Hey guys, I have a ATI Titan, I am having premature slide lock problems due to the bullet hitting the slide stop and moving it up. I filed where the marks from the bullets were on the slide stop. but was still having problems. The point when the bullet stopped touching was also the same point that the follower bypasses the slide stop. Now my gun won't lock on empty. The slide lock plunger doesnt seem to have enough tension as my other 1911's do, could this be part of them problem. I have tried different mags, and slide stop and so far have filed 2 down past the follower catch point. I have 2 more on the way one is being modded before they send it to me.

P.S. the slide not locking back really isn't an issue so long as the feeds all 8 rounds with out a hitch. I am planning on carrying this as my CCW and when I carry any gun I never have a extra mag on my so it's not like I can reload another mag even if I wanted to.

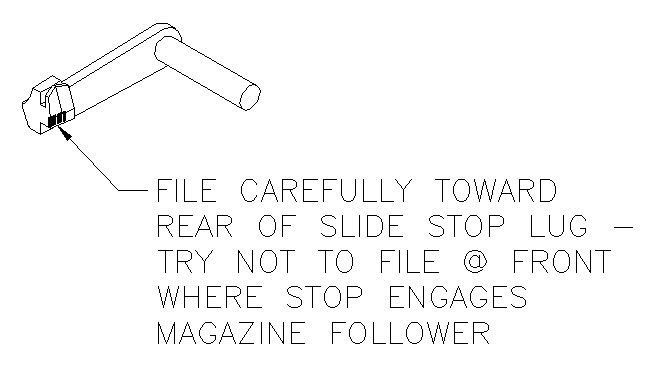

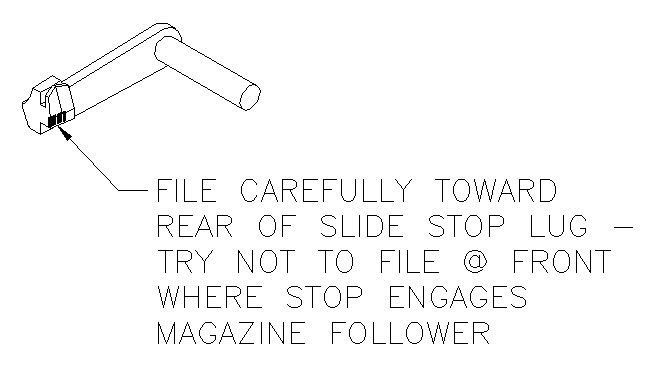

You should be able to massage the profile of the slide stop lug to clear the bullets and still leave enough to lock the slide on empty. Been there, done that.

Hawkmoon, that's one of the better pic I have seen on filing a slide stop thanks. But before that I am going to replace the plunger and spring and see if that fixes the problem. When I looked at my plunger on my S&W there is a lot more tension then on my ATI. The ATI has no tension on it at all so my guess is under recoil the slide lock is engaging

I am still having problems with it locking prematurely even though the bullet is not touching the slide stop, I made sure of that. When I got home I removed my detent and plunger spring from my S&W and wouldn't you know it, it was longer and put tension on the slide stop, I have ordered a new Colt and detent and plunger spring from midway. Here are some pics.

ATI detent on the ATI frame

S&W detent and spring on the ATI frame

Both detents side by side

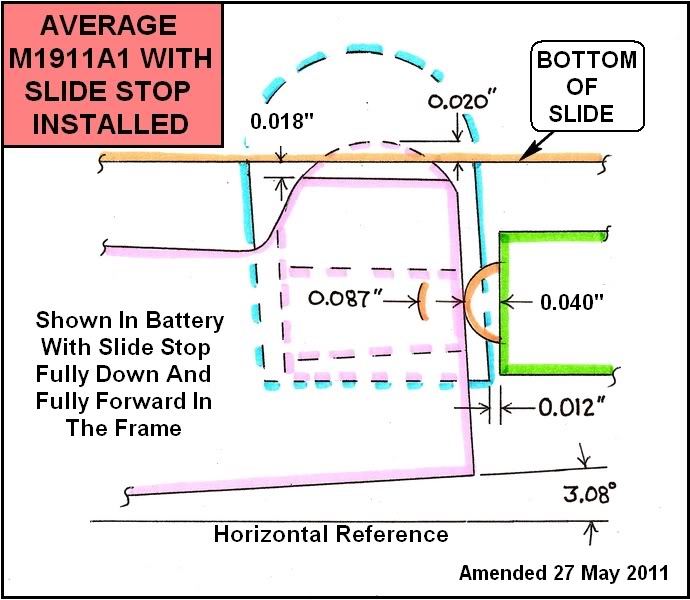

The new plunger (detent) should cure the problem as it's supposed to protrude about 0.087" according to the Ordnance blueprints as shown here:

ATI should send a set of Ordnance blueprints to the folks in the sweat shop where those things are made so they wouldn't have to guess at anything.

