I am studying the hammer slot in the aft end of the frame.

I purchased a 3"x1/4" cutter and the arbor to hold it. When I got home I realized that the arbor will intersect with the frame before I finish the cut.

After studying the drawings, I realized that I need a 3" saw with a VERY SMALL center hole (about 3/8") and the arbor to hold it.

Who makes such a beast?

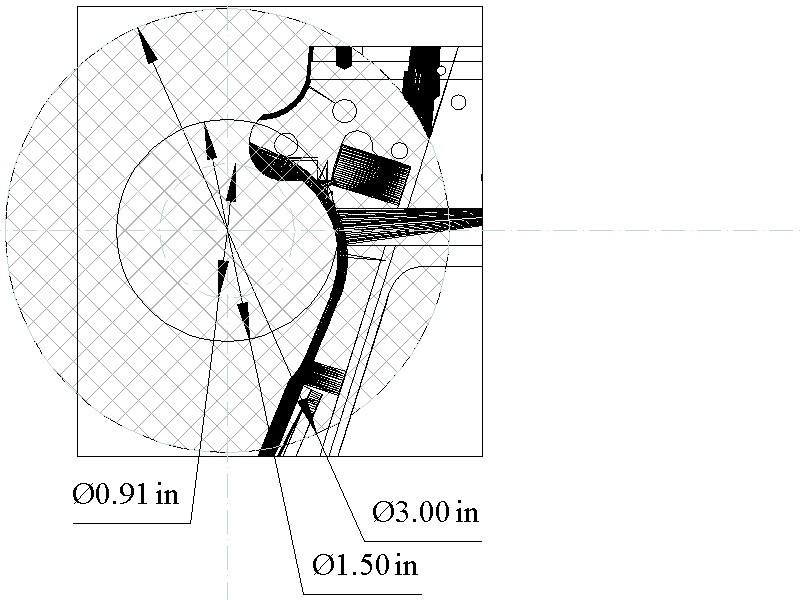

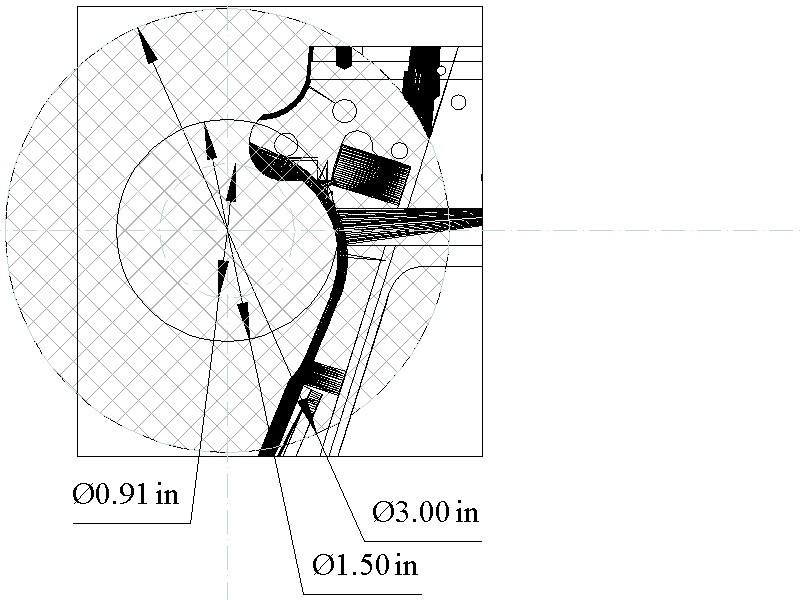

To clarify the problem, I have prepared a picture from the IGES file on www.cncguns.com

The 3" circle is the required cut

The 1.5" circle is the diameter of my arbor

The 0.91" circle is the largest acceptable arbor.

Any suggestions on where to buy the correct size arbor and a 3" saw stack that will fit it?

After further research, I have an answer.

Jewelers slitting saws can be had in 3" with 1/2" hole.

A stack of 5 0.057" and 1 0.025" will produce the 0.310 thickness required for the hammer slow.

www.mscdirect.com has that stack for about $56

They also sell the arbor to hold it for $36.79

Much cheaper than Rutland tools.

