Thread: 44????

Retrieved: June 18, 2016

Last Post: April 27, 2015

So not to highjack the 450 Bushmaster thread.

This was one of those "what if" things while waiting for some parts to show up. I was looking for ease of making brass and something that wasn't proprietary to a maker. I wouldn't want to spend 30 minutes per case to have the AK punt it to China or dent the crap out of it. Or send a barrel to someone to cut a chamber for X2-X3 times the cost of what a reamer would be and I could cut it myself. So, a 30.06 case cut below the shoulder, some 44 mag bullets that were on hand, and you get something like this.

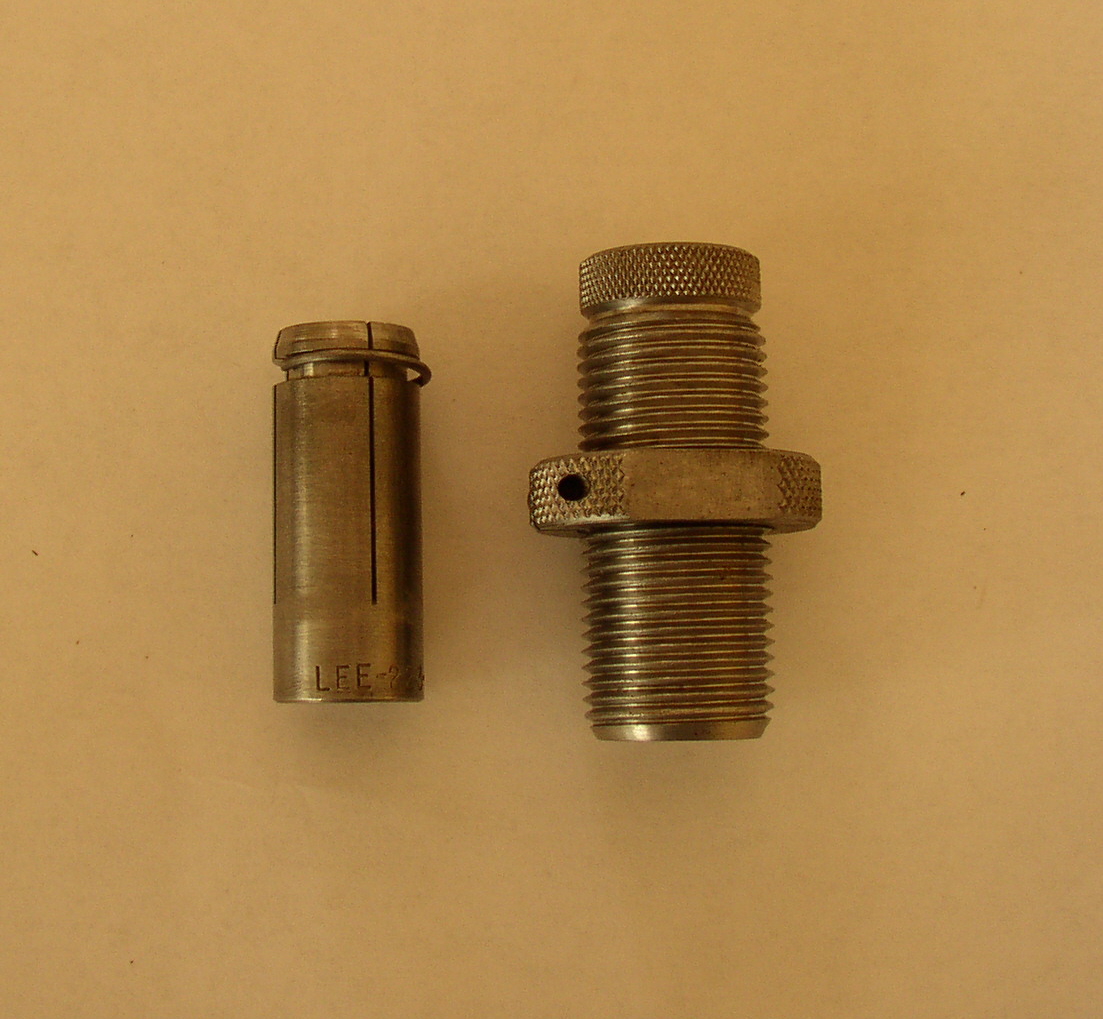

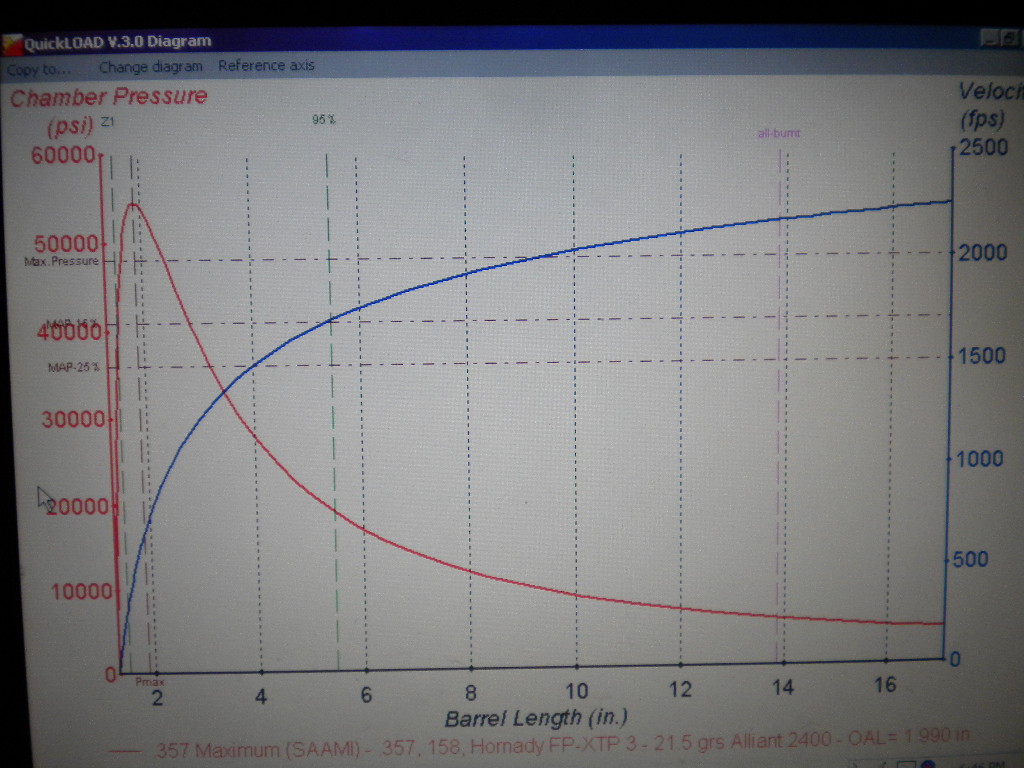

Thumbnail:

The case would have to be fire formed as you can see from the pic that there is a dip below the seated bullet. The lead on top of it was smashed in the loading due to not having a 44mag seating die at the time. The case has not been crimped. On the 44automag they inside neck reamed to a depth of .590 which might be needed to help keep the bullet from moving under recoil...don't know. A Lee factory crimp might keep it in place or might need a canalure in the case....don't know. A RCBS 44mag neck sizer is too big to start in the case, so an expander cone is needed.

To answer some of 1bigguns questions.

The left one is a standard 44mag, the center is the 44???, and of course a 7.62x39. I don't know why in the pic the case looks like it was cut with a hacksaw, it wasn't. The length is 1.700 inch. Don't remember why that length as you can almost get a 2 inch case by cutting a 30.06 at the shoulder. Maybe it was to use a standard die, but the 444 would be the only thing close or maybe it was close in case volume to another conversion cartridge to have a starting point for loading. Before setting a length I would want to get some 180 to 300 grain bullets to see what the OAL would be. It was just one of those lets see thing.

1biggun

03-22-2008

when I get a chance I am going to form some straigtend out 30-06 brass in my 444 marlin dies then cut it down to a length that will fit in a AK mag. I am thinking that with the taper making the OD larger the shorter the case gets ,that a .45 bullet could be used instead of a .44?? if this would work then perhaps 444 marlin dies could at least be used to do the forming. I am also thinking a .41 bullet would work good in cut down 30-06 brass. this would give better bullet weight to case capacity and a shoulder to head space on. there are several wild cats based on necked down 444 marlin brass. The .375 & .411 JDJ and the.375 EXPRESS (WATERS) are all made from necked down 444 Marlin brass. I think cut down 30-06 brass can be formed to make a rimless version of these. A shorter version that would fit a AK/AR mag would be a great round IMOA.

I got a new computer and hope to be able to post pictures soon of some prototypes im working on as well

us_dragunov

03-23-2008

I don't know if you saw but Tony Rumore (Tromix) had problems with the 10 round .410 mags feeding in his prototype .444 Marlin and is going to try a .375/.444 Marlin. I after trading an email or two with him though I think if the .444 were loaded with longer bullets than what he is using there wouldn't be a problem. That being said....the 4 round mags feed perfect. I know the .375/.444 is supposed to be more comfortable to shoot, but I still MUCH rather have a .444 than a .375/.444 so I am still pushing on that route.

1biggun

03-23-2008

The proplem is no one makes a longer/pointed bullet except the $40 a box hornady leverevultion stuff. Not trying to question tony Rumore skills but why would the bullet design affect feeding between a 10 round and a 4 round Mag?? I would suspect the 10 rounder has more upward spring pressure on the carrier and is causing excessive drag, or is pushing the bullet up a a differant angle. the sagia conversions use a barrel shroud as well to help guide the round if this dont work making a no shrouded version is going to be even tougher. I wonder if the mag being designed for a straight 410 shell instead of a taperd 444 marlin round is not part of the problem also??

Do you have a link to the discussion on tonys gun not feeding??

