Optimal VIS contact

I have noticed different philosophies regarding how and where the barrel lug VIS should contact the frame VIS and would like to open a discussion comparing these philosophies.

Here are the two schools of thought I have noticed:

All my 45s have (1) contact.

Please share your thoughts regarding which would be more durable.

We use the "bowtie" cut. As does Colt and most pistolsmiths I am aware of. Works great.

I'm in favor of top contact, whether it's obtained with a bow tie cut or a slight taper on the bottoms of the barrel lugs.

As far as durability, logic would dictate full contact would outlast a bow tie just because of the larger contact area. But the amount of impact stress between the lugs and VIS (top or full contact) may not be too great to begin with. Even though the Ordnance drawing specifies a 0.005" maximum surface mismatch for the bow tie, my Remington Rand's is presently 0.010" deep. No idea how deep it was when it left the factory and no idea how many rounds the gun has fired, but I don't think I'll live long enough to see it get peened away to nothing.

Another factor to consider in VIS impact stress and wear is that the lugs are travelling in an arc, are heading about 40deg down from the horizontal when they hit the VIS and are free to move forward and down a little upon impact due to the slop in the link system. The only barrel movement the VIS halts is the aftward component, the bed stops the downward component (at least in a properly tuned gun).

I don't recall anyone being an advocate of full contact - at least to the point of whacking off a nice bow tie to obtain it. And I've a hunch the reason so many frames are found nowadays without a bow tie is that it's easier to cast one that way.

Thank you for the replies. This is what I expected. I didn't start thinking about the differences between the different style VIS contact until I read this posting from Lazarus.

My homebrew Metroarms is out for hard chrome now and its VIS is the full contact version show above with a Kart Easy Fit barrel. I was wondering if I could have made the VIS more robust by adding a bowtie cut to the frame before I sent it off.

I hope that others will continue this discussion.

I agree with Lazarus in regards to the bow tie often being minimal. But reducing the lug at the bottom will take the pressure off the feet. Schuemann barrels come that way and offer a great deal more impact surface and yet protect the feet.

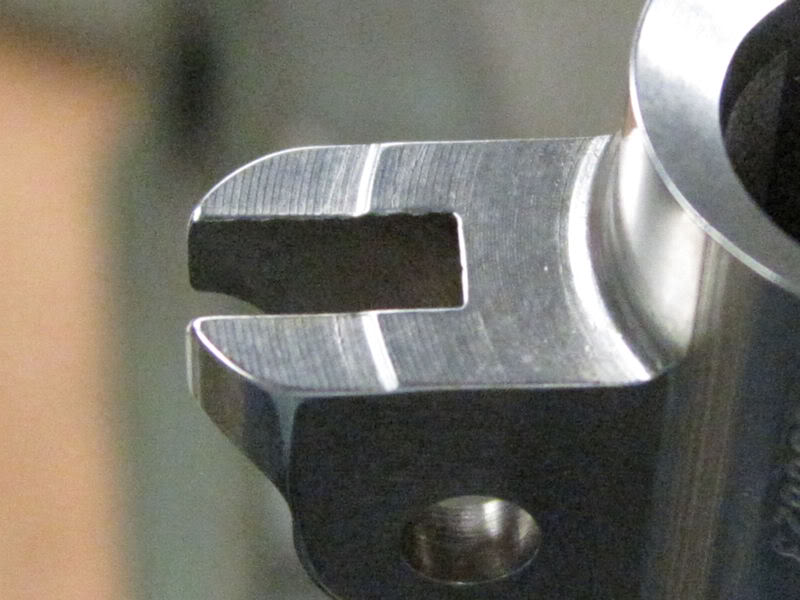

FWIW, here's a pic of that 65 year old, 0.010" deep bow tie cut - made without the benefit (?) of 21st Century manufacturing methods and modern metallurgy:

PICTURE 404

And here's one of a bow tie created in a cheap cast frame using a diamond bur in a Dremel:

So for (1) there should be a lower barrel feet relief cut to avoid VIS area contact down on the bottom of the barrel feet.

