I am just finishing up a project, a long time in progress. I have over the years gathered up a new ser.70 1911 gov. mod. and the slides , bbls, etc to make a switch cal. set, that will fire .45 ACP, .40 A&E, .38 Auto, .38 Super, 9mm. Luger, and .22 LR. I have been building a building a wood case for the set.

It dawned on me that I lost track of a couple of recoil springs, and don't know what weights they are. How do non gunsmith folks determin the weights of unknown recoil springs?

Niemi has pics of a rig that searching might turn up. However, my preferred method would be to throw them out and buy new ones. Given the considerable expense you've gone to putting this set together, I don't think I'd cheap out now.

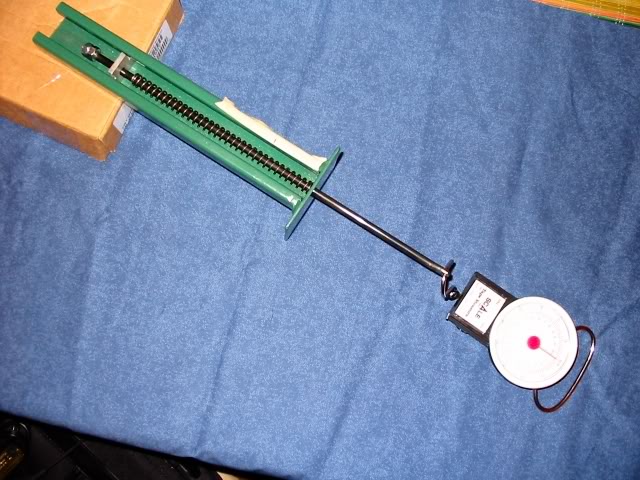

+1 for what RobL said. It's easier, less expensive and less aggravating to just get new springs - assuming you know what their weights are. If not, well, here's my recoil spring testing contraption:

Others have posted photos of other styles over the years - LogMan comes to mind. But if you know what their weights are (just not sure which is which) my advise is just to get new ones.

SDM Manufacturing offers a rig from time-to-time that I have found very useful. I spent an afternoon measuring the recoil springs that have accumulated over fifty years in my stash.

I bought mine, but you can make Niemi's for next to nothing, if you don't want to throw out & start over. That having been said, starting fresh is not a bad idea, too.

Quote:

SDM Manufacturing offers a rig from time-to-time that I have found very

useful.

Hmmm...

Theirs is a very nice rendition:

Mine's not as photogenic, but it does about the same thing:

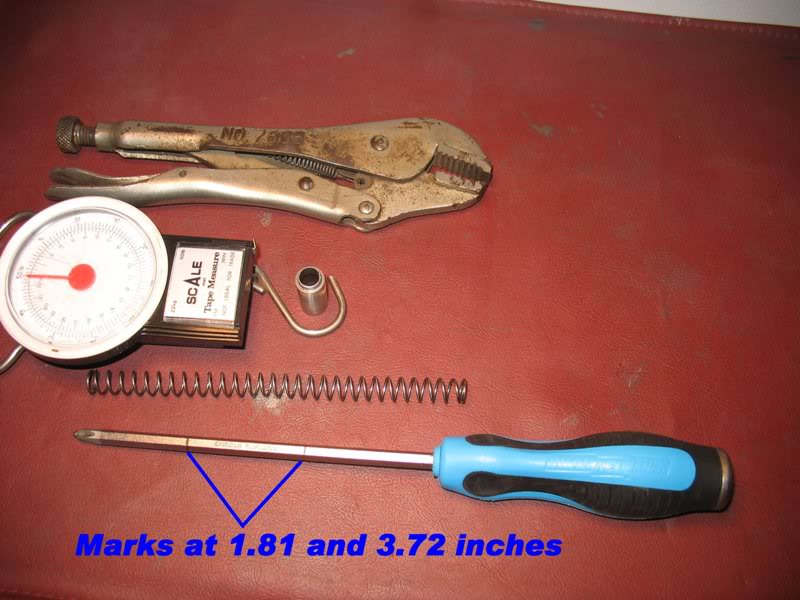

I think I am in the running for the most cheap and lazy too... I just used the stuff I already had laying around...

