That shows the radii for the outside of the slide upper outside, the lug area, and the more obvious (and shown in the drawings) barrel channel. I haven't gone through Kuhnhausen's books, but I thought it might be here and I'm just missing it.

I had drawn the three radii to show the effects of top serations. But I goofed somewhere. I don't know where I (thought I) got the measurements before.

If I understand what you are asking for, aren't those radii shown on page 7 M1911 Full blueprints (courtesy of CNC Gunsmithing) located here:

http://www.m1911.org/technic_forum.htm

Actually, I don't think that they are. I've studied that page up down and all over the place. What I need is the depth of the material from the OD of the slide to the lug cut out. If it is there, I can't find it. I've heard that it is .100, but my best measurements show it closer to .080.

Sorry, I initially thought you were asking for the dimensions shown in section J-J or K-K then compared (subtracted) from U-U, but I see now that's only part what you need...

Quote:

What I need is the depth of the material from the OD of the slide to the

lug cut out.

In Zone C4 of the slide print on page 4, the radius of the slide's top is given as ".490R TRUE", centered on "F", which I think is the firing pin hole. But I'm not sure what the other info in the rectangular box below the ".490 TRUE" means.

Because the firing pin hole slopes down at its front at an angle and is referred to as "C" on page 5, I wouldn't even know where to start figuring it out. Maybe Pdangeruss has the smarts to do it.

FWIW (probably very little) it measures 0.081" on my Remington Rand slide.

Well, you got my curiosity up but all it's done is drive me nuts the past few hours. Even though our measurements agree pretty well (~ 0.080"), my math and/or understanding of that part of the blueprint seems to be lacking.

I did it twice and came up with 0.130", but that seems way too thick based on our real-life measurements. The WWII vintage slide I measured was blued when I got it 40 years ago, but it's hard to imagine 0.050" or so being taken off the top in the refnishing process!

I've a hunch the problem with my 0.130" result is that it's based on some unknown misinterpretation of the blueprint. Wish I knew what it was. If I find out, I'll let you know.

It looks almost as if the center line of the .490" radius is different from the .72" diameter listed on the section and the center line of the .490" radius isn't indicated.

Are you looking at the front view of the slide in Zone C4 on the Page 4 blueprint from CNC Cunsmithing?

If so, I thought maybe the F with the three horizontal lines in front of it (all in a box) specified the center of the .490" radius. But, it looks like F is either the diameter or the center of the .699 + .003 inch boring for the barrel - and that's parallel to E (the way's bottom)!

And that can't be, because the top of slide slopes upward a little bit toward the back!

Where's/what's the 0.72" diameter you mentioned?

Boy, this sure is kind of confusing (to me, at least).

Forgive me, I don't claim any great knowledge about this, I'm just trying to learn, but doesn't view S on page 5 show the offset of this centerline?

I also saw that page 4 and 5 were for slide part no. 7790314, 1911a1 and Nat'l Match. Back on page 51 of the same set of blueprints they show the slide drawings for slide No. 7791435, 1911a1 and Nat'l Match. They also show the rail to top of slide height of .900 -.010 in section W-W, (it's omitted? in the same view on page 5) would that dimension make the OP's dimension much easier to derive? I also couldn't see any dimensional differences in these slides, didn't look too hard though.

Well I'm certainly glad to find out that I am not the only one confused by this. I did look through Kuhnhausen's books and didn't find anything there either. I've got an old junk slide that I *could* section, but I use it to demo some cuts, so I'd rather not. And it might not be typical anyway.

I do think that the CL is not the same for the radii. Measuring the fronts of a few slides, they seem to all be thicker at the top, IIRC. Of course, the rear is what I need to know about.

I'm getting a little bleary-eyed from peeking at these blueprints through my magnifier.

View S on Page 5 shows the angle and distance from surface E (bottom of slide's way) for only 3 things that I can see:

* 0.801 + 0.012 angled 52' is the lug recesses

* 0.701 + 0.009 angled 52' is the top of the cut for the left hand breech face guide block shown in Section Z-Z

* 0.437 +/- 0.004 angled 24' is the centerline of the firing pin (FP) hole. This is the one I'd used when coming up with 0.130" for what Dave & I measured to be 0.080"

I even tried calculating the angle from the FP hole down to the barrel bore center (F in box) at the muzzle and came up with 0.122" - still much too large, I think.

