality charcoal, but it'll be good enough until I get my willow charcoal. One possibility I'd heard about for what is supposed to be the all-time fastest BP is balsa-wood charcoal. I'll need to try that one of these days!

I added 3% dextrin, 6 grams, to the mix. It'll get dispersed right in with the rest of the ingredients, and when the time comes to moisten, it'll activate and be a nice binder.

Mill it wet, or dry? Odd, I've found many different opinions. A lot of people do it dry, without the slightest problem, and I decided to go dry. My reasoning, if the mix is moistened, it is going to clump badly and glue itself to the media, the walls of the jar, and I'll have a bad time separating it. Dry, I'll go through a strainer, right into a clean bucket, moisten and stir, and be ready to screen it.

Here is my bunker. Mosy guys use sand bags or pits. For a 200 gram sample, this will suffice. It is behind my shop, with nothing nearby except woods and the metal shop wall. I used an old steel I-beam as a backstop, then stacked bricks to absorb any blast. It is turned on and off remotely.

One thing even the good tumblers lack is a bearing for the jar. As these things turn, the jar migrates to one end or the other, and without this little widget I made, would scrape itself to ribbons in short order on the body of the ball mill. I can reposition the bearing to handle any size of jar.

The bunker is sealed, and milling is underway! I am almost half-anticipating a BOOO-OOOOM, but the more I research this stuff, the more confident i am. Even dry, so long as you use a non-sparking setup, I think it's pretty safe.

4 or 5 hours from now, I'll pop the lid and check 'er out!

CStol338

April 01 2008

Swede, I don't know about BP + ether either, that's why I made it a question, cause I never bothered to find out. I thought somebody might have the answer off the top of their head.

buster charlie

April 01 2008

Why not just use dry nitrogen they use for food storage? It would not only displace the oxygen, but displace any water vapor also.

Bismarck

April 01 2008

I have a small video of the powder I made for my muzzle loader, lets see if the link will work.

It was wet ground together with a mortar and pestle.

[IMG]http://img.photobucket.com/albums....MG] Notice the high safety precautions and the fireproof keyboard of my PC.

Swede

April 01 2008

Bismarck, that powder looks quick! I think you got some good charcoal. It's interesting, I see small burning flecks glowing red then fading out long after the bulk of the powder has gone WHOOSH, almost as if some of the charcoal pieces didn't quite get integrated completely. I bet it shoots well.

The very first BP I ever made was when I was a kid. I swiped some KNO3 and sulfur from the school science lab, but the only charcoal I could find was some thick artists charcoal pencils. I used those, made a batch ground wet, maybe 4 ounces, and that powder worked great in my 1851 Navy. I think once again we see good charcoal = good BP.

Latest test: initial results, 4 hours of ball milling... very encouraging! Pics to follow.

hammermill

April 01 2008

the smell i think is the acetone from the nitrocellose compound at least to my nose

come on swede you can have up to 50 lbs is it

gona take a while at 200 grams each

did i mention i am staying in bunker 47 of fuzzybeans unfinished projects until your finished

Swede

April 01 2008

Here's what I saw when I lifted the lid after 4 hours of balll-milling:

Looks good - completely mixed and in a grain size like corn starch.

I prepared a cup of 1/2 water and 1/2 alcohol to make a BP dough. Wearing vinyl gloves, I added the liquid to the BP, stirring, and just like flour would, it formed a dough ball.

The good part is, it is tacky, so it automatically gathers itself up with a bit of manipulation. All that was left in the bucket was a few particles.

I did add dextrin to this. Dextrin is a form of glue or binder, and that certainly helps. If allowed to dry in this shape, it'd harden up and be a real pain to work with later, so right away I went for the screen. This is a piece of aluminum window screen I glued into a frame that was specifically sized to fit over this teflon paint pan. The paint pan is ideal. Nothing sticks to the teflon... it is cheap, and also forms a perfect tray to dry the BP in.

While the BP dough is soft, it screens really easily. The whole ball went through the screen in about 2 minutes. It formed some nice grains. This time, I decided to not touch the powder in the paint pan until most of the drying is done. I think this helps maintain the grains in their current size and shape, and not collapse into dust or smaller pieces.

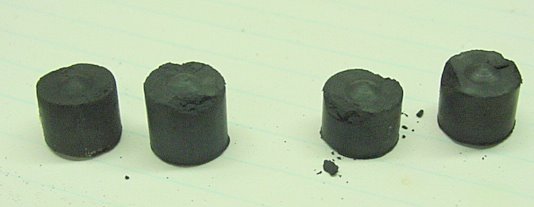

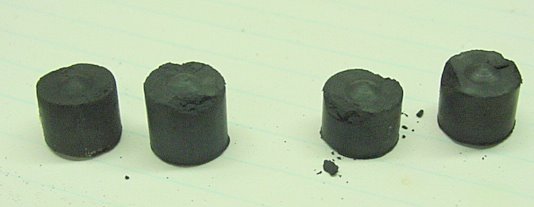

A small sample of the end result...

Nice grains, a bit fine, but no problems. The big question, how does it burn? Initial tests show an excellent powder that I think is just one step away from commercial. It is really good powder that would perform perfectly in any smokepole.

I decided to press a few nuggets in a hydraulic press.

Pressing and then rescreening is supposed to produce even better BP. I'll take some videos tomorrow, but a simple side by side comparison between this powder, and the stuff from the previous alcohol batch, this stuff is MUCH faster! Hurrah!

The next step will be willow charcoal, and after a bit more research, a very small batch made with Potassium perchlorate, which is even zippier, unless someone can talk me out of it.

Oh yes, Hammermill, 200 grams was more than enough for a first milling! The jars that came with the ball mill are HUGE. I'm guessing they could produce 4 or 5 lb of primo BP at a time.

Summary - if you want really easy, excellent BP, buy or make a ball mill. It couldn't be easier. You toss the ingredients in the jar, turn it on, and it makes BP, simple as that.

coyote65

April 01 2008

You can probably use a flour sifter to recover your media.

hammermill

April 01 2008

if you are thinking of messing with potassium perclorate

i am going to start filling sand bags for the front of the bunker

chlorates are not for gun powder

do not do it

if mixed as blacpowder it is used as salutes, and maroons and in concussion motors for a sharp salaute

i have seen 5 inch steel concussion motors split with these mixes.

as a final thought remenber to be very carefull

lest your friends comfort your widow

all of that said mpotassium burned under no confinement burns cool enough to produce vividly dyed smoke

skylighters green is wonderfully hideous

on storage the aluminum budweiser bottle is a nice storage container

sand i need more sand

Mrtank

April 02 2008

I personally am not a fan or Potassium chlorate, or Potassium perchlorate in any way shape of form. It is making a dangerous thing even more dangerous and sensitive. I wouldn't want to see you hurt. I strongly recommend agents it.

