Well this is probably one of my Most used tools and I dont know what I would do without it. Its called a Widget, and is used to re-install your thumb safety without marring frame.

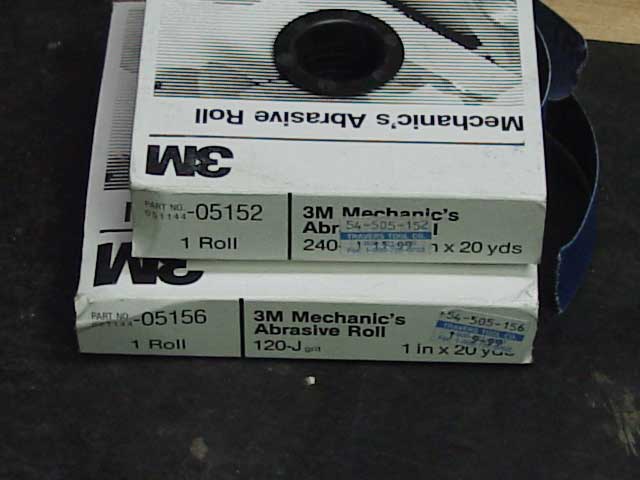

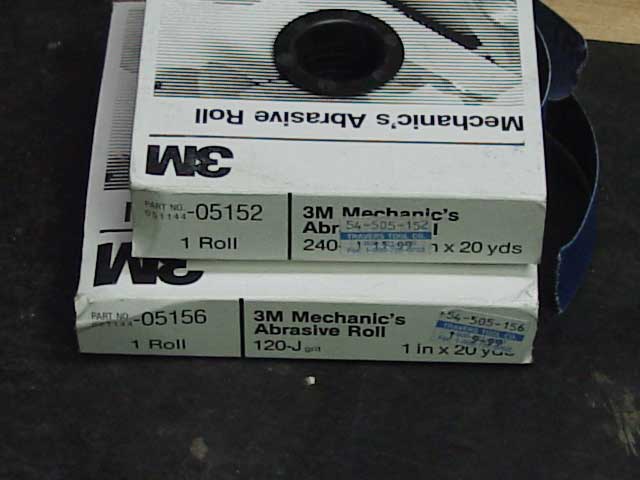

This is probably the best sandpaper money can buy it is called blue grit sandpaper and is made by 3M. It can be torn into small very narrow strips and used to polish and dehorn all manner of different things on your 1911.

This is a my front sight staking tool with replacable point. I don't use it that much though, as I prefer dovetailed front sights.

This is my Wilson's sear jig.This is probably the first tool I bought when I started dabbling in 1911's. Pretty much a must have, if you are into 1911's

These are my nylon sight punches. Guaranteed to get your sight out, or in, without marring it.

This is my Yavapi slide jig. It is used to hold my slide when serrating top of slide, opening ejection port and milling front cocking serrations.

This is my slide pusher and is used when fitting a oversized barrel to a slide.

This is a special jig designed to go into a mag well of a frame and expand. The shaft then rotates and allows the frame to rotate when checkering the frontstrap of a 1911.

This is just a small selection of my various files. A file to a gunsmith is akin to a wrench to a mechanic. I usually try to buy Nicholson files as they seem to last the longest.

This is my Wilson's Lug cutter. A must have, if you want to fit National Match barrels properly. Do yourself a favor and only buy the .196 cutter, the other one (.187) is a waste of money unless you can find a slide stop that is .187 in diameter, Not likely

These are my micrometers, they are absolutely a necessity. If you don't own any yet these will be a worthwhile investment..

These are my punches, used for all manner of punching. The one in front is a 1/16 punch with a replacable point. Very handy; as you will see the 1/16 will get damaged all the time and it's a breeze to throw another one in. Available from Brownells.

This is my chinese vise, its massive and heavy but works well. It will swivel 360 degrees and has a huge anvil to hammer things on. I also use the homemade aluminum 1 inch inserts you see in the jaws and on top of that are brownells Superhold Vise jaw pads. These are the best vise jaw inserts around bar none. If you do not own these get a pair I have had these over 5 years and they will not wear out and grip a 1911 slide without marring it when dehorning or knocking out or in sights.

This is my Brownells magna screwdriver kit. A really handy set when working on fine handguns, Ive grinded one down specifically for the bomar sight, and also one for the mag release.

These are the stones I use for my trigger jobs. They are used to polish the primary and secondary angle of a sear, polish the disconnector and the hammer. I also use them to polish the bottom side of the rails on the slide and the disconnector track on the slide. The top one is a medium india stone and the other two are ceramic stones. The white one is X-fine and the black is M-fine.

This is my lug iron sander, it is used to polish the machining marks out of the top of the two slide locking lugs on a slide.

These are my various padded vise jaws. the blue ones are Super-Hold vise jaw pads from brownells and are worth having, I use them daily.

These small handheld reamers will save the day when you get in a new match barrel and you can not get in the link pin. These open up the hole for the link pin there are two sizes available.

This is the tool I use when I want to crown a barrel. I have used it to crown normal size barrels and bull barrels.

These are my chamber reamers. One is for 45ACP and the other is for 40Cal. I use these when I fit match barrels, some come shortchambered.

This is my Rcbs trigger pull gauge, its a nice unit for the money and I use it all the time to check my work when finishing up a trigger job.

This is my cordless dremel tool that I use to polish the feedramp of the frame and to blend magwells to the frames. Its about worn out now from too much use and am thinking of getting a Foredom tool next.

My other Dremel tool, Its about worn out also and overheats when I use it for more than several minutes. Will replace it with a Foredom style tool.

This is my assortment of sandpaper rolls and cratex bits for my Dremel tool.

These are more bits for my Dremel tool.

These are my diamond burs, they work great and are what I use to bevel the inside of the plunger tube holes in the frame and also the inside of the front sight before I stake one.

Slide fitting bars that I use to lower the rails on a frame. These are designed to be placed in your frame rails while lowering them with a hammer. I use one that is .001 larger than what my slide mics out to.

This is my frame bridge cutter. As you can see in the pic I attached a T handle to it, so I can turn it by hand. I use it to cut the frame when the barrel does not bear on the frame evenly when linked down.

This is my little drill press. Its not used to often, but I love the way it looks so I thought I would show it off.

These are my black markers that I use to mark pistol internals to see what areas are scraping against other areas. I use them to fit Barrels, triggers, beavertails, thumb safeties, and a host of other parts. The top marker is my favorite, as it dries the quickest and is the darkest.

These are my various polishing sticks. The wooden ones are made by me and are 400 grit sandpaper, glued to a piece of wood. Great for polishing all manner of different things.

My milling machine, This is a Bridgeport milling machine, which is about as good as you can get. This model is probably about 25-30 years old, but these machines are well made and will last a very long time if taken care of.

These are my mill bits, and these are but a small selection of what I use. Most are carbide as they seem to last the longest, and are necessary to cut through hardened steel.