Retrieved: 06/01/2016

Last Post: 12/26/2015

Thread: 1891 Mauser in .444-1Biggun

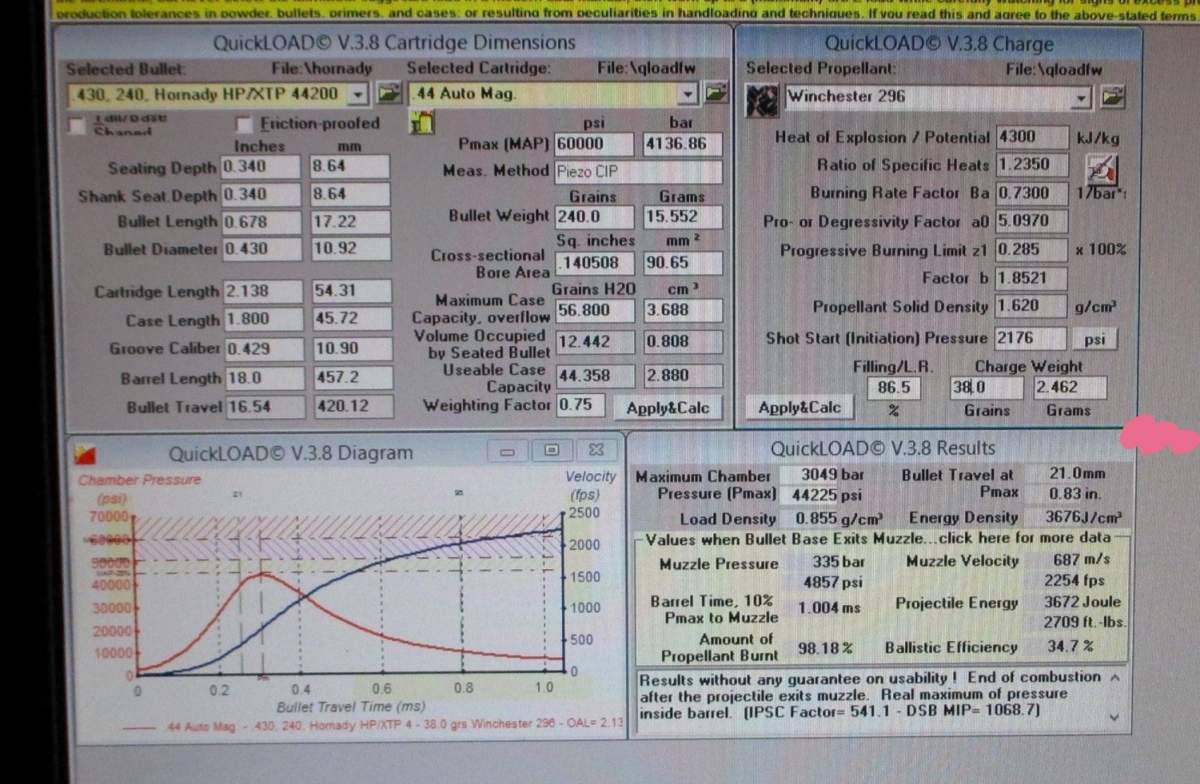

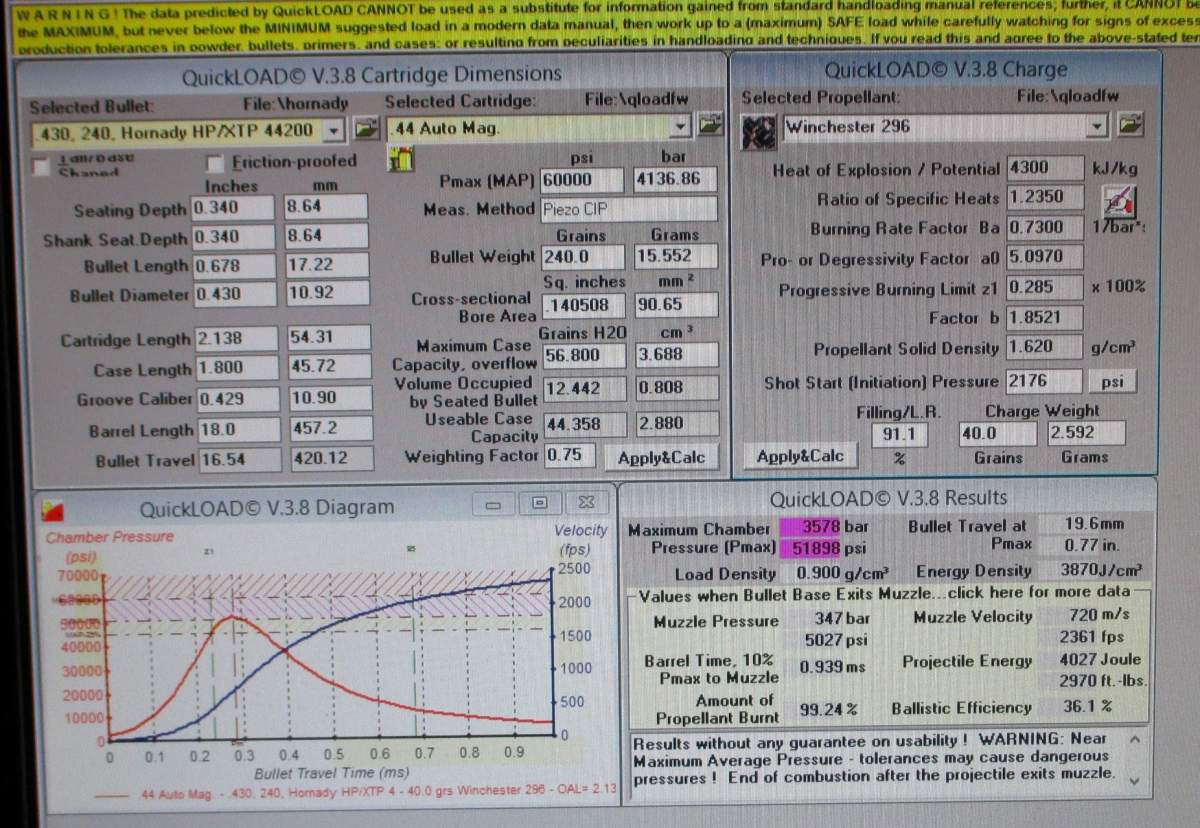

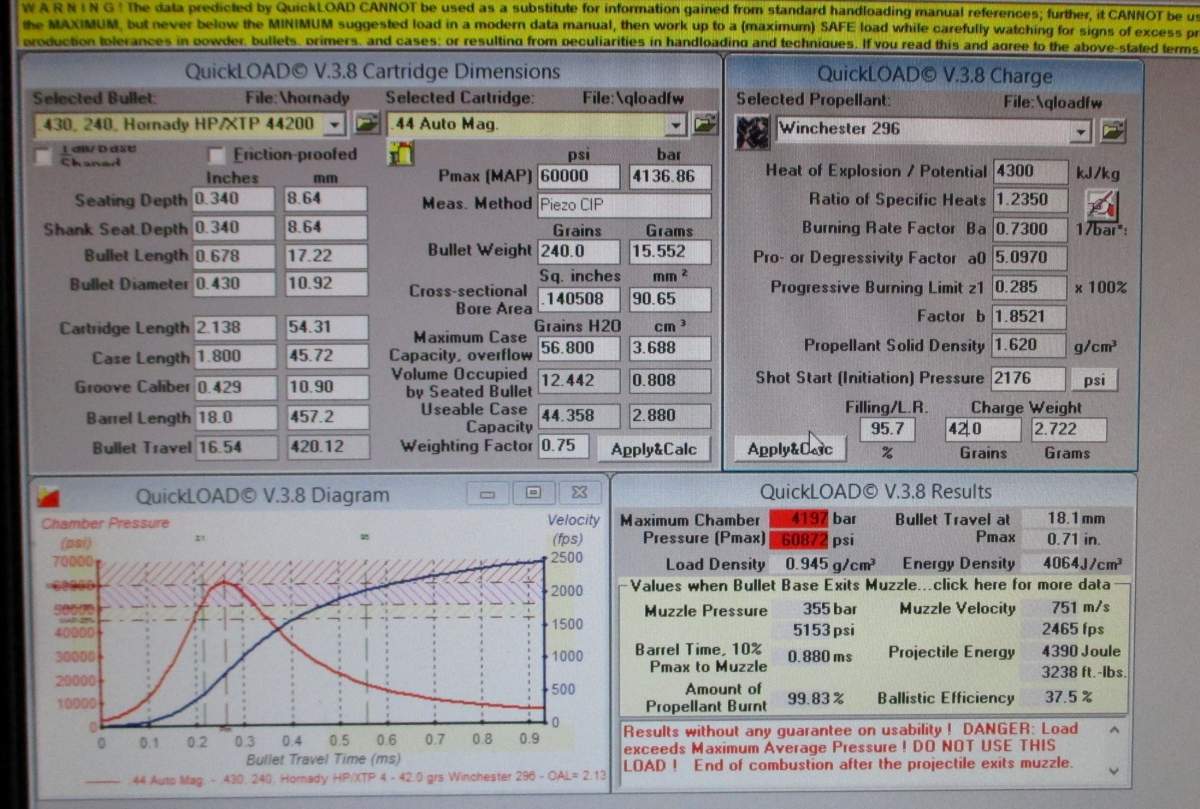

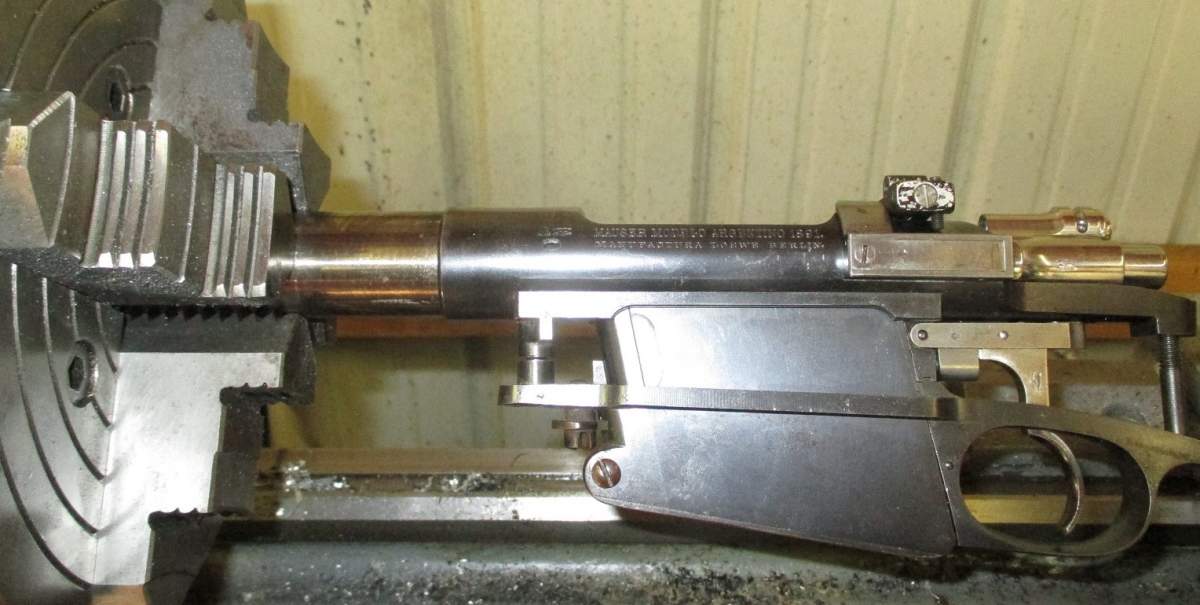

This is came out of the 44??? thread by Gunter. 1Biggun and I have been talking about a build for a while, and this past year the MI DNR changed the regulations so that a straight walled pistol caliber (.35"min) with a case no longer than 1.8" could be used in the shotgun zone. I used my 357AR rifle last year and was happy with how it performed, but I'm a big bore guy at heart. So after some back and forth I made a chamber reamer that would cut a chamber from 1.8" (for me) -2.25"(for 1Biggun). I had already picked up a sporterized 1891 Mauser that needed rebarreled for $120 a while back. It seemed like a perfect match. Depending on the pressure you want to run the cartridge at, Quickload shows that it should be about 2250 FPS out of an 18" barrel if run at 44k-PSI or as high as 2465 FPS if run at 60k-PSI. I'll be limiting this build to 44k-PSI and most likely around 40k-PSI which is actually better than what my .50 Hawken will drive them with a sabot. Here's some pics so far of the donor gun, action wrench to remove the old 6.5 Carcano barrel (yes some idiot fitted a Carcano barrel to this rifle even though the barrel was pitted inside and out), and making the reamer.

