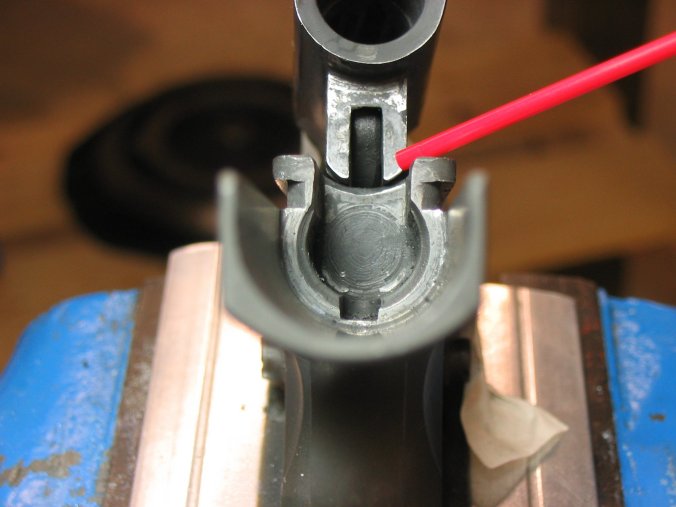

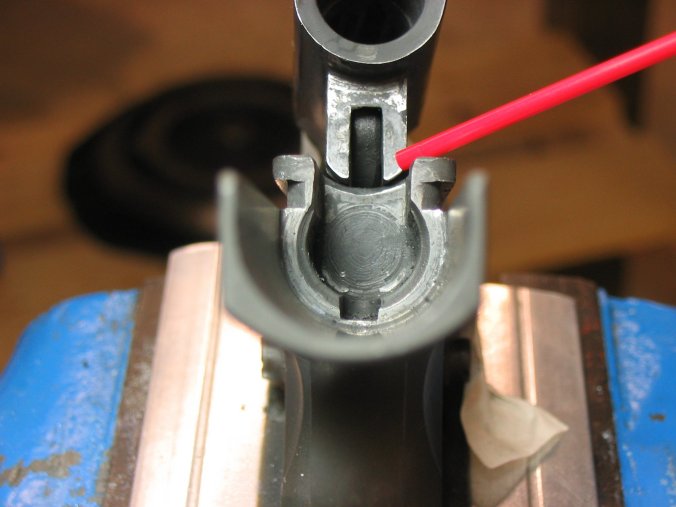

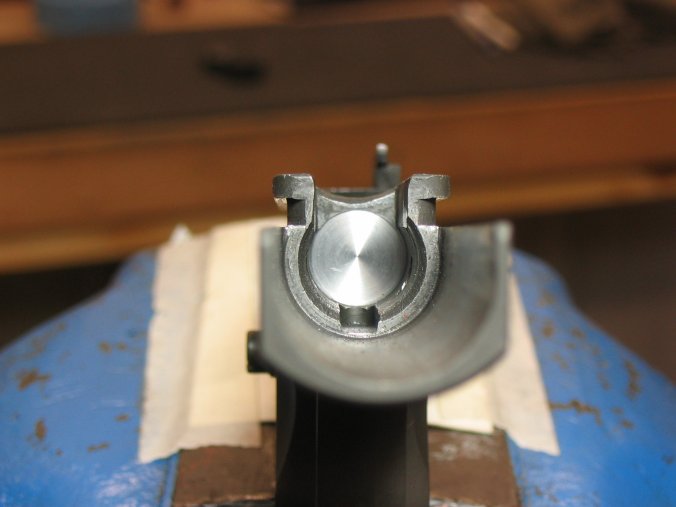

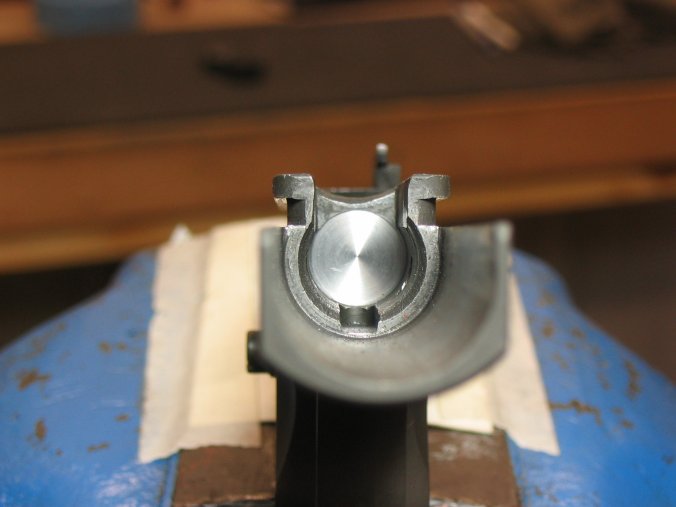

I thought I'd show those of you who might be interested a spot inside the frame that is often overlooked by manufacturers. This area directly affects the longevity of your barrel. I've seen problems here from virtually every maker, but not on a consistent basis. In other words, your particular pistol may - or may not, be set up correctly. This is the frame/barrel impact surface, AKA the vertical impact surface. It stops (or at least SHOULD stop) the barrel's rearward movement. This is not the job of the link, barrels that stop on the link will soon exhibit a failure of the link and/or pin. ‘Course the fly in the ointment of all this is that we not only want the barrel to stop against this surface, we also want it to do so in a way that does not introduce shearing stresses to the lower barrel lugs. Here's a shot of the area I've been talking about. It shows a typical unrelieved impact surface along with surface of the barrel lugs that stop on it.

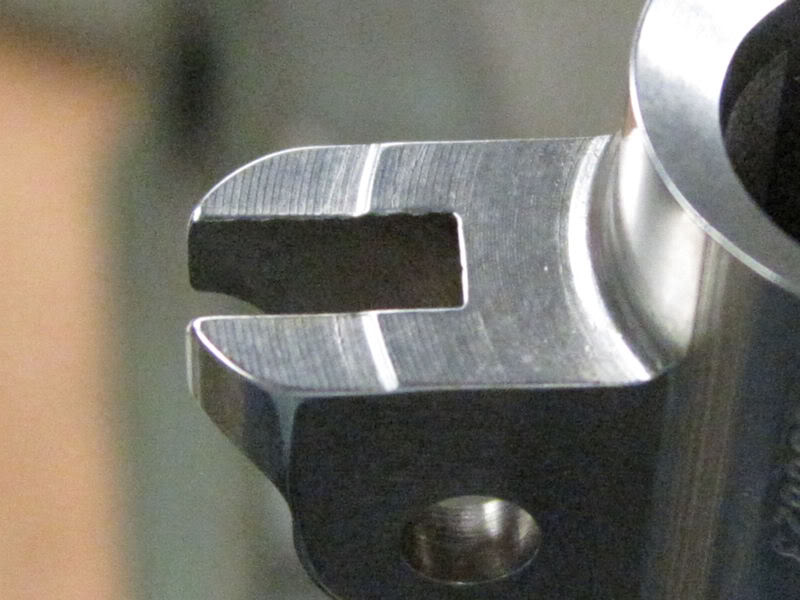

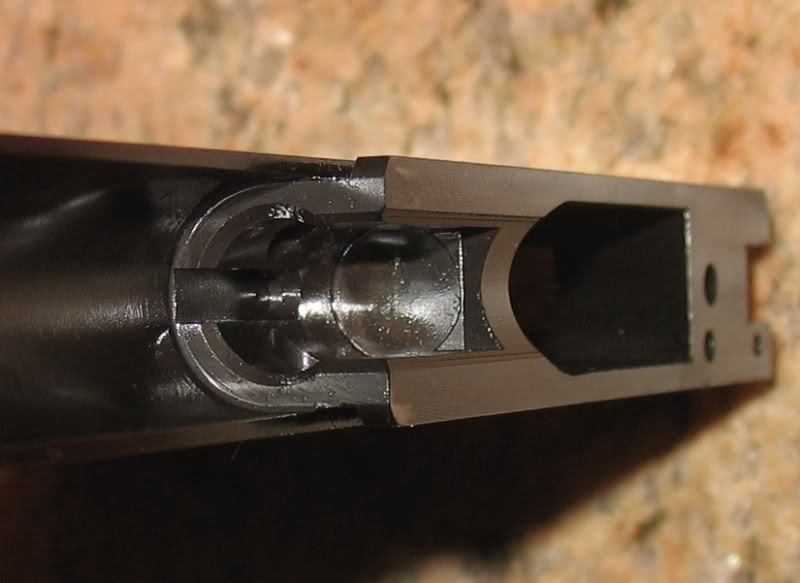

In this next shot, if you look closely, you can see where the tips of the lower lugs have been impacting against the frame. Definitely not a good thing. This is the thinnest, weakest area of the lugs and, being so far away from the lug/barrel junction, adds high stress loads to that area. Strong strikes can cause a failure at the junction - shearing the lugs, or can start bending the lug tips. I've had pistols in my shop that have had the rear surfaces of the lug tips filed back in an attempt to eliminate the problem. This, of course, serves to further weaken the tips. The correct solution to the problem is to machine clearance in the vertical impact surface. By doing this, we'll be positive that the barrel will impact in the strongest area.