On page 51, the 0.900" height just locates a flat surface milled on the top of the slide to accomodate a National Match rear sight. It's not how high the rounded part of the slide was/is.

But keep looking as long as you bear the eyestrain. The clue on how the center of that .490" radius rises toward the back of the slide is probably there somewhere. I've looked at that blueprint so many times over the years it gets easy to not see something you've seen many times before.

Your fresh eyes & mind may be the key to finding the hidden clue.

Is This The Secret?

Just had a late-night apostrophe epiphany!

If (big if) those symbols with the F .010 in the box under .490R TRUE in Zone C4 on page 4 mean the .490" radius center is 0.010" below F at the slide front and 0.010" above F at the breech face...

...then preliminary re-calculations give 0.086" as the distance from the top of the slide down to the center of the recess between lugs 1 and 2.

This is lots closer to the 0.080" we got for the measurements of our slides.

Who knows, it might even be the correct value for a mid-spec M1911A1.

After some sleep will go over this stuff again. Nitey- nite

Quote:

Are you looking at the front view of the slide in Zone C4 on the Page 4

blueprint from CNC Cunsmithing?

Yep, thats the view I'm looking at.

I'm thoroughly familier with air conditioning and architectural drawings (I'm an air conditioning designer) but these machine tool type drawings are giving me a headache.

BTW I printed pages 4 and 5 full size on 24"X36" paper on the office's drafting plotter so I don't need my magnifying glass.

The .72" dia I'm refering to is on the same view (90 degree .72DIA + .01). I took that to be the size of the "bore" of the slide (I know that's not the correct term but I don't know the correct one) but it may not be.

Maybe if I find time I'll try drawing the slide in Autocad and see if I can make sense of all this.

Quote:

BTW I printed pages 4 and 5 full size on 24"X36" paper on the office's

drafting plotter so I don't need my magnifying glass.

Oooh, sounds neat! Did the small details get fuzzy when enlarged?

Quote:

The .72" dia I'm refering to is on the same view 90 degree .72DIA + .01). I

took that to be the size of the "bore" of the slide (I know that's not the

correct term but I don't know the correct one) but it may not be.

The bore for barrel & bushing has a 0.699 + 0.003 inch diameter, and is given in Section U-U on page 5. The .72" diameter on page 4 is for the countersink (CSK) used to chamfer the bore hole to make bushing insertion a little easier.

Started another thread specifically asking about the blueprint symbols. Bound to be an old-time machinist familiar with what they mean.

Quote:

Did the small details get fuzzy when enlarged?

They're still kinda fuzzy but the text is big enough to read. These appear to be scanned electronic files of a copy, of a copy, of a copy... of the original drawings.

I've tried all the image software tricks I know of to try to defuzzify them, but the only which seems help is the Sharpen in IrfanView. And it helps very little!

I drew a sketch of the section through the slide during lunch but there was one bit of info I couldn't quite make out from the drawings. What's the degree of taper of the top (outside) of the slide from front to rear? Looking at page 4 the left side view of the slide does ".0085 BASIC TPI" indicate the taper of the top of the slide from front to rear?

If that's what that means, taking dimensional tollerances into account, and assuming I drew my section correctly (BIG MISTAKE, DON'T EVER ASSUME) the thickness of the top of the slide over the locking lug grooves could be anywhere between .07" to .10".

The thickness of the slide between the locking lug grooves should be somewhere in the neighborhood of .15".

niemi: take a look at these numbers and see if this looks like they're close to correct.

And The Winner Is...

...TOOLMAN!

Congratulations! You found exactly what I've been looking for!

And your numbers look about right too!

I feel like a real putz, as it's been there all the time - not like it was written upside down in Chinese or any exotic code.

