Recently purchased a Les Baer Concept II. LNIB, it looked it had never been fired. Broke it in with 500 rounds today and had premature lock back. Back home, a little reading on this forum, and a little troubleshooting reveals the culprit. The slide stop tab intended to be lifted by the magazine tab is getting pushed up by bullets. There was a copper streak on the tip. It scars bullets when they are run through the gun. It is far sharper than the slide stop tabs on my other 1911's. Indeed, it does not appear that this slide stop had any fitting on the magazine tab as both of my other 1911's evidence.

So the question is; how hard is it to fix? I don't really want to pay $70 to ship something back that should be easy to fix. Looks like a file and Emory cloth fix. But which file? Is is going the be a problem to blue? Any other thoughts?

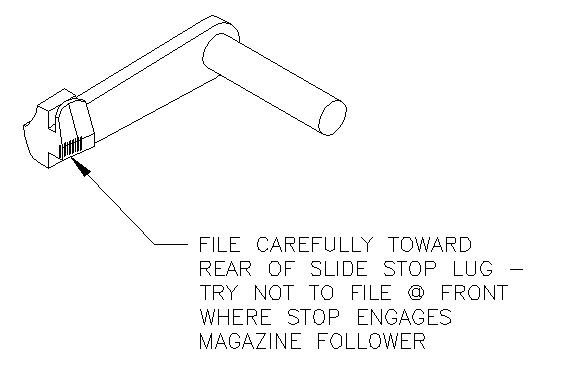

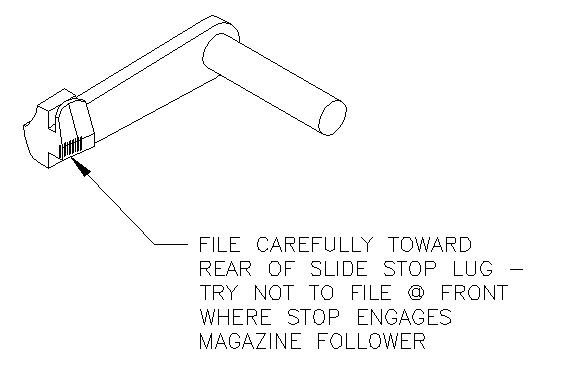

I use a small, flat jewelers' file and make one or two light passes up and down, not across, where the coppersmear is. Try it again and check for copper. Stop when you don't see anymore. It doesn't take much and a light filing action is all that's needed. Then, stone it smooth.

I use a half-round jewelers file.

Great advice and picture from Hawkmoon.

You'll find it's an easy fix.

Thanks for the picture. It helps explain. I have the copper smearing beginning at the front of the lug, not the rear. Also the front of the lug is pointed and not square as you have pictured and sticks out much further than the rest of the lug. Wish I had a camera that could take the picture.

As a result, it may be better to take a smidgen off the front, correct?

There's a dimensioned blueprint of the slide stop in our Tech Issues section (14th link down) that shows how the lug should be shaped. If you take the slide & barrel off the gun and install the stop, you can check your filing progress by inserting a magazine with a ball cartridge in it.

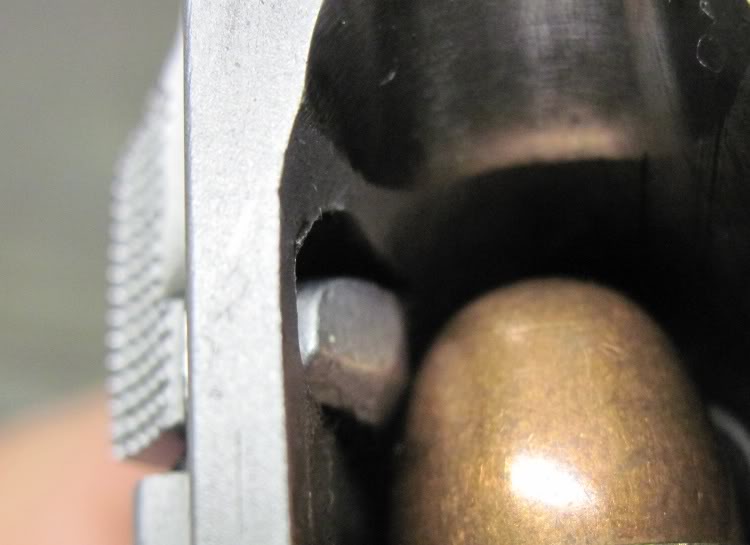

I would like to add this photo showing where the bullet typically hits the slide stop lug. This is the area of the lug that is hitting the bullet which is the same area shown in Hawkmoons graphic. Not on the front side of the lug.