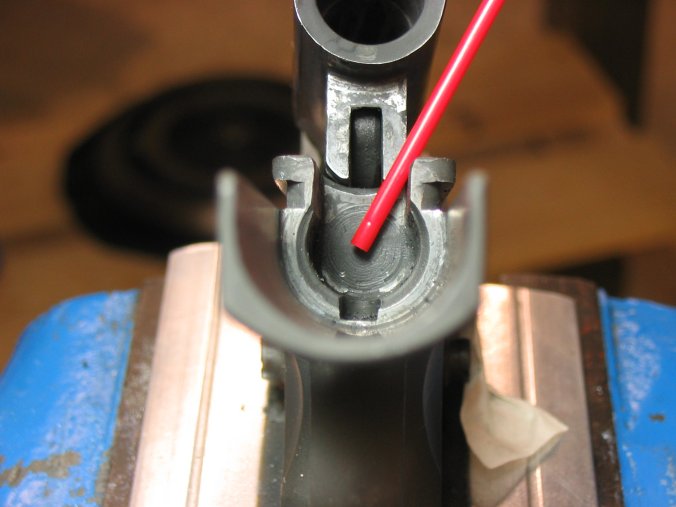

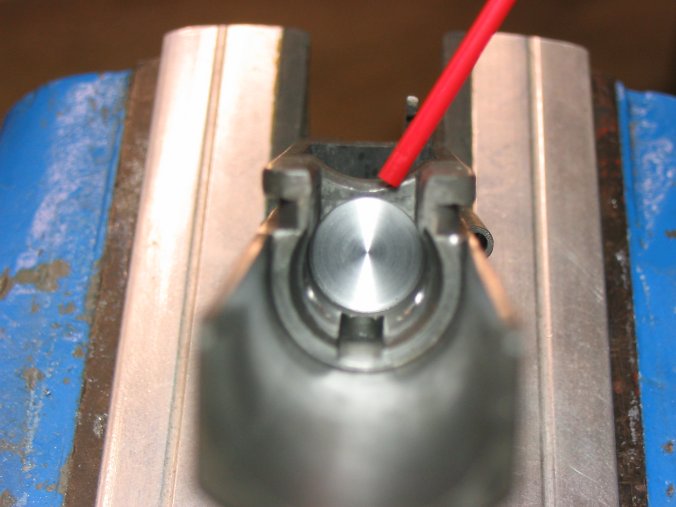

This photo shows the area after the surface is machined. The red pointer is showing the "bowtie" that results from this work. It should be standing proud of the machined area by several thousandths.

If your pistol is set up correctly, this is what it will look like. You should be able to feel a distinct edge between the "bowtie" and the rest of the impact area. At least one barrel manufacturer plainly states in his literature that failure to provide the proper clearance will void the warranty.

I noticed that at the top of the bow-tie area there is a 45 degree(?) chamfor cut into the curved portion that supports the underneath of the barrel when at full recoil, are all frames supposed to have this cut? none of mine do and are experiencing slight 'spreading' or mushrooming in that area....

The VIS relief is a detail missed by many manufacturers and smiffs.

As you stated, it can lead to premature, catastrophic barrel failure.

If its not releived in that area for those of us that have a hard time finding a local gunsmith that's decent or one that isn't so swamped he can't take the work is there a way we can relieve it ourselves?

Looks to done with an end-mill, definitely not by an amateur at the kitchen table. I wouldn't recommend fooling with it otherwise.

Call me anal but I'm a stickler for that fit. I've bought more pistols that didn't fit right in that area than did. I also like to do the 45* bevel on the top corner.

You're right, this is one area that is highly overlooked.

Excellent pictures and description Bob. Since I had my Rock Island apart, I looked at those areas:

PICTURE 404

Since it's not clean, you can see some of the impact areas. The black arrow points to where the barrel lugs are impacting the frame. Looks to me like the entire surface of the lugs are hitting. Is this correct?

The orange arrow points to the forward area of the frame where there seems to be a lot of impact as well. Should that be there?

For those without a mill, the back of the lugs below the bowtie can be carefully filed to stop the impact. It is not the best way, but it is workable and may save you lugs from breaking.

I could be wrong but just to say what I feel normally whem you fit a frame- slide-barrel group you check the movement of parts with Dykem or some kind of product to observe metal to metal friction problems.

Smoothing/polishing surfaces and sharp angles of parts like barrel lugs for exemple could avoid bad stess on parts in contact.

And why don't use epoxy/plastic coating products to produce a kind of "buffer" on the bowtie surface and barrel lugs, or even on frame/slide rails? These surfaces could be recoated every 1000 rounds for example.

This technology is used in formula one race cars and aviation industry on the helicopters rotor head parts. Some metal parts under stress and frictions are renforced with a teflon coat with high temp resistance

I just checked on my Kimber TLE-SS sn K149XXX

It has the "bowtie" and on the back of the locking-lugs, it has the mirror impact point.

Also, the "orange area" in shootcraps picture shows the impact between the frame and slide. It is flat and uniform, without any obvious "high points".

The only indication of "uneven impacting" is on the inside, port side of the slide. The frame slide rail is barely measurably longer ( towards the front, before the champher ), than on the starboard side.

Where's the Bow Tie?

I just cleaned the Kimber Team Match II and the SA TGO 2. The Kimber had the bow tie, however, the more expensive Springer didn't. Here's a pic of the TGO 2:

I did complete the cleaning of the frame but I wanted to hurry and take a picture (I was sure you'd understand). I did notice the frame had a bevel above where the bow tie would be. But as you can see, the surface is flat. What do you make of that?

How deep do you go with your relief cut? I'm guessing that you're using a 7/16" end mill.

Primersinmyshoe and Shootcraps both posted great pictures of the "wrong way". Shootcraps also shows uneven impact which raises the stress levels on the left lug.

"I did complete the cleaning of the frame but I wanted to hurry and take a picture (I was sure you'd understand). I did notice the frame had a bevel above where the bow tie would be. But as you can see, the surface is flat. What do you make of that?"

It ain't meeting the dress code.

So the proper impact area is right on the bowtie?

I know it is not correct but most of us don't have a nice new milling machine like you. Would it be so terrible to remove a few thousandths off the lower lugs and in effect accomplish the same thing or am I missing something? Granted removing that amount of metal would weaken the lug ever so slightly.

kind of off topic... but is there any place with the original "design blueprints" or specifications for the machining?

btw: at least in primersinmyshoe's photo, it appears the contact point is very flat and even.

BOB. so the "upper" part of the lugs .(closest to the barrel) are supposed to meet the bowtie and bring the barrel to a stop. right?

And by milling the relief all you are essentially doing is eliminating any possible contact by the lower portion of the lugs?

Nowlin's frame bridge cutter that is used for cuttinf for a ramped barrel install can be used with a drill to face back the VIS. The Nowlin tool comes with an insert that goes into the dustcover of the frame to center the cutter so you aren't free handing it. Not as ideal as a milling machine, but it will work for those at home with a little skill.

I used a needle file to carefully remove metal from the same part of the frame as pictured. Used black marker and the timing test (explained in Kuhnhausen's second volume) to check along the way. When satisified, I cold- blued the area so I could keep an eye on its wear. The whole process took several hours since I like to make my work "pretty" -a fast filer could do it much quicker.

Several thousand rounds later, a decent "bow tie" shape is evident on the frame. Perhaps my job doesn't look as professional (I don't have a mill), but honestly if you didn't know any better you couldn't tell I altered a thing.

I think it is a better idea to alter the frame than the lower lugs (as some have been postulating).