On a lighter note I was thinking, you could set up a screen to rotate at a set speed and press your nuggets in at a fixed rate. That way you could control the grain size, and keep it even for all of your black powder. Just some of my random thoughts. With the way this thread is making me think I may have to the buy/ do list...

Fuzzbean

April 02 2008

Man, that's some nice looking powder you are making there, Swede

.

When you finish all your research here I hope you condense your optimum

findings down into a simple recipe with specific ingredients, amounts and

times, so I don't have to use my brain anymore.

About the ether smell from smokeless, that is actually ether or something close to it, that they use as a solvent in the manufacturing process. Raw nitrocellulose looks about like the cellulose fibers it is made from, but unlike cellulose is soluble in ether. So it's dissolved in ether (or ether plus nitroglycerine for double-based) to make a dough-like stuff they squirt into noodles and chop into grains or flakes for the traditional process. Nitrocellulose was an early forerunner of all the polymers we have today, and was actually molded into things like combs and hand mirrors before they had better plastics. Photographic film was made from nitrocellulose for many years; I've read that movie film was sometimes chopped up and used for gunpowder over in Afghanistan or someplace.

You know how smokeless powder is often in the form of little tubes? Maybe a lot of people know this stuff already, but that is because the powder only burns on the surface and they want to keep a constant surface area as it burns. Ideally the surface area should actually increase, so the powder could keep up its burning rate as the bullet accelerates faster and faster down the bore. That would make a truly "progressive" burning powder, and a flat pressure curve. But that isn't possible, so the best they can do is form them tubes so the inner surface area burns bigger as the outer surface area burns smaller, and things compensate out partially.

Now ball powder is another story. The process offers big manufacturing advantages, but the powder must come out more or less in a ball shape. It's a process involving liquids that are not miscible, so the powder grains are formed ball shaped for the same reasons that oil droplets in water tend to form into balls. But a perfect ball is the very very worst shape a powder grain could possibly be. Its surface area must decrease rapidly as it burns, making a very undesirable degressive burning rate. So to compensate they coat or soak the grains in a chemical that inhibits burning. That way the outside has the most of that chemical, and the big area available at the start burns slowly. As the outer layers burn away, less and less of that chemical has penetrated inwards, so the grain burns faster and faster to compensate for its smaller and smaller surface area. This works out very well, except that the outer surface has so much of that chemical on it that it can be hard to get the powder to ignite in the first place. Which is why magnum primers are often needed with ball powders.

I'd stay away from chlorates or perchlorates for making powder. One thing, aren't those super dangerous when mixed with sulfur? Even without the sulfur, they are bad news. When I was a kid I discovered some common stuff you could buy from Sears that was made of sodium chlorate. We used to make gunpowder by mixing it 50/50 with sugar. One time my friend was ramming a bullet down the sticky bore of my home-made gun (a section of rusty Springfield 03-A3 barrel I plugged with a bolt) and the stuff went off. It tore his wrist open for about 4 inches, and made our fiberglass fishing pole ramrod look like a piece of rope. We had intentionally set the stuff off by hitting it with a hammer many times before, and should have known that would happen sooner or later.

Swede

April 02 2008

Hammermill, Mr. Tank, and Fuzzbean, thank you. I will not mess with the perchlorate in any fashion until I am ABSOLUTELY sure whatever recipe calls for it, is safe and proven.

Chlorates: Maybe after 5 years of extensive practical experience. For now, it will not even be in my shed.

Fuzzbean, that's some cool information on the smokeless powders, especially the ball powder. In college chemistry, we nitrated a LOT of paper and cotton. Heck, we'd nitrate just about anything in small quantity to see what we could get out of it. The problem with smokeless powder, gun cotton, etc (for stupid kids like us) is that it wouldn't go "bang" unless it was confined. I still made some nice salutes by packing nitrocotton into a 35mm film canister, and wrapping it up in a lb of duct tape.

With the goal being a true high explosive, we tried desperately to make TNT. Our best effort yielded a waxy yellow solid. When we saw that, we thought we had succeeded, but analysis of the solid showed that it was DNT, di-nitro toluene, and not TNT. We also learned that it is very toxic. We disposed of it as a hazardous waste. Never did get caught. And we're lucky to have passed through that idiocy unscathed.

That stuff was all long ago, in my very, very stupid era, and I have no strong desire to do it anymore - thank goodness.

I'll do another little video, comparing this ball-milled powder, to the alcohol powder. I think the speed of the burn compares much like my first video, where it was greenmix vs. alcohol. The alcohol prepitated BP, while not as fast as the ball-milled, really is good powder that I would not hesitate to shoot.

hammermill

April 02 2008

we frequently disolve nitrocellose in acetone to make a coating for fuse and other compounds.

nitro cellose movie film would burn really good hence the old projector rooms had asbestous walls lined with metal and all openings had fuse links holding them open.

also considering that light came from a carbon arc rod being the projectionest must of been hair raising to say the least.

Bubba45

April 02 2008

I read in an Nat'l Geographic that the Afghan Rebels used old movie film for propellant in loading 303 Brit shells while fighting the Ruskies . They experimented with cutting size for regulating burn rate.

jkilroy

April 02 2008

I used to do a lot of this pyro stuff when I was a kid. (13 or so) I was lucky enough to have a friend who had parents that encouraged this type of hobby. Imagine today a parent buying black powder and fuse so a child could make home made fireworks in the garage? Probably be on some federal list or behind bars.