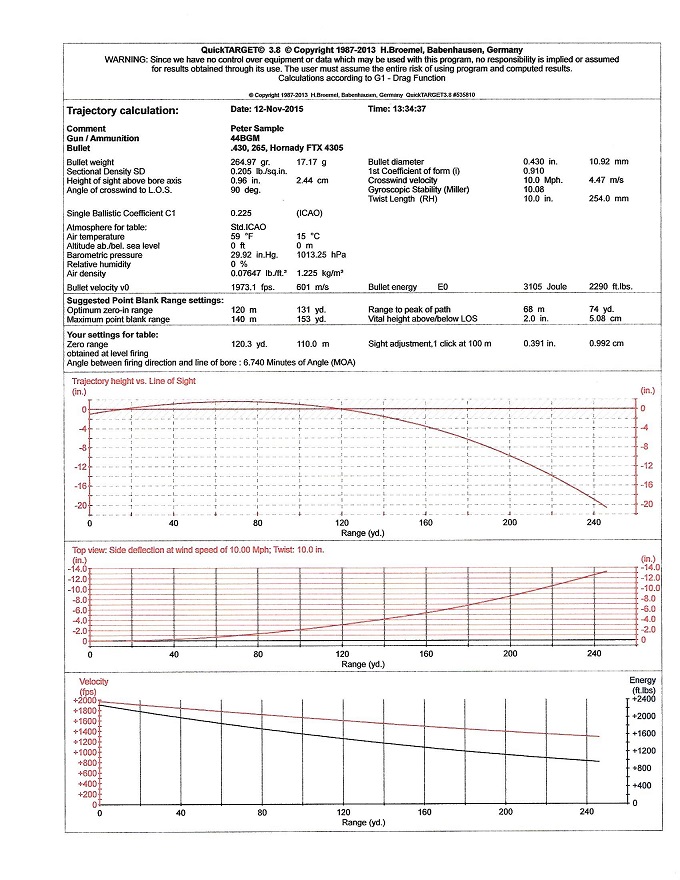

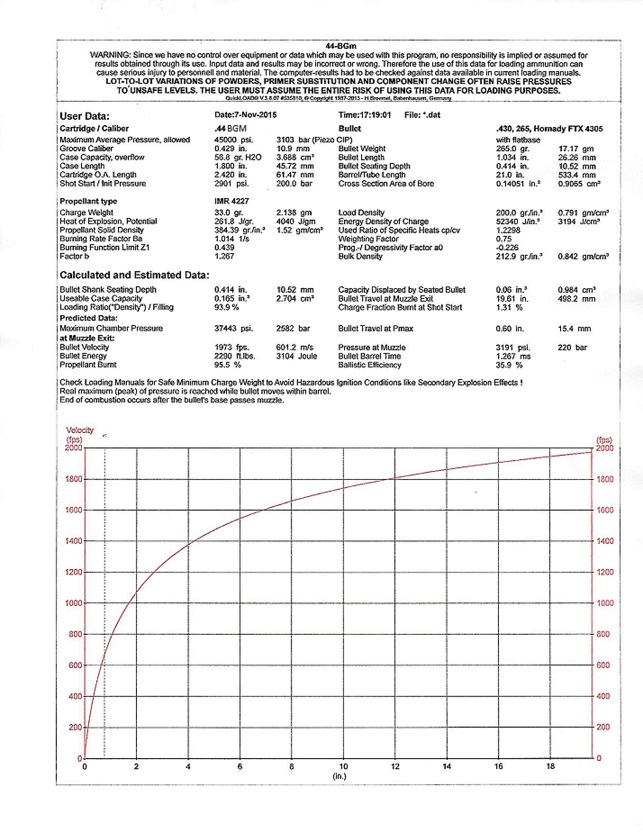

Here's some of the Quickload guestimates. The case length and water capacities on QL were changed to match the formed cases. Once there is a gun to shoot them in I can spend the summer working up different loads like I did with the 357AR a couple years back. For forming brass I went with R-P 30-06 brass that were run though 44 Auto Mag Pistol case forming dies including neck reaming, annealed and run though an expander die.

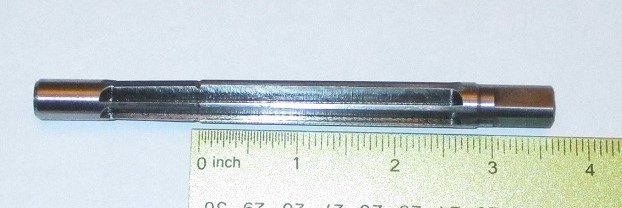

I already had 44 Mag and 444 Marlin dies, so after running the cases through the expander die they were just resized in a 444 Marlin die. R-L 444 Marlin, 444-1Biggun, 44 Mag.