A few comments, if I may. For the kitchen-table smiths out there who are now considering taking the Dremel to the frame abutment, it is important to remember that removing too much material from the vertical impact surface (relieving up too high vertically) is also a very bad thing, as this introduces point-loads into the barrel lower lug upon impact, which introduces very high shear stresses. Of course, stress is force per unit area. Reduce the available abutment area too much, and stresses go through the roof.

Further, in my experience, far more lower (and upper) lugs are damaged or sheared off due to improper barrel clearance (i.e. lack of adequate barrel upper lug/slide clearance, and/or frame abutment vertical impact surface being located too far forward) than anything else. In this situation, the barrel finds itself in the situation where the barrel, upon unlocking, is caught by BOTH the moving slide and the stationary frame. Bye-bye lugs... As such, it's appropriate to determine if barrel clearance and frame abutment location are adequate FIRST, before ever machining the frame. For example, in the case where the abutment is too far forward, the entire v.i.s. needs to be recessed a few thou to allow proper unlocking clearance. And then, there's the situation where the top of the frame abutment is contacting the barrel underside.

One final thought. I'd suggest always clearance checking the lower lug with Dykem as a first step, before whipping out the Dremel. You might find that, although you don't have that "bow-tie" on the frame abutment, you also don't have any contact with the lower lug tips. The old "if it ain't broke, don' fix it" adage comes to mind.

I agree with Dave on what he said; in short what he described to you is called timing. I have a racegun in the shop now that was not timed in the correct manner; the gun needs a new slide and new barrel because of shearing of the radial lugs on both.

Just a few personal observations:

I regards to tuning for timing, in 99.5% of the guns across my bench, the rear of the barrel's lower lugs is machined back, not the VIS. The usual exceptions are the Para hi-cap frames.

Using calipers, measuring from the bowtie to the slide stop pin, I find .335" to be an ideal number. With Colt's this is a given, Springer's too.

Wil Schuemann fully and accurately describes a 'timing test' on his website.

It is not very easy to understand and requires some thought, but it is valid.

www.schuemann.com

Bob, very nice post and pictures. I made some center cutting piloted reamers awhile back but couldn't make them cheap enough to sell.

Aleaddict,

You mentioned above using a 7/16" end mill, I would not recommend using that. The prints call for a .449 hole, 7/16th is .437. Most holes are .449 and a few larger maybe up to .451-52.

You need a long length of shank to git down inside the dust cover to bore the tunnel, what could happen is the 7/16th mill might flex in the tunnel and a flute could catch in the top opening of the frame and grab a big chunk of steel and rip it out... real nasty.

What you need is mill ground safe on the sides with no flutes to pilot the hole. My reamers are ground solid on the sides and only cut on the face with a .15 radius on the corners. I counter sink the cut about .015.

What you could do if you have a spin grinding jig is grind down a long length, 4 flute center cutting 5/8th mill to .449

BTW I haven't had time to check all my 1911s but so far none of the six I checked have the formal uniform (bow tie).

I have a Colt with a "bowtie", but with more than 30,000 rounds through it, I can now see wear marks below the bowtie on the frame and on the bbl lugs.

How much wear or marks before you would do something? New bbl, refit or modify the frame?

I have checked my two recent acquisions for the bow tie, an early mod. 70 and a "like new" Norinco. Both have the bow tie. The Colt looks a bit more defined but not by much. I suppose this is all about impact and the solid and steady movement of the barrell in motion, thus the timing. What I do not understand is why Primerinmyshoe's SA TGO2 does not have a bow tie at all. Is it that the barrell takes all of the impact on a flat surface from top of vertical rails and thus moves in a steady motion? Surely SA has addressed this issue.

If nothing has broken or failed in 30,000 rounds, I don't think I would worry about it. Check it when you put a new barrel in. Barrels with contact problems in this area fail before 5,000 rounds as a rule.

Hey Pete,

Glad you jumped in! Pete modified - in the extreme - the cutter I use on the VIS. It leaves a gorgeous finish.

Quote:

What you could do if you have a spin grinding jig is grind down a long

length, 4 flute center cutting 5/8th mill to .449

I noticed some contact between the top of the barrel and slide lugs so I purchased an Iron Lug from Brownells to dress the inside of the slide. I'll also examine the VIS (vertical impact surface ) and barrel lugs for wear. The Scheumann link posted by pistolwrench really helped to understand what "timing" is all about, too (thanks, Chuck).

What about aluminium frames?

I have a XS CCO that I've had for a long time. It has the bowtie but you can barely see where the lugs are starting to make contact in the circle cut. The bowtie is doing what it should but with the frame material being softer, should I have this cut "touched up" at some time down the road?

I've got a Springfield MC Operator that doesn't have the bowtie. You'd think that, if this is as big a deal as y'all say it is (and I'm sure it is!), Springfield wouldn't make the mistake on one of their "upper-end" models. How worried about this should I be? Is this something I need to send out to the 'smith to fix immediately, or can I wait until the gun is broken in and decide if there's something else I'd like to do to it? Shuold I worry about fixing it at all?

This is a problem that showed up mainly when gunsmiths started hanging comps and things on the end of the barrel. The weight tilted the front of the barrel down and the lower part of the lugs hit the frame with lug breakage resulting.

Even without the bowtie you won't have a problem on a noncomped gun if the lugs hit evenly as shown on the TGO springfield. If the lugs hit only on the bottom half they will break.

FWIW, keep in mind that the cut which creates the 'bow-tie' was merely a production design, so as to virtually guarantee in a mass-production environment that the standing lug lower tips wouldn't make contact with the abutment v.i.s.. It was designed this way so as to allow repeatable results, and reduce or eliminate hand-fitting work. Is this the only way to get the job done? Of course not. Is it the 'best' way? I'd say that's debatable, if not doubtful. As an engineer, I'd like to see v.i.s. bearing surface area maximized, while keeping shear stresses reasonable, and eliminating deformation potential for the lower tips. Bottom line, if the rear tips aren't making contact, then they aren't making contact. Just make sure the REST of the barrel is unlocking and bedding properly...

Quote:

is there any place with the original "design blueprints" or specifications

for the machining?

Dave Severn's point, that it was a manufacturing process that ensured desireable results in mass production, is excellent.

As to k_dawg's question:

I don't have them .

I checked some of mine today when cleaning. Ed Brown Kobra, 2 STI Trogans, and 1 SpringField. No Bow Ties. If this is so important, which I can belive it is, than why can't you buy the proper cutter? I mean the 1911 is almost 100 years old. Someone must have designed and built the tools to make it by now.

Quote:

This is a problem that showed up mainly when gunsmiths started hanging

comps and things on the end of the barrel. The weight tilted the front of the

barrel down and the lower part of the lugs hit the frame with lug breakage

resulting.

Even without the bowtie you won't have a problem on a noncomped gun if the lugs hit evenly as shown on the TGO springfield. If the lugs hit only on the bottom half they will break.

I think this is a very, very well, put statement. I also didnt think the tgo with full even contact was a bad thing either. I personally believe it would be for "mass" production like unforgiven said...

Checked my SA 5" GI, VERY faint bowtie, almost like it was drawn on.

All this talk of "bowties" has me wondering. Are there any factory guns that are better when it comes to having the "bowtie"? If I stick with Colt or Kimber, is that a pretty safe bet, or does it vary not between manufacturers, but between actual pistols?

I just picked up my SA GI Milspec this afternoon and headed over to my gunsmith to have it checked out. We were appalled at what we saw. The VIS was cut at the top, about .020 deeper than the bottom of the VIS, causing the bottom of the barrel lugs to strike the bottom of VIS. The cut is in such a way that only the very bottom of the barrel lugs make contact. I have not fired the pistol, but it was obviously test fired at SA. I am going to try to return it for an exchange or a refund. I'll give an update when I find out more. Any suggestions?

Am I to understand that the bowtie is the impact surface of the lugs?

Why is this such a small area? Surely having the bowtie milled out to the top will increasee this area (as in some of the pics others have sent in), thereby increasing the impact area and distributing the forces exerted against the lugs as they come to a stop?

If my thinking is correct, and if this were an ideal world, this impact area should be slightly off vertical. The angle should be the same off vertical as the angle at which the barrel is off horizontal at it's most rearward position. The barrel is tilted, so the lugs are tilted and their impact area too should be tilted. Is my thinking correct?

That question has been asked many times and I don't think it's been answered. What part of the barrel lugs should be striking where?

Every Colt I've looked at has had the bowtie, Kimbers as well. None of the Springfields I've seen (granted, that's only 2) have not had the bowtie.