So far it has been right on the mark with new Wolff springs... and I've noticed that most springs still have the same pull after a thousand rounds...

It looks like I use the same gage as Hawkmoon... I guess I'm just lucky...

I like the hands free style.

Thanks All, for the pictures & info. I love to make jigs, and tools that make life easier and more interesting. Just for the fun of it, I intend to build one for measuring spring weight. Where would be a good source for scales? are the ones shown fish scales?

What are the scales shown on your tool BigJon?

That scale is a Chatillon IN-025M 4oz. marks.

The one I use is a cheap fish/game scale from the sporting goods aisle at Wal-Mart.

I much prefer BigJon's setup, but I hadn't seen one like that when I made mine.

Thanks for the info. Where did you find the Chatillion scale BigJon?

I pretty much finished up the case today, that I mentioned, for the switch cal set. I will post a picture on the conversion thread.

I have my version of a spring gauge about completed, with the exception of the compression gage part of it. Having never used a spring weight gage, I don't know if it is important to know the compressed length of the spring or not. Is there a reason for measuring the compress length that I don't understand? Pardon my ignorance, but I want to learn.

Yes, if simply to check that the compressed length is correct for the gun. Remember that the Officers springs are shorter to begin with. So would suggest the scale be built to work with all springs. The compressed length at full recoil is nearly fully compressed anyway.

Thanks for the information BigJon. I will add the length scale, and finish my gauge now. I have added some other inovations. I will post a Picture sometime.

Quote:

Having never used a spring weight gage, I don't know if it is important to

know the compressed length of the spring or not.

Knowing the compressed length is critical. Without knowing it all you can do is measure the force needed to compress the spring to its solid length. As an example, the standard recoil spring for a full-sized 1911 has a rating of 16 pounds. But 16 pounds is the force needed to compress the spring to 1 5/8 inch - which is not quite its solid length of about 1 3/8 inch as shown here:

PICTURE 404

So why is the rating measured at 1 5/8 inch? That's almost exactly the length the spring gets compressed to when the slide is fully aft.

1911 clones with shorter barrel lengths have different values of standard ratings and associated compressed lengths. One thing you must get to know and understand is the difference between a spring's "rate" and a spring's "rating". Lines 7 & 8 in the specification, above, are statements of the springs "rating".

Realize the scale gets longer as the weight goes up, and give it enough room to work.

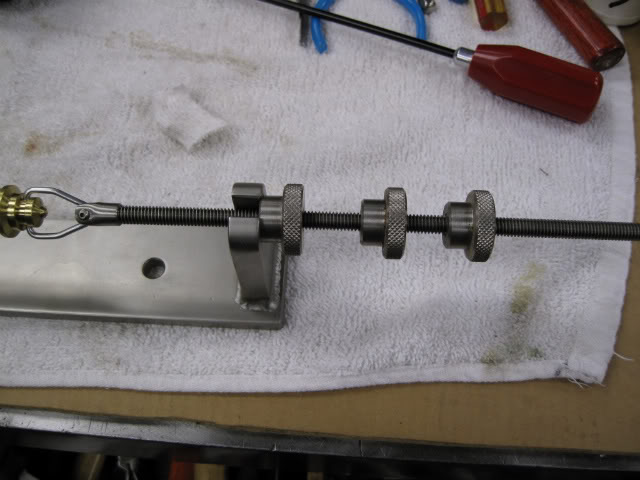

Thanks for the extra info. It will help me design the compression scale indicator. After reading the info that you friends sent, I will replace the inch scale with a homebrewed brass scale, or indicator. Here is the weight measure scale to date.

I should have waited untill I found out more about how the gauge works, to build one, but I have only had to remake a few parts by getting the cart before the horse. I wish now, that I had found a scale like the one BigJon used. I could have used an electric screw driver to crank the thing instead of making a crank, and might change that. I think I will make an compressed spring indicator that will read all the sizes of springs that I have, instead of an inch scale. I have tried to copy the US Army specifications that Niemi24s posted, but, can't get it to copy. I am going to take time to type it out I guess, as it looks very usefull.

Quote:

I am going to take time to type it out I guess, as it looks very

useful.

It's probably useful only from a historic perspective because when you do the math to find the rating of that spring at 1 5/8 inch, it works out to a little over 14 pounds.