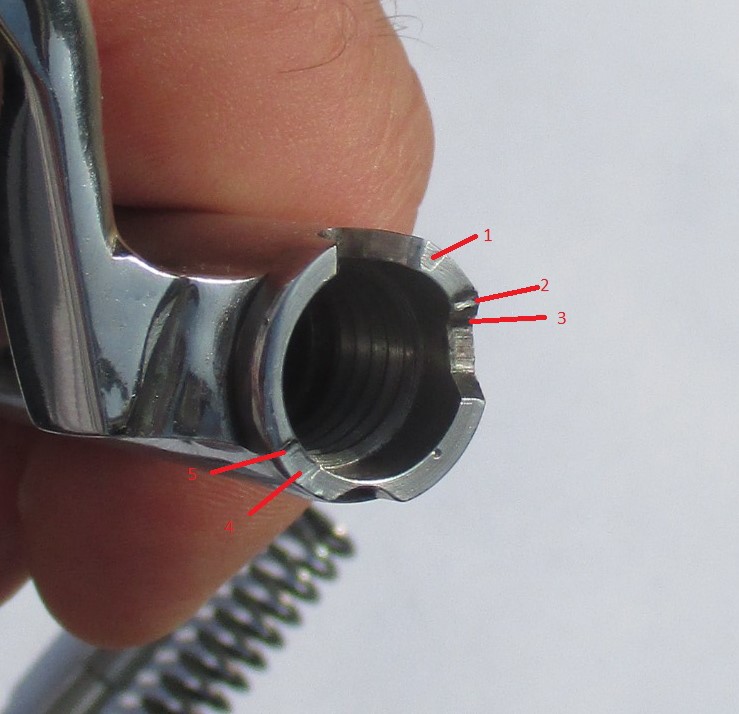

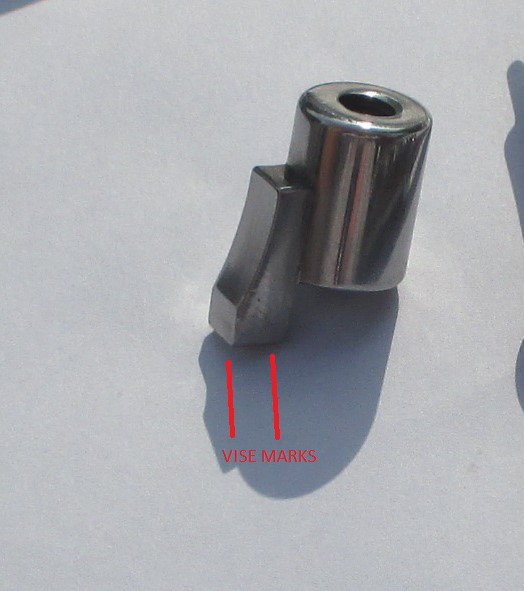

I have a GM .429" 1:20" barrel waiting to be profiled, threaded and chambered. I'm debating making it an octagon or just following a basic stepped barrel similar to what the stock is inletted for. I'm leaning towards the octagon. The 1891 Mauser has almost no gas handling features compared to other models. Later production ones added the wings on the bolt sleeve to block gas running straight down the left bolt rail into your face. I tracked down a original 1891 late version cocking piece with the wings. Otherwise you can change out the firing pin, cocking piece and bolt sleeve to a 93-96 type. Here pics of what those little wings do. In the bottom pic you can see how the shape of the bolt face directs gas down the left bolt rail which is wide open except for the ejector right to your face. In the two pictures above it you can see how the latter style bolt sleeve blocks off the bolt rails. I also plan on adding a vent to the receiver and bolt similar to a 1893. Can't hurt.

The shorter 444-1BG rounds wouldn't feed through the original magazine so a filler block was needed. The mag spring is actually two flat springs that cantilever off of each other and the floorplate. So a new mag spring and follower will have to be made, but the magwell block is done. I left it with a bit more space forward of the XTP bullets for the pointed Flextip bullets that are now available. That's where it's at right now. Once I finish up a few barrels I can get back to work on it.

It's a Fajen stock. I wish the comb wasn't quite so high. You have to press your cheek down on it hard in order to get a good sight picture. The replacement barrel will be thicker at the muzzle and will have a higher front sight from centerline, so perhaps it won't be an issue. I want to try to shoot it with the iron sites, but want to keep the option open for a scope. Otherwise the comb would get cut down enough for a comfortable cheek weld.

How does this round compare diamention wise to the 44 Marlin? 1/4- 3/8" shorter? The ballistics you mentioned are impressive. This is the building stuff we like to see here! Keep it coming.

I did the QL stuff based off of a 1.8" case length v/s a 444 Marlin at 2.225". 1Biggun wants to go a little longer since he isn't in a DNR restricted area. Once he gets his case length and volume figured out we can figure out the performance for his which should be better. The 444 Marlin is limited to 51k- PSI. If you run the 444 Marlin with a 18" barrel through QL along with 48.3gr of IMR4198 and a 240gr XTP you get just under 2300 FPS at 42K-PSI which is the fastest loading in my Hornady book (24" barrel gets 2400 FPS). Using different powders and the same 240gr XTP QL shows 2250 FPS at 44k-PSI, 2360 FPS at 52K- PSI and 2450 FPS at 60K-PSI. So it compares well to 444 Marlin and can beat it if loaded in a strong action. Mine isn't so I'll be happy with middle of the road 444 Marlin performance. I even did the calculations for a AR-15 at 39k- PSI and got around 2150 FPS with an 18" barrel. I'd load it down in an AR-15 though as I still don't trust how thin the barrel is at the minor diameter cut at the stub shoulder.

That Fajen stock is the same one the 03 Springfield I re-did recently has and it's a great stock for scoped rifles. My vote on barrel profile would be the octagon, just to make it stand out a bit and make it something a bit different. Ya it will make a little bit more work, but not so much that it would be too bad really, and I think it would just be neater looking besides.

Hell, with little as there is to build out there now, why not do something just a bit different from what you probably have already built anyways? I've kinda gotten to that point that whatever I build, don't care if its, guns, cars, whatever it may be. Whatever I do now, I'd like it to be just a bit different from what you'd normally see, even if it may take a bit more time,,, but what the hey, are you on a production schedule where time is really a issue anyways?

Plus when you're finished, you'll just be scratching your head trying to figure out what will be next!

I just think the round barrel really wouldn't set it off as anything really different or unique... which it really is. Sounds like a fun project though and I love that 444 Marlin cartridge too. I kick my ass I ever sold my lever gun in that caliber.

I'm not sure what you're looking at for sights, or if you've even planned that far yet, but I have 2-3 sets Redfield or Lyman? micrometer type receiver sights that, if I'm not mistaken, are all Mauser profiled. You might even be able to talk me out of a set if that is the route you go. Ya never know? I sure wouldn't charge anywhere near what you see them on line for, just to see them get used instead of them just sitting in a box on the shelf. Kinda sounds like you're leaning open sights by the comment about the high comb. I have high ones and I think one set of lower ones too, I'd have to double check to be sure.

I might have others options too. So Let me know what route you go and I'll scrummige around and see if I may have something you'd like, I still have several Mauser parts left kicking around here I could probably part with if you need something. And if you want something like just a standard Mauser sight, no biggie, I'll just give you a set. Keep me posted when you decide what you're going to do, maybe I can help this project along.

A P.S. My stock is a bit different now I think about it, mine doesn't have the Sinsibel forearm, how ever ya spell it?

Yes any of these old rifles need to carefully evaluated to there strengths before using one. Any old rifle has its risks and is a valid concern.

His reamer will cut a much deeper chamber than the 1.800" his round is an it gives the option of basically a 444 Marlin rimless. The 444 Marlin rimless was my original choice for a AK build when Gunter (who stopped posting here for) asked me about doing a shorter version that did not need a modified AK mag well length. So I/we switched to a shorter version. It is possible to run a little bit more case length in a AK/AR length mag an a slight gain could be seen. IMO setting the case length at just under 1.800 so it id legal in a few states is the smart move here.