Will fiddle with the numbers after supper and get back. Nowadays, I just fiddle with the mid-spec values and just WAG the tolerance. Doing the calculations with the tolerances included almost triples the work. Besides, the tolerances can add up to some ridiculous values.

Many thanks for finding the slope.

The math leaves me completely baffeled. I hafta draw these things to scale in Autocad to get them correct.

I'm just the opposite. Fairly good with the math, but all I know about CAD is how to spell it!

The following are vertical slide dimensions at the centers of the two recesses between the radial locking lugs. The three mid-spec values for each recess are, in the order given:

* Thickness of slide top

* Distance from slide bottom to bottom of recess, and

* Total height of the slide

Aft Recess: 0.111" / 0.902" / 1.012"

Fwd Recess: 0.113" / 0.897" / 1.010"

Slide thickness at the top center at the front = 0.140"

These based on the assumption the center of the 0.490" radius at the front of the slide coincides with the center of the bushing/barrel bore. The tolerance for each of these values is in excess of +/- 0.010" by a not insignificant amount!

Your slide may vary. Mine certainly does.

Thanks again for your help Tool Man. How do these agree with your CAD results?

OK, now that we have a winner... can anyone get the numbers back to me? With all the revelations and epiphanies and measurements and drawings, I missed the actual number. Alright, so one of us is slower than the others.

My wannabe CAD, Turbo CAD, tells me that the top should be .080" +/- JMB knew thick. Is that the final final FINAL answer or just the final one? I do some numbers and some CAD, but often the "twain don't meet".

I was really hoping for .010, but I can't make that work.

Another question about this, since they show the top of the slide as a taper, .0085 TPI, all the other specs I could see in these blueprints were in degrees and/or minutes (curiously interesting). That taper comes out somewhere close to 30 minutes, I think, couldn't really measure it accurately. Is it possibly parallel to the firing pin hole in view S, which shows to be 24 minutes?

I was kind of surprised by the results too. Went over everything a few times and found no errors, but that certainly doesn't mean there aren't any.

In the morning I'll see if I can put together a dimensioned drawing that'll show how I came up with what I did. This'll make it easier for you, Tool Man or anybody else to scrutinize my work.

But getting it all so it'll be readable at the Photobucket size limit might be tricky. If you (or anybody else) is willing you could PM me your email address and I can send it as an attachment that'll be lots bigger and easier to read.

Quote:

That taper comes out somewhere close to 30 minutes, I think, couldn't

really measure it accurately. Is it possibly parallel to the firing pin hole

in view S, which shows to be 24 minutes?

0.0085 TPI = 29.2 minutes of angle, so the angle between the slide top and the FP hole is about 5 minutes. Not truly parallel - but real, real close.

I'd initially though the FP hole slope had something to do with the slide top slope, but after Tool Man pointed out the taper on the blueprint, that thought got sent to the recycle bin.

quote:

0.0085 TPI = 29.2 minutes of angle, so the angle between the slide top and

the FP hole is about 5 minutes. Not truly parallel - but real, real close.

Thank you, I thought I was going blind, not from knowledge, but it stood to reason that it was either the same or very, very close. The slide is level through the sights when the gun fires, it seems, and that would give a very close to in line "center" for the firing pin, chamber/barrel, and it is also very close in the drawings, just labeled differently.

This though is just not a true enough center for these older eyes...

Actually the slide does not align with the tops of the sights. It's not really noticable, but the front sight is normally around .060" lower than the rear. And that varies according to how high the lug are set into the slide, among a couple of other things. Part of the discussion and probably confusion to some (like me) is just how much higher the barrel sits at the rear than the front. You might think it is just the lug engagement, but then there is the barrel clearance to the slide when the barrel is bedded in the frame. So there are all sorts of gremlins in there. Oh, JMB, where are your drawings! Then some bits of evolutionary change from his design would get into the act.

Quote:

Actually the slide does not align with the tops of the sights. It's not

really noticable, but the front sight is normally around .060" lower than the

rear. And that varies according to how high the lug are set into the slide

I knew about the sight height difference and it's plain in the drawings, the downward slope to the barrel in the slide. I just assumed (oops, big mistake) that when it all came together, the thicker to the rear slide, sight height difference, the downward slope to the barrel all equalled each other.