This thread reminded me to check my latest purchase for the bowtie... a Rock River Commander. Not only does the gun not have the bowtie, it appears the lower tip of the lugs is making pretty heavy contact with the frame. It appears that the ~250 rounds I've put through the gun have moved enough metal that there is now some light contact at the upper part of the lugs, near where they join the barrel. I'll probably touch the lower tip of the lugs with a file and then some sandpaper to get some clearance there. This thing is an absolute tack driver and I'd hate to have to get a new barrel for it.

Am I to understand that the bowtie is the impact surface of the lugs?

Why is this such a small area? Surely having the bowtie milled out to the top will increase this area (as in some of the pics others have sent in), thereby increasing the impact area and distributing the forces exerted against the lugs as they come to a stop?

If my thinking is correct, and if this were an ideal world, this impact area should be slightly off vertical. The angle should be the same off vertical as the angle at which the barrel is off horizontal at it's most rearward position. The barrel is tilted, so the lugs are tilted and their impact area too should be tilted. Is my thinking correct?

I did complete the cleaning of the frame but I wanted to hurry and take a picture (I was sure you'd understand). I did notice the frame had a bevel above where the bow tie would be. But as you can see, the surface is flat. What do you make of that?

Hmmm... My Springfield MC Operator looks just like this, although, maybe a bit deeper of an impression of the lug. It looks like there is pretty even and complete contact between the barrel lug and the frame, which I would think would be a good thing.

I then took apart my Springfield Champion that was built at the Gunsite smithy. This is a custom pistol, built on the SA frame and slide. It is identical to the Operator. You would think that if anybody knew what a 1911 was supposed to be, they would be the ones. They seem to like the full contact, rather than a bowtie.

Quote:

They seem to like the full contact, rather than a bowtie.

It seems that if you don't have the bowtie, full and even contact is acceptable. Uneven contact, like just the lower part of the lugs hitting will cause an uneven stress and eventually may shear the lugs.

Unless of course, this is a big secret that is just seeing the light of day.

I would agree with the earlier "conventional wisdom" that all things being equal, a consistent and even full content would be best. However, the tolerances would be very tight, and probably requires a lot of hand fitting. Meaning $$$

The lower-recess, which creates the "bow tie", is an economical method to prevent the lower-points of the lugs impacting first.. and creates a firearm that is easier to produce, but doesn't sacrifice reliability.

Checking one of my more used 1911s, I am sure over 50K (maybe closer to 100K), I can tell it had the "bow tie" but now it appears that it has been beaten back and into submission so that the lugs contact the entire surface. Since it has sustained this ill treatment so far I will not send it to Bob for his work but I will insist that all new purchases have this done.

I thank Bob Rodgers for the education.

BTW A recent pistol I received from him has the "bow tie". Go figure!

Quote:

I would agree with the earlier "conventional wisdom" that all things being

equal, a consistent and even full content would be best. However, the

tolerances would be very tight, and probably requires a lot of hand

fitting.

The lower-recess, which creates the "bow tie", is an economical method to prevent the lower-points of the lugs impacting first.. and creates a firearm that is easier to produce, but doesn't sacrifice reliability.

If it's an economical method, why isn't it being used on the higher end and semi-custom guns mentioned??

I believe the impact surface is vertical as the 1911's barrel is horizontal when it links down. When locked up the chamber is higher than the muzzle.

I'm not completely convinced contact on the full area of the lugs is better than having the bowtie. Certainly the more area the lugs have to contact the less wear there will be when you start counting the rounds through the gun by the 100k's.

When the full face of the lugs is hitting, the moment on the lugs is higher than if just a think strip at the top is hitting. And I think the thin part of the lugs at the bottom that are cut out for the slide stop should not hit anything. Even if the contact looks even, nothing is perfect. Some part of the lugs is hitting before the rest... and I want to be guaranteed the lower feet are not hitting first. And powder fouling, dirt, sand, lead shavings, brass chips, etc. can get on that impact surface and change what hits first.

So I think the best contact would be a thin strip (but NOT point contact) as high up as possible. But not too thin, as that would wear away quickly.

Quote:

If it's an economical method, why isn't it being used on the higher end and

semi-custom guns mentioned?

I'm surprised by the little things missed by higher end production companies. More and more I'm getting convinced the only way to go is to get a Colt and have a good smith that knows 1911's inside out work on it.

But, I shouldn't have to take a new pistol to a smith for something they should have done at the factory.

I'm starting to think this bow-tie is a frilly that don't really give you anything if the barrel is installed correctly.

I think I'll print this thread and show it to my smith for his opinion.

The guns are fine as the come from the factory... they don't NEED to be worked on. But it's little things like this that I insist on being done when guns are up in the $2000+ range because I want the peace of mind that I'm going to have the replace the barrel due to shooting it smooth... not because of it breaking.

And it's one of those things that's so simple and easy to do the only reason I can think of for companies not doing it is because they aren't aware of it.

Quote:

If it's an economical method, why isn't it being used on the higher end and

semi-custom guns mentioned?

Because they are taking the time to individually fit the peices, for higher quality and performance?

I just checked 4 caspian frames and they all were well-dressed with bowties.

I think there is one major thing people are missing. The Bowtie is to fix a problem that might be happening, NOT a standard milling process that was skipped to save time. Maybe most guns do not need such a fix. If your high class gun did not come with a bowtie it could be that it does not even need it.

If you read the Timing Test link on http://www.schuemann.com he explains when and if your gun needs work. If you add a bowtie and your gun does not even need it your going to cause more damage then if you just left it be. Signs of this problem my not even be seen until hundreds of rounds later even if looked at by a top gunsmith before shipped from the factory.

I work on a lot of cars and people all the time do something to their car because Joe Blow told them it was the right thing to do on his exact same car. Every car (even the same make and model) is different and that goes for guns too. Every car has a different tune. Sure there are numbers a book gives you but that only gets you close enough to turn on the car. The remaining tuning must be done as all the parts get worked in. The price of having a "tuned" action is having a smith work on it. That means extra time checking things and many rounds down range. If you want your Top Notch Springfield with that kind of fit expect to pay more and have a few hundred rounds fired through it before you see it "NIB" at your dealers. That's why custom guns are so much more. As said before, you get what you pay for.

Please read the link on http://www.schuemann.com or send it to a good gunsmith for inspection before you have any work done on it.

Well my Colt has a picture perfect bow-tie although I still havent been convinced why a 1911 needs it. Surely a nice flat surface is better?

Great post. I've actually had customers send frames back because they did not understand the reason for a relief cut in this area. It is very clearly pointed out on the 1911 A1 military blueprints

gary@caspianarms.com

Quote:

I think there is one major thing people are missing. The Bowtie is to fix a

problem that might be happening, NOT a standard milling process that was

skipped to save time. Maybe most guns do not need such a fix. If your high

class gun did not come with a bowtie it could be that it does not even need

it.

This is very well put and very true. Just adding the bow tie did not fix a timing issue if the gun has one. Most of the time the radial lugs on the barrel and in the slide will suffer first; if the damage is bad enough both will be ruined. I read on another forum (by one who claims to be the best pistolsmith in the world) that the radial lug damage is called flanging and the fix for this is to file or dress the barrel radial lugs to remove the flanging. Filing or dressing the radial lugs does not correct the timing issue that is causing the problem and the shearing of the radial lugs of both the slide and barrel will continue.

As bu-bye pointed out understanding the timing test is the key to the barrel's longevity.

Here is a pic of my SA Mill-Spec. It has a little over 3,000 rounds through it. It has nice even uniform marks that are a mirrior image of the barrel lugs. As you can see all edges are beveled to stop the peening saw in a earlier pic. I have had great luck with this pistol(except for a few weeks ago) I posted about the FTRTB and Hammer follow, well a good cleaning fixed the hammer follow, and new wilson springs solved the FTRTB problem.

I personally would break the bottom feet corners slightly and call it a day.

The worst ones are like the picture of the springfield. we have all seen them where the feet hit at the bottom only, and where they rip the bottom lug out of the chamber.

I would vote for the bowtie with one disclamer, the relief cut is to be no deeper than necessary. perhaps .002 would be nice. But if you relieve it say .015 the barrel will beat the smaller bowtie back till it stops on the fuller impact, or shears off the link or breaks the slide stop, not a goal.