However, where does one find one of these ball mills? Is it like those old setups for polishing rocks except with different media?

big art

April 02 2008

Swede that was a good bit info on home made BP. when you posted the link for skylighters it rekindled an urge to try making my own BP. I didn't buy their book at this time in part because I have come across some ideas or recipes that you have not mentioned in your writings. I am making my ball mill using 6" pvc pipe for the tumbling jugs and constructing a water wheel to power it, I have a small creek with sufficient flow to do the job. In my research I discovered the sulfer is used to lower the ignition temperature by about 100 degrees C. A very good BP could be made comparable to Goex BP without using sulfur at all but you do need to add more charcoal. This mix is said to work well for cap & ball guns but causes misfires in flintlock guns, I am guessing that is based on using the sulfurless mix in the flash pan. If it were possible to use a charcoal and saltpeter BP to propell the bullet and use a charcoal,saltpeter, and sulfur BP in the flash pan one could save money by eliminating the sulfer for most if not all of your BP needs based on whether or not you use flintlock guns. Eliminating the sulfur also reduces the white smoke and sulfur smell, you still get the fouling. I also plan on testing my BP by shooting thru a croney and comparing penetration with comercial BP. On making charcoal it is better to use branches less than 5cm dia. with the bark removed and if having trouble locating good woods pine can be used its not as good as the previously mentioned soft woods but still better than hard wood charcoal. My goal is to buy as few chemicals as possible and still have a BP that is comparable to comercial grade BP. Good luck on your quest for a good homemade BP. Art

hammermill

April 02 2008

if you go to skylighter look at the newsleter section

if on the west coast firefox enterprises is another although some what hindered source

Swede

April 03 2008

Art, that is some very interesting info, indeed! I think I will prepare about 4 different green mixes, starting 65:35 KNO3:Charcoal, and maybe 60:40, 55:45, etc, and compare the burn rates in an unscientific manner. If we can narrow down the ratio, I'll bal mill it and get a good batch. Unfortunately the ratio will vary with the type of charcoal. The stuff I am using is "mixed hardwoods" and not the best.

I like your concept of a self-sustaining, water-wheeled BP mechanism. I've made charcoal in the past... I do know how to do it, but I've kind of reached a point where I have so much going on, I've decided to just buy the stuff. I look forward to the willow arriving. But I do believe it is important to know how to make charcoal. Maybe one of our Aussie friends will go into a bit of detail for this thread. I am hoping, when it is finished, it will be a sort of treatise on various means of making BP, which of course is a true emergency propellant, and all-around useful stuff!

Swede

April 03 2008

I do agree with that, and the sulfurous smell is part of the charm, too.

Part of me though is thinking homemade BP could be critical in the future if Washington sleazebags attempt to really hurt us in a legal way; no more smokeless powder, each round of ammo has a $5 tax, or simply elimination of the 2nd amendment. If we could come up with a safe, easy, and effective way to reload, let's document it. Maybe a less smoky BP could have "tactical" uses.

Letting my imagination run amok, let's say we are reduced to nothing except what we can make in our homes. I know there are ways to make primers, but that can be iffy. We can always make a matchlock or flintlock. I'm picturing two powders, a sulfurous variety for the pan of the flintlock, and a speedier, less smoky powder for the ball.

I've heard that some of the BP substitutes have added ingredients just so they'll smoke, and that in their native state, are smokeless. I'd love to get the recipes for some of them, but I'm guessing they are just highly modified nitro-based powders with burn modifiers added.

Swede

April 03 2008

Man I'm going nuts with this stuff.

ALL red-blooded, REAL MEN MUST look at this site.

"Pyroguide.com" it looks like I'll be busy for a while.

Here's a great article on making super-fast Balsa Wood Charcoal on a home BBQ grill.

brokengun

April 03 2008

Swede, before you go nuts, and since you raised the very serious question about future prohibitions on re-loading and potential ammo taxes, have you ever thought of making your own smokeless powder?

I have never done this, seen it done or used it but i have read that a 30 caliber rifle powder can be made using potassium nitrate, granulated white sugar with a little iron oxide thrown in to control burn rate.

Supposedly it creates a fairly fast rifle powder and I'm just guessing that it would be similar to IMR4227.

If I remember right it's a flake type powder and it you must use the proper sized screen to make it or the burn rate will be off.

geodkyt

April 03 2008

If I need to use a home made BP powder mix "tactically", I'm making a Howda pistol (probably with an electrical ignition), loaded with shot. It will be used on a relatively unsuspecting and definately solitary target who has a better weapon, and rammed into his torso before firing. The smoke from ignition won't be an issue.

Frankly, the chances that I'd ever need to do it are so slight as to be incalcuable -- there's WAY too many armed individualists in this country for us to be held down by opporessive force any time soon that takes control quickly and strongly enough that there's no opportunity for a realistic rebellion with current ordnance to spontaneously erupt. (Cool, huh? Having the ABILITY to rebel makes it less likely that it will be necessary to rebel. A somewhat self regulating system... maybe those old dead white guys weren't so dumb, after all. )

So, for me, BP is all about the nostalgic recreation of the historical mythos this nation was founded on. I'll leave the tactical employment to my ancestors. For my purposes, I want it all -- smell, smoke, BOOM!

coyote65

April 03 2008

Swede, are you going to run the various products thru a Chrono? I would be interested in what the difference is between "Good" and not so good BP. Years ago I read an article in a BP mag that was dispelling BP old wives tales. They had a test barrel with a pressure guage and a chrono to determine FPS. The big conclusion I remember out of the article was that BP is a really slow burning powder compared to smokeless. I am wondering if you can improve the speed of BP by just pulling it out of your mill while it is in the talcum powder consistency and using it for a substitute for smokeless?

kanton

April 03 2008

Swede's "thinking homemade BP could be critical in the future if Washington sleazebags attempt to really hurt us in a legal way" is true today. A local gun dealer told me he doesn't carry BP because a $250 annual license makes it unprofitable.

A good book is "The-Do-It Yourself Gunpowder Cookbook" by Don Mclean. In Chapter 7 he discusses a mixture of saltpeter, sugar and rust.

.22shooter - second acct for JackfromOz

April 03 2008

For Kanton YES!!! a wonderfull book but a little lacking in preperation tips but the recipies all work well.

Swede, Jack read your post last night and had his friend Blue Dragon from the muzzle loaders send me this a short while ago.

jack and warrens Charcoal cookery

They are preparing the summer charcoal cook for next 2 weeks and will document the Direct method of making charcoal. Maybe indirect as well depending on avaiablity, cash and costs.

Jack wrote a shorter version for the Adelaide University Regiments Rifle and Pistol Club and the "Mountain Men" BP club many years ago and stated he needed to update it and also make it for everyone not just bush folks who speak 'Strine, and so he has grabbed Blue Dragon ( warren) to edit the work.

Warren used to write for the popular magazines here back when and is a regular on many BP and ML forums.