But after niemi24s verified the numbers, I see they only balance themselves, not equal themselves, to become such a straight shooter. They just aren't parallel when they do it. Gosh, what a mind put this thing together... It's so simple and very complicated!

You all can rest assured that my thinking about this has been successfully relocated over to the "wrong again column".

niemi24s: Your calculations are right in there with my cad sketch. I ignored the +/-.010" overall tolerance indicated on the drawings, but with the cutter travel tolerance for the locking lug grooves being listed as +.03 you can have a pretty fair bit of variation, anywhere in the .070" to .10" range according to my CAD sketch.

If the slide were perfect (HA! yeah right, find one for me), according to my cad sketch the thickness of the slide at the front of the ejection port would be .1007".

When you only consider the tolerance of the locking groove cutter travel, + .03", the thickness of the top of the slide at the same location would vary between .0707" and the aformentioned .1007". Now when you take into consideration the overall tolerance of +/- .010" indicated in the title block of the drawings the thickness of the slide at the same location, the front of the ejection port, will vary between a minimum of .0607" and a maximum of .1107".

The thickness of the slide between the front of the ejection port and the aft locking lug groove will vary between a minumum of .1517" and a maximum of .1717".

But we all know this ain't no perfect world. We do all know this, right? Don't we?

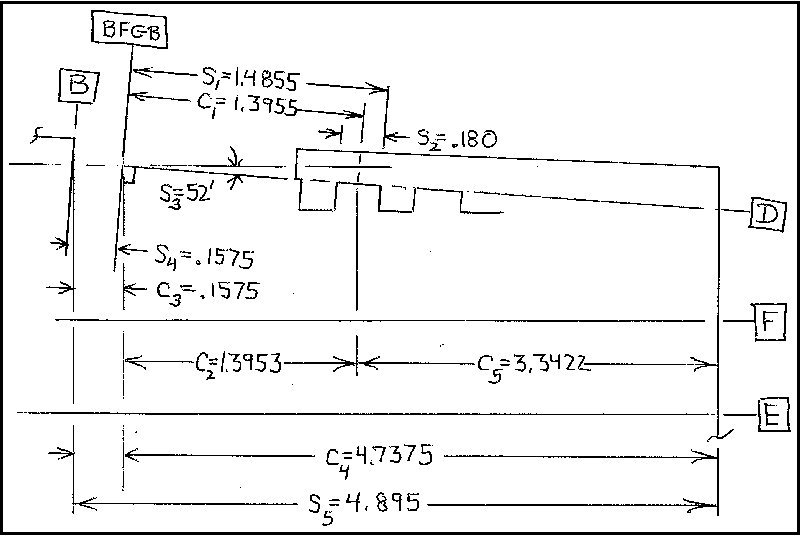

Here's how I came up with 0.111" as the thickness at the center of the aft recess. S = specification (mid-spec value) from our blueprints. C = calculation, initially rounded to 4 places past the decimal then to the nearest 1/1000" in the final result.

STEP 1: Find the horizontal distance from the recess center to the front of the slide.

C1 = S1 - (1/2 x S2) = 1.4855 - (1/2 x 0.180) = 1.3955, but at 52'

C2 = C1 x Cos S3 = 1.3955 x Cos 52' = 1.3953

C3 = S4 div Cos S3 = 0.1575 div Cos 52' = 0.15752 ~ 0.1575

C4 = S5 - C3 = 4.895 - 0.1575 = 4.7375

C5 = C4 - C2 = 4.7375 - 1.3953 = 3.3422, as shown below:

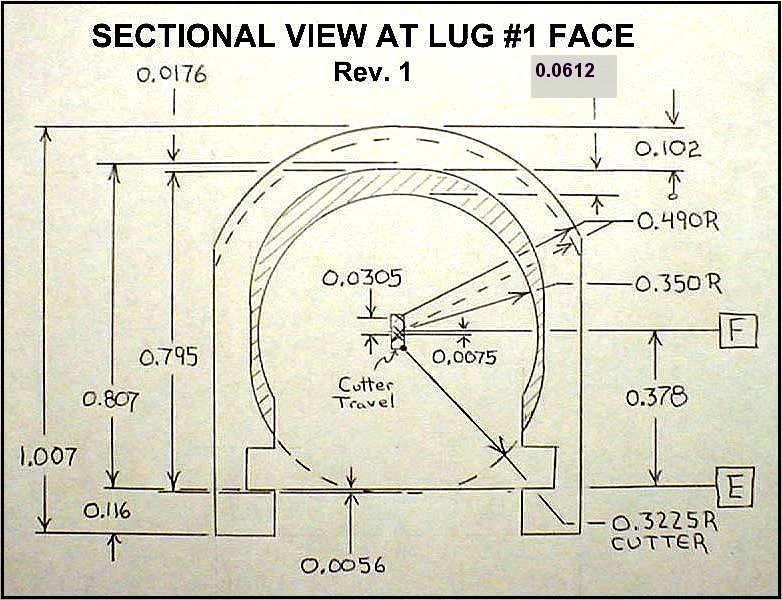

STEP 2: Find the vertical distance from Reference [E] to the slide top at the center of the aft recess.

C6 = S6 + S7 = 0.378 + 0.490 = 0.868

C7 = C5 x S8 = 3.3422 x 0.0085 = 0.0284

C8 = C6 + C7 = 0.868 + 0.0284 = 0.8964, as shown below:

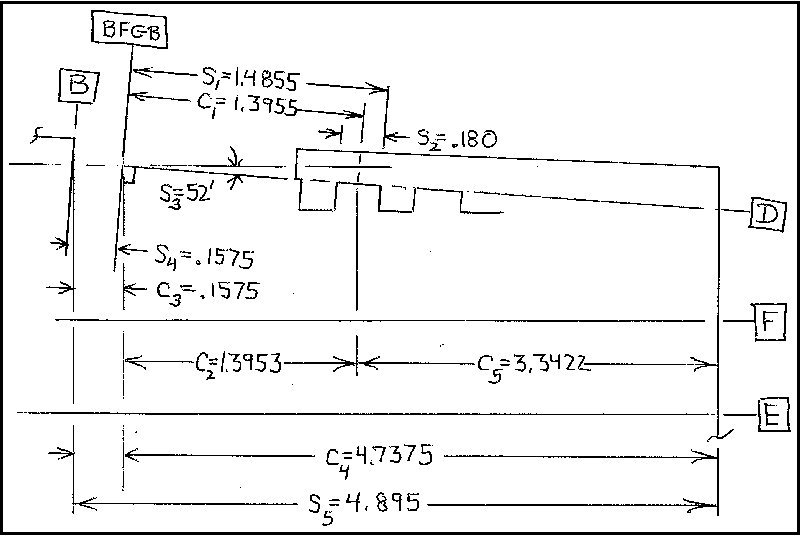

STEP 3: Find; the vertical distance from Reference [E] to the center of the aft recess.

C9 = C2 x Tan S3 = 1.3953 x Tan 52' = 0.0211

C10 = S9 - C9 = 0.807 - 0.0211 = 0.7859, as shown below:

STEP 4: Finally, the thickness of the slide top at the center of the aft recess is found.

C11 = C8 - C10 = 0.8964 - 0.7859 = 0.1105 ~ 0.111 inch

This 0.111" thickness is based on mid-spec values and assumes the center of the 0.490" slide top radius coincides with Reference [F] at the slide's front.

Let me know if you see any math or method errors.

Heavens! You make my head spin. I haven't touched trig since I was in college and that was a long time ago.

I just now checked my drawing and made a minor correction. With the slope of the .490" radius top of the slide beginning at the nose of the slide the drawing indicated .1114" thickness at the center of the aft recess.

The first time I drew the slide I began the slope of the top of the slide at the aft end of the front sight's milled flat spot. I had also somehow (?) began the slope at .485" above -F-. Don't know how that happened. Anyway this correction changes my numbers a little bit.