100 FPS + or - is not going to make one lick of difference at the range this round is intended for (under 300 yards) on a deer or anything else. The Leverlution bullet in 265 grain is designed for the speeds this round will easily produce an have been proven in the field.

This will also be a great subsonic round an also a great cast lead round if you want to shoot cheap I'm sure reduced plinker loads will not be a issue either. Anything that gets hit by a 265 grain pill going over 2,200 FPS is going to have a bad day.

My thought on a bolt action for myself are for a longer round run at 60,000 or higher. This would outperform a standard 444 Marlin by a large margin and would outdo a 45-70 in most cases. Basicaly a 444 Marlin about 200 FPS faster.

There has been an AK barrel in .44 cal profiled here on the bench for about 5 years or so waiting to get chambered for this round (1.800").

This version fits Moleman's state's restrictions perfectly. IMO the .430 bullet is the best compromise of speed / bullet weight an trajectory and case taper you can obtain in a 1.800 long straight case on deer.

This round should be doable on any .44 Mag Handi-Rifle if it was rechambered. As I recall that was gunter's plan for testing the round. I have had my eye open for a 44 Mag barrel for mine. Not sure the twist is optimum however on the H&R.

This would give MI hunters a cheap way to have a little more in their zones.

The 45 Raptor that has been made after this round was designed uses special brass (Starline) that's close but not really workable with common brass that uses a 45 cal bullet its designed for AR-10 guns. It's basically a rimless 460 S&W It has zero taper an does not use a .458 rifle bullet but 45 pistol type bullets. The bullets it uses have a poorer BC not that its really going to matter at 200 yards. Its not a bad round but I feel the 444 1BG will feed and extract better an be much cheaper to load and shoot. There are IMO better hunting bullets in the 44 cal than in the 45 although I have not looked at what the 460 S&W guys hunt with much.

I'd love to see a tapered octagon barrel or even a straight octagon to round but that is not just a bit more work its a lot more work an if you get it wrong the barrel is junk however. If you can pull it off then it would really have a what would have to be a modern classic. I hate that term but what would be more descriptive than a early sporterised Mauser with a octagon barrel shooting a modern wildcat with big bore modern technology bullets meeting MI hunting regulations?

If you can pull it off I'd think that rifle would be worth well over a grand to the right guy in the right state.

Sprat, That is a concern for me as well and the reason that it will only see pressure under what is suitable for a small ring action. It made it through military service, and a second life as a sporter before I got it. The action seems in great shape and I'm sure whoever sporterized it cut up a nice looking rifle in a higher pressure cartridge (around 56k-PSI for 7.65x53 Mauser). The Argentine crest has been ground off and cold blued, the handle isn't as shiny as it once as, and most of the carbon blue has worn off of the ejector housing. I suspect it was rearsenaled at some point for being 120 years old and still having most of the bluing. By the "F" prefix ser# it was produced in 1893 at Loewe Surplusrifle Forum ? View topic - Dating M1891/M1909 Argentine Mausers. Dropping the pressure down to around 35k-PSI still gets you decent velocity, around 2000-FPS and depending on what powder I will be starting at least that low and working up.

Twa2471, I'm leaning towards a hooded front sight and a peep rear sight. It currently has an aluminum Williams peep sight on it and the stock is inletted for the sight base. Its base is aluminum and the anodizing is flaking off in some spots. I'd prefer a steel one eventually as long as they bolt up to the existing holes.

Hummmm, I'll look through the bases I have to see what I may have, are you going to reuse the Williams? If so put up a pic and the model # of it and I'll see if I can match it up with a steel base or better condition aluminum one from what I have kicking around here. I have a few ramped fronts also but I can't remember just what I do have left now without digging, I know I also have some hooded globes with interchangeable apertures, but I don't think that's what you're looking for? Right?

Let me know the specifics if you do use the Williams and I'll see if I can help you out. Remember, I'm an old Mauser fan so I've got lots of Mauser related stuff handy, especially sight stuff. So it's a good possibility I may have exactly what your looking for, never know?

Oh BTW, your receiver is the same radius as the Sweed Mausers isn't it? It's been a while sense my last small ring and I can't remember right now, but if I remember right, it is?

My first rifle was a mint 1891 Mauser in 7.65. Back then cases were unobtainium; I had to buy the RCBS forming die and cut down .30-06 brass.

I reloaded a lot of ammo for that rifle... and I kept reloading it until the cases split down the sides or the case heads separated. Which took half a dozen loads... I didn't know, and didn't learn until *much* later, that the problem was the ammonia-based cleaner I was using attacked the brass and weakened it.

Anyway, I'm *quite* familiar with the gas-handling characteristics of the Model 1891. Plus I shoot left-handed.

Maybe a hundred times over a couple of years, I had a case fail and got a faceful of gas. While startling the first few times and annoying later, I didn't find the "problem" to be a big deal.

You could drill a hole in the receiver ring to relieve pressure at the source, and one in the bottom of the bolt to bleed gas out of the firing pin channel; it'd probably reduce the puff quite a bit.

Originally Posted by moleman

It's a Fajen stock. I wish the comb wasn't quite so high. You have to press

your cheek down on it hard in order to get a good sight picture.

I have a big fat Charlie Brown head and I have that problem with the original military stock... your stock has lots of drop, which is unfashionable nowadays. I like that kind of stock because it means I don't have to roll my head to the side and look across the bridge of my nose to find the freakin' sights.

If the pad is too high a wood rasp and sanding block will do a clean job of removing the ugly lump of wood. If you add a scope later any reasonably low rings should keep it down within your normal cheek weld. As far as I'm concerned either a lot of shooters have heads shaped like a hatchet or the pads are a styling leftover from ancient times when scopes stood on two inch tall rings.

Other than the might-as-well-be-required-by-law Monte Carlo lump, that's a gorgeous stock! I used to think the Schnabel forends were peculiar looking, but they're grown on me over the years. I really like the feel of the one on my Remington Model 8.

I had to open up the barrel channel on my Enfield forend when I went from .303 to .45-70. I bought both of the small wood chisel sets Harbor Freight sells. I wound up using one particular chisel for almost everything. It took about eight hours total to open up the channel; I'm no kind of woodcarver and that was my first attempt at opening up a stock. It turned out to be a lot easier than I expected, though slow. I put a heavy coat of black ink on the barrel with a laundry marker, held the forend against it and gave it a whack, and then carved away the black spots. "Repeat until done." I was worried about winding up with a wavy edge at the top where the barrel goes in, but that turned out to be a complete non-issue.