I must admit that it is fun going into the Rutland tool store locally. I do have to leave my wallet in the car though.

The jewelers saws are described as good for shallow slots only. I suppose I should use my 1/4" side cutter to cut as far as possible and then deepen the hole to the final dimension with the jewelers saws.

We just went though this same problem on our STI build and decided to just mill it out straight with a standard end mill.

I too used a straight end mill, long .250" with a straigth shank from memory, works fine, leave it to one of the last cuts and there is not much meat left anyway, on the S_I frame anyhow.

You could go to a 4" dia saw since you have the arbour, it would make no difference to the workings, just keep the end points in the same spot, if that makes sense.

A 4" cutter is an interesting idea. To keep the endpoints the same, the hole will be a little shallower where the sear fits. I will have to check for interference and/or clean out the hole with a 3" saw stack.

I started cutting the hole with the 3" cutter and made it through the beavertail portion and then the cutter stopped cutting. One moment it was working great and the next moment it was dull. I was using 250 rpm and a steady stream of oil. I suppose HSS cutters and steel forgings are a rough mixture. I will get a cobalt cutter in 3" and 4" and see what happens.

I decided to cut the slot in the frame first because that provides the clearance required to undercut for the grip safety. I bought a few sacrificial 1/2" HSS mills to grind the undercut tools with and I did not want to use them any more than I had to so I was removing all the extra metal.

Any ideas on speeds for a stack of jewelers saws to cut a steel forging? I suppose slower is better.

When I machined my 1911, I bought 3 3" inch saws blades (I think they were 0.057" thick). I bought these from MSC. I thought I was going to have a problem with the blades stacked on top of each other, but it machined perfectly... I was really happy with the cuts. The following link shows a pic of the cutter I used... http://www.roderuscustom.tzo.com/cgi- bin/ib3/ikonboard.cgi?act=ST;f=10;t=291;st=15

Your stack convinced me to go the same route.

I studied your steps on your website. Did you machine the frame from aluminum?

I am a bit concerned with using HSS saws on a steel forging and having the saw dull the same as the side cutter. What is a good speed to use for a 3" saw?

Yes, I machined my frames from 6061T6 aluminum. If I remember correctly, I believe I used 800RPM @ 0.5 IPM You may have to slow this RPM down a little bit since your cutting steel. I would probably try 3-400 RPM @ 0.5 IPM

Quote:

I bought a few sacrificial 1/2" HSS mills to grind the undercut tools

Do you mean 1/4"?

I have 1/4" mill for making the thumb safety cutout. But it looked easier to cut the grip safety undercut from a 1/2" mill.

When I dulled the 1/4" saw I had the speed at 250RPM and the feed was slow with lots of oil. If I keep the tooth velocity the same as a 1/2" cutter a 250RPM, I must slow the mill to 41RPM for a 3" cutter.

I suppose I will use the slowest speed (150'ish) and hope for the best. I can't afford cobalt or carbide slitting saws.

Quote

I can't afford cobalt or carbide slitting saws.

You just might be able to... I bought a couple 3.5" diameter, 1" arbor, .077" thick solid carbide saws on Ebay for... are you ready for this? $22.00 apiece! You need to keep an eye out there, as this sort of deal comes up every so often.

When I was first getting started I was shopping for some heavier parallells to help with setup tasks... some guy had an auction for a batch of assorted parallels (pair of 1x2x12, pair of 1/2x1x6, pair of 3/4x1x9, + several others), with the auction starting at $15. No mention of manufacturer and the photos showed them to be a little stained, obviously used tools. No one was bidding on them, and while they might not have been the best on the street, I felt that for $15 I'd at least have something to start with, so I bid and won the auction. When the package showed up it turned out that they were all Browne & Sharpe tools, and while a little shopworn, in eminently servicable condition. If I wanted to replace the 1x2x12 pair, even an el-cheapo import pair would cost about 90 bucks... and if made in USA, about $400!

Moral of the story... watch Ebay and keep an open mind. There's a ton of great deals out there.