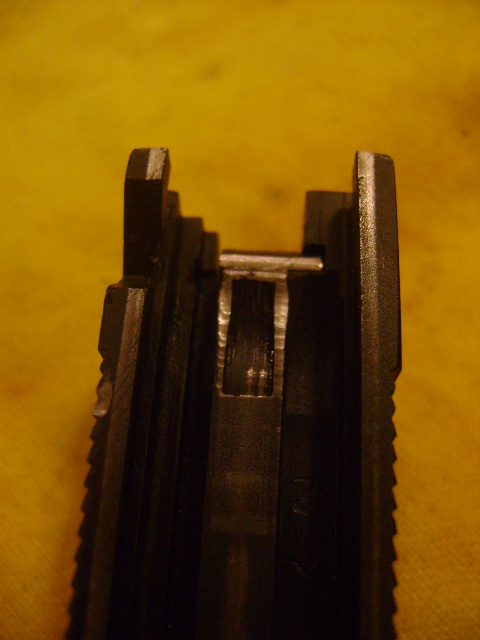

Looks like the slide on my officers sized pistol is showing wear from the hammer (around the disconnector relief). How much is too much? 630 rounds through this pistol, which is stock except for grips.

My old Lightweight SA full size shows essentially zero wear in this area, hence my question. I did a brief search on this site and didn't find anything about this potential issue...

The slide is also showing some wear around the slide stop notch...none of this is giving me a warm-fuzzy feeling.

Appears it may be a hardening issue, but not sure. What's the hammer look like?

Got a pic of the slide stop notch? May be the slide stop not getting all the way seated into the notch, and is peening a bit?

Don't know for sure how much is too much, but whatever it is IMHO you're getting real close to it!

Make sure the mainspring's not binding by manually pulling the hammer all the back slowly while listening and feeling for any sign of "catchiness".

Lock the slide back and see how far down from the disconnector rail you can move the hammer face.

Remove the recoil spring and move the slide back slowly. Listen for the "click" indicating the sear has engaged the hammer hooks and then see how much farther down the hammer moves as the slide is moved the rest of the way back.

Compare the contour of your hammer face with the blueprint in our Tech Issues section, accessed via the link "M1911 Full Blueprints". Pay particular attention to the slight radiusing toward the top of the hammer face.

A nice clear picture of the hammer showing its face contour might be helpful.

Looks to me like the firing pin stop is not long enough. The steel in that area of the slide is not very hard... it's not supposed to be cocking the hammer. I wouldn't shoot it anymore until you get that squared away.

I don't think the wear on the sides of the disconnector cut is caused by the slide cocking the hammer. The hammer is already cocked by the time it reaches that part of the slide (or, more correctly, by the time that part of the slide rides over the hammer). What I suspect is happening is that the hammer is being pushed beyond the normal cocked position upon initial impact with the firing pin stop, and then instead of riding the stop and slide it is "catching air" and then rebounding into the slide right at that point with some force.

In other words, the depression of the two sides of the disconnector cut isn't "wear" so much as peening.

That's what I think is happening, and I have a similar condition on a pistol (which I bought used, and it was that way when I bought it). Problem is, while I'm reasonably secure in the diagnosis of the problem, I haven't a clue how to correct it.

Quote:

Remove the recoil spring and move the slide back slowly. Listen for the

"click" indicating the sear has engaged the hammer hooks and then see how much

farther down the hammer moves as the slide is moved the rest of the way

back.

An easier way to do this is to cock the hammer first - instead of trying to cock the hammer by manually moving the slide back. Then move the slide back so the FPS touches the hammer. Then see how much farther down the hammer spur goes as the slide is moved fuly aftward.

What I'm thinking is that if the slide rotates the hammer too much farther than what's necessary to cock it, perhaps the rebounding hammer might gain too much momentum and impact the disconnector rail harder than usual. Maybe.

Might also be that the hammer spur could be getting forced into contact with the grip safety by the slide. But that's not too likely unless the gun has a beavertail grip safety with an incorrect hammer.

Perhaps even a seriously under-strength mainspring could contribute to hammer bounce.

That's all the zebras I can think of - for now!

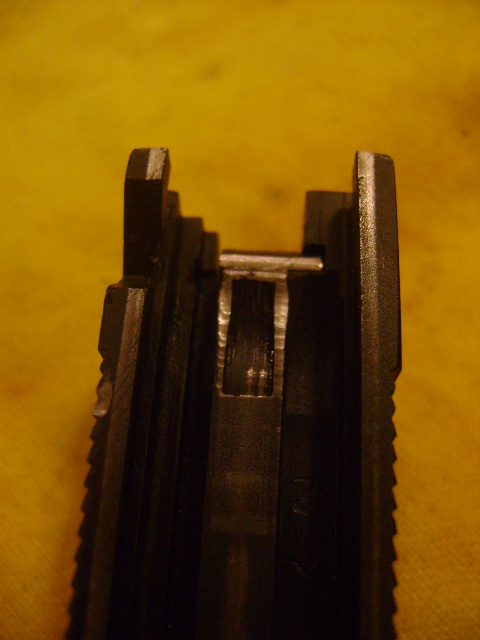

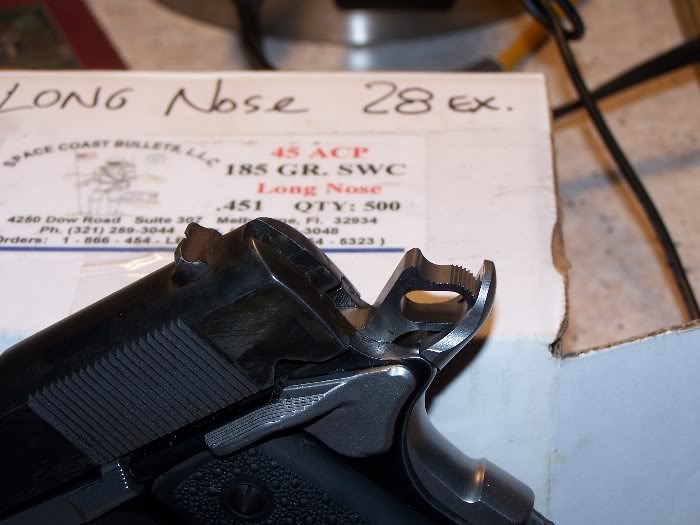

A couple pics. The measurements will take more time.

Wear like that is fairly common on Series 80 Colts which have one side of the rail beside the disconnector cut drilled out for the firing pin obstruction.

This is severe wear for an intact rail and that little shooting.

Top of the hammer which is making the wear contact doesn't look bad.

Does the hammer have a little overcock - some travel back out of contact with the bottom of the slide?

If I lock the slide back and push the hammer down as far as I can (beavertail safety has to be pressed down, too), there is about a .060" gap between the hammer and the slide.

Also not visible in the picture are witness marks on the beavertail safety from where the hammer is hitting it. Not sure if that is normal or not.

If you look at the first photo in the first post, the two narrow rails flanking the disconnector cut are visibly deformed -- mushroomed. This is not "wear," this is peening. The hammer is whacking the slide and hammering that spot, which is vulnerable because there is so little material there.

I'm pretty sure that's what's happening. I just don't know why, or how to correct it. Where's 1911Tuner when you need him?

I can get at least .060 or more (est. not measured) clearance between the hammer face and the slide by pulling the hammer down to contact with the grip safety WITHOUT having to depress the grip safety. At no time do I have any contact betwen the grip safety and the hammer under normal conditions. Id think something here is suspect? I also noticed that the C&S hammer has been flattened at the top where the contact is happening.

Quote:

If I lock the slide back and push the hammer down as far as I can

(beavertail safety has to be pressed down, too), there is about a .060" gap

between the hammer and the slide.

That's good. It means the slide is not contact-driving the hammer spur into the grip safety.

Quote:

Also not visible in the picture are witness marks on the beavertail safety

from where the hammer is hitting it. Not sure if that is normal or not.

I'm not sure either - got no background in that kind of grip safety.

I do, however, have a fuzzy recollection of someone posting long ago that this may be normal because when the hammer's being cocked by the slide, the inertia of the hammer can move it out of contact with the slide and bump the safety.

What weight mainspring is in the gun?

I think Hawkmoon is right that the hammer has peened the edges of the notch.

I think you can prevent it by taking metal from the top of the hammer.

As the slide comes back it drives the hammer down enough to do as you've done by hand and then the hammer hits on rebound, on it's way back to full cock position.

Hammer too tall.

The mainspring is too light. The damage is coming from the hammer impacting the slide after rebounding off the grip safety. If the hammer is correctly sprung... which is a little tricky in these gun with abbreviated mainspring housings and short mainsprings... it will impact behind the disconnector slot... and usually at the junction of the rail and the firing pin stop instead of on the thin areas at the slot.

Here's a photo of the correct rebound/impact point on an old WW2 Ithaca USGI slide.

Modern, hardened slides don't show this kind of peening as quickly as the old, softer slides did... unless the hammer hits the thin sections of the rail adjacent to the disconnect reset slot.

Picture too big to show here. Try this link. Enlarge for detail... bottom RH corner.

I don't know the mainspring rate... everything is "stock" on the pistol thus far. I haven't called the manufacturer yet, but I intend to call them and send it back there for service... the unit is "under warranty". It will be interesting to see what happens.

Any thoughts on the long-term implications of an issue like this, if it is not addressed?

Thanks again for everyone's input so far...

Hawk asked me about a similar gun over the weekend. One key in the post is Officers like, the sides of the frame show a lower quality gun so there may be a heat treat issue. The sides of the disconector cut out are thin by Govt model standards also.

I concur with Tuner that the main spring is on the soft side, the slide cocks the hammer and the hammer comes back down to rest as the slide moves by. unfortunatly it happens to be right in the cut out area.

As Hawk mentioned this is even worse on the Ser 80 guns. (this and other things) having the plunger effectivly remove one side of the cut out and the hammer well, hammering the cut out.

We have and do weld these up and recut them should the need arise.

D&L sports is coming out with a hammer where he is asking us to match the angle of the flat so the impact area of the hammer is larger and not a small radius. This and a full power main spring (which sounds counter intuitive ) should keep your guns running. This also says that you are not alone, others are having problems also.

When they are "Gone" the slide actually stops on forward motion by the hammer Jamming into the cut out. Good you found it early.

geo

www.egw-guns.com

Quote:

D&L sports is coming out with a hammer where he is asking us to match the

angle of the flat so the impact area of the hammer is larger and not a small

radius.

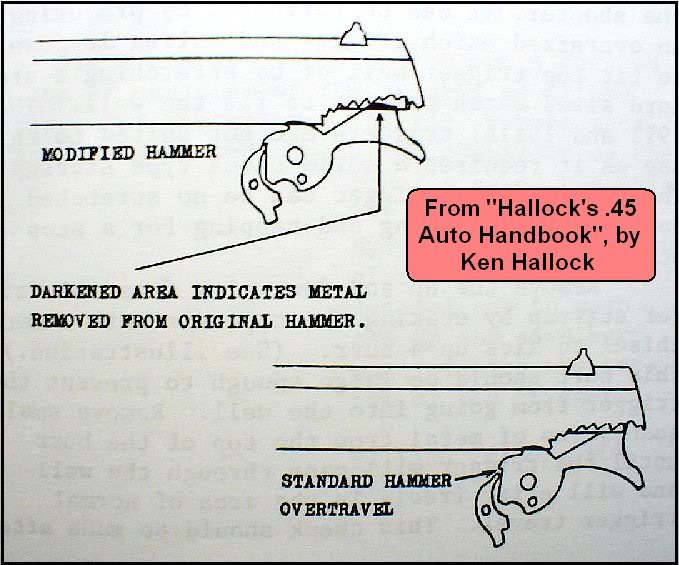

Hallock describes a way to keep the slide from overcocking the hammer too much by modifying the upper portion of the hammer face. This from page 148 of his book:

Doing this with a larger radius between the larger lower and smaller upper portions of the hammer face flats might reduce the severity of the peening on Dsoine's slide. A new mainspring should reduce it even further.

Dsoine: Just out of curiosity, who made (or should I say, tried to make) this slide?

Quote:

Hallock describes a way to keep the slide from overcocking the hammer too

much by modifying the upper portion of the hammer face.

Which shows that poor ol' Ken didn't understand that the hammer doesn't cock by smoothly riding the slide rail. It's slammed violently back, and bounces off the grip safety tang...and back onto the center rail. As the slide goes to battery, it drops the hammer back to the sear. All his modification would accomplish is to reduce the distance of that drop.

Why does the hammer need to be able to hit the slide on rebound.

I don't have the Hallock book, or even know of it, but it seems to me that the material removed, rather than limiting the overcocking has simply limited the reach of the hammer when it rebounds.

The modification doesn't limit the reach of the hammer on rebound, all it does is spread the impact out over a larger area.

I don't think the question is "Why does the hammer need to be able to hit the slide on rebound." The point is, that's what happens, because the slide is still in the way when the hammer rebounds. The trick is to either adjust the timing so the hammer doesn't strike the slide at the point where it's hitting those two (or one) skinny little rails, or else flatten out the hammer face as suggested in the hope of spreading the impact over a larger surface area.

Quote:

Why does the hammer need to be able to hit the slide on rebound.

Because if it fell straight back to the sear, it wouldn't take very long to shear the hooks and beat the sear crown.

Quote:

it seems to me that the material removed, rather than limiting the

overcocking has simply limited the reach of the hammer when it rebounds.

Hallock's modification reduces the distance that the hammer drops as the slide goes to battery, limiting impact between the hammer hooks and the sear. It's done to prevent hinkin' up those finely-honed trigger jobs.

Quote:

Hallock describes a way to keep the slide from overcocking the hammer too

much...

These are my words - not Hallock's - and I got them wrong. Hallock makes no mention of the hammer cocking process, but only the benefit of the hammer modification for the sear and hammer hooks as the slide returns to battery. My bad.

Sorry K.H., wherever you might be, for putting the wrong words in your mouth.

I think Ken's passed on. Can't remember where I heard it... or when.

As I continue to think about this... other things that may or may not be relevant with this pistol:

The pistol was returned under warranty for a new firing pin stop - extractor clocking. The issue was fixed and I've had no FTRB since.

I just noticed the front sight is loose.

This pistol has always thrown the spent casings forward (and to the right). FWIW. Casings are dented, too.

I add these things because "it's a system", right?

Gentlemen, I am volunteering to be the official Guinea pig on this one. I knew my Para-Ordnance P12.45 had the same problem (not as pronounced or as far progressed) but until this thread came along I hadn't given much consideration to how it might be repaired. I just set the pistol aside and stopped shooting it.

Now that George at EGW has informed us that they have a repair procedure for this (for which I nearly broke my arm patting myself on the back, because before I saw George's post this morning I was discussing the feasibility of exactly that procedure with a friend last night), I will be sending him my slide to undergo the repair.

Quote:

pistol has always thrown the spent casings forward (and to the right).

FWIW. Casings are dented, too.

The extractor is probably causing it due to the length of the hook... too deep in the groove... and not releasing the case freely. The case rolls backward and bangs into the rear corner of the port that's formed by the curved top and the flat side. That corner is what is causing that dent, and that's the reason for the rollout notch... or "Port Flare" as some have come to call it.

Then, the extractor releases it just as the slide starts forward... and it bats the brass forward.

If your pistol has an extended ejector, it increases the tendency because the case rim gets into a bind between the extractor claw and the tip of the ejector. There could also be a little too much length of the extractor's nose.

I know that little things like this tend to make you question the functional reliability of the pistol... but everything that you've mentioned is a fairly easy fix, assuming that the fixer knows what causes it and what to look for. Oddly enough... many warranty station armorers don't.

Run a Ciener Kit for awhile on a Commander and see how the hammer beats the heck out of the rail at the notch.

I run a kit on 3 different frames and they all do it.

Is there a way to test where the hammer is hitting on a new or newly built pistol? Can a pistol be tested ahead of time to detect and fix an issue like this before it becomes a problem?

Never tried this, but it might work:

* Lock the slide back, degrease the disconnector rail up to where the hammer's resting and coat the rail with sight black or a sharpie marker

* Load 1 round in a magazine, insert magazine, hold down the hammer (so it won't disturb the coating just applied to the rail) and with the hammer held down chamber that one round from slide lock using the slide stop.

* Release the hammer onto the sear

* Fire the gun, then with the slide locked back after this last (only) round you'll hopefully be able to see where the hammer made first contact - the aftmost disturbance of the sight black/sharpie you put on the rail.

If you try this, let us know whether it works or not.

99 days turnaround time - the manufacturer sent me a new pistol.

After I send some rounds downrange I'm going to try measuring the impact point as discussed above. I intend to watch this closely over time - I already have my closeup pics of the area.