Probably 5 years ago we convinced Storm Lake to make there 45 barrels with a relief cut from half way down the feet to the bottom. Burt Had Mentioned that barrels had failed when they contact at the bottom of the feet only. they went with a small relief and the problem disapered.

We just happen to make a cutter. It was designed for ramp barrels (Wilson / Nowlin cut) but works fine to true the frame up. it is a 1/2" M 42 co blank, the last 1" is turned to 29/64 dia. the bottom is flat cutting not an endmill cut.

And to the guy with the post about the Yankee wood shop. It ain't about the tools, it knowing what to do with them. I can put a kid in a 12k Nardini lathe with digital read out to bore bushings out. and if he doesn't know how to set teh speeds, feeds, angle of entry height of the tool and put the boring bar in the correct spot in rotation he will get Zero finish. Big Dollar tools do not a gunsmith make.

Quote:

I would vote for the bowtie with one disclamer, the relief cut is to be no

deeper than necessary. perhaps .002 would be nice. But if you relieve it say

.015 the barrel will beat the smaller bowtie back till it stops on the fuller

impact, or shears off the link or breaks the slide stop, not a goal.

This is a very important and telling statement! Notice the words "beat the bow-tie back". This tells us that the surface area of the bow-tie is insufficient to resist the bedding forces, and it is yielding. The proper corrective action? Increase the surface area of the bow-tie. Point loading stinks!

Quote:

... can anyone recommend a good DIY fix, to keep this from causing any

serious problems down the road?

Bevel the back of the feet with a hand file.

I have a Springer that was sent to Tripp for some work including fitting a Nowlin match barrel. Needless to say, I was more than a little disappointed to see impact marks from the lower legs and no "bowtie" whatsoever.

I thought I should add this for whatever its worth. As for me I'm pretty clueless in this area so I would probably follow the book.

In Jerry Kuhnhausen's Volume 2 shop manual he states on page 197="Under no circumstances should any metal be removed from the barrel's lower lugs, rather than from the frame, to correct any discovered problems. Removing metal from the rear of the barrel's lugs will weaken the lugs and void the barrel warranty".

I don't know about the barrel warranty I just wonder if it hurts in the gun in any way. If it don't, then this is probably the quickest and best way for anybody without the proper machinery to modify the frame. This is again, for whatever its worth...

Very educational - I read every post last night just before pulling down the Wilson CQB for cleaning. I'm happy to report it has a proper bowtie that is standing proud.

It will be interesting to check the others in inventory, especially the wide body .40 that had a broken barrel lug inside of the first five thousand rounds or so. (It was promptly repaired under warranty so no need to point fingers, but very interesting, indeed.)

Help! Distance between bowtie and slide stop needed!

Does anyone know what the min and max distances that are 'allowed' or 'normal' between the rear edge of the slide stop cross pin when fitted and the front edge of the barrel feet to frame impact area (or bowtie). I'm away from home and don't have access to another 1911 to compare this dimension.

I think the correct dimension you're looking for... is measured from the center of the slide stop pin to vertical impact surface area, or 'bow tie' as you refer to it. Print says .431 +.005

Here's a pic of one of my 70 Series Gold Cups. Not sure but probably 1500- 2000 rounds through it, maybe not that many.

So, how does this look? What about the marks (don't know if they qualify as peening) @ 8 o'clock and 5 o'clock?? Well, the "marks" that I was concerned about were nothing more than the inside of the slide stop holes.

Looks good from my house Walter. As mentioned above by George the relief area under the bowtie should not be more than a few thousandths deep. Too deep and you run the risk of the bowtie peening back and causing issues.

Just checked my circa '99 Colt M1991 Stainless Gov't. Nice butterfly. Thanks for the great post. I had read about this issue on Hilton Yam's (old) website, but could never visualize just what he was talking about. This cleared it up "right quick".

I was checking my 1911's for the bowtie and found my Para 16-40 had no bowtie. Then I read you post re: timing and the exceptions being the Para hi- cap frames. Would you be so kind as to explain why Para hi-caps are the exceptions and, what being the exceptions means. The more I read the more confused I am becoming! Thanks.

I was checking my 1911's for the bowtie and found my Para 16-40 had no bowtie.

The ramped barrels are exceptions, the frames are cut entirely differently.

This Just Figures

I hope by now that people have read this entire thread, instead of just the first post. By reading the just the beginnnig, it seems likely that you will come away with the understanding that once again your gunsmith or gun manufacturer has screwed up and left out a step that is necessary for the "real" and "proper" tweaking of a 1911 gun. But having a CNC mill and the tooling to go with it is not the final answer in every case.

As others point out, taking an end mill to the VIS is neither recommended nor necessary in the majority of cases. This milling is a purely expedient step for those who might not have the necessary time or inclination to perform the necessary "fix". In many cases the small "bow tie" strip is a tiny little surface that now must withstand the full forces of barrel link down. In many cases the cute little bow tie gets battered and the effective position of the VIS moves backwards.

Take a look at post #27, by primersinmyshoes. This picture shows a perfectly good VIS, with no sign whatsoever that there are incorrect stresses being developed on the lugs. Yes, we want most of the force to be toward the top of the lugs, but this does NOT mean we want ALL the force concentrated along a tiny strip of metal, even though it is in the "correct" place. Perhaps more accurately stated would be that we DON'T want the force to be concentrated at the bottom of the lugs. That requirement is a far cry from machining away 95% of the VIS!

Thanks for Dave Severns for pointing this fact out several times, and stating that the actual timing of the barrel drop is usually a far more important point than the marks left by VIS impact.

To summarize, the concepts you should associate with milling the VIS to form a bow-tie impact surface are: expedient, usually unnecessary, sometimes detrimental long-term. Personally I would rather receive a new frame with mid- spec dimensions and a flat VIS, than a frame sporting a bow-tie cut and other unnecessary tweaks to the rails, the frame bed and the feed ramp.

Caveat emptor.

Looked at the VIS in any Colts lately? Think maybe, just maybe, they might know a thing or two after all these years?

I agree. I found his statement " the concepts you should associate with milling the VIS to form a bow-tie impact surface are: expedient, usually unnecessary," (SNIP) to be slightly strange to say the least.

One would think that it wouldn't be "expedient" to mill the VIS and to further state that it is unnecessary I would disagee with also.

Oh well, to each his own. I'm glad that my pistols have been given this "unnecessary" step even if it isn't "expedient".

Before everyone jumps down Sparks throat I have to agree with part of what he's saying.

As I stated in an earlier thread just cutting the bowtie does not correct an incorrect timed gun and from this thread some may think the bowtie is the cure.

If the VIS is correct in it's relation to the barrels lower lug during the proper unlocking phase of the timing sequence I see no need for a bowtie on the VIS.

If correction needs to be done to the VIS I feel it would be better to mill the complete VIS instead of just a portion.

By doing this the timing should be corrected, relieving any undo stress on the lower lug of the barrel.

With all do respect to Bob Rogers just because Colt does something does not mean to me that the fix is correct. What Colt may find is that the bowtie is the least expensive way to add a little longevity to the barrel lower lug. It would be a considerable cost to Colt or any manufactuer to have to pay employees to check and correct the timing in every gun thats built.

The vertical impact surface relief is not intended to alter linkdown timing.

Its purpose is to eliminate impact on the lower portion of the barrel's lower lugs.

EVERY SINGLE GUN I BUILD OR FIT A BARREL TO has this relief.

Now I suppose it could be that I don't know what I'm doing, but...

I would not suggest betting money on that.

Quote:

Wil Schuemann fully and accurately describes a 'timing test' on his

website. It is not very easy to understand and requires some thought, but it

is valid. www.schuemann.com

This is the post I referred to when I asked why Para hi-cap frames were the "usual exceptions." I am relatively new ot 1911's re: working details, so any info on why my Para has no bowtie and my S&W does would be appreciated.

With Para frames, I frequently need to re-cut the VIS to achieve proper linkdown timing. This is a different thing than the VIS relief.

Refer to the dimension of .335" from slidestop to VIS. The paras I have had to remachine were about .325", .010" short.

Wouldn't you remove material from the barrel not the frame.

As long as the frame is square.

As a general rule you remove material from the piece that is least expensive and more readily replaced which for most of us is the barrel.

Quote:

...Wouldn't you remove material from the barrel not the frame.

As a general rule you remove material from the piece that is least expensive and more readily replaced which for most of us is the barrel.