A 375 woul be a better round in my opinion for hunting any way and better rifle bullets avaliable. I think guys are getting stuck on the mine is better bigger than yours thing. I am starting to wish I had not bought a 44 blank but got a .375 instead

us_dragunov

03-23-2008

Yeah...I asked him to try some of the Hornady bullets and he said he did, but only in the 4 round magazines and they fed fine. He also said he loaded up some 300 gr bullets that were pretty long and they fed fine out of the 10 round mag. I'm not stuck on a bigger round....jI ust prefer one that I don't HAVE TO reload for.

Here are the links:

Tromix 444 Marlin Project Has Been Scrapped. - forum.Saiga-12.com

.375 versus .444 Marlin (pic) - forum.Saiga-12.com

hcpookie

03-24-2008

That's pretty interesting! I am curious about this but like I said before I'm not convinced the .44 is the best platform, because of the singular fact that bullet selection and barrel selection is rather limited.

1biggun

03-24-2008

I wonder if a custom cast bullet mold could be made to make a bullet that was longer and more pointed. not sure the tip would hold up in feeding I cant get those links to open up for reason

1biggun

03-24-2008

got the link to open.It seems like the issue is that the sagia mags are not compatable with the 444 marlin. I hopefully will be able to overcome these proplems with a custom mag in my rimless version. I am really starting to wish I had started with a .375 first. the 444 marlin is shorter than a 308 so maybe it is doable. I want at least a 5rounder for hunting as this is the whole point of the build for me. I do admire the fact that Tony will not sell a gun unless it is 100% reliable. since it isnt with a Sagia mag he wont sell it. I have no doubt that a custom mag could be made to make the sagia conversion to work on a custom build. Gunter I still like the Idea of a AK Mag length .44 0r .45 or .458 round sorry to high jack this thread. maybe it can be moved to my 444 marlin thread????

Gunter

03-24-2008

Your not highjacking....just more to think about. Good info all.

The 44 bullet was just what I had on hand. I don't know how much the taper would be with a 45 bullet. I don't have access to the thickness of the case right now, but when back I'll check and see what the taper would be. There are longer more pointed lead bullets up to 500 grains if I remember right. There are some 300 grain jacketed that are pretty pointed. I'll need to probably get a 223 mag and figure out a crimp die to see if it would work.

hcpookie

03-24-2008

Originally Posted by 1biggun

It seems like the issue is that the sagia mags are not compatable with the 444

marlin

Actually not true. The mag will feed up to 4. The magazine is built for a rimmed round - .410 - and not the "rimless" .444. Also, the builder didn't want to muck with magazines, so it would be more proper to say the .410 "no magazine" conversion doesn't feed as many as he wants. Not a nitpick, just trying to make a point. I suspect if you wanted to build a new follower you could get it to work. If the .444 rounds don't truly "single stack", then doing a conversion will involve a new mag.

Now to apply this to a .44 "SUPER LONG" build... the magazine would need to actually single-stack it because if not, the spring force will be consumed trying to push the rounds into the side, and not into the feed lips. A true double-stack would probably work just like VZ's .45 Win Mag if you don't mind the extra work.

1biggun

03-24-2008

HC I was referriorng to the 10 round sagia mags not working correctly with a STANDARD444 marlin in the Tromix conversion. It is obvious there is a issue with it using some factory loads or Tromic would not have shelved it.(I should and will keep my rimless project on a seperate thread )

I have no doubt that IF TROMIX wanted to modify a mag and or reciver it would be doable. I was looking at a used sagia 410 to modify thus weekend but passed. I have one 410 now but dont plan to modify it.

The 44super long would be a great round I dont know if it would be any better than the 450 bushmaster but it is possable that the 450 AR mag could be modifed to fit a AK. the firts step in my mind to building a 44 superlong would be to come up with a standard dies that will size the brass and a way to seat and crimp the bullets. the next would be a way to ream a chamber Of course a custom one could be cut for about $150. I personaly make the round longer to take the full length of a AK mag with the heavyiest bullet avaliable or usable.the beauty of this round would be the use of 30-06 brass and the avalibilty of it.

us_dragunov

03-25-2008

I am sure Tony (Tromix) could make the .444 Marlin work without too much trouble...maybe a slight modification to the magazine....like HC said a new follower...something...his issue is that he is making these for resale and doesn't want to deal with magazine work, nor does he want to deal with whiners and customer service issues when people use the 10 round magazines and start having feeding problems. I completely understand and respect that. That being said I still want one. I'll deal with my own 10 round issues....lolol

On another little note I believe SureFire Magazines is now making a 10 round for the Saiga 410...I wonder if it would work any better? Hmmmmmmmmmmmmmmmm??

1biggun

03-25-2008

I would think that if someone ironed out the bugs and came out with just a 444 marlin to saiga 410 barrel conversion kit it would sell (hint hint). The liabilty would scare the crap out of me however. I really want a 444?? in a PISTOL so a saiga conversion will not help me much. that is why I am trying the rimless thing with a standard AK kit.

are the surefire mags 2.5" or 3"???? I want some 2.5" mags for my gun I Only have 3" now

1biggun

03-25-2008

quote:

What kind of load would you start with on this? I'm not sure but

perhaps one of the .45 Win Mag loads?

I would think the 458 x 1.5 barnes would be close.

there is also a 445 super magnum on page 217 of the COTW book that describe it as a 44 mag with 3/8" added to the case.

there is also the .44 wesson on page 339 of the Handloaders manual of cartridge conversion that has a 1.63 case length that should be pretty close

also the 44-40 extra long ( can be made from cut down 444 marlin & Possably rimless with 30-06 brass) it has a 1.58" case length page 340 of the Handloaders manual of cartridge conversion this a very old round I could not find dies for it. the standard 44 -40 is also close and may also maybe doable with 30-06 brass in a rimless version it has a 1.30 case length. very close the .44??? I have been eye balling the last two for a rimless version made from 30-06 brass with standard dies.one of the above loads should be close once the case capacity is determined

Gunter

03-26-2008

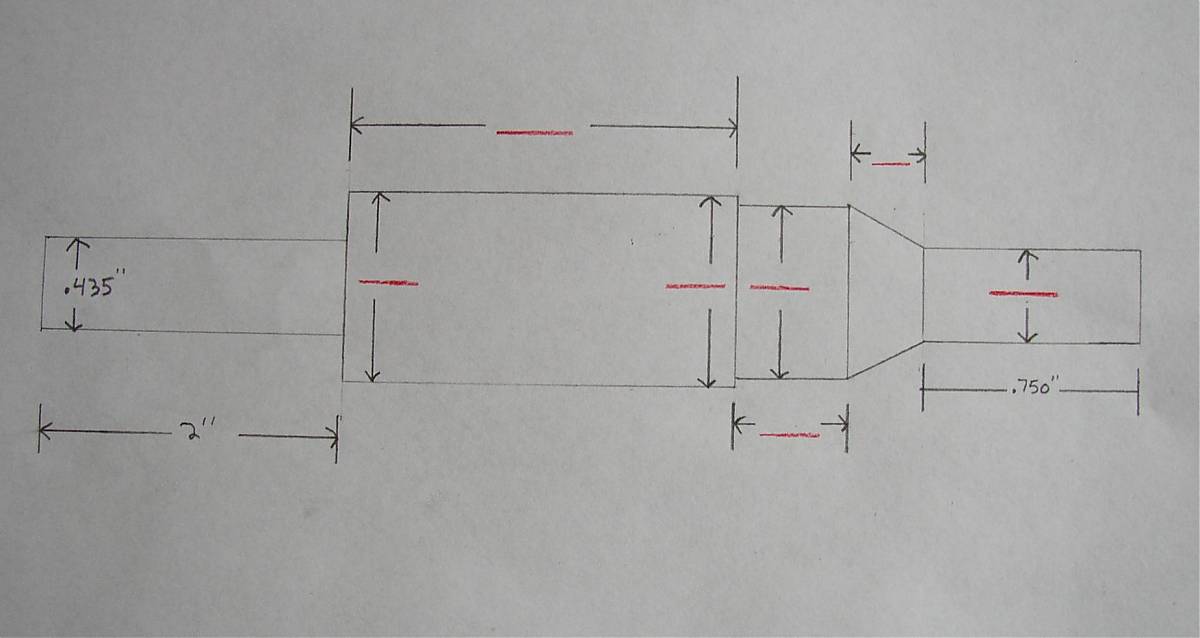

Ok, back home and dug out the notes so here is the whys:

The reason I cut it at 1.700 is that is the length that the 44 Ballard Extra Long is cut at before opening it up. Yeah it's based on the .220 Swift, but should be close enough to get a safe starting load. Plus it left some OAL room for different bullets in the AK mag.

Now the rest is in "around" numbers because I was using the cheap digital calipers. Mouth rim thickness after sizing is .016. For some reason I didn't write down the OA loaded mouth size, but I think it was around .459-.460 range without a crimp. The base of the unfired Winchester 30-06 case measured .464, so no going with a bigger bullet without inside reaming. Now if you cut it a little longer the mouth rim thickness might be a hair smaller after sizing.

That is where I stopped because I was going to get a 444 die set and see if maybe it could be used as the FL die. The base should be close, but don't know what the size is at 1.700 in the die. 1biggun maybe you could measure one of the 444 cases at that distance and see if it is close to .459-460. I agree the first step is to be able to produce ammo without too much work so we don't have to spend 10 minutes looking for the case that the AK just punted into the weeds.

ETA: The 445 Super Magnum is close to this.

1biggun

03-26-2008

I dont have a actual 444 marlin round. I have the 444 marlin dies I could go cut off a O6 round an run it through a die an see what I get though I may have to fire form some how first to blow the round out first not sure. I suspect it is going to be larger than what a .430 bullet will need. if the 444 marlin is correct at 2.225" then with the taper it is going to have a significantly larger ID at 1.70

I keep seeing the base dia of the 30-06 listed at .470" in all the books but I keep coming up with .462-465 on everything I measure as well ??????? the 444 marlin is listed at .470 as well.

