Hey folks, I am in need of some input about the issue mentioned above. I am a lefty and have had some incidents with the slide catch being pushed out by my support hand index finger, so the simple solution was to file it down so it is flush with the frame. However, it seems that the slide jamming was due to other reasons, I went and shot the pistol today and still had the same jams happen every second or third magazine. I own a Citadel CS in .45.

Could you provide some more info? What ammo are you using? Did you break it in with 300 rounds of FMJ? How exactly is it jamming?

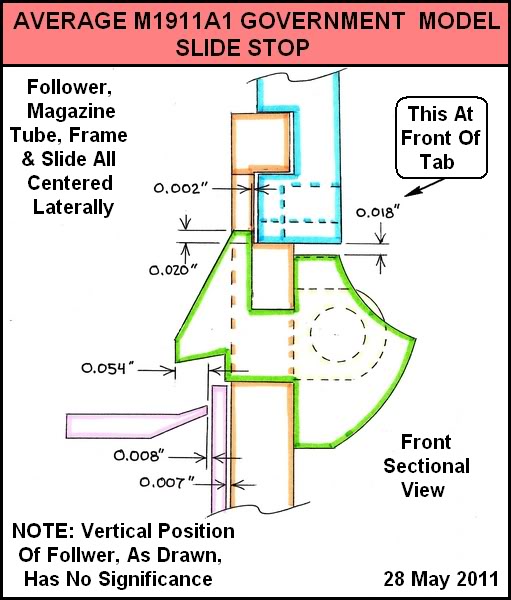

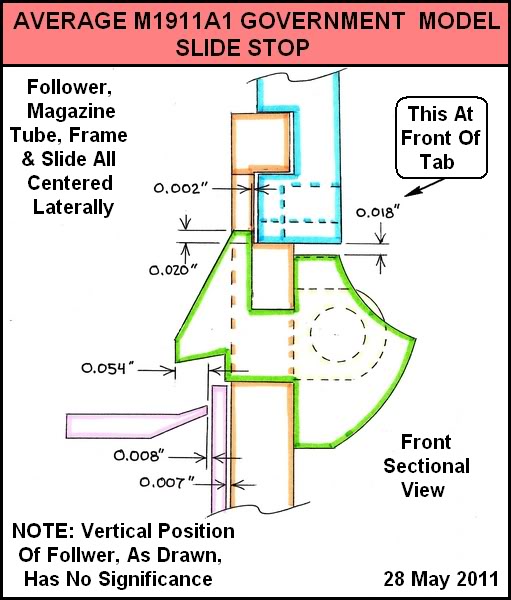

The only place the slide stop (SS) should be able to get moved to the left is when the disassembly notch in the slide is directly over the top of the "knob" on the aft end of the SS, as shown here:

In addition to the SS knob being too short (dimensioned blueprints are available in our Tech Issues section), the SS plunger may not be exerting enough force on the back of the SS to keep it in place. Maybe the plunger housing needs a good cleaning or a new spring.

I am using 230 grain Winchester white box ammo and have at least 1500-2000 rounds through the gun, i just installed a 22 pound recoil spring as well from wolf which is factory spec. attached is a picture of what the slide looks like when jammed.

PICTURE 404

Well, the photo clearly shows that the slide is NOT jammed on the slide stop, so please provide a photo of the ejection port when the gun is jammed.

I am not very savvy when it comes to naming parts, it may be that i am referring to the slide release instead if that makes any sense.

I gotcha...

What he's asking for is a picture where the bullet enters into the chamber (rear part of the barrel) when this malfunction occurs.

I think, but I'm not sure, that Hawkmoon meant ejection "port" rather than "post".

The slide stop is often called a slide "release." It's the same part.

But the catch part of yours is NOT in the hold-open notch, so your slide is not locked open by the slide stop. Therefore, whatever is causing the stoppage is internal and the filing you did on the slide stop accomplished nothing other than ruining the part so it can't hold the slide open as it is supposed to.

Now the problem is to figure out what IS causing the stoppage. Which is why a photo looking into the ejection port at the stoppage might help.

I think I figured out what is causing the jam, the fact that I am able to remove the slide release when it is aligned with the "hold open" notch tells me that the tip of the slide release inside the frame is too short and hence allows it to hang up on the slide.

here are some pictures

PICTURE 404

PICTURE 404

@Hawkmoon: i did not file down that area, i filed down the protruding round part on the right side of the pistol so my finger wouldn't be able to push it out while i shoot since i am a lefty.

It does appear by the photo that the slide stop lug is binding the slide and stopping it. The slide stop lug on the inside should be riding against the inside vertical surface of the slide rail and that is what keeps it in and the part that passes through the dis-assembly notch. yours appears to be able to ride under the slide and that locks it. Probably got worn from before. I will suggest that the slide stop be replaced.

A little slow at getting this up, but the added photos confirm.

I agree with that idea. the question is how did that get worn out? is it something that happens normally with use or is the metal on these pistols too soft?

The photo in Post #4 seems to show the upper "knob" of the slide stop to be peened over and underneath the bottom of the slide. That knob is supposed to be inside the slide and above the slide's lower surface.

This indicates either:

* The slide stop is out of spec with the distance from its ledge that sits on the bottom of the frame hole to the top of its knob is too short (it should be 0.256 - 0.005 inch) or

* The bottom of the SS lug hole in the frame is too far down from the top of the slide (it should be 0.4525 ± 0.0075 inch).

Whichever is the problem, it looks like that SS needs to be replaced. But if the bottom of the hole in the frame is too low... call the folks who make the gun for a new frame.