I recommend taping some towels or bubble wrap on the stock when carving. I did most of my work at my desk, and because I'm clumsy I kept banging the stock against the desk and nearby objects while working on it. I'd get fixated on where I was working, turn it a little bit to get a better angle, and "clonk!"

This is going to be a schweet build...

Originally Posted by moleman

if loaded in a strong action. Mine isn't

It's not?

The 7.65x53 runs at 56,500 PSI. And it has nearly identical ballistics to the .308, which runs 4,000 PSI higher pressure.

The '91 might not be as strong as a '98, but it's no weakling. And the '91s were made with fanatical attention to quality control, as opposed to some wartime or licensed production '98s.

Gas vent in the receiver and bolt are done. Laid out the vent location, and cut it with an 1/8" end mill. Once it was done I figured the 1/8" carbide endmill would snap before it would walk the bolt, so I put the bolt in the receiver, lined up the end mill in about the middle of the slot and plunge cut the bolt while holding it shut and pulling it back. The angle of the pic makes the bolt vent hole look like it's at the back of the receiver slot, but it's pretty well centered if you look dead on.

Twa, I'll have to figure out the height the front sight needs to be along with the barrel profile. I made a profile drawing over the winter I'll have to locate again. Comparing that to the sight that was on the old barrel should get me in the ballpark.

I sent the bolt out to get bent as my welding sucks and I figured I'd get the bolt too hot if I used my neighbor's torch on it. Got it back Saturday and apparently I'm not the only one that shouldn't bend bolt handles. The bolt looked great, but when put in the action it was bound up and wouldn't rotate to lock into position. Figuring it just had some polishing compound in it I started taking it down and almost couldn't screw off the bolt sleeve by hand. Before it took very little effort to remove it. The safety on the 91's is an odd duck for a Mauser as it is either on, or off. There is not middle position where the firing pin is locked and the bolt can be worked and the firing pin assembly removed. Since it's a cock on closing bolt all you have to do is lift the cocking piece up with something non-marring (a little piece of wood, plastic or something like the edge of a wood work bench) just enough to clear the cocking cam slot. It appears that they clamped the cocking piece in a vise by the sear surface and pulled on the bolt body while screwing t on and off. During that time the sear surface was mushroomed and the cam surface on the cocking piece slammed into the back of the bolt body at least 5 time (some look like double strikes so perhaps more). I believe these all occurred on reassembly as the rear of the bolt clearly got too hot and is now softer. The peened areas also hadn't been smoothed out when they polished it. I was able to remove the displaced metal and mostly remove the divots through the cam slots but the bolt still binds and probably shouldn't b used since at least the back half was annealed. The ID of the bolt was also .007" out of round in the buttress threads and binding. I sent these pics and got a refund, but I'm still out shipping and a bolt body. Perhaps I'll just get a carbine bolt for it since they come with an arched handle. So a little delay on the build. NOS bolt bodies are available so I'll get one and start over.

.jpg

Slowly been plugging away on this build. Got two NOS bolts in, one is a bent

cavalry type and the other is a straight one. Installed in the action they are

within .0005)

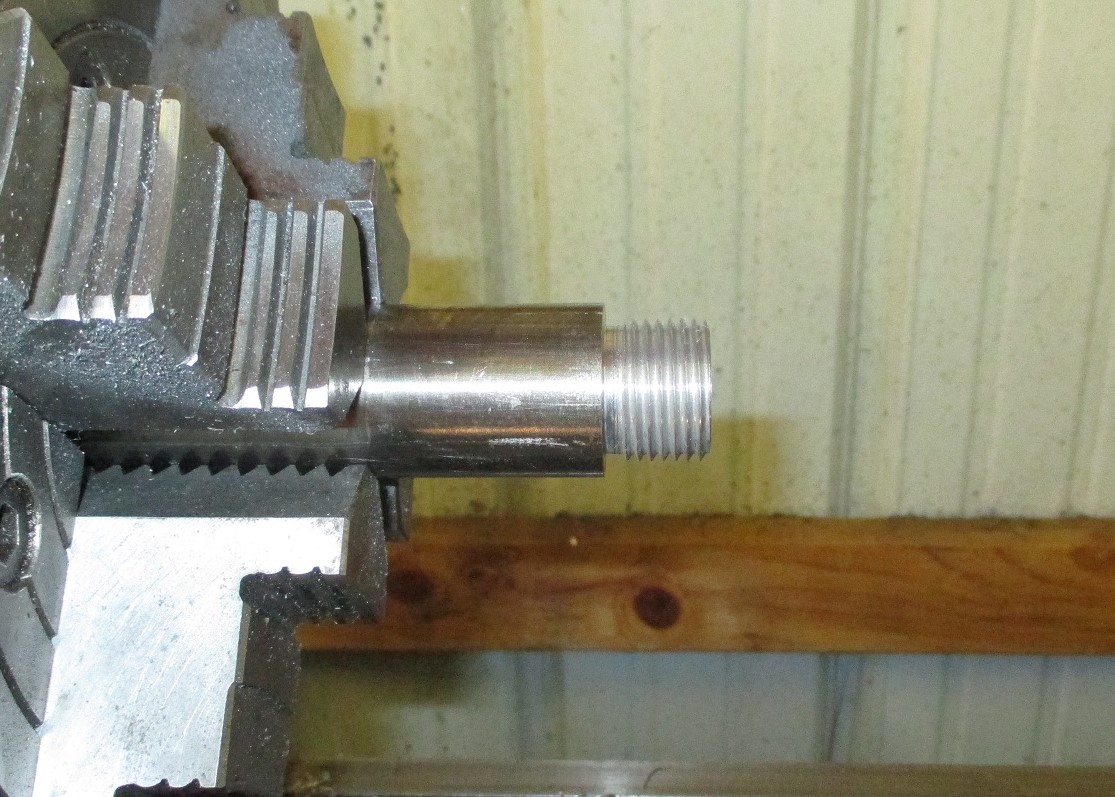

I haven't worked on this for a while but wasn't sore enough to stay out of the shop so I worked on a couple of other projects and threaded the barrel today. I'll need to make the HS gauges before chambering it.

Got it chambered today. The first reamer I didn't get hot enough before quenching, and it didn't hold up. Started on reamer #2 earlier this week and hardened it today, sharpened it and tested it out. No issues. Next up, cut 5"- 7" off of the blank and then cut the flats.