1biggun

03-26-2008

well this is not going to be as easiy as I thought I cut a 06 case down to 1.850 ran it through a set of 444 marlin dies. the first problem is the 30-06 taper is sharper so the marlin dies only opend up the first 3/8 or so I seated a bullet and I come up with a case mouth of .459 the case is smaller behind the bullet. this would likely fire form out and could be shot as is. the problem I see is the very little taper from the base to the the case mouth base=.465 - case mouth=459 leaves a differance of.006 between the 2 ends. I wonder how this will feed and cycle with such a slight taper? the 444 marlin specs show the case mouth at .453 not sure how this is possable with a .430 bullet. perhaps It will crimp down some but i doubt it. I really need to get some 444 brass to measure. also calibrate my calipers. I took pictures now I have to figure out how to post them????

1biggun

03-26-2008

this may? have a picture of a 44??? extra extra long BIGGUN VERSION

Gunter

03-26-2008

That sounds about right on the mouth size and slight dip under the bullet. I used a 44mag expander to open the case up pretty deep. I wonder if it might help to anneal the case first or if it would make it worse.

ETA: Never mind. I see you got the pic up.

Looks good. So would the 444 die work for the FL die? If we could make a longer expander or maybe use the 44mag.

1biggun

03-26-2008

hey it worked!!!!!!! 30-06 on the right. the over all length of the 44??? is slightly to long for a 7.62AK mag but it would seat further down to fit. It does fit in a 223 plastic mag but the lips will not hold the round in it is close however. I suspect that a steel 223 mag with a custom follower and the lips bent in would single stack nicely. my tool post has enough travel to bore in that deep I am thinking the chamber could possably be bored at a angle instead of cut with a reamer. how bad could I screw it up?? the worst is I shorten a barrel another 1.850" the bullet shown is a 265 GF jacketed flat point.

1biggun

03-26-2008

I am not sure I had my 444 dies set up right they are used hurters and the sizer and the expander appear to have to share the same adjustment rod with differant expanders. the round could be fire formed or like you said a longer expander rod could be made to open up the entire case. I am not entirely sure that the bullet is correctly and crimped. it may just be pushed in with the seater, it is seated pretty firmly it kind of looks like the bullet may have just expanded the case though. I need to find some directions for these dies. 444 marlin uses a sizer a seperate expander and a seperate seater. I also need a taperd expander to straightend out the 30 cal mouth on the 30-06 brass to do full length 444 marlin as well. I need to get a 44 mag die set for a friend any way so I can try it when I get one

hcpookie

03-26-2008

It looks like you guys are close on this! You should use the expander before using the seating die. You may need to spray some lube on it to keep it from seizing. Believe me when I say that it is a bugger to remove a die that's stuck in a case!!!

1biggun

03-26-2008

My problem is there are a bunch of differant parts there is 2 differant expanders and only one adjusting rod between the sizer and the expander. I am not sure how it all assembles or if parts are missing. I know you size then expand the mouth then seat then crimp in seperate dies on a 444 marlin. but not sure If I have the parts assembled correctly. for each step

I am thinking size it with a 444 marlin die and possably seat and crimp it with a 44mag die.

I really have my heart set on a 444 marlin rimless as I want the extra power and will be shooting it in a pistol so I want all the muzzel velocity I can get. I may find however that this 44??? (the name is starting to grow on me) will hold all the powder I can burn in a 14" barrel an a 444 marlin may be over kill. the 450 bushmaster and the 458 socom will likely bolth out perform the 44??? but If I can make it happen on 30-06 brass who cares. I can afford to shoot it.

hcpookie

03-26-2008

Whatever you guys do, you should consider ensuring the overal length will be < 2.25" so it will fit into an AR magazine, that way it will not only fit in an AR mag, but also have a wider appeal for AR wildcatters.

1biggun

03-26-2008

I agree it needs to be short enough that the hornady leverelution bulletes will work as well ,if an when they become avaliable. By the way my 444 seaterdie will NOT properly seat the bullet the part that pushes the bullet in place. it will not screw in far enough to make contact with the bullet. it will not roll crimp also it will however will hold the bullet pretty thight in the case after a couple passes I got the case mouth down to.455 I will try to find some 44mag dies to play with

hcpookie

03-26-2008

hahahaha I'm sitting in my hotel room watching MACK demo the .50 Beowulf on Future Weapons... the point of the short was to demo the Beowulf's anti- material capabilities. I must say, it was impressive. A few points - the .50 Beo uses 400 grain rounds (didn't know this). Also, emptying a full magazine of .50 Beo puts a half-pound of lead downrange!

I know my .45-70 can use 500 grain rounds (and YES I plan to load some!).

How big of rounds are available for the .44 size?

1biggun

03-26-2008

I have seen 300GR I think there are some custom stuff IN 325 in 44. I think after you shoot some 500gr 45-70,s you will be looking for some ligther loads in a hurry

Gunter

03-27-2008

LOL. I just put the ??? because I didn't know what to call it.

Speer has the Uni-Core 300gr jacketed soft points. If you go with plain lead then there are some 500gr. Most seem to be in the 240gr range.

I watched that also. Has a little more kick than a 5.56.

hcpookie

03-27-2008

Call it the .44 GUNCO SPECIAL! Why not? There is a "Guns and Ammo" round in the wildcat database...

Gunter

03-27-2008

Looking for magazines, so do you think a metal Romanian single stack 223 magazine would work? Hunting here is with a 5 round max magazine.

Gunco Special sounds good.

Or maybe the Gunco Earth Shattering High Caliber 4 Mile Range Heat Seeking Special. I think that I got most of the MSM buzz words in there. lol.

1biggun

03-27-2008

I dont have a single stack 223 mag but Im guessing it would be to narrow. I put it in a doublestack plastic bulgy Mag and except for the lips not holding the roumd in place it seemed to fit ok. sectoining a G2 308 mag would work possably but would be a lot of work.

1biggun

03-27-2008

could name it the 444 GSRSM (Gunco Super SHORT Rimless MAGNUM) drived from a short 444 marlin rimlesss

or just the 44 GM

or the 44 BBSKMA ( Beowulf Bushmaster SOCOM Kiss My Ass )

or the 430-06S would allow adding a 4 to the exsiting head stamp the S stands for short would be able to make the factory head stamp look original.

THE 44??? is a cool name to excuse me while I whip out the ole 44 question mark!

the 444 TT (444 Triple Threat)

MY main concern would be the feeding and extraction of empty brass with very little taper. head spacing off the case mouth is also a issue.

the .41 and the .375 versions of this round should not be overlooked.

This round would work very well on 223 length bolt actions very well also and you can bet If I have to shell out for a reamer there will be a savage bolt action 44??? barrel for my 223 made.

gunter

03-27-2008

lol. I like the 44 BBSKMA .

Like you said the .375 might be better as there is a wider range of bullets. The .375 Shannon and .375/38-40 Rimless would be close. Plus it would have a shoulder to headspace off of. Not a big fan of headspacing off the mouth either.

hcpookie

03-27-2008

Honestly the mag modification isn't really that hard! These would fit into a G3 mag with a little extra space. Right? Could you cut a mag short, leaving enough for tabs, then add a spine with holes that the tabs can fold in to.

Or you could do like VZ and I are doing and just buy some square tubing and use some AK mag springs.

1biggun

03-27-2008

It seems to fit the G3 mag very well just to long. I was thinking of just taking a section out in the middle doing some type of overlap and a couple tig welds. I have like a dozen from when tapco had them cheap. I had planed to mod one for my 444 marlin build as that round is shorter than a 308. this would free up some trigger guard space on that build. I think a 450 bush master or possabley a 458 socom AR mag might be workable but the cost and still having to mod it might not be worth it. the g3 would need a differant springng if it was modifed. I think a steel 223 mag with a lip mod would be the easiest not the cheapest though. I think a single stack would be the best as far as getting it to feed. I am starting to think a custom reamer might be worth the $$$$

1biggun

03-31-2008

Barrel twist will have a large factor as to what bullets this or any .44 based weapon can shoot. Is there a place you can buy taperd case expanders?? I am thinking of getting new 444 marlin dies likely RCBS so I can get bits and pieces to intechange of the same brand. that way if this round does come to fruitation It can be reloaded with currently avaliable dies and listed part numbers sort of a way to standardize it. I am sure if one could get final version built and a gun that functions correctly that custom reamers and die sets could be made that would be worth the money.

I am still thinking a .41 0r .375 version might be better. yea the .45 bushmaster,458 socom and .50 grendal are bigger but so what. they also have slower MV and kick like hell. How many people really want one other than the mines bigger than yours thing?? In reality with the limited powder capacity a .375 0r .41 or .416 bullet is going to likely have better performance and accuracy further out. the .375 has bullets up to around 300 grains and the 416 has bullets up to around 400 grain. (about he same as the .44). The the 325 grain bullet that the 416 rigby and the 416 weatherby use, would possably be a good choice for hunting. there is a 400 grain round nose solid for you guys that think you are going to go Rambo and need to shoot through solid doors and army tanks and all that. IMOA it is cool to say yea mines bigger than yours BUT how many guys actually hunt with a 460weatherby magnum??? there is a reason that 7mm to .35 cal rounds are the most popular in north america. unless I am going RINO hunting in Wisconsin soon I thing maybe a little smaller might be a lot better. If you want to give it a Macho name call it the 375 Anti SUBURBAN SUPRRESSION HOSTILE OVERLY LOUD ELEMINATOR. OR A.S.S.H.O.L.E for short. LOL

hcpookie

03-31-2008

My dad would be all over something like a .41 because that's "his" caliber... most all the performance of a .44 without the nasty aftertaste

quote:

Now I'm interested in how you would shoulder the .44 GS to a .41 - is there

enough there for a neck?