The Les Baer slide stops might be oversized so that they could be used for a .38 Super / 9mm, which has a slightly deeper lug than the .45. Yours probably just wasn"t trimmed enough. Of course they could be oversized as to be fit accordingly as are most of the parts for these pistols.

You may have a 9mm slide stop in a .45 Auto pistol. When I converted a .45 to 9mm I ordered and installed a 9mm slide stop. It was doing exactly what your pistol is doing -- locking the slide before the magazine was empty. I reinstalled the original .45 slide stop (which isn't supposed to work in a 9mm) and all was good.

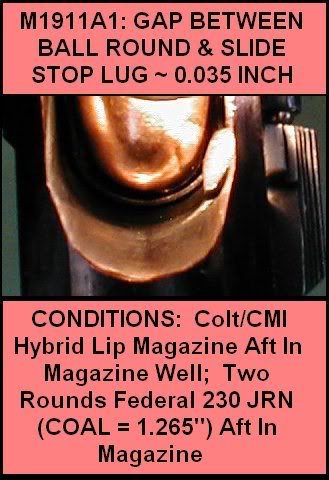

Here's how my 45 Auto wadcutter gun looks like when viewed along the axis of the front of the magazine:

The gap may seem a bit extreme, but when fired with ball ammunition the second round down (the one that actually bumps the stop lug up) begins its upward lurch when it's parallel to the slide. And when it's parallel to the bottom of the slide it's a little longer horizontally - so the gap's a little less.

And the gap can be a lot less if the cartridges are forward in the magazine - as I think they probably are just after the slide smacks the frame at full recoil.

Quote:

The gap may seem a bit extreme, but when fired with ball ammunition the

second round down (the one that actually bumps the stop lug up) begins its

upward lurch when it's parallel to the slide. And when it's parallel to the

bottom of the slide it's a little longer horizontally - so the gap's a little

less.

And the gap can be a lot less if the cartridges are forward in the magazine - as I think they probably are just after the slide smacks the frame at full recoil.

That drawing I posted was created to explain what I did to cure this problem in a Para-Ordnance P13.45 that I bought used. In my case, it would consistently lock the slide with one round left in the magazine. Although the pistol was represented to me by the shop that sold it as previously-owned but NIB, unfired... it HAD been "bubbafied." There were other parts either changed or modified, too, but the one of interest here was the slide stop... which comparison with other Paras of the same vintage proved was NOT a Para- Ordnance part.

Para magazines all use polymer followers, and the ones available at that time had no dimple/pimple to hold the last round back (don't know if Para now uses a dimple). The polymer was slippery enough that the last round would be nudged forward just a bit by recoil, and that was enough to allow the ogive of a standard 230-grain FMJ bullet to push up the slide stop when it tried to feed.

Filing down where I showed in the sketch solved the problem for me. I used a rounded (arched, would be a more accurate term) file in order to echo the shape of the bullet. In my case, that's where contact was being made so that's where I filed. If your follower shows brass marks elsewhere on the lug -- file where you see the marks.

I certainly encourage taking off as little as possible. I went very gingerly, and I didn't achieve full correction of the problem until my third or fourth attempt. I would file a little, take the gun to the range and shoot it... and then come home and file some more. Rinse and repeat as necessary.

Looks like it is fixed. I took a smidge off and ran 100 problem free rounds through the gun, including rapid fire.

I am still getting a touch of copper smear, but no lock back. Also I have not polished yet. Will likely polish it smooth, run a few more hundred and see how goes.