.1097" at the front of the ejection port (mid spec).

.1114" at the center of the aft recess (mid spec).

.1708" at the aft most point of the slide between the ejection port and the aft recess.

Now taking the tolerances into account, that gives us a min. thickness of .0714" at the center of the aft recess and a max. of .1214" at the center of the aft recess. Also we now come up with a min. of .0797" at the front of the ejection port and a max of .1197 at the front of the ejection port. The aft most point of the slide between the ejection port and the aft recess now becomes a min. of .1608" and a max. of .1808".

Note: cutter travel tolerance for the recess + .03", overall tolerance +/- .010"

Quote:

...with the cutter travel tolerance for the locking lug grooves being

listed as +.03...

The way I read the blooprint, that 0.03 tolerance range is for the bottom extent of the cutter's travel. The top extent of cutter travel seems to be established by Reference [D] which (although angled at 52') has a vertical tolerance of + 0.012" (in the 0.801 + 0.012 dimension).

Still a lot of total tolerance, however. Probably close to +/- 0.020"!

FWIW, an old Springfield Armory print (from The Sight's website) doesn't give a taper for the top of the slide, but rather gives a height for the aft end of slide. It's hard to make out but it looks like 1.027 - 0.004 inches. That's around 0.020" less than the more recent RIA print data yields. The slide front geometry appears the same on the SA print, so that would reduce the height to the top of the slide at the aft recess by about 0.009" and the thickness by that same amount.

Quote:

The way I read the blooprint, that 0.03 tolerance range is for the bottom

extent of the cutter's travel. The top extent of cutter travel seems to be

established by Reference [D] which (although angled at 52') has a vertical

tolerance of + 0.012" (in the 0.801 + 0.012 dimension).

Hmmm... good point. Doesn't reference -D- just indicate the 0 degree 52' angle? I don't see where they locate a beginning point for reference -D-. I'm no machinist, I specialize in building construction, so this is getting a little out of my league. In section J-J reference -D- is indicated at the top of the cutter travel, but reference -D- slopes at the 52' angle. I'm not quite following that. The cutter traveles upward to create the recess.

The starting point at the breech face guide blocks for [D] is established by the horizontal line extending to the right from the blocks and ending with .801 + .012 under it, down to [E]. It's that + .012 which specifies the tolerance for the cutter's upper travel limit. All this is in View S on Page 5.

At least that's the way I have it figured out.

It sure looks like that's the starting point. If that's the case I get .1164" thickness at the center of the aft recess.

P.S.: It seems a lot like work to me. Speaking of work, if I don't get back to work and stop goofin' off I'll be in trouble with the boss.

Quote:

What I need is the depth of the material from the OD of the slide to the

lug cut out... I've heard that it is .100, but my best measurements show it

closer to .080.

Well, after all this, I guess what you heard is closest to what the blueprint data yields.

No idea why we got about 0.080" on our slides at a place where the mid-spec value seems to be about 0.111".

FWIW, my slide measures 0.126" thick at the top of the front, and mid-spec is 0.140" making it about 0.014" less there. The total heights at 4 places along the length of the rail average about 0.017" less than their mid-spec values.

But, it's a WWII era slide. Guess it's just got a thin top - kinda like I'm getting!

My Colt Series 70 was made during the dark days of Colt, the late '70s or early '80s and I allready know the tolerances ain't to good. I kinda hate to measure mine but I guess I ought to anyway. I allready know the depth of the barrel lug recess we've been discussin' is the absolute min. per specs and the overall stack height of my pistol is low if not below spec. Some of them just turned out like that.

Quote:

I kinda hate to measure mine but I guess I ought to anyway.

Are you reeeeeeallly sure you want to do that?

Could be worse knowing what it is than just wondering what it is.

No I really don't want to measure mine. I might just leave it layin on the bed side table where it belongs. Considering the tolerance problems I'm thinkin' I'm going to get me another 1911 to take to the range when I can afford it and leave the Colt on the bed side table.

I just don't think my Colt will hold up to regular range trips and a high round count. But she does great as a house gun.