HC on page 321 of the manual of cartridge conversion there is the .41 Jurras. it is a 1.298 long necked down cut down 30-06 case. it does in fact have a neck. its what I have in mind but longer to fit in the ak mag.

on page 286 there is the .375/38-40 another cut down 06 shell it is 1.125 long

on pg 282 there is the .375 shanon same thing but 1.315 long

I think all that it would take to make this is the correct set of custom dies.

some of these would fill the same void that your 9x39 would

Gunter

04-01-2008

The .416's would be a little pricey to just go plinking with for me. $1+ a pop just for the bullet.

I haven't found a tapered expander for this. I was going to turn one on the lathe, but just don't have the time right now. I think that RCBS all uses the same thread so if one was made it might be able to be used between the 444 and 44mag die which ever one would work the best. I was going to get a 444 die, but Midway is out.

I have a metal .223 single stack on the way to see if it might be useable. In an AR mag the round just noses into the front of the mag and the last round just pops right out. Maybe someday there will be an AK 450BM magazine.

For the .375, can the std 7.62x39 be necked up? No fuss with mags and bolt face opening.

hcpookie

04-01-2008

I still think the best magazine will be a straight no-taper design. Curious to see how that 223 mag will work.

I don't think the x39 can be necked up to accomodate a .375 without using an expander die. I neced up to .358 and it is basically a straight-walled cartridge like that. Nothing to headspace from, either. So if you did, and had to ream it, you'd be getting the brass pretty thin I think.

1biggun

04-01-2008

quote:

For the .375, can the std 7.62x39 be necked up? No fuss with mags and bolt

face opening.

No 7.62x39 not big enough DIA

quote:

I still think the best magazine will be a straight no-taper design. Curious to

see how that 223 mag will work.

I have been thinking that a straight single stack mag made from tubing or bent in a break would be very doable. the round is very straight.

To be honest I think if one were to make there own mags then they might as well make the round slightly longer and forget about the AR mag length. One of the great advantages of the AK is the mag well can easly be enlarged. this sort of brings me back to my original 444 rimless marlin idea. I want something that still allows use of a standard reciver and gives good finger clearance in the trigger guard. If a 223 mag can be done easily then I will want to do one in that length as well. I do have a AR reciver sitting here that I am not sure what to do with. a AR & AK in 44???? would be cool.

I wonder if a reamer maker would cut us a deal on several reamers on a group buy?? or get one reamer and have one guy do several barrels. the head space issues are still a concern in 44 to me.

--------------------------------------------

quote:

The .416's would be a little pricey to just go plinking with for me. $1+ a pop

just for the bullet.

UH yea just started looking at that. Yikes found some for around 75 cents each (speer) also saw some at over $4.00 each(trophy bonded sledghamer solid 25 for $135)

cast lead would be doable for plinking . the .410 pistol bullets are cheaper but kind of defeats the whole idea of using rifle bullets.

the .375 still looks very doable and might be the best round all of them. the price is better, selection is good, better MV and lighter recoil. and better optimazation of limited powder capacity.

Gunter

04-01-2008

Was looking at the .41 JMP automag that you posted. That little shoulder didn't sound like much, so I drew the top of the case out and it is more than what I thought. RCBS makes a die set, forming die, taper expanding die, trim die, and neck reaming die.

If you really wanted something big you could use the 400gr .410's for the 450- 400 Nitro Express.

1biggun

04-04-2008

I really need to know if 44 mag dies can really seat and crimp it. I need to get a way to expand the 30-06 brass down to the base so I can properly full length size it in the 444 marlin dies.

hcpookie

04-05-2008

A thought - the .375 or even the .41 Mag bullets need a neck, right? OK.

Take this one step further, and open up the .06 cartridge at the neck BEFORE you cut it. Presto, you have a neck for your .375 or 41 Ragnarok and you could probably use .06 headspace gauges.

Yeah, I know it kind of takes away from the original .44 idea, but since you're thinking about varations I figure that couldn't hurt. You could still use .06 mags like a BAR mag, or possibly 8mm mags like the MG-15 mag.

1biggun

04-06-2008

If you cut at the neck were would you seat the bullet?? another alternitive for a large bore in that length would be necking up a 358 win (358win is a necked up 308) to .375.

I have some RCBS 44 mag dies coming to play with on the 44???. I think I will try to fire form the cut 06 brass in my 444 marlin dies to blow out the case then try to seat and crimp with the 44 marlin dies. Once A actual gun it built then fire forming can be done in it. I think the 06 brass can be taper expanded as well. I have been wanting to build one of those in die fire forming set ups anyway. It might be possable to just cut the 06 brass to size expand the neck the neck, seat the bullet with 44 dies then just shoot it in the built gun plinking with lead bullets. the fired brass will then be blown out. the catch 22 is you need a round that is all formed and finalized to design the chamber off of.

I am thinking a throating reamer can be used first then follwed by boring the sligtly tapered chamber in the lathe by using the tool post set at the proper angle. how ever the chamber is cut, it is going to need a very prounced step from chamber to free bore to headspace off of.

1biggun

04-06-2008

I found this while looking around. if it were rimless it would be very close to the 44??? the 445 super magnun is made with cut down 444 marlin brass. it apears that it is sweaged or turned down at the base. loads should be pretty close though.

http://www.sixguns.com/tests/tt445sm.htm

Gunter

04-07-2008

Been away for a few days. The 223 single stack still is not here.

The RCBS expander for the 44magnum die is a 9/16 SAE thread, so I will have to turn a tapered one or turn a bushing to use the expander setup out of the 7.62x39. The 7.62 has two removeable expanders so it shouldn't be to hard to turn another to .426 (size of the 44mag expander).

1biggun

04-07-2008

Gunter you may want to make 2 differant ones on with a lot of taper and one that will reach all the way down almost flush to the bottom. When you expand do you have to have a die to support the case or can you just run in with the expander sticking way out????? I was looking at my adjustable reamers and it might be doable for cutting a straight wall chamber (like HC suggested some were). I was thinking it might be possable to add a pilot to the threaded part of one of these. it looks like a piloted thrating reamer can be had for around $30 my thinking is run that first then set up the adjustable reamer with the correct tapper and run that in second. it looks like the adjustiable reamer will cut a sharp edge to headspace off of. Just thinking outloud here.

1biggun

04-07-2008

quote: The 7.62 has two removeable expanders so it shouldn't be to hard to turn another to .426 (size of the 44mag expander).

you are going to want the expander bigger than .426 because 44 mag is a non taperd round. the 444 marlin is bigger at the base than 44 mag so you are going to whant a bigger expander. I think what you want to do is expand the entire cut 30-06 case straight (no taper) then run it back through the 444 marlin die to give it the taper. then run it through the 44 mag die to do the neck and seat the bullet. my prototype brass resulted in .456 at the neck and .465 at he base. I am thinking you would want a expander .009 larger than the bullet. my bullet measures .429 (on my cheap calipurs) so that should give a expander of .438. now I am assuming the brass is the same thickness all the way back to the base. it may not be and also all brass is not the same. millitary is thicker so if you are useing that then then it all goes out the window. I am using some remington for my inital set up. what I am invesiong in the finished brass is a nice straight taper from the base to the area were the bullet is seated aprox .450 back from the mouth.

hcpookie

04-08-2008

ID reaming can be tricky because you would need to ensure you don't cut into the web at the base.

You can get a neck reamer and run it down into the case to the depth you require. I'm thinking about doing a slightly different version of a neck reamer to ream the ID of the military brass like this:

1. Make a sulfur casting of the inside of the good cartridge, *or* cut it in half. Either way, I would get the actual ID measurements of the entire cartridge.

2. Either find an adjustable reamer or build my own to match the ID. The taper will ensure the web at the bottom will be preserved. The pilot could be the primer hole.

3. Chuck it in a drill press or case trimmer and trim the brass.

I think it should be that easy. The benefit of doing this is that you have the greater case capacity without sacrificing safety.

This is what I've thought up for the .06 brass I'm going to cut down to 45 Winchester Magnum.

A question - have you looked around on other wildcatting forums like the accuratereloading.com forums? Someone may have already paved the way and may have some tips/insights to help out.

Gunter

04-08-2008

Funny you should bring that up HC. I was just there last night reading a thread that was close to what this is only using a full length .06 case. They were asking about a rimless 444 Marlin like 1 biggun wants. The two main concerns were taper for feeding/extraction and headspacing off of the mouth with the pressures that it would run at. I can post a link to the thread if it's not against the rules here and you might have to login to read.

They got into using .416 bullets with a shoulder and going up to a .284 case and using a shoulder with the .429. The 450 BM has to headspace off of the mouth, so guess Hornady got it to work?

The easiest might be to just go with the .375 Shannon or the .375/38-40. .375 rifle length barrels are easy to come by and a good selection of bullets.

hcpookie

04-08-2008

I have an account over there, I'll try to check it out later.

The BM is going to be easy to headspace - the gauge itself needs to be 1.7" to ensure it is bottomed out, and you're going to set it from that. The same thing would need to be done for the 44 ?? by making sure the gauge has a distinct edge to contact the edge of the chamber. I don't really see what the trick is, because all other straight-wall cartridges like 9mm, .40 SW, .45 ACP, etc all do the same thing.

Could you blow out an .06 or 308 case to eliminate needing to cut it down? That would be quite interesting. That's what I was thinking when I said cutting at the neck and using a taper expander to open the remaining taper of the case to full size. You could fireform it too, I think. Either way, you would end up with an .06/308 case that is misisng only the neck and is enlarged to .44 caliber size. Then you'd need to find an appropriately large magazine and you're set.