Part 1 is the science of charcoal, what wood makes good charcoal, how to prep willow for coaling and a basic build for a coaling kiln from scratch. ( uploaded now, see link)

Part 2 will be pics of the process and a description of process's and what to watch for and how to recognise the signs of coaling or burning ( burning is bad)

Part 3 will be experiments with stale or old BP and differing charcoals to show the results and if they can get enough papyrus they'll do a nitro- cellulose mix if practicable.

Jack only has 2 weeks in South Australia and apologuises if its a bit rushed but he has to return for his VA doctors appointments and cant afford to miss them.

Swede

April 04 2008

Quote (.22shooter @ April 03 2008,22:03)

Jack and Warren's Charcoal Cookery

This is an OUTSTANDING document, thank you! Would you mind if I distributed it to others interested in BP? Thank you for your thoughts.

Coyote, I have no current plans to test the BP beyond the crude "looks fast" small burning piles. I've got plenty of Goex, and at least I can compare it to that. Oddly enough, there are many fireworks types who claim to have done better BP than Goex, and I don't doubt this because Goex does in fact use mixed hardwood charcoal due to cost and consistency.

brokengun and Kanton, I think exploring propellants other than BP is an excellent idea. I do have the ingredients for the KNO3, Iron Oxide, and sugar recipe, and I'll see if I can come up with an easy method. My problem: I will not put anything except BP into a frontstuffer because of the potential danger, and I'm a bit leery about loading unknown stuff in my cartridge rifles. I wish I had a beater gun that I could mess with. I'll see if I can't come up with some way to test. We know that modern smokeless powders burn slowly unconfined, and they will only work propely in a firearm, meaning if we simply make a little pile of powder and light it, it doesn't tell us much about its potential.

royce

April 04 2008

As a side issue, many of us (meaning probably just me) have never touched black powder or fired a BP firearm.

What does all of this BP manufacture mean to me if I don't have a BP firearm?

Can I use BP in a regular cartridge firearm?

A bolt rifle or my modern Peacemaker?

MikeB

April 04 2008

I've shot pyrodex (newfangled BP substitute)in my 44mag...

worked good I'll guess about 45acp performance. I put together a Dixie Gunworks kit .54cal "Hawkins Style" rifle and I shoot it with Goex... and it is great fun to shoot, even if the other guys on the firing line have to wait for the smoke to clear to see thier targets. I also shoot BP in my little cannon ( at least I used to. Last 4th of July I fired it a couple of times and it attracted the police helecopter and a couple of squad cars... So I won't be fireing that in town anymore.)

The other good thing about BP is it's low pressure. So it is perfect for simple "homemade guns". It don't get much simpler than a match lock and many locks are available for building flint and percussion guns.

The one real downside to BP is it is often hard to get ( can't be shipped, stringent storage rules, and fees...

geodkyt

April 04 2008

BP is best used in manually operated arms, as it is quite dirty. Remember that all of the manual operating systems were first successfully done with black powder. Your right arm (for instance) is more capable of applying additional force to deal with powder fouling than a gas or recoil system.

Semiautomatic and full automatics generally waited until "smokeless" power was available (although there were examples done with BP). The Gatling gun and other "manual machineguns" bridge the gap, and were successfully employed with BP.

CStol338

April 04 2008

Quote (royce @ April 04 2008,11:13)

Can I use BP in a regular cartridge firearm?

I agree with geodkyt, it can be used in just about any firearm but it isn't reccomended.

Some good examples of BP cartridges are still around today though. Like the 30-30 winchester 30 caliber - 30gr BP or 45-70 45 caliber 70gr BP or one of my personal favorites that I still load BP is my 32-40 WCF 32 caliber - 40gr BP and there are lots more out there.

A couple of good books on reloading BP are "SPG Lubricants BP Cartridge Reloading Primer" 4th edition revised, and "Loading the Black Powder Rifle Catridge" by Paul Matthews.

Swede

April 04 2008

From kit or scratch pick a period and go for it.

Very tempting! I've got a flintlock pistol that I'd call a kit but it's pretty rough, plenty of work left to do. It's been boxed for a while, awaiting just the right moment.

Generally, bigger is better when dealing with BP. Just about any rifle caliber 40 or larger will probably do OK with BP, and in some cases do more than OK, like the big old Sharps buffler guns. I've got two .45-70 Sharps, one a C. Sharps Arms M1875, the other an Italian knockoff of the classic 1874. I've got the brass, the dies, the bullets. All I need now is a chronograph to really experiment with this stuff.

I tried a .30 M1 carbine cartridge PACKED with 4F. it fired fine, but did not cycle.

Interestingly, the early Maxim machine guns were designed for BP cartridges, and worked well - a testament to Maxim's genius. He took the fouling into account, and that made the gun even more effective when the smokeless cartridges came into being. Those African Natives learned a harsh lesson - do not mess with the Maxim.

In an emergency, you could probably easily kill game with any .30 caliber rifle + BP. If your gun is a semi-auto, you may be required to cycle it for each shot. And be sure to clean like crazy, with an aqueous cleaner, for Mr. BP is very corrosive.

Swede

April 04 2008

Oh yes, today I milled a 70:30 KNO3:Charcoal mix. No sulfur. I will test it now and see how it works... hang tight a moment.

brokengun

April 04 2008

Homegunsmith Funny...

While doing some research into sinus conditions and treatments I discovered

that Swede

may be practicing medicine here instead of making BP.

I've just learned that gun powder was used in early homeopathic medicine!

The way I understand it a special grade gun powder was mixed into the formulas.

Talk about blowing your nose.

http://www.sinuswars.com/Ingredients/Ingredients-SinusWars4.asp

nevadablue

April 04 2008

swede, you should make a test action, just a simple block chambered for, say 45-70 or something like that. I think there is a thread somewhere here showing a test device. I'll do some looking.

Bubba45

April 04 2008

MikeB, an update, BP can be shipped. www.powderinc.com ships all over the U.S. Good prices too. Get it while you can.

hammermill

April 04 2008

if your going to get some order as much as you can to save on the haz-mat fee but watch the 50 lb figure

MikeB

April 04 2008

Thanks Bubba and Hammermill... I get it from that last surviving gun shop in my neck of the woods and pay about $20/ lb.

Not that much more than powderinc. I've been told that I'm not allowed to store more than 5 lbs here in the peoples republic. That maybe without a n approved storage locker. Don't quote me on that I haven't seen the law myself.