Aw! Measure it, Toolman. Until you do, you'll wonder when it will fail. Remember that some 'smiths are taking 0.030" or more off the top and getting by with it. You won't be that low.

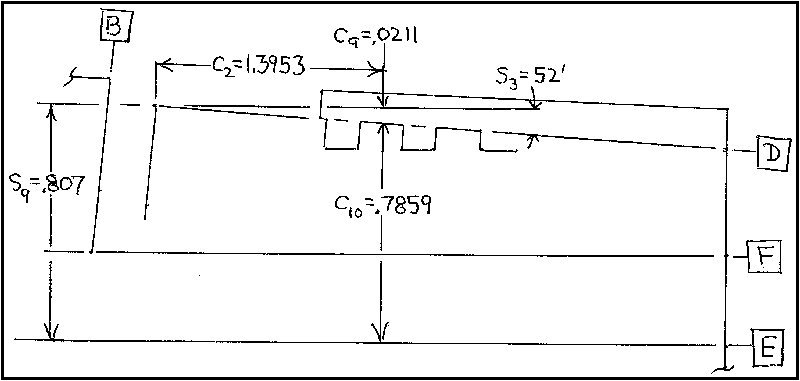

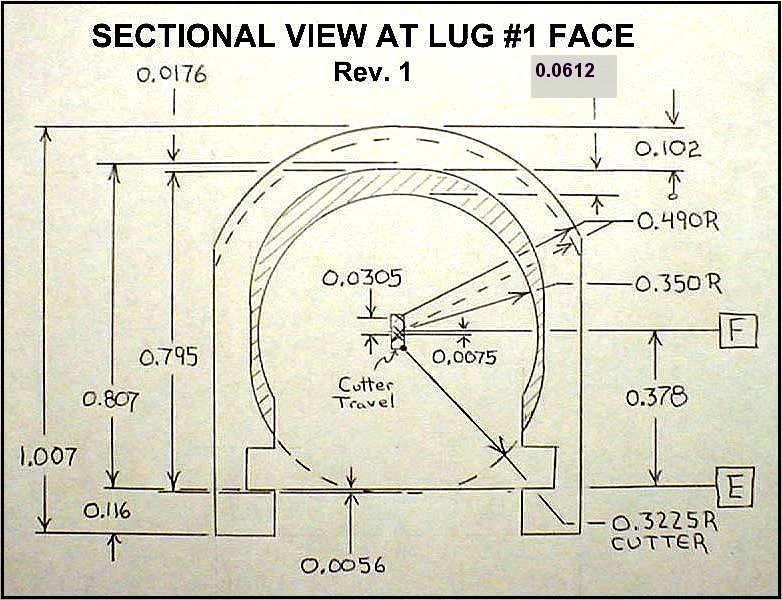

What I want to do is draw a rear view of the slide with a circle for the barrel channel, another for the lug channel, and then the OD. This section to be at number one lug cut. This is to show a customer what is left after slicing and dicing the top end. He is concerned about strength. And if he is, I am. But he really really wants it done.

So if the slide is 0.490 radius of a CL and the barrel channel is 0.350 off a CL, are they different CLs? And what about the CL for the lug cut? Where is it?

This seems like it should not be so difficult. Of course, I never claimed to have the thinker of JMB, nor will I ever.

Quote:

So if the slide is 0.490 radius of a CL and the barrel channel is 0.350 off

a CL, are they different CLs?

They are both off the same centerline, shown and referred to as [-F-] on the blueprint.

Quote:

And what about the CL for the lug cut? Where is it?

The lug cut does not really have a centerline, in the true sense of the word. This is because the lug cutter (with its axis at an angle of 0 deg 52') has it's center moved around inside the slide in a rectangular pattern.

The upper extent of the lug cutter's travel is established by reference line [-D-]. [-D-] begins at the breech face guide blocks at a point 0.801 + 0.012 up from reference line [-E-] and angles down at 0 deg 52' from that point. It's buried in View S on Page 5.

Have a very crude sketch of the rear view I think you're looking for around here somewhere. Will get it to you or post it here if I can find it - and it's readable.

