I have an old (1958) Colt National Match .45 that has been worked on in dribs and drabs over the last few years.

The leaf spring and hammer are stock, but the sear is (I think) a Wilson part, installed a few years back by a pistolsmith to replace the original coil- sprung sear. I recently fitted a new extra-short Dlask trigger myself. I've also installed an Ed Brown competition mainspring.

I use the pistol for bullseye and occasional IPSC, plates, and so on, and the trigger weight is quite satisfactory at 4 lbs. I've taken all the unnecessary overtravel out, and the Dlask trigger even takes care of forelash (reset travel, for lack of a better term.) But there remains a certain amount of creep.

From reading our host's Sistema chronicle, it would seem to my uneducated but analytical eye that 1911 trigger creep is a function of hammer/sear hook engagement.

Assuming that polishing the trigger raceways and stirrup sides does not cure the problem, would my next logical step be to get a matching EDM hammer/sear set from one of the reputable manufacturers, like CMC or Nowlin?

you are correct that creep is caused by the relationship between the hammer and sear. these two surfaces must meet perfectly to break clean with no creep. many people call any slop grittiness or play in a trigger creep even though it isnt creep. if you can feel gritty mushy feeling when the hammer and sear are disengaging each other you have creep. if the feeling in the trigger happens before that moment your problem lies else where.

It isn't gritty at all, just grabby. Like pushing a cold stick of butter sideways across a cold marble slab- it seems to take forever.

Eyeballing the trigger while dry-firing, it looks like I'm having to move it maybe .005" before the sear releases.

Guess it's time to try a new drop-in hammer & sear set. Can anyone recommend a good spur bullseye hammer, one that's relieved on the sides? Neither CMC nor Nowlin seem to have them.

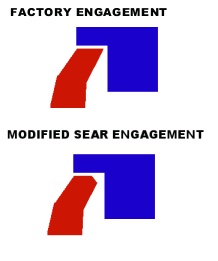

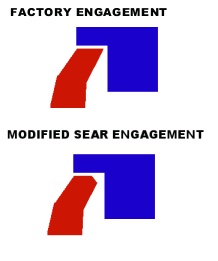

One old trick, discussed in Hallock's book among others, is to put a bevel on the nose of the sear in order to reduce the engagement surface that actually contacts the hammer hooks.

Here's a rough drawing of the concept. I don't recall the specifics at the moment and I'm not in my Gun Library, so perhaps Blindhogg or someone can chime in.

Besides deep (0.020" is the norm) hammer hooks, the other area that causes trigger grief are undersized sear/hammer pins. This can cause the parts to 'squirm' and is not apparent until the parts are installed.

Thank you all for your replies. On the topic of the pins, I must mention that of all my 1911s, the one with the cleanest trigger pull has a McCormick match oversized pin set in it, along with everything else. Didn't know the pins might make a difference; I just threw them in because it seemed daft not to. Live and learn.

I have found that putting a secondary or release angle on your sear can make all the difference in the world as far as creep is concerned. Below is a link to alittle more info trigger job

The part about adjusting the overtravel screw has come in very handy of late.