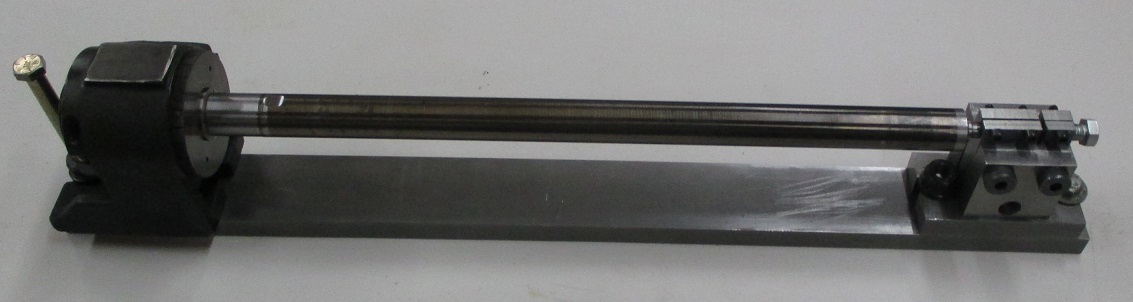

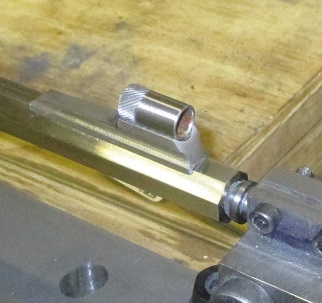

Worked on the riser block for the drill/mill so the 21"+ barrel, indexer and tailstock will fit on the 28" table. Need to round up a few more things before milling the flats. And the reamer I made to chamber the barrel. The chamber on this rifle is 1.8" total so it is legal for me to hunt with in our shotgun zone, but I made the reamer longer so it should be able to cut a chamber longer than a 444 Marlin with ease. From the case mouth shoulder at .456" the reamer tapers up to .471" at 1.8", then is straight from there to the end of the flutes.

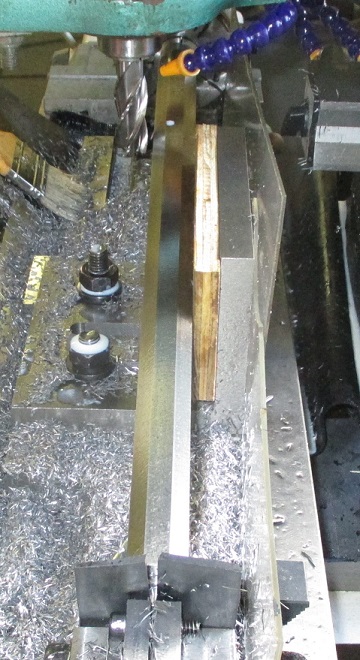

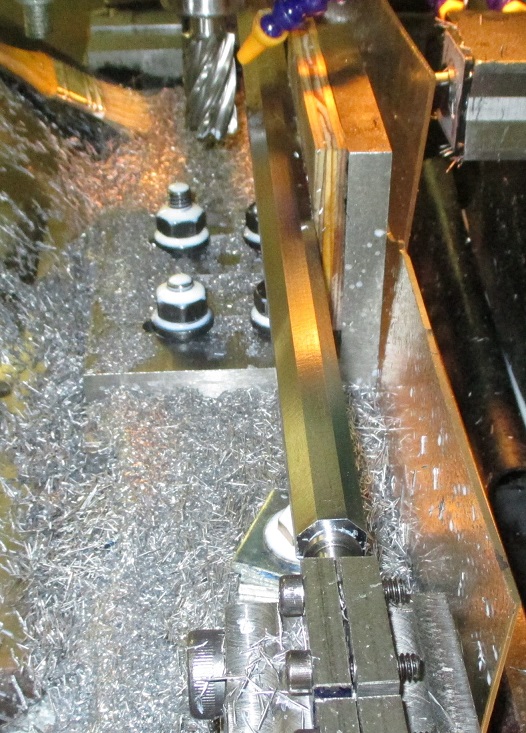

Started milling the flats today, got the muzzle down to 1.070" from 1.2". Lots more chips to come off before we hit .760"

I've likely got around 104 passes left. Sounds like a lot, but there's 8 sides. I also can't believe you missed the obvious, All those chips will make nice flechette rounds for the shotgun. Think I've already stuck 3-4 in my fingers.

Got it down to only .075" off each flat left unless I decide to leave it a little thicker. It's.910" at the muzzle right now.

1" at the chamber end just ahead of the tulip, and .750" at the muzzle... Now I'm looking at it and comparing it again to my 444 Marlin I may take the chamber end down to .950" and the muzzle end down to .730"ish. The table was cleared of chips two times prior to these pics, so a lot of chips came off of that barrel. Need to order a dovetail cutter for the front sight next as well as draw file the barrel and sand it to remove the machining marks.

Spend the day draw filing and sanding out to 800 grit. Then crowned the barrel and broke the sharp edge at the muzzle. Then back on the jig for a final sanding. The front sight will need soldered on before bluing, so one will need to be made or ordered. The tip of the front sight needs to be around 1" above centerline of the muzzle, so basically the sight and base need to be .625" tall from the top of the barrel. I have a few front sight blades that will work, and a 3/8" dovetail cutter on the way. That would just leave milling out a piece of scrap into a front sight shaped object that fits the barrel and deciding if I want it to be hooded or not.

Do you break the muzzle burrs with a bullet inserted and a twist?

No, I've always just used the same sharp rounded tip HSS cutting bit to cut the crown then use a red 3M pad pressed up against it with my finger while it's still spinning for/rev just enough to smooth it out and not round it off. This one was finished out to 800 grit to match the rest of the finish. Just going for minute of deer on this one.

Decided to just make a front sight based off of the hooded sight on my Hawken rifle that have legs that wrap around the top flat. Cut a 1" long piece of 1/2" tube, and a 1/2"x3/4"x3" out of a 1/2" plate. It's basically profiled except for a lightening flute down either side between the base and hood and a bunch of filing and sanding. Going with a post and bead for the actual sight.

Got a little bit more work done on the site. It still needs a lot more of the machining marks removed and abrasive blasted before it gets soldered on, but I took a couple pics of it sitting on the barrel.