@ Niemi: thanks for the insight, ill have a local gunsmith look at the frame just in case the cut is too low. there are a few shops around town that stock 1911 parts to ill try on a slide stop and see if that solves the problem.

Quote:

the question is how did that get worn out? is it something that happens

normally with use or is the metal on these pistols too soft?

To begin with there is not very much material on the lug to provide much interference to hold it in, but enough under normal circumstances. However, with the left handed hold the bumping or pushing inadvertently on the pin end can over time cause wear. First it pops out through the dis-assembly notch and gets banged pretty hard each time, I think this may have been the problem. After fitting a new one, do the same treatment to the pin so it will not get pressed into the notch while firing.

I'm not trying to spend your money but if you do need a new slide stop, I recommend the "Wilson Combat" Bullet Proof. It has a groove in the end. This groove will help or prevent you from engaging the slide stop when shooting left handed.

You can dimple the end or have a gunsmith do it, but the Wilson part is a better option IMHO.

BTW, I'm left handed so I know that a lefty can inadvertently engage the slide stop when shooting.

Quote:

It has a groove in the end.

Ken could you explain this groove. I'm not aware of a groove variation from the original design as far as holding it in the gun better.

I'm interested in this as well, I checked out the WC website and the slide stops look identical from what I can see.

Brownells sells a long spotting drill that goes through the plunger housing to put a small dimple on the aft end of the SS to help hold it in place a little better than the stock, flat end:

http://www.brownells.com/.aspx/pid=..._SPOTTING_DRILL .

A year or so ago, Log Man posted a photo of the aft end of a slide stop on which he formed a horizontal groove to help control the SS's up & down motion and also make the SS easier to install. I think that photo's in a thread dealing either with "idiot scratch" or "inadvertent slide lock".

The Wilson Combat Bullet Proof slide stop has a horizontal groove in the end of it. The tip of the slide stop plunger rest in this groove. The function is the same as the dimple. The groove is square on top and has a slight bevel on the bottom side. This holds the slide stop in position until the magazine follower pushes it up. This is the only slide stop that I know of that comes with this groove in it.

The slide stop is hardened. Kunhauesn shows the dimple being done with a 1/8 end mill. The tool that Niemi posted about makes the mark in the correct location.

A transfer punch can also be used.

A Dremel tool can very carefully be used to make the dimple, but its kind of easy to be out of position. Be there done that, right and wrong.

I can't post a picture of the one I have at the moment.

That modification is to allow easy installation and does not interface once the stop is installed.

http://newforum.m1911.org/showthread.php?t=58913

You may have to log on to see pictures.

This doesn't sound like it would help retain the stop in the installed position though, which has been the OP's problem.

Oops!

Thanks for the correction and the link. I must have misremembered.

Here are your pictures... probably not the ones you want, but I think this is the idea you're trying to convey...

Quote:

This doesn't sound like it would help retain the stop in the installed

position though

It won't hurt either. If the plunger is resting in a groove instead of on a flat surface it should help, but that isn't why the groove is there. If the slide stop is out of spec it needs to be replaced, as you suggested.

I'm also under the impression that the OP is in need of a new slide stop, and he is left handed and was inadvertantly pushing up on the slide stop while firing his pistol. I'm a lefty and understand this issue. Therefore I thought the Wilson Combat Bullet Proof slide stop was a good choice.

The lower picture in Traxxis post shows the dimple that is used to modify the slide stop to prevent premature lock-up. I've done this to my guns because a lefty can sometims push the slide stop up while firing.

The Wilson Bullet Proof has a horizontal groove there.

Quote:

and he is left handed and was inadvertantly pushing up on the slide stop

while firing

Not really, the OP was having a problem of pushing the slide stop pin out from the right side, and that was locking it up.

Maybe if I could read correctly; being pushed out, not being pushed up.

add: Just reread the first post, MHA

And I'm guessing that the slide stop got gradually chewed down so it would fit under the slide from the pressure applied to the end of the pin on the right hand side. With this pressure pushing the "knob" against the inside of the frame, every firing would see the take-down notch go by the knob and either peen it over a tiny bit or chew off a little piece.

Wonder if that lower, inside edge of the slide got messed up?

UPDATE: I went and tried out a Wilson combat slide stop to see where the problem lies. As some fellow members suggested, it appears that the SS was in fact out of spec. Due to this the recoil was causing it to slide out from under the hold open notch.

Just for giggles, give us a nice clear close-up photo (with the slide removed) of the aft end of the installed SS with its aft end fully down. I'd like to see how much the top of the "knob" extends above the bottom of the way (groove) in the frame.

It should stick up about 0.020" or about 1/6 of the width (height) of the groove.

And what I'm thinking is that if it doesn't stick up far enough the same thing may happen to the new SS. Oh yeah, use the new SS for the photo.

Quote:

And what I'm thinking is that if it doesn't stick up far enough the same

thing may happen to the new SS. Oh yeah, use the new SS for the photo.

Here you go.

PICTURE 404

PICTURE 404

PICTURE 404

It's a little difficult to tell for sure, but by laying a 3X5 card at where I think the bottom of the groove is in your last photo it looks to be OK.

But you've got the gun in front of you, so a 0.020" feeler gauge laid in the bottom of the groove should be at the top of knob - give or take a little bit.

Another thing that needs to be considered is how much vertical play the slide has on the frame. The average M1911A1 has 0.004" of play, and when the slide's up on the frame (as is likely during the gyrations following a shot) that will reduce the overlap of the SS knob from 0.020" to 0.016".

How much overlap do you have with the slide up on the frame?