1biggun

04-08-2008

Id like to see that link. I think that its ok we have been postink LINK s on every thing else. I dont think it is ok to post a COPY of another site???????

Gunter

04-08-2008

Here's the thread:

Max bore for -06 case? - Topic Powered by eve community If it is against the rules, mods please delete.

I forgot to answer one of your questions 1biggun. On the 44 magnum dies set the first die is the FL outside die and primer pin. The next die is the inside expander. The expander die has lots of room between the outside of the case and the inside of the die. So really it is just sort of self centering.

Has anyone heard of sealing problems when going over the 36,000 psi (SAAMI 44 mganum) with straight walled cases? Plus the 44 Ragnarok might need to be inside reamed to a depth like the 44 automag to keep the bullet from walking in under recoil.

hcpookie

04-08-2008

I found this nugget while reading that thread -

"Ken Howell's book Custom Cartridges lists it as the .444 Marlin Rimless (aka .425 Rimless Express.) Basically, a .30-06 basic case trimmed to 2.225" (same length as the .444) Headspaces on the mouth just like a .30 Carbine."

Interesting, no? That would eliminate a great deal of effort. ".30-06 basic" brass. I wonder if that means untapered. I know the "45 basic" brass is what .45-70 is made from, it is trimmed down to size to make .45-70. Where to find "basic" brass is the question.

Also this:

"The 10.75x57 Mannlicher was chambered in both the 1888 and the 1898 Mausers.

The 10.75x57 was the 8x57 expanded to .424 bullet diameter,it was introduced around 1900 and became obsolete within a few years.Measurements were base .468,shoulder .465,and the neck was .448.

It is believed that headspacing problems were responsible for it's being dropped from Mauser's line of chamberings.Feeding problems and the fact that it was underpowered for the game it was used on may have contributed to it becoming obsolete."

That's another option - use 8mm brass. The 8mm base is very close to a .308/.06 base and in some cases (if not all) the bolts are interchangeable. A neck of .445 should work for for a .45 build as well... slight reaming and it would be perfect.

hcpookie

04-08-2008

Originally Posted by Gunter

Has anyone heard of sealing problems when going over the 36,000 psi (SAAMI 44

mganum) with straight walled cases?

I have not. The .45-70 max loads for heavy rifles approach 40-50,000 CUP depending on whose loads you reference.

quote:

Plus the 44 Ragnarok might need to be inside reamed to a depth like the 44

automag to keep the bullet from walking in under recoil.

Crimping is another solution to ensure no bullet walking. I would like this more than reaming because I'd be concerned about long-term brass flow, and the possible need for additional future reaming if the case were to expand after repeated firings. But maybe I'm being too analytical about it?

Gunter

04-08-2008

Now to blow our minds a little more.... how about a .243 WSSM necked up and rebated rim?

I think that the one in the pic is a 45 ACP bullet. That would give us a shoulder. Wonder how the chamber wall thickness would hold up in an AK sized barrel?

1biggun

04-08-2008

Has anyone heard of sealing problems when going over say 20-25,000 psi with straight walled cases? Plus the 44 Ragnarok might need to be inside reamed to a depth like the 44 automag to keep the bullet from walking in under recoil.

I cant see why this would be a problem! The 44??? will be nothing more than a 444 marlin but shorter with no rim. the 444marlin is loaded to aprox 45,000 psi does not have to be inside reamed or have sealing proplems. perhaps the longer full length 06 case will have more problems due to less taper over a greater length?? the 50 beowulf is pretty straight and I dont think the 450 BM is inside reamed to keep the bullet from moving back.

I hope to design my 44??? to crimp on the groove on the 265 GR bullets that I have. My biggest concerns are getting that big flat bullet to feed into the barrel with out jaming or binding the breach ID is only .035 larger than the bore. it is going to need to go in pretty straight.

A .375 version keeps looking more atttractive to me

My 44 mag dies should be here any day. and I have a barrel blank, but that is susposed to be for the 444 rimless but I have been thinking the shorter 44 might be just as good and work on a standard reciver. plus if it is a bust I can always rechamber to the longer 444 rimless down the road. It looks like all I can turn on centers in my lathe is 19" so that is what any of my 44 builds will be with the numrich blanks will be limited to.

the 99 dollar Question is who is going to step up and be the first to buy ,build, or bore a sussceful 44??? reamer or chamber

1biggun

04-08-2008

I think the WSSM necked up and fully loaded would excede the safe threshold of the AK(what ever that is) not to mention the amount of barrel it would displace as HC pointed out. If I recall correctly the levithan series of ammo used various WSSM necked up and cut down for the mini 14,s. Of course you could down load the WSSM wild cat but then you might as well stick to cut down 30-06 brass IMOA.

I read the link about the rimless 444 posted by gunter and relized that it basicaly said the same stuff that I had been saying about the head spacing and using 444 marlin dies on 06 brass. I am starting to think a phone call to some one like Z hat might be a wise decision at this point. I feel if the 450 bushmaster will feed and headspace in a AR then the 44??? should be doable in a AR and likely a AK as basical the 44?? is just a slightly smaller ID version.

hcpookie

04-09-2008

Another thought -

You could use 7mm brass since it is not only the same rim size as .308, but it is slightly longer and would probably require no I.D. reaming when cut at the shoulder...

http://stevespages.com/jpg/cd7mauser.jpg

vs. 308:

http://stevespages.com/jpg/cd308winchester.jpg

The good thing is that 7mm mauser brass is relatively easy to find, and you can even find once-fired brass at several places.

1biggun

04-09-2008

I was thinking that the 30 benchrest brass might work for a .375 or .41 build necked up and still fitting in a AK mag. its pricy. but about the right length

Do you have a link to the 7mm mauser once fired brass?? I have a M98 with a shilen barrel that I need to load for.

1biggun

04-09-2008

I got my 44 mag die set today it is a 4 die set so i am going to have to figure whats up with that. I think one die is a odd ball seating die unmarked and is square at the top??? going out to cut some 06 brass up now.

hcpookie

04-09-2008

4-die sets usually include a crimping die.

1biggun

04-09-2008

this appears more like a misc die that he through in (ebay used crap)

I went out and cut some 30-06 brass to 1.850 expanded straight (as best I could with some misc die parts)1. sized it in my 444 marlin die with the original expander removed.

2. rexpanded the neck/bullet area with the 444 marlin dies. 3 seated the bullet with a 44 magnum die it didnot give much tension on the bullet so I 3. ran it through the 444 marlin seater and it seems to put a good squease on the bullet.

I ended up with 3 rounds that If I had primed and powderd would not be afraid to try to fire.

The only reason I needed the 44 mag die was that the 444 marlin seater/ the part that pushes the bullet down would not screw down far enough to fully seat the bullet. I really think this can all be done with a slightly modifed die set. Or perhaps a differant brand of 444 marlin dies that has a longer seating range. I can easly modify my seater to work and still be functional to do 444 marlin as well. A expander to straighten the brass out is a must if you want a nice taperd round. I think once I come up with chamber you could skip the expanding and just fire form the case buy shooting it.

I then went out and made one with primer and powder just to say I have the first functional 444??? biggun special or a 11x46 Gunco special or a 430x1.85" or the 444 rimless short mag or the 444 SURT well any way I got the round now I need the gun.

1biggun

04-09-2008

OH YEA IT FITS IN A STANDARD AK/AR LENGTH MAG! 2.180" LOADED LENGTH ON THIS PATICULAR ROUND. IT WILL NOT STACK CORRECTLY IN IT HOWEVER. THE 223 ROUND WORKS BETTER BUT WITH 4 ROUNDS IN IT, ITS NOT PERFECT AND THE LIPS NEED TO BE PINCHED IN SOME.

hcpookie

04-09-2008

Very cool!

You're going to need a straight mag, no doubt. You could either:

1. Adapt a .308 magazine to fit, or use one of the .308 Saiga mags out there.

or

2. Cut off the top of the AK mag and weld it to an appropriately-sized length of rectangular steel tubing.

Gunter

04-10-2008

Congrats! Looks like Midway has the 444 Marlin dies back in stock so I'll be ordering them today along with a factory crimp die. Did the standard 444 Marlin die roll the mouth of the case much? What size expander or expanders did you use to open the case up before sizing in the 444 Marlin die?

I was going to make up a dummy chamber to test feeding if K-Var would ever get the .223 magazine shipped. If we can get it to feed then we should be set. Then time for a chamber reamer.

1biggun

04-10-2008

I expanded it WAY oversize with a misc expander turned backwards. I never really measured it but it was bigger than a .45 bullet. I even got one stuck in my die and had to pound it out with a hammer. I cut a round lengthwise, and the walls do get thicker toward the bottom. so care needs to be taken not to cause damage at the base. perhaps a taperd expander that would match the brass would be doable. if you expand down about 75% down you get pretty good results. I get no roll crimp with the dies I am useing likely due to the shell case being shorter. a couple possabiltys here,1. shorten the die or2. maybe a 44 mag crimping die I am concerned that the 44 mag die will try to size the case down as the 44 mag has a smaller OD,.3. I am planing to get a Lee factory crimp die ($10) in 444 marlin and try that it might need to be shortend to work on this round. the factory crimp die works by puttind a series of littlr demples at the neck. I think this would be better than a roll crimp for head spacing issues and also does not require a groove.

I am still very concerned with feeding and extraction of this round. I converted the case demensions of the 450 bushmaster specs that HC posted to inches. I found that the 450 bushmaster tapers down .022" from base to mouth. My round only has .009" less than half. this means that the bushmaster has a .013 more clearance when entering the breach. the tromix 444 marlin has a shrouded barrel to aid feeding the same as the .410 SG so non of that build applies here. I am expecting to have to champer the breach considerably (not sure how much case/base can be left unsuported?) and a lot of feed ramp and or mag work to get this thing to feed. to get them to fit in a AK mag. IF the Hornady bullets were avaliable this would likely be easier. The hornady bullets might require a shorter case I left some room with this case length for a longer bullet but not a lot. I want to build a bolt gun as well if I buy a reamer so even if I cant get this to work on a ak the reamer will still be of use. I am still looking for a way to do this nearly straight chamber with out a $150 reamer.