Here's a more readable version of the one I found:

As the section is drawn perpendicular to the rails, the broken line was added to emphasize the slide top is lower at the slide's nose (by 0.0305").

Quote:

These based on the assumption the center of the 0.490" radius at the front

of the slide coincides with the center of the bushing/barrel bore.

This assumption was found to be incorrect.

View D on Page 4 of our blueprints shows the top front corner of the slide (before the flat for the front sight is milled) to be 0.485 - 0.005 inch above the CL of [-F-]. This locates the center of the 0.490R slide slide top 0.0075 below [-F-] for a mid-spec gun.

This, in turn, means the slide heights and thicknesses previously posted must be reduced by 0.0075 inch. Aaarrr-r-r-r-ggghhhh!

Will correct the drawings and re-post them.

Hope nobody made any slide-ruining decisions based on the erroneous values.

I just corrected the misteaks in it and added "Rev. 1" beneath the title. When you open the thread/pic again you may need to poke your Refresh button to get rid of it from your temporary internet files and display the new one. Here it is again just in case:

Ignore/Delete Post #32

The belated discovery of the true (I earnestly hope) location of the center of slide top's radius (see Post #47) means some of the calculations including the last one and the second pic in Post #32 are incorrect.

But, edit time has expired for Post #32, so just ignore it.

Better yet if somebody could delete it, please do so.

I'm a little uneasy about leaving erroneous data lying about in cyberspace.

It may be public domain, but I like to get permission to be ethical.

Thanks also for the correction and (re)drawing. "No slides were damaged (here at least) in the viewing of this drawing."

Quote:

What I need is the depth of the material from the OD of the slide to the

lug cut out.

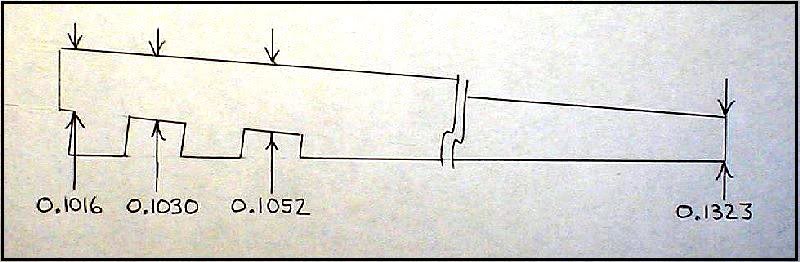

Before the drafting Crayolas are put back in their box, here's the pertinent thicknesses from the front of the ejection port to the slide nose:

There's no scale and the angles are exaggerated to show why the thicknesses increase a little from lug 1 to lug 3. The nose thickness is prior to any flat being cut for the front sight.

Do the .795 and the .0056 dimensions in this drawing come from the relocated centerline in post 48? I'm trying to understand why that's below the E reference point.

Quote:

Do the .795 and the .0056 dimensions in this drawing come from the

relocated centerline in post 48? I'm trying to understand why that's below the

E reference point.

The .795 is the mid-spec value (of .78 + .03) of the vertical extent of the lug cutter's cut, shown in Sections J-J and K-K. Relocation of the center of the .490 radius did not change this.

The relocated center for the top's .490 radius is 0.0075 below [F]. It ends up there because the slide nose is located .4875 (mid-spec value of .485 - .005 in View D, Page 4) above [F] so the center of the .490" radius is below [F] by their difference, or .0075".

The curve at the slide nose and the radius for the nose are shown as broken lines in the drawing. The .4875 dimension was not shown in the drawing.

Quote:

The .795 is the mid-spec value (of .78 + .03) of the vertical extent of the

lug cutter's cut, shown in Sections J-J and K-K. Relocation of the center of

the .490 radius did not change this.

Thank you, got lost for a minute, but you did originally say for a mid spec gun. I overlooked that. I need to read closer.

I almost always enter the mid-spec values in my drawings because the calculations are almost always done using them.

So, unless the tolerance given on the blueprint is stated as some single +/- value, the dimension numbers in my drawings differ from those in the blueprint by 1/2 the tolerance.