Made a simple sling swivel base mostly on a 1880's E.E. Garvin horizontal mill then finished it up on the drill/mill. Soldered it and the front sight on with force44 solder. Still needs a little cleanup, but it's starting to look like a barrel. You can see the 1/2" scrap steel the front sight base was made from in the soldering pic.

Got a little more done, barrel torqued on and the barrel channel mostly opened up. Not as bad as I thought it would be, but messy with the Prussian blue. Still needs a little bit of work before I'd call the barrel channel done and drilled for the front post before I can go shoot it... Suppose some ammo and the rear sight would be nice too. Then if all is well single shot we can worry about the mag spring and follower.

I've been running numbers through quickload and it looks like using Reloder-7 and a 265gr flex tip at 2000 FPS gives a very mild 36K PSI. Using 45K as the max pressure and R-7 you can get it up to over 2100 FPS. I had planned on using other powders, but I'd be happy with 2000 FPS and 36k PSI in this rifle. I've used a 240gr 44 bullet with a sabot in my muzzle loader since 1993. CVA says it supposed to be around 1880 FPS and I know it will push that bullet lengthwise though a deer and break the shoulder on the way out. It's not much, but another 25gr of weight and 120 FPS is better than what my muzzle loader puts out. Even with the pressure down that low it's not far behind my 444 Marlin.

Ended up making a front sight post out of 1/8" brass rod with a .090" bead on top of it. Likely I'll turn it down to .070" or so after deer season as it is currently sighted in and ready for the 15th! Still need to make a follower and mag spring, and eventually rust blue it but that can wait. Did a pretty good job bore sighting it, 25yds about 1" high and a little right of center. Only had to move the sights 5" down at 100yds and 2" over to hit in the center. Groups were in the 2-3" range and many were touching which leads me to believe that with a finer front post or a scope it would do much better, but not bad for what it is. Couldn't find Reloder-7 locally so the cases were loaded with 33gr of IMR4227 with a 2.42"COL which Quickload says should push the 265gr bullet at 1973 FPS at 37,443 PSI. Since it is sighted in for that I'll use the same load for hunting next sunday and not monkey with anything. The flash made the barrel look darker for some reason, but it's still bright steel color at least until after season when it gets rust blued.

Load data for the mild pressure rounds I'll be hunting with this year. Looks like with a 120yd zero the bullet never raises or drops more than 1-5/8" out to 140 yards.

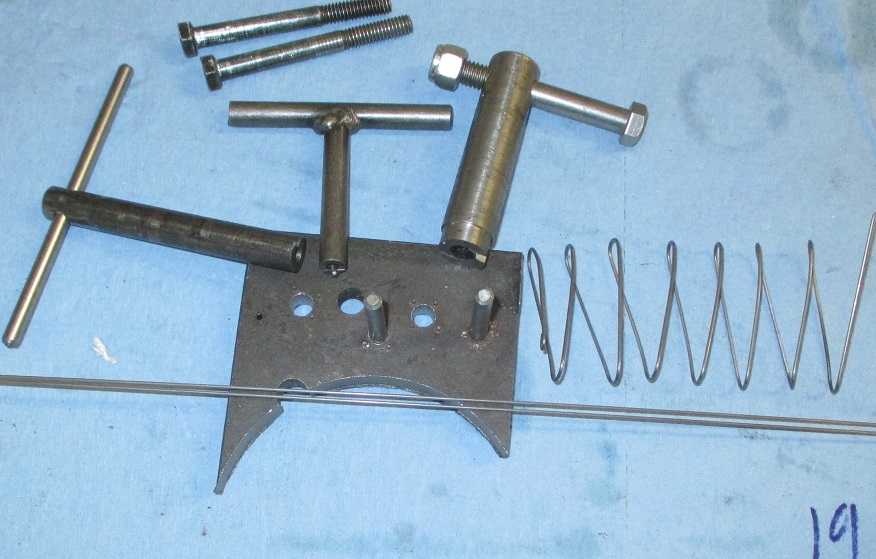

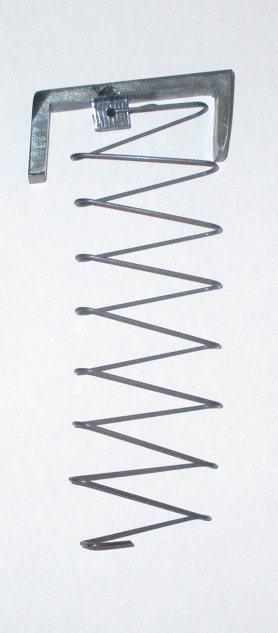

Got a rough follower done, although I'll make another one since the mill tried to eat this one. Wound the .062" music wire spring with the jig and baked it at 500 degrees for an hour. Because of the shape of the follower the gun now only holds 4 rounds, but that'll be just fine.

Yea it all looks good. At 200 you better just put it slightly above its back.

Guys this is a very mild load BTW. There is a lot of room to go with this round on different actions.

The energy numbers are impressive.

When his round hits about 2200 FPS with bit more pressure it is considered a BIG game round. Deer are medium game.

I was playing with the numbers on Hornady's website that calculates enrgy bullet speed and bullet size an gives it a rating.

The energy numbers are interesting. This round at 200 yards has about 400 pounds more energy that a 30-30 at the same range.

IMO the set up he has is a really god deer rifle for 200 yards it certainly will kill at 300 . range estimation will be come important .

I think for his intended use on deer an staying with in the MI laws for were he is hunting this rifle is about optimum for its intended use as bolt action.

With a 1.8" straight wall case length limit there are only a few challengers worth considering. The 460 S&W in a rifle or the 45 Raptor that is a non- rimmed version of the 460 are a couple.

The 44 BGM will shoot flatter than those. A 50 cal version would need too much pressure to have the speed with the limited case capacity. IMO this round is about as good as it can get when you factor in trajectory an energy and its intended use. I think if it were in a modern rifle at 65,000 PSI it would really be something if the bullet's work at the higher speeds OK. Keep in mind the bullet Moleman is using is the exact same one used in the 444 Marlin Hornady factory loads. This round can meet or exceed a 444 Marlin if loaded up.

Its made from very easy to get 30-06, 270 or similar brass. 45 raptor cases are $1 each.

My favorite 44 Mag load is 24gr W296 or H110 and a 240gr bullet in my pistol. At the muzzle it produces 1195 ft-lbs. I've taken many deer with that load while pistol hunting. This mild 44BGM load doesn't drop to 1200 ft-lbs until 180 yards if Quick target is correct.