1biggun

04-10-2008

quote:

I was going to make up a dummy chamber to test feeding.

Thats not a half bad idea. just drill a hole in some round stock or a old yugo barrel this would save the risk of messing up a good barrel an chamber when working the bugs out.

I wonder If a reamer manufactuer would cut a better deal on several reamers at once???

hcpookie

04-10-2008

For the crimp, try this:

1. seat a bullet to the proper length 2. adjust the bullet seater way out 3. screw the die down closer to the base until the crimp is formed 4. screw the bullet seater down to the bullet

This should give you what you need. Too much crimp is usually bad, so don't make that mistake. Some of the factory 308 I have is crimped so tightly that the bullet is deformed!

About getting the mag to feed -

Consider setting back the center support if you have to. I managed to get my .308 build to work by relocating the center support back about 3/16" or so. It is now 5.1" from the front of the receiver. I had to cut the hammer some near the pivot to get it to fit without getting stuck on the spring. A small tweak, but it gives you quite a bit of extra space to play with!

1biggun

04-10-2008

Hc the problem I have is the die bottoms out on the shell holder before it forms a crimp with the 444 marlin dies. the 44 mag dies start to reform the larger case when I try to use them.

I think this thing is going to kick like hell and there is going to need to be a pretty decent crimp. not to mention that the bullet is going to have to contend with a bullet guide and the breach opening to load its self. I also want to avoid a roll crimp as it will affect headspace. I am really hopeing a lee factory crimp will be the answer in conjunction with a crimp groove in the bullet. Right now I am working with hornady 265 GR semi jacketed Flat Points as being my primary load for this build. before I finalize my case length I need to make sure the barrel twist is correct and what other bullets I may want to use, I am sure that I want to be able to shoot cheaper an lighter cast lead stuff as well but suspect that this thing is going to be finicky as far as feeding. I wonder how the bushmaster is crimped??

Gunter

04-10-2008

Yep, I was thinking a 444 Lee factory crimp also. We wouldn't want to roll crimp with case that headspaces on the mouth.

The test chamber could be a stub that has been made a slip fit into a trunnion. The barrel pin will hold it good enough for testing. What have you guys found for clearences on chamber specs? Someplace I recall .003 per side for a total of .006. That seemed a little big.

Finished the adapter for the expander holder, so next will be a couple of different sized expanders.

hcpookie

04-10-2008

.006 would not be too loose for an autoloader. That gives you .003" for case expansion. I don't know if that would be enough for a straight-walled case like this. The good thing is if it is not, you can cut it bigger with another reamer.

Look back at my chamber casting thread and you'll see my Romy "G" kit chamber casting is .006" larger at the neck than reloading specs, and .003" larger at the base:

http://www.gunco.net/forums/f244/chamber-casting-35607/ LINK 404

Im not sure of the clearance needed for a round like this. the more clearance the easyier it will feed BUT the less accurate it will be and the more the brass will get worked. I figure it would be very wise to consult a reamer manufacturer at that point. I am thinking also that IF I have a reamer made I may have it done with out a throat and ream the throat seperatly with a $30 throating reamer that way I can adjust barrels down the road to work with differant seat depths and free bore dimensions.

By the way I did not have to aneal the rounds made from 30-06 it was once fired remington brass. The 308 brass I have is military and the base is slightly bigger .469 vs .465 of the 06 brass. 308 brass could likely be used if the neck and throat were anealed and expanded straight as the neck area will be needed. just thought it was worth mentioning.

I also made one round out of some 270 brass and it was the same as the 06.

the beauty of this round is that any casing with a .465-.470 base can be made to work if it is 1.850 or longer. making it easy to find brass and a lot cheaper to shoot than the 450 BM 458 SCOM 50 BEOWULF!!!

the only down side to this round is limited bullet selection vs the .458 and a very slight powder capacity loss. From what I can tell the other round like the 458 scom are clasifed as pistol round are not that HOT to begin with so I dont expect to see much differance in MV and energy. in fact the 44 is likely to have a better MV especially with the lighter bullets it CAN use that the others cant.

hcpookie

04-10-2008

ETA - the Clymer site should have reamer specs for .444 marlin. Get those, compare to a reloading manual's cartridge diagram. There's your spec.

I just noticed the Clymer reamer site is "under construction" again

http://www.clymertool.com/design/index.html

Gunter

04-11-2008

The BBT dropped off the 223 single stack and it is a no-go. The front is way too narrow. Back looks great but no way you could get the round in there without major rework. Oh well it was worth a try.

1biggun

04-11-2008

Bummer. I am thinking of just shorting a 308. or sguare tubeing. A double stack steel 223 mag would be a better canidate. the fit in the poly mags almost like a single stack but the lips are to wide to keep it from poping out.

1biggun

04-12-2008

The round will single stack nicely in a double stack 223 mag but the width of the the lips is slightly to wide to hold the round in place.

1biggun

04-13-2008

yea I thought that might be the case wasent sure.

I was at a cabelas store today they had some 450 busmaster ammo behind the counter. I got to take a look at it I saw no crimp on it. it looked pretty much like the 44??? but smaller and a slightly rebated. nothing remarkable. also got got to check out a new rugger 10-22 pistol on sale at $299 might have to get one down the road.

1biggun

04-16-2008

44??? in a G3 mag fits good but mag is to long This would be a cheap starting point Im thinking about just cutting a section out of one and welding it back together and using a AK spring or a AR spring. capacity would be the same as the original G3 what ever that is. I am still a very concerned about getting that bullet in to the barrel

hcpookie

04-17-2008

Looks nice. I don't think I'd be too worried about the extra space, because these rounds should not tilt the follower. So long as the tip clears the front of the mag and hits the feed ramp, you'll be OK. I adapted G3 mags to work, but it takes some filing to get it just right.

Are you going to ream the inside to get more powder capacity?

Also, I used steel mags and was able to spot weld the locking lugs. Not sure if aluminum brazing would work for the alloy mags. Something to think about. ETA: G3 mags hold 20 rounds. If you need to squeeze the magazine feed lips to force the mag into a single-stack configuration for feeding purposes, then you'll lose a couple rounds in capacity.

Also, I was thinking more about the feeding of the straight-walled cartridges. I am working hard at making my 45 Win Mag feed doulbe-stack and I think I can do it with reasonable reliability. The trick is to get the rounds set back away from the locking lugs enough that there is ample room for the round to "line up" in front of the bolt before it gets to the breech. In other words, set the front of the bullets back away from the locking lugs. If you do cut the magazine down some, you could make that happen.

You could also do like VZ58 and I are doing and buy some rectangular tubing and bend it yourself. In the long run, that may be easier vs. cutting and rewelding a G3 mag. I spent something like $25 and have enough tubing for about 10 45 WM magazines.

These shorter mags will require an extension to move both the feed ramp and the forward locking lug backward by .75" or however much is required. This "shim" can be shaped to funnel the rounds more into the middle without worrying about them getting stuck on the trunion locking lugs.

Food for thought!

1biggun

04-17-2008

quote:

Are you going to ream the inside to get more powder capacity?

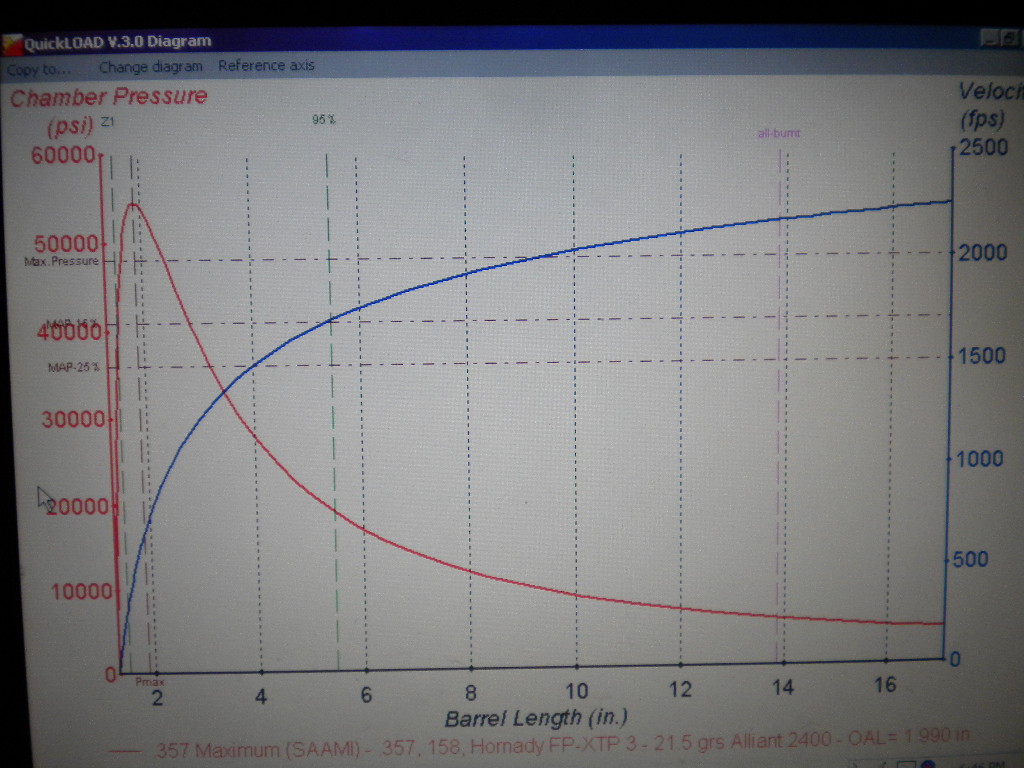

NO I feel the case should have enough capacity to meet the needs I have in mind for this round and I want all the wall thickness I can get for head spacing of the mouth. the 44??? is over 1/2" longer than a 44 mag with a larger case OD at the base. IT should be plenty. My goal is 1800to1900 FPS this is only a rough guess but is based on what other simular rounds do. I am expecting a case capicty of aproximently 53-55 GR,s. this should make it a very capiable deer hunting round my intended purpose, and knock down what ever doors and walls and water jugs and dirt clods the Rambo guys think they need.

quote:

Also, I used steel mags and was able to spot weld the locking lugs. Not sure

if aluminum brazing would work for the alloy mags. Something to think

about.