But I'm saving me willow branchs and watching while Swede demonstrates the Black Arts.

Swede

April 04 2008

Sorry about the "just a moment..." It turned into several hours.

A small pile of sulfur-free BP, milled for 5 hours, and as fine as talc, burned very well. It was much faster than the first green standard powder in the video, but not as fast as my best milled powder. It did smoke, exactly the same as normal BP.

But something was missing... the smell! The smoke had a weird, clean, "chemically" smell, totally unlike regular BP. It was odd!

Some thoughts - The charcoal I used for this test was junk hardwood, milled from a bag of BBQ charcoal from Home depot. The proportions - totally made them up. I can see that with a better charcoal like willow, in the optimum proportion, it would work, and probably very well.

This experiment I think shows that sulfur-free BP is feasible, and might be a player if one has no sulfur. But unless we can figure out that there is some advantage we don't recognize yet, I can't see making it unless you have no sulfur.

The three components in BP have been around for hundreds of years. There's nothing new under the sun with BP, and I'm pretty confident that nations who defended themselves with BP weapons would have skipped the sulfur if, in doing so, there was no loss of performance.

But all in all it was pretty cool and I think it's worth doing again when I get some decent charcoal. And those of you waiting for seismic indications - so sorry! You'll have to put up with my blatherings a while yet. Time for some quality sleep... Good night!

buster charlie

April 04 2008

So if one wanted to mess around with this, would one of the cheap harbor freight rock tumblers and some lead sinkers from a sporting good store be a good start on the cheap? Any other sugestions for easy to find grinding media?

buster charlie

April 05 2008

For the tumblers, they offer them in 3 pound and 2X 3 pound setups. how many

.50 cal lead balls would you think would be sufficent for a 3 pound tub? Also

the 2X setup is only a few dollars more, but part of me thinks the single tub

is a safer setup in case something went wrong.

Swede

April 05 2008

Buster, I bought that exact rock tumbler from HF (the 2-jar version) before I bought the larger ball mill. The quality isn't the best, but it does work, the jars are actually pretty decent, and you don't have to load two jars on it, you can load just one.

One of those little black jars requires maybe 400 .50 cal balls... it's a bunch more than you might think. I've milled with both lead balls and with brass slugs, and I'll be honest, I like the brass slugs MUCH better. For some reason the lead balls really hang on to the mix. I ended up working much harder separating the meal powder from the balls, than I did from the brass slugs.

If you want to try the balls, you can cast your own, or you can buy them from Dixie gun works. DGW had by far the cheapest price at $9 per 100. At Cabela's they were $15 or so. If you want to do brass slugs, a length of 3/4" diameter rod is cut via bandsaw (or hacksaw, if you have the energy) into 3/4" lengths.

I deburred mine by tumbling them with some of the abrasive grit that came with the rock tumbler.

Jars - DO NOT BUY JARS! You can make them perfectly out of PVC pipe. The classic PVC jar is a length of pipe, capped one end, and the other end, you use a transition, say 3" to 2". On the 2" end, you make use of one of those rubber caps with a hose clamp. Another option, buy a pair of test/blowout plugs that fit INSIDE the pipe. The problem with those is there is a tiny bit of metal that is exposed to the mix. We must cover that. Here's how...

Swede

April 05 2008

PVC pipe test plugs fit internally into a section of pipe, and by turning a wing nut, a rubber biscuit is expanded, sealing the pipe perfectly. There are several brands... look for the "Oatey" brand, as I think it is much nicer than the others. In the U.S. Lowe's carries them.

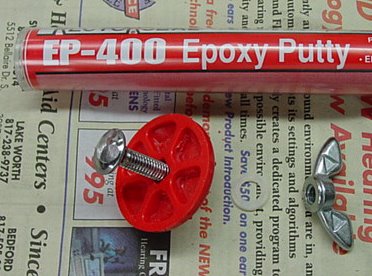

They consist of two plastic disks, a deformable and thick rubber ring, and a 5/16" carriage bolt. The head of the bolt is the metal we are concerned with. Beneath the head is a rubber washer. Remove that.

We are going to use epoxy putty to fill in the plastic cap and cover the bolt. Those who have worked with the epoxy putty in a stick know that it is some pretty amazing stuff and should easily withstand the abuse of a ball mill.

Epoxy on plastic is more of a mechanical bond than anything, so it is best to at least roughen the plastic. I used a dremel tool to create some undercuts and generally roughen the plastic...

This is the brand I used. Lay your stuff out and be ready to roll, because it sets in about 10 minutes, no more.

Mix the epoxy putty. Roll a bead like play-dough and place it below the head, like so:

Then, tighten the screw down pretty hard with the supplied wing nut.

Build up the rest of the encap into a mound of smooth epoxy. I recommend using vinyl or butyl gloves. I actually chucked the bolt in my lathe and on a very slow speed, used the palm of my hand and fingers to give it a nice shape. You can use dabs of water; that will help smooth it out. This is what it looked like:

It will get quite warm. After it sets, reassemble the plug. Your plug is now ready to do some serious ball milling! To use these, you cut a length of pipe, perhaps 6 to 12", insert the plug into one end, add your media and chemicals, and install the second plug, sealing the jar. These are 2" plugs, which I bought for milling small test batches. For real production, go 3" and preferably 4". Have fun, be safe!

I'm off on a 2-day trip, guys, got to make $$ to eat and buy toys. In the meantime, let's think of alternate firearm cartridge propellants along with the BP. I'll get some video up, too, of the new ball-milled batch, which is good stuff.

I've been looking at KNO3 + sugar - based fuels, and they do look promising. I think the trick is going to be in the corning / graining. Maybe some extrusion dies and a hydraulic press? We'll see!

http://www.chuckhawks.com/difference_black_powders.htm

Added: Excellent read on BP substitutes.

Note the use of "Sugars" as the fuel source! This could be it! If we could avoid Nitric acid (used to create real smokeless powders) and get a decent propellant, we'll be set!

big art

April 05 2008

Swede, in rechecking my research an 80 to 20 mix might get you closer to optimum performance in a sulferless BP.... BP had pretty much reached its peak as far as power by the mid 18th century. About 1875 the Swiss, because they were unable to see their attacking enemys after firing large volleys while defending their their castles started to develope a smokeless BP. With the advent of smokelss powder in the late 1800's the BP guns and canons were soon obsolete on the battle fields. That is the reason smokeless BP never gained widely accepted use. I am sure Swiss would have done their best to keep this developement a secret for as long as they could.... I see you are going in another direction with your experiments so I don't expect you try this mix.