Thanks Niemi24s, The ATI detent protrudes out .051, just a little off

I'm also having premature slide-lock-back problems, on my new Kimber Eclipse Custom II 10mm. One failure in each of my total of three range sessions (50 American Eagle FMJ's each session). Kimber is sending me a new slide-lock, and I'm hoping to try it this weekend.

I have noticed that, when I remove the mag, and pull the slide back until the square notch in the frame is aligned with the slide-lock, that I can freely move the slide-lock up and down (into and out of that notch) ... I had expected that the plunger would provide at least a small force downward on the slide-lock, but there doesn't seem to be any spring-loading at all on the slide-lock. Is that normal? (I'm a complete newbie to 1911's, and so I don't know what's normal and what's not, yet).

Quote:

... I had expected that the plunger would provide at least a small force

downward on the slide-lock, but there doesn't seem to be any spring-loading at

all on the slide-lock.

You must have missed my huge colored drawing in Post #7. The plunger exerts about 2 pounds of force on the aft end of the SS, but it doesn't get resolved into any appreciable downward force. That force is mainly to keep the SS where it happens to be and not to move it to or return it to any particular position.

How much force does your plunger exert on the aft end of the SS?

Quote:

How much force does your plunger exert on the aft end of the SS?

The slide-lock seemed to be completely free to move up or down ... essentially no resistance in either direction. The last time I had it field- stripped, I pushed on the left plunger, and it DID feel springy and fairly strong. And when I reassemble my gun after cleaning, I definitely need to expend some effort compressing that plunger when I put the slide-lock back in place.

I wonder if the plunger is too short (like I think yours was), and is hitting its stop before it presses on the slide-lock at all (once the slide-lock is installed).

Quote:

Perhaps you missed it again! Quit wondering!! LOOK at the drawing in Post

#7! See if the plunger tip extends out about 0.087" as shown on the drawing

in Post #7 when the SS is removed!

I don't currently have a way to measure with that degree of accuracy ... maybe every 1911 owner needs a micrometer, not just a measuring tape!

It sounds like you are telling me that, even if it's necessary to compress the plunger when inserting the slide-stop, the plunger may nevertheless be too short to keep the slide-stop from moving up and down too freely once the slide-stop has been installed.

Can you post a post a pic with the slide stop and one with out the slide stop that shows the plunger. Hopefully when you get the new one from Kimber it will fix the problem

The angle of the end of the slide stop may be your problem.

If the end of the slide stop that the spring loaded plunger rides against is machined at a negative angle the plunger will have a tendency to work the SS up into the notch in the slide and lock the slide back.

To check if you have this problem, look at the slide stop. Examine the slide stop's end that the plunger rides on. Try to determine if it is angled so that the distance to the top of the flat is longer than the distance to the bottom when measured from the center of the slide stop's pin.

If it is you have found your problem.

And although the angle Douglas 34474 is referring to is not shown on the drawing in Post #5, it is 90 deg +/- 1 deg when measured between the lower edge of the arm and the aft "vertical" surface. When installed and down the aft surface is about 3 deg forward of the vertical. The sides of the "doghouse door" cutout in the frame are 4 deg forward of the vertical and form a visual reference.

Still haven't gotten the replacement slide-stop from Kimber ... I'm hoping to get it in time for a test this weekend. And when I install the replacement, I'll try to get some comparison measurements on how much the left plunger pin protrudes from the plunger tube (with both old and new slide-stops, and with no slide-stop.

Quote:

If the end of the slide stop that the spring loaded plunger rides against

is machined at a negative angle the plunger will have a tendency to work the

SS up into the notch in the slide and lock the slide back.

I'm not sure what you mean by "negative angle". But what I CAN clearly see is that the rear "vertical" surface of the slide-stop is rotated noticeably counter-clockwise (CCW) relative to the rear "vertical" surface of the rectangular opening in the frame. So, moving the slide-stop upward would compress the plunger spring ... which means (I think) that any vertical force on the slide-stop due to the plunger would tend to push the slide-stop down, not up, which would be the desired result. But if that is true, the force must be fairly small, because when I hold the slide so that its notch is above the slide-stop, I seem to be able to freely move the slide-stop up and down ... i.e., I don't perceive any force resisting me when I push it upward, or any force tending to keep the slide-stop as far down as possible.