I now know the difference between the spring "rate", and the "rating". To complete my Spring weight Scale, to gauge all the spring lengths for the standard Colt models, such as the Commander, Officers etc. I will have to rebuild the Rod that my scale uses for the spring to slide onto to be compressed, as I made it 5/16" in diameter to more closly fit the ID diameter of the standard Gov. mod. spring, and the inside spring of the Officers Mod. would take a 1/4" rod. I will also have to know the free, and compressed lengths of the other common Colt models. Is there any place that I could find those lengths?

While free length can be indicative of a particular spring, and condition, simply checking the weight at full recoil compressed length, and the weight at in battery length, is a benchmark for comparison.

Might as well build a rod with a 3/16" rod also in case you ever own a .380.

Quote:

I will also have to know the free, and compressed lengths of the other

common Colt models. Is there any place that I could find those lengths?

They might be somewhere on the Wolff Gunsprings website but as BigJon said the free length is not too useful. As far as the compressed lengths at full recoil I've got scribbled on my blueprint: Commander = 1.125" and also 1.150" ± 0.005" (with no idea which is correct - if either is) and Officer's = 0.700".

Wolff uses 1.625"GM, 1.125"Com, and .700" Officers for full recoil compression.

It is begining to dawn on me that there are a lot of vairables. Also experience is invalueable. You are right Joe, I might as well remake the complete compression rod system adjustable, and include .380, 32, and also .25 springs.

It can come in handy. After I fabbed up the thinner rod I checked the compressed length on my Sig P238 and then installed the stock round wire spring and tested the spring for rating.

God was that ugly.

It is no surprise why the round wire springs used to collapse. The compressed length in the tester almost telescoped the spring right before my eyes! I put the flat wire spring in right then.

Sure I made an adapter rod for mainsprings as well, why not?

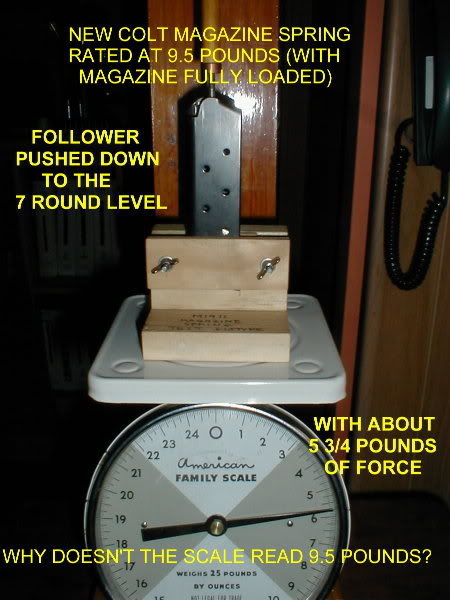

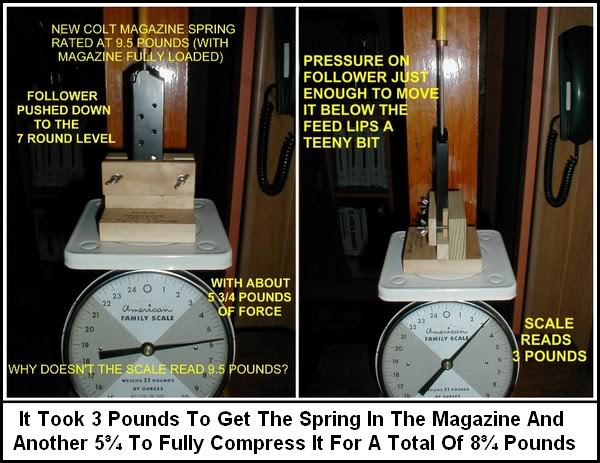

Perhaps the only advantage to the monstrosity shown in Post #3 is that with a fairly simple adapter, magazine springs can also be tested:

Please disregard the text in the image.

Quote:

Is that like..."pay no attention to the man behind the curtain!"?

Not really. When I first built the adapter to test magazine springs I was initially puzzled by the low reading - hence that image with question. When the answer (perhaps even the correct answer!) got figured out another image was made. Here's both of them pasted together...

...with what I recall being the answer to the puzzle. Some aspects of testing compression springs can be a little befuddling - to me, at least.