Fuzzbean

April 05 2008

I don't know about using lead balls in the milling process for black powder. Seems like some lead would be ground into the mix and then when you take deep breaths of the smoke and hold them you'd be getting lead in your lungs.

Anybody know anything about making powder from vitamin C? Some school teacher I met at a gun show years ago told me this, and I thought maybe he was pulling my leg. More recently I read that some of the commercial substitutes are made from vitamin C. I can't remember what you mix it with, maybe saltpeter. It sounds pretty simple, if you got lots of pure vitamin C available.

There was also something called "Golden Powder" that I got info on from a gun show or NRA convention back in the 1980's. They said it was non-corrosive, safe to ship, edible, moldable into caseless ammo, etc. etc. but then I never heard another word about it. I thought it might have been an investment scam of some sort, as they seemed to be looking for financial backing more than for customers. Or maybe that was the vitamin C too.

kanton

April 06 2008

According to Wikipedia at http://en.wikipedia.org/wiki/Gunpowder

"A simple, commonly cited, chemical equation for the combustion of black powder is

2 KNO3 + S + 3 C > K2S + N2 + 3 CO2.

A more accurate, but still simplified, equation is[6]

10 KNO3 + 3 S + 8 C > 2 K2CO3 + 3 K2SO4 + 6 CO2 + 5 N2.

The products of burning do not follow any simple equation. One study's results showed that it produced (in order of descending quantities): 55.91% solid products: potassium carbonate, potassium sulfate, potassium sulfide, sulfur, potassium nitrate, potassium thiocyanate, carbon, ammonium carbonate. 42.98% gaseous products: carbon dioxide, nitrogen, carbon monoxide, hydrogen sulfide, hydrogen, methane, 1.11% water."

Thus taking deep breaths of the smoke, even if it were produced without lead is not a good idea! I would worry more about lead poisoning if I were standing in front of the barrel!

Spartiate

April 06 2008

Quote (.22shooter @ April 06 2008,03:43)

acetic acid anydrous (sp?) is a big no no in the US i found out just

today

By way of clarification, just in case you do find a way to navigate the legal hurdles and decide to google a supplier:

Vitamin C is either ascorbic or citric acid (not sure which makes good gunpowder). Acetic is vinegar. Acetylsalicylic is aspirin.

Machine_smith

April 06 2008

Here you go, I found these awhile back but my studies stopped short of throwing something into the ball mill. Maybe It'll help you guys and I'd love to see a homemade replica powder.

US patent "H72" Organic substitutes for charcoal in black powder

http://patft.uspto.gov/netacgi....N%2FH72

US patent "4,497,676" Gunpowder substituted composition and method

http://patft.uspto.gov/netacgi....4497676

US patent "4,128,443" Deflagrating propellant compositions

http://patft.uspto.gov/netacgi....4128443

Swede

April 06 2008

Acetic anhydride is unfortunately used to turn Morphine into Heroin, and is one of dozens of chemicals, some of them common, that is on a DEA watch list. Buyers of these chemicals are scrutinized closely.

Machine_Smith, thanks for those patents. One of the lines jumped out at me...

"3. A composition according to claim 1, wherein the oxidizing agent is potassium perchlorate and the organic carboxylic acid derivative is sodium benzoate."

Hmm, I just happen to have both of those on hand!

I'm hoping for simplicity sake that our answer for a nice, simple, and safe PROPELLANT will be some intimate mix or melt of KNO3, a sugar, sucrose, dextrose, or fructose, and perhaps one or two additional "secret" ingredients. Melted, extruded hydraulically through a bank of small holes, and cut with a blade so as to create consistent grains.

Totally off topic, I launched my first simple homemade firework today using the alcohol precipitated BP. Worked like a charm!

Fuzzbean

April 07 2008

Vitamin C is ascorbic acid. It has little if any use related to illegal drugs that I know of.

I think making powder from vitamin C sounds interesting, if it can be got cheap. The pills from Wal-Mart probably contain too much filler stuff, but maybe the pure vitamin could be extracted in a really desperate situation.

I'm skeptical that gunpowder made from sugar will work without gumming up your barrel something awful, though maybe a balanced mixture might burn more completely than the chlorate powder of my childhood.

Swede

April 07 2008

Guys, it is a simple fact that the production of BP or other propellants blurs with the production of explosives. I don't see how we can experiment with propellants and not deal with chemicals that may be a component of an explosive, or by pure, random chance, a drug precursor. Yesterday in a garden store, they had out perhaps 6 ea. 5lb baggies of KNO3, looking very pure, the consistency of sugar, priced at $6.00 each. I asked if they had any larger bags. When they said "no" I bought all they had, and nobody blinked an eye. I refuse to feel guilty about buying what is a completely legal product, just as I wouldn't feel guilty about buying a firearm, or a box of sudafed tablets.

I appreciate all the offers of help to set up some sort of a test rig. My 1875 Sharps (a very strong falling block) is too nice to risk; the 1874 Sharps too weak. How about a Contender pistol? And if so, in what caliber? How strong is this pistol? I'm thinking a .357 magnum barrel, and start with .38 special brass, "test powder" and a chronograph.

We delve into a potentially very dangerous realm with alternate propellants. How pressures peak, the speed of the burn, weight of the projectile, all add into it.

I think the goal should be a BP substitute that behaves like BP, is easy to make, and delivers reliable perfomance rather than extreme pressures and velocities.

Swede

April 07 2008

Look at this one:

A composition comprising 70 parts of potassium perchlorate, 30 parts of sodium benzoate and the following percentages of water gave ballistic results as indicated in the following table:

% H2O Peak Pressure Muzzle Velocity

2% 25,000 1650

5% 18,000 1700

10% 10,000 1577

15% 7,000 1310

25% 2,500 1231

All loadings were in a 0.222 commercial cartridge with a 53 grain bullet. At 25% water, the mixture is a slurry.