Chuck and Dave are just funnin' you a little. You answered your own question. As a "general rule", yes. Always, no. It's not just about the "least expensive and more readily replaced" part. It's about getting the gun to run properly and live a long time.

As luck would have it, I just had a pistol in the shop that received the treatment you're advocating. To his credit, the smith that installed the barrel recognized the fact that the lug tips were striking the VIS, BUT instead of relieving the VIS, he thinned the lower half of the back of the lugs... waaaay too thin. It's only a matter of time now.

Personally, I'd rather wear out a barrel in a more traditional way.

Been perusing this thread for a while, finally checked my guns. ALL my Colt's are done, NONE of my Springers are. In retrospect now, 2 of my 3 Springers have broken the barrels at the lugs . You'd think that if a gun gets sent back to replace a broken barrel, they'd take the extra time to do it right.

tsp- mine was done at Springfield after I sent it in for a new barrel. Some jobs are not as distinct as the picture above. Mine is clearly there, but only a few thousands it would seem.

Quote:

I think you guys missed the point

No offense, but I think you missed the point. Correct me if I'm wrong Chuck, but the reason to relieve the frame in this particular case is because if you modify the cheaper part (the barrel) it will become too weak and eventually fail. Then you have to replace the barrel, once, and again, and again as the lower lugs will possibly continually shear off with any real use.

Point being, you want to relieve the frame to insure barrel longevity.

It does no good to modify the cheaper part if by modifying the cheaper part it means it will fail.

By the way High Country, these guys are funnin' with you because Pistolwrench is a guy named Chuck Rogers who is a very well known 1911 smith, check out the website in his sig line.

Springfield mil-spec

Stress = P/A. Reduce A (area) with same P (load) = GREATER stress. Greater stress = BAD. Ideally, one should strive to eliminate impact loading on minimum section areas (tips) of the lugs, while keeping stresses as LOW as is possible throughout the entire affected region. This will maximize both barrel and frame life in this regard. While the 'bow-tie' method will protect the barrel, it greatly INCREASES point load stresses imparted to the frame. Unfortunately, depending upon the geometry of the component fit and the toughness of the material used, this can result in set-back of the bow-tie frame VIS, via peening. I would agree with Mr. Hunter's last paragraph. For me, at least, there are better ways to skin this particular cat.

Edited to add: Just went back and re-read a couple previous pages...all this stuff was covered way back in posts #98 and #100. Sorry for digging up the past.

Not trying to be confrontational but, what do you suggest as ways to "skin this cat"... Just open to suggestions... The relief cut is only around .005 deep.

I'm late to the party but have a couple of questions. My RRA Pro Carry (Commander size) just broke the barrel legs off. Sheared the sucker as a complete unit clean off the barrel; it was like someone took a big Vice-Grip and literally tore the barrel leg assembly clean off.

Standard 18# recoil spring changed about every 1K rounds (yeah, it's overkill, I know) and give or take 3K rounds through the gun. Nothing but Blazer Brass, Blazer alum and occasionally some Ranger RA45T (not the +P) through it.

Since it's at the factory I can't tell you if it has the bow-tie relief cut, but my full size RRA does have it. So does the Caspian I built in the Dave Sample class several years ago. I have a Springfield Champion with a Bar-Sto barrel (professionally fitted) into a Caspian slide that uses a ramped barrel, but the barrel leg (for lack of a better term) appears to be hitting high so no problem.

But my Baer does NOT have the bow-tie relief cut. I did the blue marker thing on it, and the legs appear to be hitting right at the leg/barrel junction consistently (i.e. pretty high).

So for those of us that have done searches on this problem and found this thread, if there is no relief cut should we get one put in? Can we do this ourselves, or does this require a mill/lathe/whatever? If we can see that the barrel legs are indeed hitting up high, should we be concerned?

Would this apply to a 3" 1911 as well? My barrel's LL's seem to be hitting the same (vis) spot as in your pictures, but the lower lugs look different due to the ramped barrel.

Is there a measurement that can be made to see how far out of spec it is and how much metal needs to be removed?

Its hard to tell from my pics, but the lower lugs are definitely striking the lower portion of the VIS leaving small dents. I dont think that the bowtie check applies to my gun either.

My Baer has the bowtie cut and so does my Wilson and my Brown

Mr Baer may not be so Keen on you altering the gun he made for you?

You can do a bow Tie cut with a drill press but you want to be in the low RPM range say 350, not all drill presses go that slow. a Good square vise, we like Palmgren at our shop, and simply a Kiss of the cutter to do the relief.

Has to be a flat bottom cutter, Should be a 1 pc cutter. A simple end mill will have a concave bottom and leave the center high which will not be in your favor.

Barrel breaking off especially a carbon steel barrel is not a normal thing. If you sent it back you can't check other things that could contribute. Timing as mentioned earlier in the post, making sure the barrel totally disengages from the top lugs before impacting the frame. Barrels bounce a little also. if your gun has .002 between the barrel and the slide when out of battery you will want to lower the barrel bed which also alters the timing. Typically not the place to begin for gunsmithing.

The local electric supplies store has a sign I like: "Electricity is not a hobby". Goes for barrel timing too. NOT that No one can do it and Certainly it can be checked at home but moving surfaces and lowering barrel beds is far better done by or with someone with experience. Of course you have to start somewhere. That is where Welding comes in too

Kimber CII

Baer PII

Quote:

Mr Baer may not be so keen on you altering the gun he made for you?

So my question re the Baer is this: If I do the blue marker thing and the lugs are hitting up high, even with no bowtie on the pistol, do I have a reason for concern here?

In the "It's the same, only different" Department: Have a Kimber ProCDP which has no bowtie, and the barrel legs are definitely hitting on the full leg surface, both sides equally. Since this frame is aluminum, which is softer than the steel of the barrel, is this still an issue? I wouldn't know how the frame could be modified (e.g. milling the spot out on a mill machine) without the need for re-anodization.

Valid point with reduced area and an aluminum frame.

The Storm Lake relieve the bottom part of the lugs (half way down or a smig more) may be a good alternative. If you marked the middle and relieved gently from there down to the bottom removing say .005 at the bottom over time it may well beat in far enough to recontact. The coating on the frame is probably tougher than the aluminum so I concur to leave it on and not bowtie the alum frame.

This thread made me curious. My 2009 Springer Mil Spec has a bow tie.

Quote:

The Storm Lake relieve the bottom part of the lugs (half way down or a smig

more) may be a good alternative. If you marked the middle and relieved gently

from there down to the bottom removing say .005 at the bottom over time it may

well beat in far enough to recontact.

I'm sorry, but I'm a little confused by your reply. Are you saying that I should file/sand the bottom half of the lug/lug legs on the Baer by .005 or on the Kimber ProCDP barrel? Would I want the lugs to "recontact" on the ProCDP aluminum frame?

I'm more concerned with the Baer than with the Kimber, as I wouldn't think (and you know more than I, so please correct me if I'm wrong) the Kimber would be an issue with the steel lugs contacting the softer aluminum frame. I will re-mark and re-cycle the Baer tomorrow to see if there is any contact happening and then advise accordingly, but in the meantime - can you clarify your response for us?

Quote:

I will re-mark and re-cycle the Baer tomorrow to see if there is any

contact happening and then advise accordingly

So today I re-marked and re-cycled the Baer, and I also did a visual on the width of the lug feet. The lug feet of the Baer are noticeably narrower than on a standard 1911. On my RRA the barrel lug feet are .0108" wide as measured front to back (and not from the center of the hole as Kuenhausen shows in his manuals) but on the Baer they are .082 from front to back.

This leads me to believe that the barrel lug/feet were shaved down by the barrel manufacturer to ensure the feet did not impact the frame surface, hence, no bow-tie needed.

In my marking and cycling today, the only contact I found was at the top of the lug and the top of the frame where the bowtie would have been were it installed. Absolutely no contact below that point. I guess Baer is simply doing it differently.

Quote:

the barrel lug feet ..on the Baer they are .082 from front to back

I ain't a Chuck Rogers or a Bob Rodgers, but that seems a bit too thin to me.

Indeed. Bear in mind that my measurement technique was probably completely erroneous; as I said, the Kuenhausens show the measurement from the center of the link pin hole to the back face of the lug legs. Looking at it, you can see a difference from another 1911 barrel.

I've not heard of any problem with Baer barrels breaking their legs or shearing the lug so maybe for their pistols it works ok. I dunno. It certainly isn't making any contact where it shouldn't be making contact.