Quote:

When installed and down the aft surface is about 3 deg forward of the

vertical. The sides of the "doghouse door" cutout in the frame are 4 deg

forward of the vertical and form a visual reference.

So I think you are saying in the above description that the aft "vertical" surface of the SS should be rotated about 1 degree CCW relative to the aft "vertical" surface of the rectangular opening in the frame (3 degrees CW minus 4 degrees CW = 1 degree CCW). Mine is definitely rotated in that direction (CCW), but it looks to me like it's probably more than 1 degree. But I THINK that should be a good thing, as far as trying to keep the SS from "floating up" and catching the slide.

Quote:

So I think you are saying...

I'm saying just as shown in the drawing in Post #5. The difference is about 1 deg, but the "doghouse door" cutout sides are about 1 deg more CCW than the aft surface of the slide stop when the stop is down. At least they will be if made to Ordnance specifications.

And yes, when the stop is pushed up it compresses the plunger spring slightly which resists that upward movement a little bit.

Also, there's no real reason to actually measure how far the plunger protrudes when the stop is removed. If it sticks out about twice as far it's OK - provided the spring is as strong as it's supposed to be (holding the plunger out with a force of about 2 pounds).

You can improve the "bite" of the plunger on the slide stop by putting a small, shallow detent in the end face of the stop. I've only had to do it on one pistol, but it was easy and effective.

Use a Sharpie marker, Dykem blue, or just a match to darken the end of the slide stop. Assemble the pistol, and move the slide stop up and down several times -- enough to leave a clear mark showing the range through which the contact point of the plunger moves.

Remove the slide stop from the frame. Take a small (1.8" or so) ball cutter in a Dremel and just touch the end of the stop, with the ball's point of contact centered on the highest point of plunger contact. Just make a tiny dimple for the plunger to engage.

Here is a pic of what hawk was sorta talking about. This is a Pic of a cut I did on my slide stop for one of my springers

Thanks for that description ... interesting idea. I received the replacement Kimber SS yesterday ... I'll install it today, and hopefully test it this weekend. If that doesn't fix the problem, then I might try your fix on my original SS. Thanks.

Perhaps one other possibility would be to replace the plunger spring with something stronger ... is that even possible?

Quote:

The new plunger (detent) should cure the problem as it's supposed to

protrude about 0.087" according to the Ordnance blueprints as shown here:

Also, the aft edge of the frame opening looks completely parallel to the aft

edge of the SS to me (on the drawing). That's definitely not the case on my

gun, but I'm not sure that that would have anything to do with my problem.

Also, the aft edge of the frame opening looks completely parallel to the aft

edge of the SS to me (on the drawing). That's definitely not the case on my

gun, but I'm not sure that that would have anything to do with my problem.

OK, I installed the new slide-stop this afternoon. It is clearly different than the original: it compresses the plunger quite a bit more ... quite a bit harder to insert, and I also am no longer able to release the slide (to load a round) by pushing down on the slide-stop tab with my off-thumb: I now have to just pull back on the slide and release it, to load a round. Here are the measurements I took (all giving the amount of protrusion of the plunger):

1) 0.063" for the original SS,

2) 0.078" with no SS inserted,

3) 0.038" with the new SS.

Measurements 1 and 2 show that the plunger WAS pressing at least a bit on the original SS. And with no SS inserted, I WAS able to push the plunger in against a smooth and strong force ... no evidence that the plunger was hanging up on some irregularity, and not pushing on the SS.

Measurements 1 and 3 show that the new SS presses the plunger inward noticeably more than the old SS did.

So I have some hope that the new SS will solve my premature lock-back problem ... I plan to try it this weekend.

(updated with 4th range report):

So far, so good: I shot about 80 rounds today, without getting the premature lock-back problem I got during the first three sessions (50 light rounds, about 7 rounds of medium-power, about 8 rounds of nearly full-power, and about 12 rounds of full-power). So MAYBE the Kimber replacement SS is going to solve the problem. But since I only saw one such failure during each of the first three sessions (each with about the same number of rounds), I won't really know that the problem is solved until I've fired a LOT more rounds without a failure. (The three failures were all with the light rounds).