I have a very nice tig welder so if I want to use aluminumit will be ok. I also have about 10 of the steel mags that tapco had so cheap back when.

As far as the mags go check this out here is the 44???? in a FAL mag. If cut down they would be almost perfict. (see next post for pics)

1biggun

04-17-2008

THE 44??? IN A FAL MAG!! the bullet fits perfect in the conture of the mag and this mag seems to send the bullet more to the center. They are more money ($10-$15) not to bad but not $2 lie the G3. the FAL mag is narrower and would fit into a AK trunion a lot better. I want to be able to make this fit in a AK/AR length mag well on a standard reciver. If I cant make that happen I might as well skip it and just build the 444 rimless marlin project on a custom reciver instead.

1biggun

04-29-2008

I started working on my barrrel to day. It is going to need to be turned on centers to get the OD true to the ID it is way off center. It will have to be then chucked and profiled then have the muzzel turned and crowned and then it will need to be turned around rechucked and then ran on a steady rest to do the chamber.

I am going to try to bore the the chamber with a boring bar after I run a throating reamer in first (we will see) the worst thing that could happen is I have to make a shorter barrel. the chamber only needs aprox .005 of taper in 1.85" If I can bore a round hole straight I should be able to to it at a taper by using the steady rest feed.

I have no plans for a front site as it will be scoped or a red dot I am thinking a FAL gas block to keep the od larger. I am thinking of a custom RSB like on my varmit build.

This is going to be a lot of work

Gunter

04-30-2008

Let us know how it goes and yes it's a lot of work, but you already know that from your 223 builds. I sort of got burned out on the 308. Need to get it back out and finish it.

1biggun

04-30-2008

This is going to be a lot tougher than the 223. On that build all I had to do was chuck it true on the muzzel end and run the live center into the chamber and turn the breach end to 23 mm and the rsb to around 1.00 then cut a untaperd section were the gas block went for a couple inches, in fact the 223 still has the factory bluing on the barrel. took about a hour or so. this 44 barrel needs every thing plut its like 1.25 thick im thinking a couple days and at least 3 set ups. may have to abort for awhile untill the

17-223 is done that needs to be ready in a month for praire dogs

Gunter did you get your Lee factory crimp die in 444 marlin yet?? was wondering how that worked out.

hcpookie

04-30-2008

Don't sell yourself short. I turned a 1.25" barrel blank down to an AK profile in a Saturday afternoon/evening. It won't necessarily take that long if you have a power feed. Setup and truing is, IMO, about 75%-85% of the work. Get it straight and the cutting will go MUCH MUCH easier.

Oh I almost forgot - expect to make an RPK-sized or bigger barrel, because the .44 is so much bigger. Just an FYI - I konw you already know

1biggun

04-30-2008

Ive got power feed. the problem is the bore is not true to the OD its way off. I am going to have to make a brass pilot that the barrel will fit tightly on then drive it with a dog with the other end in a live center. just to cut one ends od true to the bore ,then flip it around and put that end in the chuck, so that I am now turning the OD true to the ID . This all has to be done before any profiling can be done once profiled then each end will have to be trued and crowned or chamberd in a steady rest.

Next time I will at least find a Turned blank! That way the ID an OD are true to each other and I can just chuck it in a go.. I have a rough blank that still has forging seams in it and the bore is over a 1/6 out of center.

Im looking to have at least a 18" barrel and closer to 20" I am looking at leaving it a pretty heavy barrel likely the OD of a FAL gas bloks ID. the Tromix 444 marlin conversion uses all the Siaga 410 barrrel parts so that must be a pretty thin barrel. even though I want a pistol in this calibur I think I am going to build a rifle first. to work out the bugs on

1biggun

04-30-2008

A few pics of the blank. its 20.5" long saw cut on the muzzel end way out of center and has a profile in it and forging marks. It was $45 aprox from Numrich. Wish I had just bought a turned blank

hcpookie

04-30-2008

Do you have a 4-jaw chuck? If so, and if you can pass it through the spindle, then it should be short work, since you could actually center it.

1biggun

04-30-2008

I Have a 4 jaw an only a 4 jaw but it wont pass through the spindle on my 9" south bend. I have a 12" clausing but it is out of service for the foreseable future. the steady rest is an issue also as the out of service one is the only one that I have a rest for.

Maybe I should be fixing my equipment instead of building guns for the last 4 years. LOL

I might have to fix the clausing 12" before getting serious about this build. or find a differant barrel. this blank was purchased for my 444 rimless marlin build originaly but I was getting pretty excited about the 44?? that I decided to go with it plus it will use a standard reciver were the other will need a 308 type reciver.

hcpookie

05-01-2008

That's funny, I feel like I'm in the same boat! I need to buy a 4-jaw and just don't have the time to get around to it. The 3-jaw that came with my anemic little mini lathe just sucks.

Gunter

05-01-2008

No 1biggun, the Lee factory crimp is still on backorder from Midway.

1biggun

05-26-2008

went to a gun show yesterday and found a steel mag marked 223 10 round it is longer than a Bulgy plastic mag so it is possably a 15 round. it had a 5 round follower in it. it wont fit in my 223 varmit build that is fitted for bulgy and pro mags. Im not sure what it is . BUT it will hold a 444?? pretty well and it is steel so I can weld on it.

1biggun

07-31-2008

I havent given up on this project. I have a 44 mag barrel coming for my H&R handi rifle I plan to ream it to 44????WTF and use it for load development it is a strong action incase I get the loads wrong and a cheap way to get another gun+ it will be nice to have once I get the AK project done, things are being stalled due to lack of $$$$$$$$$$$$$$$$. I was hoping to have it done by november for deer season not sure Im going to make it.

Gunter

07-31-2008

Cool! Just getting into the Handi thing and picked up a 30.06 barrel. Now I'll have to be on the lookout for a 44mag. Keep us posted on how it goes.

1biggun

07-31-2008

There fun n cheap to play with im going to rechamber a 223 into a 22-243 middlestead. this will be a 1-9 twist varmit slayer shoots 50 grainers at 4000 FPS APROX, barrel life will be limited but for 150 dollars its worth a try. the graybeard sight has a lot of info on these.

1biggun

09-30-2008

bump 41 cal info around page 5. the 41 jauras is close

there is to much thought put into this 444???? for it not to be built buy a few guys here it is completly doable. mine would be done If I had bought a better blank.

a 375 and a 41 version would really be a good round as well

Gunter

10-15-2008

Here's some more info on the 444 rimless. Looks like the 44??? is just a short 444 rimless.

A "Rimless" 444 Marlin... - Page 2 - Shooters Forum

Don't know what's up with the link. Go to the box at the top of the page and click DAW A "Rimless" 444 Marlin.

I gave up on finding a Handi 44 mag barrel, so a 44 mag barrel is on the way. I'll make it into another insert for testing.

hcpookie

10-15-2008

Sounds like they've done some of the ground work for you! Other than length, sounds about like the same deal. You could probably - maybe - use .444 reloading dies and run the seater down deeper to seat in the shorter cartrige. Or just cut of the bottom 1/2" or so.

Gunter

10-15-2008

That's what I was thinking on cutting the 444 dies off.

1biggun what is the mouth od on the 3 you made up?

1biggun

10-15-2008

Good link to bad his sight wont open up. its two years old.

My case mouth OD is .457 with a .4295 bullet pressed in(hornady 265GR ) Keep in mind that I have not crimped it any so it might reduce if we can find a way to crimp in the bullet like with the lee factory crimp. THIS IS WITH REMINGTON BRASS AND LIKELY WILL VARY FROM BRAND ESPECIALY MILITERY BRASS THAT IS THICKER. I was able to make my rounds with out cutting a die down. I need to get a expander for this round so can have straight consistant brass to play with.

I got to admit I feel a little bit exhonerated knowing that Im not the only crazy guy out there thinking like this. I also feel like I have done a pretty good job of thinking ahead as it seems that I have most if not all the bases coverd for the 444??? or the full length rimless 444 marlin (wich was the original plan for a AK and still a good one IMOA). He is using a reamer and a seperate throater just like I thought would be best although I still think it might be possable to cut THE CHAMBER with a boring bar set at the correct angle. I wonder if he ever thought of it as a autoloader round like we have LOL??

quote:

I gave up on finding a Handi 44 mag barrel, so a 44 mag barrel is on the way. I'll make it into another insert for testing.

your loosing me here are you building a handi rifle for testing??? or just using the barrel on a AK. I think this a good idea to build a handi from a 44 mag and if it dont work you could always open it up to a 444 marlin as long as the extractor issues can be overcome. That 44-06 he was doing sounds pretty cool as well on a bolt gun. I have a couple of handi rifles and was thinking if I bought a reamer I would do a bolt action and a Handi as well just to off set the cost of the reamer.

In need to decide on a overall length and stick with it. it sounds like it is important to keep the bullet lead short and for a specific bullet. I really wish hornady start selling or some one else would come out with a pointy bullet for this round.