Or for (2) no barrel relief is necessary because the bowtie cut won't allow the barrel feet contact the frame down low.

Neat-O... please correct me if I am getting off base.

Anybody have an estimate of how many rounds of +P ammunition it would take to peen a bow tie VIS down by 0.001"?

Anybody have an estimate (or knowledge) of how many rounds of standard 230gr ball ammunition it would take (or does take) to peen a bow tie down by 0.001"?

Anybody have an estimate (or know) what the difference might be (or is) between a milled bar stock frame and a frame cast from old rusty ground up Subaru fenders?

My limited knowledge on gunsmithing suggests that this 'even contact Vs bowtie' debate is part of the reason why, when it comes to ramped barrels, some 'smiths prefer the Wilson/Nowlin style (flat vertical impact surface, easy to adjust for a top-first contact), while others like the Para/Clark variety (curved, less flexible). I think I read something to this effect in the Schuemann website, but I can't find it since they re-did it... BUT, I remember that Schuemann recommends a Clark cut, on longevity grounds.

Quote:

Anybody have an estimate of how many rounds of +P ammunition it would take

to peen a bow tie VIS down by 0.001"?

I don't know but my old rusty ground up cast metal Metroarms frame showed a very distinctive VIS witness mark after about 1000 round but I don't know if the finish just got removed there or if there was an actual impression in the metal. All of my other > 2000 round 45s have marks too but they are probably just where the finish is removed. I could check my TRP to see what it has... FWIW I did check the hardness of the MA frame to be 40-43 HRC scale before I started my project.

Here is the VIS from my TRP Operator with over 3000 rounds:

It shows barrel impressions (peening).

Wouldn't call that peening, just an impact mark, the feet seem to be the lightest. That's fine, if concerned just take a little off the back side from the feet tips to about where the pin hole starts. A few thousandths and they won't hit at all.

I will look into dressing the knees of my Metroarms barrel (Kart) when I get it back. That pistol had the same markings on the VIS. Hopefully I won't need to because would rather leave the hard chrome on all working surfaces.

I like your photo of the TRP. To my way of thinking, that setup is the better choice of the two methods. Niemi's photo shows the alternative, a bowtie cut that is done just right with plenty of material in the triangles. There will never be a problem with it.

However, I have more than one receiver that sports the very tiny triangles. All recently made CNC production, etc. Removing the tiny triangles is a pain, plus you are fooling with the front-to-back VIS placement which can lead to trouble.

The subject is almost identical to the debate over whether the barrel should

touch the bed or not. The creation of the bowtie involves an extra machining

step on the receiver to save a couple of light swipes with the file on the

back of the barrel lugs. In effect, they are saying that you, the gunsmith,

aren't smart enough to fit your barrel correctly. The bowtie cut will work

fine if done right, but that doesn't make it mandatory like the industry tells

us it is. If the cut is not done correctly, you have a potentially expensive

problem on your hands. In my case, I'd prefer to be the one that wrecks it!

I would like to thank everyone for their valuable input regarding this topic:

We have found two different approaches to mitigate potential barrel problems:

Potential problems:

Barrel fatigue failure where the barrel knees (lower lugs) fail by either:

A) Link pin pull-out from constant impact loading of the pin due to

improperly timed barrel.

Solutions:

A) Correct barrel timing: Lower the barrel bed or move either VIS to

eliminate pin loads. This allows the barrel knees to contact the frame to stop

barrel rear motion relative to the frame.

BigJon

This cut on a Schuemann barrel works with either VIS treatment.

Same deal. We are in control of the horizontal. We are in control of the

vertical. Let me be the one to do it. At least I can decide how I want to go

about wrecking it.

I agree. If milling the VIS left a horizontial block, then that would be

better in my mind. A solid non-deforming stop that would still be easy to move

a little if needed. Could be done EDM.

No being a gunsmith, it "seems" to me having the Schuemann and/or storm lake

barrel cut eliminates the need to mill a "bowtie" in the frame and a better

'mouse trap'.