Quote:

I've not heard of any problem with Baer barrels breaking their legs

I have a friend whose Baer has sheared lugs twice.

I had a lower lug foot break on one of my Baers....twice. They replaced the barrel and it happened again. Each was about at 5K rounds.

The third barrel is holding up just fine at about 15K so far. I spoke to Les about it after the second time a few years back at SHOT. I asked if the VIS should have a relief. He said they angle the feet so they don't hit. He said the barrel was misfit and the timing was off. I'm not so sure the lugs are angled by looking at the gun but the barrel is still in one piece (and it's a very accurate gun.)

The barrel lugs impact that area regardless, what difference does a slightly raised "bowtie" shape make?

I think if it were critical, all manufacturers would have included this relief.

It's so that the top of the lugs take the impact (where they are strongest) - not at their feet. The circular area is milled-out to stop the feet from hitting there and making sure that if anything hits the frame, it's only the upper, stronger part of the lugs.

I don't have the relief-cut on my little RIA, but the lugs are hitting at the top anyway.

Oh, I see. SA 1911's don't have this, and I've only heard of one that had it's lugs shear off - and it was a rental EMP9 with a million rounds through it.

Quote:

The third barrel is holding up just fine at about 15K so far.

Like I said, I HAVE heard of Baers breaking the lower leg feet! OK, so it happens on the best of 'em. I stand corrected!

From what I've learned here, it's not so much whether or not a bowtie exists. The important thing is to find out where the lug is hitting the VIS. If it's not hitting high, time to get it fixed before it breaks on you like mine did.

My Valor has the bow-tie relief cut , my Baer does not . Crap, I wish I knew that before I sent it to John Harrison, he could have done it then. Poop.

Hi Bob and other smiths, lookers and other gentlemen and gentle ladies keeping up with this thread. I saw this thread before I bought my first 1911 2 months ago and on my inspection I thought my bow tie looked correct. This threads been brought up through another in the DW subforum and upon closer looking, well here's pics.

IMO, the bow tie looks "folded" over horizontally over the middle. I know from reading there are just as good of ways to be setup that doesn't have the bow tie, but Im just not smithy enough to tell, especially since it's my first 1911. Btw, this a 2010 VBOB bought brand new with about 500 mixed rounds through. So let me know what you think. Am I in good shape or no? Thanks for your help!

my DW has an ramped barrel so no issues but my kimber's aluminum frame has marks where the lower lugs have been hitting. not sure what I should do about it. maybe I should sell it and buy another DW.

Just checked my new Kimber ...

Perfect "bowtie"

After reading this thread I checked my gun and i'm glad to see my 2010 Kimber eclipse II has the "bowtie" relief cut

Because the machining involed is a bit beyond the average amatuer 'smith, I was wondering if a different approach would work.

Could you just relieve the lower legs on the barrel instead of the place on the frame where they legs hit? It seems it would have the same effect.

Am I missing something?

No you are not missing the point, clearance is clearance. This approach is taken by some barrel manufactures to protect their product. Here is a Schuemann barrel out of the shipping tube.

Just checked my Colt Combat Commander 9mm. Sure enough, it has the little bash marks on the barrel feet : (

Just checked all my 1911s.

All five Kimbers have the bow tie.

My one Para does not.

Now, the disturbing part...

My Baer does not.

My DW CBOB does not.

My Guncrafter Industries (.50 GI) does not.

I will have to consider putting the "boutique" 1911s up for sale and sticking with the ones that work today and will probably work a while from now...

orionengnr, wouldn't it make more sense to just modify the barrel feet on the guns that don't have the frame relief rather than sell the guns?

My new Supper Carry Custom Kimber has a beautiful bowtie. After a break-in (including 10% +P) no marks on feet or below the bowtie.

Thanks Log! That falls under the umbrella of; "well, hell ya! I'd have thought of that if I had another 30 IQ points!"

I think this is accurate? The "bowtie" is a fix waiting for a problem to develop. Sometimes the "problem" exists out-of -the box, and sometimes it develops. We're talking lower barrel lug/VIS fit and barrel fitment. If the gun's built right the bowtie is superfluous; maybe still a good idea though... stuff happens.

My older Pointman major doesnt have the "bowtie" but the impact outline on the abutment is more pronounced from the upper legs and grows more faint toward the bottom.

On closer examination, I see that the feet on the Kimber barrel (SCC) are cut in like the Schuemann barrel lugs (but not as deep) and cut on the back of the lugs goes up higher on the lugs -- so it looks like there is a matching bow-tie where the lugs meet the barrel. The impact surface seems to be at the highest point possible -- bow-tie to bow-tie. Nice touch for a stock barrel.

The circled areas are from the guide rod head and the center one is from the link during assemble.

Thanks for the response LOG. So the center mark is nothing to worry about, should be be concerned with the other two from the guide rod head?

Perfect bowtie on my 2009 manufacture Colt (model 1991 Commander)...

Funny how every time I learn about one of these subtle points, I find that my Colt has it correct.

While I respectfully admire information given to me from those that offer guidance that they clearly know more about this than I do... The full contact method was once explained to me that this method it meant to supply superior accuracy of action over reliability from a weapon than may get dirty in challenging service. Ala mil spec in that sense.

In my infantile understanding of the assembly function crossbred with engineering experience... Would it not be better to have the full pattern printing EVENLY for proper alignment and impact load sharing to improve accuracy of the action over a smaller patch high on the angle point (fulcrum)?

Granted off angle impact serves no beneficial purpose (like what was shown in the original post with only lugs printing). Off angle contact definitely is not the way to go, but until someone can explain the bowtie benefit to me any further that performance in a dirty weapon or increased reliability I fail to understand the benefit over the full contact method shown in various pictures of SA pieces.

I'm certainly willing to listen. This is an excellent post that spurs the kind of debate that many of us can learn from.

I just picked up a Range Officer on Monday but it does not have the bow tie and has not been relieved.

IMHO a bow-tie VIS cut in not optimal. The bow-tie cut is used to help manufacturing. Bob Rogers fixed a 1911 that the lower (tips) of the barrel knees where hitting the VIS as I outlined in one of his pictures here:

He fixed this problem by end-milling in to the VIS to make a bow-tie cut.

Notice how thin the bearing surface is on the top of the bow-tie because of the big chamfer below the barrel bed?

I always watch out for this in all my 1911s. I mitigated this risk by removing material from the lower legs of my barrels as shown here:

The problem I have with a Bow-tie cut is that it leaves a very narrow strip of material at the top of the VIS..where it takes the full impact of the barrel... and it deforms quickly under hard use, until eventually, the VIS is too far rearward.

I like to see more full VIS contact like these 1911s:

Take a look at the "bow-tie" cut on this Remsport frame that I am currently working on.

Before:

I would never build with such a slim bow-tie cut

After:

Much better

And I measured the distance from the SS hole to VIS and it was still right on:

.5348 - (.201/2) = 0.4343 in spec:

So I'm still not sure, on a properly fitted and timed barrel should the back of the lower lug make contact with the frame when linking down or should it have no contact like Kuhnausen says in his book pg.66 ?

So I'm still not sure, on a properly fitted and timed barrel should the back of the lower lug make contact with the frame when linking down or should it have no contact like Kuhnausen says in his book pg.66 ?

As an added note, if no contact is made wouldn't all the stress be put on the barrel link and pin and the slide stop...

JK is correct too.

Don't forget that the barrel sweeps a circular path to the VIS. Think of it like the barrel knees roll down on to the frame VIS like a flat roller. I believe that JK wants everyone to making sure that there is a gap (no binding) between the lower barrel knees and the VIS during the VIS contat event. Otherwise the lower area of the barrel knees would contact the VIS first and possibly tear the barrel apart because of excessive loading.

Contact path should be from top to bottom... not bottom to top...

The JK manuals are great, but some of the information must have been ad libbed as it really isn't correct, and doesn't make sense. As it says, it shouldn't touch at this time, meaning it should touch at some time. When the barrel is linking down, it should be stopped by the VIS, if it were stopped by the bed the link would be in extension and that would eventually result in a broken or stretched link or bent or broken pin.

Or a broken off barrel foot ripped out lug or a broken slide stop. None of which are particularly attractive.

And you're looking for Just Right.

Too much drop down and the barrel places the case so far down the extractor that it affects extraction and ejection. Often associated with ramp barrel cuts.

Too little and the barrel bounces up from the barrel bed and re engages the top lugs wile the VIS is slightly engages resulting from the dreaded barrel foot separation disease.