"In a similar manner, the compositions prepared by blending 75 parts of potassium nitrate, 15 parts of sodium benzoate, 10 parts of sulfur and 3 parts of water had an excellent velocity-pressure ratio."

hammermill

April 07 2008

if it burns anything like a kno3 and sugar smoke pot not much will be left although ignition may be challenging.

sorry guys my coments previous were intended to be general in direction without starting a flaming war.

that said my chemical bill is sometimes bigger than the car payment when it comes to pyro stuff

6 dallors a bag for 3 lb bags is not bad the best i can do is 1.85 prilled in 100 lb bags atf lisence and i pick it up

frieght is a killer anymore

Swede

April 07 2008

Well, the first "alternate propellant" shot was a total success. Talk about easy and anticlimactic... and of all things it was with a .22LR.

The propellant was a very crude mix of KNO3 and potassium benzoate, ground in a mortar and pestle, moistened, screened, dried. I pulled a bullet out of a .22, replaced the powder, and reinstalled the bullet. Pulled the trigger and it went BANG. I'd guess the power to be about like a .22 short, but trust me, that powder I put int here was junk, barely mixed. I need to try a ball- milled batch.

Potassium (or sodium) benzoate is a fuel, and KNO3 the oxidizer, and that's all it takes. Common fuels that match well with KNO3 include just about every sugar you can think of. I used K-benzoate as a starter because it is a common pyrotechnic chemical, but not so common that you can walk into Home Depot and buy it. Ithink the goal here is to drive to a store and buy the stuff necessary for a safe emergency propellant. Sugar is the answer.

Honestly, if you can make BP I consider that to be one of the best alternate propellants because it is KNOWN. There's nothing about it that's a mystery. it's relatively safe, you cannot overload any modern metallic cartridge, and it works. All three ingredients can be found at a U.S. Home depot - Stump remover, true BBQ charcoal, and sulfur flowers for plant disease like fungi. But it can be a bit of a headache to make GOOD BP... so I will continue to play with KNO3 and sugars, and see if I can't come up with a means of making a propellant so easy, anyone can do it in a few hours, most of that being drying time.

Perchlorates are tempting, but they are not good as an alternate/emergency propellant because they are difficult to find. Pics forthcoming.

Spartiate

April 07 2008

As far as oxidizers go, the most common (and reputedly very powerful) one I can think of is pool chlorine. I don't know how well it would work (in my younger, wilder days--you know, the age where you read every warning as a challenge )--I tried mixing it with gasoline with no drastic effect, but it might work better with a solid fuel. Any other members have any experiences with the old HTH you'd like to share?

Swede

April 08 2008

Yesterday I did three small green mixes, and by "green" I mean very brief and simple mechanical mixing with a mortar and pestle. You can get a decent idea of the energy of the burn, and the residue it might leave, with these green mixes. Once you narrow into a particular compounding, from there you can go on to a more intimate mix to improve the performance.

All of these mixes are from published and verified sources as being "energetic propellants" like rocket fuel. I am not making anything up, and it would be foolish to do so, when all the data is already out there... it just needs to be investigated.

Mix 1: 75:15:10 KNO3, Potassium Benzoate, sulfur. This is BP without the charcoal. I am simply substituting the benzoate for the charcoal. A yellow solid that handled well, it burns and behaves, from what I can see, like BP. I made it more out of curiosity than anything else, as there is no reason to make this stuff unless you think potassium benzoate is easier to come by than charcoal!

Mix 2: Fired from the .22 yesterday, 65:35 KNO3, Potassium benzoate. A white powder. It wasn't as energetic as mix one, and left significant crud behind, but it easily and successfully fired a fine shot, with more than adequate power for small game. The barrel looked badly fouled after only one shot, but remember, it is a green mix, not well prepared.

Mix 3: Potassium Perchlorate and Potassium Benzoate, 65:35. I added a bit of dextrin to make better grains, green mixed, turned ito a dough, screened and dried. This stuff is FAST, burned very well, and left little residue. Another not-very-useful test, as again BP would be a better choice, but it is part of the learning process.

Mix 1 and 2 are pictured here in their small sample bottle. Neither of them seems shock sensitive. i could not ignite small bits despite healthy whacks with a tack hammer.

Now for the movies. I am not knowledgeable about CODECS and other means of making these files smaller, so I simply tried to make them very short. And that's what they are, short! Each one is a burn test of maybe 1/2 of a gram. I announce what the powder is, then apply the torch. Each is about 1.3 megs.

First, for reference,

Goex 2F Black Powder:

Second:

My very best ball-milled BP. I'd say it compares favorably with the Goex!

Third: Mix 3,

Potassium Perchlorate : Potassium Benzoate, 65:35 3% dextrin added which gives it a yellow tint. This is the fast stuff. Remember, all it got was a 5 minute mortar and pestle job, which is terribly inefficient. if this stuff was ball-milled, it'd really go. Frankly, I think it may be too dangerous to ball mill. The professional Pyros afaik ball mill only BP. Other mixtures are made mechanically, by screening, sifting, other more gentle methods.

Today, I am going to try sucrose (confectioner's powdered sugar) and KNO3, stump remover, in a couple of green-mix batches. If I get a hot one, I'll process it with dextrin and screen it. Dextrin is a very useful product, as a binder. It gives the grains mechanical strength, and remember, it can be made by baking corn starch on a cookie sheet at 400 degrees for 6 to 8 hours. One pound of corn starch will yield enough dextrin for years of use.

geodkyt

April 08 2008

I believe that chlorine will also produce some corrosion that makes BP look like Bullseye.

Mtdew

April 08 2008

Quote (Swede @ April 08 2008,12:00)

Mix 3: Potassium Perchlorate and Potassium Benzoate, 65:35. I added a bit

of dextrin to make better grains, green mixed, turned ito a dough, screened

and dried. This stuff is FAST

watch out with whistle mix (or as it's sometimes refered to "organic" flash)

Swede

April 08 2008

Hahaha! I just found out that this composition is in fact called whistle mix in the fireworks industry. I think you and hammermill need to point me in the right direction. I'm reinventing a wheel or two here.

brokengun

April 08 2008

swede; I have read that iron oxide helps speed burn rate of a sugar, KNO3 powder mix.

I've heard this mix being referred to as a flash powder but its considered to be a good 30 caliber rifle powder.

Swede i also like your idea of creating a controlled particle size by pressing the powder through a hydraulic press.

I know in pelletizing a binder is normally used to help the pellets hold together is that your intent by adding dextrin to this mix?