Let the 'cheaper' and replaceable part take the "hit". Easier to adjust

also... yes?

I did have a Gold Cup with a bit over 25,000 and the "bowtie" on the frame

was "mushed in" compared to my other Colt.

I just thought of another (of many) irritating "mandatory" cuts that are now

done routinely by the CNC process. This cut is a 45 degree bevel on the edge

between the VIS and the barrel bed. The amount of metal removed during that

process is unpredictable, ranging from just a tiny bit to a large hunk

removed. We understand that the sharp edge might interfere with corresponding

corner between the barrel lug and the barrel body. It depends upon your

particular barrel... and they are all going to be a little different. But if

your frame happens to be one with a very large bevel, your VIS contact now has

been moved downwards whether you like it or not, whether you need it or not.

I probably would take off the sharp edge myself - just a little - and touch

up the lug-to-barrel radius also. A little from both places and just enough to

avoid interference. The idea is sound, but it seems like the decision should

be up to the smith and not up to the CNC software programmer.

As always, great catch Lazarus... then a shallow bed-to-VIS cut must be one

more thing to look for in a quality frame. It must be a clearance cut for the

barrel to lug transition because some barrels have larger fillets there than

others.

Out of curiosity I checked my Colt's New Agent for reference and it looks

like Colt cuts a 30deg or 20deg relief there and uses a shallow bowtie cut.

She still looks great with less than 1000 rounds(intentionally):

I don't think the 'bow tie' needed by design.

There are two distinct machining steps in play here. The first would be to

mill out the smaller cut for barrel lug clearance. This would be cut with a

standard vertical mill, moving the work into the cutter.

The second cut makes the larger round hole that forms the bottom of the bow

tie. This cut would be made with an end cutting end mill, plunge cut from the

end of the hole.

Trying to make these cuts bottom out at the same point would be difficult.

Therefore the 0.005" difference allowed between the two.

But the Bowtie cut eliminates any possible lower barrel knee contact with the

VIS on the frame thereby eliminating fitting the barrel in these areas. More

frame machining allows less barrel work and if the frame work is a CNC machine

cell then we just reduced the amount of hand fitting required to build a

pistol. This means lower labor costs.

Just out of curiosity, has anyone ever seen a bow tie on a cast frame?

Yes. One of my coworkers has a new Citadel with a cast bowtie in the

frame... I noticed this when I inspected his pistol after a range visit.

Interesting. Thanx Eric. Not knowing a thing about casting things like 1911

frames, I had assumed making the shallow, round depression to form the bowtie

would complicate the casting process, make it a little more expensive and

therefore not be done.

Another assumption bites the dust!

Quote:

I recall that the bowtie cast wasn't very shallow. It is my understanding

that the lower threshold for these type casting depths is about 1mm or .040-

inch or ten sheets of writing paper thickness.

egumpher

19th July 2010

B) Barrel knees tear off from constant impact loading low on barrel knees due

to improperly fit barrel or poorly made frame.

B) With the both VIS contacting each other we have a new problem two

different approaches to solve problem B)

i. Precisely machine both the frame and barrel to fully distribute VIS

contact

ii. Machine a special frame cut (bowtie) that will accept a variety of barrel

knee profiles and accept higher contact stress levels as the price of being

able to use different barrels. This would be a viable solution if we assume

that most modern shooters keep 45s for home protection and pride of ownership.

Either way, the modern shooter probably won’t shoot tens-of-thousands of

rounds to break anything.

19th July 2010

Lazarus

19th July 2010

BigJon

19th July 2010

auto45

19th July 2010

Lazarus

20th July 2010

egumpher

20th July 2010

douglas34474

20th July 2010

egumpher

20th July 2010

niemi24s

20th July 2010

egumpher

20th July 2010

niemi24s

20th July 2010

egumpher

20th July 2010

I had assumed making the shallow, round depression to form the bowtie would

complicate the casting process

Return to 1911 Archive