YOU KNOW THAT IF 3 OR 4 GUYS POOLED THERE MONEY TOGETHER AND BOUGHT A REAMER AND THROATER(THROATER COULD ALSO LIKELY BE USED FOR THE ROUGHER) THIS WOULD BE A LOT CHEAPER TO DO FOR ALL OF US. I WOULD WANT A REAMER THAT WOULD WORK WITH BRASS MADE FROM A STANDARD RCBS OR LEE 444MARLIN DIE. IF THE DIE HAS TO BE MODIFED BY SHORTING IT SO BE IT AS LONG AS IT IS REPEATABLE AN STANDARDISED FOR OTHERS TO DUPLICATE. I WOULD ALSO LIKE TO MAKE THE OVERALL LENGTH SHORT ENOUGH THAT ANY BULLET THAT CAME ALONG IN THE FUTURE LIKE THE HORNADY LEVERLUTION SOFTTIP, WOULD STILL ALLOW IT TO BE SEATED OUT PROPERLY AND STILL FIT IN A AK/AR MAG .THEN IF THE THING ACTUALLY FEED AND FIRED THE REAMER COULD BE REPRODUCED FROM THE PRINT AS NEEDED.

I AM CERTAIN IT WILL MAKE A NICE BOLT ACTION OR SINGLE SHOT ROUND. iM A LITTLE CONCERNED ABOUT GETTING A ALMOST STRAIGHT ROUND INTO THE CHAMBER WITH OUT JAMING

Gunter

10-16-2008

As for the Handi, I was wanting to get a 44 mag barrel for the SB1 frame. Then work the chamber over the 44???. I just ordered one of the barrels that HC posted and am sure it will need to be sleeved for use either in the AK or as a barrel insert for the 10ga Handi barrel (do not install inserts or high power rifle barrels in standard Handi shotgun frames). I'm going to try it in the Handi first and go from there.

Yep, one of the things we need to decide on is the length of the case. I also think that it would be best to cut the chamber and throat in two different operations. I was looking at Clymer yesterday and they don't show a throater for the 44 mag. So everything might need to be special made.

Looking at the 45acp at the mouth there is only .001 clearence and .003 at the base. Like you said just switching to Mil-spec cases might result in a round not chambering. I'm going to get a 444 die set and use your steps and see if the cases come out the same as yours.

hcpookie

10-16-2008

A few thoughts - you may be able to get away with .44 mag dies, just run them in shorter. Maybe... depends on case diameter at the point where a .44 base would normally be. That, with the purchase of a .444 Marlin full-length sizing die, and you may not need to make any mods at all!

About the case length - everything needs to fit in an AR / AK mag. That dimension is the starting point as I have understood it. Exactly which AR frame is open to debate - .308 size (AR-10) or .223 size (AR-15) frame? The use of an AK frame is actually pretty easy, since you have a .308 AK to work with, and that would need only a barrel swap! That may be worth the extra cost of the rifle, because magazines are now available from several places!

Personally I think that the 1.7 size is good enough - 1.75 maybe? It assumes you'll be using .308 / .06 family brass as the parent cartridge.

Feed angles for this should not be a concern. It may need a new feed ramp, but other than that it should feed fine, unless you're using a hollow point so big it looks like a shot cup. That may be a moot issue anyway.

About the expander issue - this is exactly what I was concerned with for the .45 WinMag with the "donor" brass I'm converting. Without fireforming, it will create an hourglass-shaped case since the parent cartridge is slightly tapered, and you're enlarging slightly beyond that point.

Fireforming is the only practical way to "fix" this issue and make it a truly straight taper without building a fancy expander that is purpose-built to expand that sucker out. That said, you COULD shape the brass to the final shape using only reloading tools, ASSUMING you build yourself a "full length expander". If you do that, then the brass forming would be like this:

Cut the parent cartridge to length

Expand the parent cartridge with the "full length expander"

Full length size the brass in a suitable full-length sizing die (444 Marlin?)

Neck Ream for .44/.41 bullets > optional step, possibly not necessary, (this is done for .44 Automag so it remains to be seen if this cartridge would need it...)

Expand like normal

Seat bullet like normal

Crimp like normal

That would get you where you need, and you would not need to fireform. I am experimenting with this very thing for my .45 WinMag because I'm sitting on enough donor brass to make this worth my while. The only difference here is the "full length expander" for the .44 ? / .41 ? cartridges will be longer!

Making a full-length expander is simple - mount the expander ball (aka ram) in the lathe and cut it to shape. The normal expanders have a taper near where the top of the original cartridge sits so it flares the case... you are going to cut it back so that point is higher up on the ram, closer to the threads. Polish and you're done. I am using a .44 expander for my .45 WinMag "full length expander" experiment. I'm doing all of this because I don't know that I will be able to fireform all of my brass due to my work schedule, and I am genuinely curious if this will work. I don't see why not, except that I may need to anneal the cases first. They aren't getting expanded much, but you never can tell if you'll split them. We'll see.

1biggun

10-16-2008

quote:

A few thoughts - you may be able to get away with .44 mag dies, just run them

in shorter. Maybe... depends on case diameter at the point where a .44 base

would normally be. That, with the purchase of a .444 Marlin full-length sizing

die, and you may not need to make any mods at all!

I tried 44 dies and they hit the case way before the bullet is seated due to the taper of the larger case. so I think it is safe to rule out 44 dies except possably shortend way down and then only to crimp. I was able to make my rounds with just 444 marlin dies and some misc die parts that to be honest way over expanded the neck and would not reach far enough down to do the rest of the case. there are commercialy avaliable expadder dies that will work. all that needs to happen is get the case expanded sligtly over size 75% of the way down. resizing it in a 444 marlin die will get it back to were you want it.

quote:

Personally I think that the 1.7 size is good enough - 1.75 maybe? It assumes

you'll be using .308 / .06 family brass as the parent cartridge.

IMOA we can go longer right up to were I made mine possably just a tad shorter. there is lots of clearance in a 223 mag with a 265 bullet that was seated to the canalure. I am not positive a hornady leverlution bullet will fit but it woud be as simple as buying a box of 444 marlin or 44 mag and bulling a bullet. as far as going with heavier bullets like cast or 300 grain jacketed it will work as is also keep in mind as bullet weights go up powder must be reduced. so seating the heavier bullets in some will not really hurt an thing.

My plan is to size to make sure the hornady stuff will be doable in the future. and add just a little extra.

1.800-1.825 is what im thinking 1.800 comes out to roughly 46mm. this round could easly be called a 11 x 46????? (1.810)

I want to give this thing as much case capacity as possable so that with light bullets it will really take on the 450 bushmaster, 458 socom. 50 beowulf in the FPS/trajectory race.

here is a few picks of my round in a promag. the problemwith plastic is the mag wil need to have the lips slitly pinched in or added onto to keep the round sitting flat.

hcpookie

10-16-2008

Yeah that "over expanding" part of the expanding die is what I'm talking about - cut that point back closer to the threads so the tip of the expander can reach deeper into the cartridge to open it up deeper.

Maybe taper it based on the measurements of the case and presto your "full length expander" is done. Actually now that I think about it you'd need to do that because you would not want to expand way down at the bottom where the web is, because you'd end up getting the expander stuck in the case! That would be a bugger to remove!

1biggun

10-16-2008

Pics of 3 444???? in a pro mag 223 pro mag. note how the round tips up. also pleanty of room for a 265 grain .

as far as aover expanding that was only because I was using what I had on hand. it would have not been a issue at all with the correct mandrel. the only reasion it needs to be expanded as far down is the 308 & 30-06 have more taper

If all that was done was fulllength sizing of a cut 30-06 round it would still work fine you would just have a slight hour glass shaped round for the first firing. it still would likely shoot fine and cycle and all that. If you look cloosly at my rounds there is still some slight receding below were the bullet is seated. It would kind of be like shooting a 22-250 in a 22-250 improved chamber it will shoot fine and form the case at the same time.

personaly I will expand first as accuracy is a issue and slight case capacity varations will hurt it some.

for what its worth the 30-06 brass is easier to use because it allows you to cut below the neck. 308 would recuire cutting and expanding the throat.

also trimming 444 dies some would not hurt as the base of the round on reminton brass is .466 not the .473 listed in most books. the rim and base is not even close to touching the die even when doing a 444 marlin rimless round.

IMOA die trimming is only going to be nessacry if you want to roll crimp with that die, since it will not reach completly to the top of the die. . Roll crimping is not advisable here as we need to head space of the mouth. I am hoping a trimed down lee factory crimp die can be used if it is even nessacry to crimp at all. A 44 mag die cut way down might crimp as well but will not work for sizing.

honestly feel I could shoot the ammo I have made as it with the correct load of powder.

1biggun

10-16-2008

quote:

Yeah that "over expanding" part of the expanding die is what I'm talking about

- cut that point back closer to the threads so the tip of the expander can

reach deeper into the cartridge to open it up deeper.

thinking back on this some more the whole reason I had to expanf with a mandral in the first placewas because the original expander in the 444 marlin dies was way to big to just open up the 30-06 case and would crush it. I had to open the mouth sligtly to get the expader started. other than that it would have formed brass as is but with a hour glass area past were the bullet was seated.

quote:

Yep, one of the things we need to decide on is the length of the case. I also

think that it would be best to cut the chamber and throat in two different

operations. I was looking at Clymer yesterday and they don't show a throater

for the 44 mag. So everything might need to be special made.

I agree 100% this will allow barrels to be custom made for specific bullets by adjusting the leed.

I saw .430 throaters some were and they were only like $30. i think they use them in forcing cones and cylinders on revolvers. they must be avaliable as guys play with .44 rifles a lot.

quote:

Looking at the 45acp at the mouth there is only .001 clearence and .003 at the

base. Like you said just switching to Mil-spec cases might result in a round

not chambering.