The cure for that is lowering the barrel bed needed on match barrels commonly. as barrel diameter approach .69x there is not enough room so the bed needs attention.

Barrel fitting is the not a good first gunsmithing project.

Don't worry too much... I have fit a meager two Kart Easy Fit barrel to pistols with much success and now I want to attempt a more standard barrel fit.

Here is a picture of the contact area between the original Remsport frame VIS

cut and a Bar-Sto barrel I bought for the build:

I decided that the bow-tie contact area between the frame and barrel knees was unacceptable too small so I painstakenly removed the small bow-tie triangles to increase the surface area of the working VIS. Then I checked to see if the frame was still within spec.

This tiny bow-tie supports my opinion (and it is only that) that a bow-tie cuts may most often work fine but can sometimes can be too small.

And if done correctly, a full contact VIS is superior to a bow-tie cut simply based on a 10X increase in surface area contact. (another opinion)

About the barrel knees: I understand that the barrel knees VIS is perpendicular to the slide rails but since the barrel is traveling along a circular path, rotating about the slide stop pin with the barrel, it has no other path to follow then to move from top-to-bottom while impacting the frame VIS. This is why I stated that the preferred load path of the barrel-to-frame VIS is from top to bottom. A bottom to top contact would load the barrel knee tips and stress the barrel too much.

Possibly by identifying what is the worst we can locate what is the best.

Bottom only contact is a no no. IT puts extra stress on the feet and they can break off.

Especally with the heavy relief cut on the Korean frames the tiny bow tie will as you noted too small a contact.

So the forum gun would use a cut like Storm lake went to where the lower 1/3 of the barrel feet are relieved but contact from at least the middle of the feet up is maintained. The bow Tie beating back will get to What Log talks about stressing the link, link pin and slide stop.

I stand by my method. It is not based on one or two guns with minimal round count.

If the frame you're working on had enough material on the vertical impact surface for you to remove the raised material of the relief cut and still remain in spec, what would the point be? If, as you postulate, the thin bow- tie area would cause the surface to to deform over time and eventually allow lug tip contact, you could have relieved the rear of the lug tips then if you deemed it necessary. I'm betting you'd be pretty surprised at how many rounds that would take, assuming proper heat treat of your import frame.

There is a company out there who almost never relieves the VIS on their frames. When (and I've seen it happen several times) a gun is sent back to them minus the lower lugs, it's returned to the customer with a new barrel fit, and... wait for it....

the VIS relieved.

Before I found this thread I was looking at the Kart barrel that Springfield fit to my G.I. and I noticed that the bottom tips of the lower lugs were digging in to VIS. It has under 1K rounds through it.

The gun does have a faint bowtie, but I don't think it's proud of the rest of the VIS.

I filed about 3 or 4 mils off the bottom end of the lower lugs.

I haven't shot it since then, ya'll think my lugs are gonna break off?

Here's the VIS

Here's what I filed off.

I'm still waiting to hear Bob's experienced opinion about whether or not full contact on the VIS is better then just having the top part of the bottom barrel lugs impacting on the bow-tie? In other words, if the barrel lugs are impacting evenly on the VIS from top to bottom would that negate the need for making the relief cut?

And how much does this explanation to do with the relief cut being made?:

Quote:

FWIW, keep in mind that the cut which creates the 'bow-tie' was merely a

production design, so as to virtually guarantee in a mass-production

environment that the standing lug lower tips wouldn't make contact with the

abutment v.i.s.. It was designed this way so as to allow repeatable results,

and reduce or eliminate hand-fitting work. Is this the only way to get the job

done? Of course not. Is it the 'best' way? I'd say that's debatable, if not

doubtful. As an engineer, I'd like to see v.i.s. bearing surface area

maximized, while keeping shear stresses reasonable, and eliminating

deformation potential for the lower tips. Bottom line, if the rear tips aren't

making contact, then they aren't making contact. Just make sure the REST of

the barrel is unlocking and bedding properly... - Dave Severns.

So the relief cut (bow-tie) is not part of Browning's original 1911 design?

Different opinions and explanations:

Quote:

What Colt may find is that the bowtie is the least expensive way to add a

little longevity to the barrel lower lug. - Hunter Customs.

Quote:

As luck would have it, I just had a pistol in the shop that received the

treatment you're advocating. To his credit, the smith that installed the

barrel recognized the fact that the lug tips were striking the VIS, BUT

instead of relieving the VIS, he thinned the lower half of the back of the

lugs... waaaay too thin. It's only a matter of time now. - Chuck Rodgers.

So even if the lower part of the barrel's bottom lugs aren't contacting the VIS, by taking off material from the lower portion it will eventually lead to the lugs shearing off?

Quote:

This approach is taken by some barrel manufactures to protect their

product. Here is a Schuemann barrel out of the shipping tube. - Log Man.

Quote:

I think this is accurate? The "bowtie" is a fix waiting for a problem to

develop. Sometimes the "problem" exists out-of -the box, and sometimes it

develops. We're talking lower barrel lug/VIS fit and barrel fitment. If the

gun's built right the bowtie is superfluous; maybe still a good idea

though... stuff happens. - Sophijo.

If sometimes the problem develops or it is a problem out of the box then the relief cut would seem to be a good solution. Again, that all depends on whether or not 100% even contact is better then just the top portion of the lower barrel lugs contacting the bowtie. That's the question I hope someone with experience and authority can answer once and for all.

Quote:

So the forum gun would use a cut like Storm lake went to where the lower

1/3 of the barrel feet are relieved but contact from at least the middle of

the feet up is maintained. The bow Tie beating back will get to What Log talks

about stressing the link, link pin and slide stop. - George, EGW.

Hey George, so as long as there's enough meat on the VIS and the bowtie is cut properly then the bowtie should be able to take quite a beating, right? The proper link size is important in relation to how much VIS you have, correct? Do you feel that a flat VIS with even contact from the barrel lugs is the best situation or would you still remove a little metal on the lower half of the barrel feet?

This is a pretty interesting situation. We have a lot of really respected 1911 builders disagreeing (in part) on this issue. Some feel it's fine to remove some material from the lower portion of the barrel feet while others feel that that will only weaken the barrel and eventually cause a catastrophic failure (lower barrel lugs will eventually shear off). Their solution (those who agree with the latter position) is to relief the VIS, creating the bow- tie.

Things I've learned so far (I think):

1. As long as the relief is cut properly (not to deep, on the shallow side) then there shouldn't be any deformations or peening, correct?

2. Rather then the cut just being an easy fix do to time and money, it seems like the bowtie would negate more problems then it would theoretically cause.

Unanswered questions:

1. If the lower barrel lugs contact the VIS perfectly flush (without the relief cut) is this type of contact superior to just the top portion of the lower barrel lugs contacting the top of the VIS?

2. If the relief is properly cut into the VIS and the upper half of the lower barrel lugs are solidly and evenly hitting the bowtie and someone still decides to file off material from the lower portion of the bottom lugs on the barrel, will this removal of material still weaken the structural integrity of the barrel and eventually cause the lower lugs to fail and shear off?

The area of the remainder after a bow tie cut is not large.

If the feet touch at the bottom only this can cause the dreaded barrel foot separation.

Chuck's note says the guy went way too thin. Relief on the lower third of the feet can be .005 and be a workable solution.

Total contact top to bottom has probably been around a long time. One issue that can creep up is powder, jacket, primer material getting behind the feet causing the bottom only to contact again wrenching the foot off the barrel.

I think I remember earlier in this volume that the bow tie cut should not be a .050 relief cut but enough to true the face and get things on track.

Aluminum frames especally will beat a bow tie only back till full contact is re established.

My vote is kiss with cutter till true. clear bottom third of barrel feet so you have over half contact.

George and I are in agreement. No one has advocated hogging out the VIS to create the relief, although I go in deeper than a "kiss." Thinning the rear of the lower lugs would obviously prevent contact. As George stated, there's a definite limit to this, too.

I've seen thin lower lugs bend. They are in in play not only during recoil, but also as the gun returns to battery. The VIS relief gets me full profile lower lugs AND eliminates the possibility of tip contact.

Some Springer G.I.'s have the relief but the machining is pretty rough. I guess that's due to the tool wearing down over time because they do so many thousands of frames. Instead of a nice and smooth circle under the bowtie, the area is rough, like a bunch of concentric circles moving out from the center, lot's of tool marks.