Swede

April 09 2008

brokengun, the dextrin gives the grains physical strength when activated with water. Without dextrin, what seems to happen is this - you get your powder, turn it into a dough, and screen it by simply rubbing it through a screen. What comes out looks pretty nice, but the grains are fragile and after a bit of handling and jostling, they begin to abrade one another, and you end up with powder that has an inconsistent grain size. Some of it is sized as- screened, but some of it turns to dust, which then settles to the bottom of your ziploc, bucket, or whatever you are using for storage.

When you add dextrin, maybe 2% to 5% by weight, you slow the powder down slightly, but you give the grains much better strength, and they don't break apart as easily.

In the fireworks trade, homemade BP usually goes through another step. The screened powder while still damp is pressed, usually in a hydraulic press, into pieces that look like hockey pucks. Under pressure, the mass fuses, and that puck is amazingly hard and strong. THEN, the puck is once again screened, this time using screens of different hole sizes, and thus graded by grain size. The act of compressing the BP supposedly dramatically increases the burn speed, and the grains (these are called "corned" grains of BP) are even stronger. When you look at Goex, you see how uniform it looks, and the pieces do not break down... that is what you get when you corn the powder. The shinyness of Goex is from graphite powder, which I have not tried yet.

I need to get back on track, and while the more exotic comps are fun, the original goal was simplicity, so it's back to KNO3 and sugar. I do have some red iron oxide to try as well.

Swede

April 09 2008

OK fellas, today I searched Mrs. Swede's kitchen and could find NO confectioner's sugar. I don't have enough time today to ball mill regular table sugar.

But I did find...

MARSHMALLOWS!!

Being almost pure sugar, I am melting some marshmallows as I write. Going to try a 14:10 KNO3:MM compound. I'm guessing it'll be a smoke bomb, but not a propellant.

Swede

April 09 2008

HAHAHA! Marchmallows were a bad idea. They melted nicely in the microwave, and I mixed the KNO3 outside, into the marshmallow. It turned into a rubbery, oily-feeling dough. If you had an extrusion machine, it'd be ideal (IF it actually burns well) but handling the marshmallow dough... well, it's too sticky to ever be screened.

I did find the confectioner's sugar, so I will now get serious and try a proper KNO3:Sucrose propellant. I may not be able to report on it until tomorrow night.

MikeB

April 09 2008

Martha Stewart says you can make confecioners sugar out of granulated sugar by whirling it in the blender. And, since Martha say it and it is food you might get a way with using Mrs. Swede's blender.

geodkyt

April 09 2008

Yeah, there's more to marshmellows than sugar. In store bought ones, it's likely to be gelatine.

Swede

April 09 2008

Well, after the marshmallow disaster (they actually burned - slowly) first look at a 65:35 KNO3:Sucrose mix, ball-milled for 3 hours, is impressive. I knew it would work well, as the rocket guys have been using this stuff cast for rocket fuel for a long time. The trick will be in the granulation of it. I'm going to mill it for a while longer, then make an alcohol/water dough once more, and screen it into granules. I'll also try a bit of iron oxide (rust) which is supposed to catalyze. Iron Oxide fits into the "easy to get" category since it can be made with pool acid and steel wool biscuits. But I suspect the granulated mix, even without iron oxide, confined in a cartridge, will make it go "bang" nicely.

MikeB

April 09 2008

I think you can get iron oxide at an art store... or concrete supply... the stuff they use to make concrete red... probably a ceramic supply too.

Cobbler

April 09 2008

I have a bunch of iron oxide on my car. I wonder if a bath of KNO3 would make for a quick disposal method

hammermill

April 10 2008

next my friend swede will be making hot loads with chile pepers and blackened steaks. sorry i couldnt stop myself

i have some lab grade iron oxide if you need some

mike b thanks i need to check out the concrete store

marshmellow sauce yuck lots of foods are geletans and oil.

Swede

April 11 2008

There definitely ARE a bunch of very useful chemicals available to peons like us from pottery and ceramics craft stores. Manganese dioxide (for parkerizing), iron oxide, and plenty of chemicals that the pyros use to color their fireworks stars. Hammermill, TY for the offer, I do have some red iron oxide at hand.

I now have a complete set of stainless steel screens, running from coarse to fine mesh. These I still need to mount in their wooden frames, which I am going to do before I go much further with this. I think the screening/granulation process is important to get good results for an improvised propellant. Until now, I have been using an aluminum window screen, and that, or a stainless steel kitchen strainer, will work just fine for a casual batch.

Swede

April 12 2008

I am going to start what will be probably the final "How to" installment, namely, the use of KNO3 + Sucrose as a propellant. This is as simple as it is ever going to get, unless you are one of the types who likes to turn match heads into explosives and propellants. I'm not going to even touch that.

To execute this propellant will require 2 ingredients, sugar, and potassium nitrate. If you have red iron oxide, it may help, but at the time of this writing, the jury is out. Tools - a scale or balance. In a pinch you can make a balance out of common materials, and use small identical objects (like coins) as units of measure. For example, to obtain a 65:35 ratio, you can use 65 pennies, then 35 pennies, or multiples of the two; or, you can use 35 bullets, round lead balls, or sacks of concrete if going large scale. It doesn't matter. You just need to be able to weigh stuff. A piece of window screen. Plastic containers and spoons. Booze. Yes Booze, or a 75% mix of denatured alcohol + water is even better.

Optional, for better grain strength - corn starch which we will turn into dextrin.

I'm going to do a 50 gram batch. We want to go, BY WEIGHT, not volume, 65% KNO3, 35% Sucrose, and a few % added dextrin. We start with the fuel, sucrose, or table sugar. Use powdered confectioner's sugar, if possible.

Next, the KNO3, potassium nitrate. Stump remover, fertilizer, etc.

Finally, we add a few grams of dextrin, which is a binder for the grains to come. Dextrin is made by baking corn starch at 400 degrees for several hours until it turns tan to golden brown. it is very easy to do, so don't hesitate making some dextrin.

Our goal is to get these two ingredients to be INTIMATELY mixed. If you simply stir them around in a bowl, IT WILL NOT WORK WELL AT ALL. You can use a mortar and pestle if you don't mind hours of tedious grinding, but there are better ways.

All of this is somewhat risky. Nothing pyrotechnic is not, but the propellant we make here is quite stable, moreso than black powder. It is more difficult to ignite, burns less fiercely when unconfined, and in general I am comfortable working with it. If you can make BP, this is easier and a bit safer.

Our options to intimately mix these ingredients:

A ball mill (best) which is what I used: