Series 70 from the 70s that's been shot a lot.

Bottom of slide dragging on top of dust cover, dust cover scratching outside of recoil plug area. I know the fit isn't particularly important, but the drag and the rattle bug me. From looking at it and reading around some, it looks like the only thing to do is weld up and refit the front of the rails. The slide is already smaller at the bottom than the top, so I don't want to squeeze it, and I can't peen the frame rails down to tighten, because then the slide will just sit lower... right?

Also, what do you think made the scratches across the top of the frame rails? Almost looks like someone took a chisel to it in hopes the burrs would tighten up the fit, but they look like there's bluing in them, so I guess they've been there since new? Sorry, pic doesn't show them very well.

If the bottoms of the slide rails continue to rub the dust cover when the slide is pushed down and kept down in contact with the frame, the only methods I know of to avoid the rubbing are:

* File down the dust cover

* Have accu-rails installed

* New slide

* New frame

If the slide does not rub the dust cover when the slide is held down and kept down in contact with the frame, peening down the frame rails will keep the slide down on the frame and thus eliminate the rubbing - without filing down the the dust cover.

Decided barrel lockup was more important than dust cover top rub and peened 'em down, a little more on one side than the other since the slide was slightly offset and rubbing one side of the oustide of the spring plug bore on the inside of the dust cover.

It's nice 'n tight now, thanks.

Quote:

...a little more on one side than the other since the slide was slightly

offset and rubbing one side of the oustide of the spring plug bore on the

inside of the dust cover

Barrel rifling twists the frame into the hand of a right-handed shooter... this twist (torque) also contributes to the left rail taking more of the downward load on the frame... thus wearing differently than the right rail...

No biggie! Someone good with a 2 oz. ball peen and a set of railing bars. Run the rails down and out.

Quote:

Barrel rifling twists the frame into the hand of a right-handed shooter

I'm not so sure about that. A few years ago Log Man posted results of a test in which two people shot 1911's with the usual left-hand twist barrel and also a right-hand twist barrel and shot them left- and right-handed. As I recall, changing barrel twist didn't change the way the gun twisted in the same hand but changing hands with the same twist gun did change the way the gun twisted. The conclusion was that barrel twist had no perceivable affect on which way the gun torqued in the hand - the difference was due to the structure of the human arm.

Then there's this...

...and if the barrel gets torqued CW so does the gun - and CW is out of the hand of a right-handed shooter. This also matches my sensations on the rare occasions when I've felt it as a right-handed shooter with a left hand twist barrel.

[Edit: rotational notations are as viewed looking forward]

The pictures do not reveal a worn out pistol that I can see. Usually a really worn out pistol will have a lot of wear on the rails and the bottom of the slide and peening on the VIS. I think this gun can be easily tightened up by a good Smith. The dust cover rub is common on older Colts. The only problem ran into on tightening up some of the older pistols is the the bringing down the slide when it is tightened up. The slide aggregate is pulled down with the rails and the Bl lugs are pulled down as a result.

This can cause the lugs to be much thinner between the link pin and lug surface. I would pull it down and as I went, would check the distance and lug fit not to be less than 78 or so thousands. The slide can be relieved slightly in the forward section of the slide bottom and the dust cover just squared up level to alleviate your problem of the rubbing. Just keep a good recoil spring in the gun and make sure the VIS has been relieved with a Bow tie cut.

Quote:

the difference was due to the structure of the human arm.

Nice pictures, but think you got lost with the rotational torque. The torque whether felt or not comes from the bullets inertial force of not rotating, but the barrel has other ideas and forces it to rotate. Therefore the barrel is rotated CCW. If for instance you turn a bolt into a tight nut, the nut wants to turn the same direction as the bolt.

Quote:

Nice pictures, but think you got lost with the rotational torque.

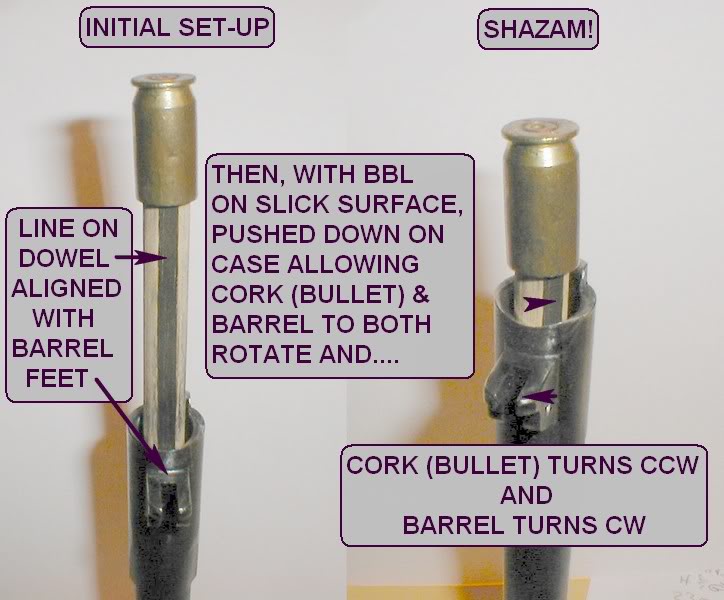

So in a barrel with a left-twist such as this one...

...which will cause the bullet to rotate CCW, the bullet (the driving force in all this) will cause the barrel to also rotate CCW? What happens to the business of equal and opposite reactions? Is that principle held in abeyance? If so, what made the barrel in my little experiment rotate CW when the bullet rotated CCW? Did the bullet decide to reverse rotation on those rare (two, as I recall) occasions when it felt as if the gun nearly rotated itself out of my grip (rotated CW) when fired?

I think your "turning a bolt in a tight nut" analogy fails because the bolt is being turned (and not simply pushed) by a force external to the bolt-nut system. When I pushed on the case placed over the dowel I didn't turn anything. The left-hand twist rifling in the barrel turned it.

You're right Niemi, the barrel's felt torque, if felt, would be CW. I've just noticed when shooting two 1911s one in left and right hand, the top of each tend to rotate towards each other.

Ha! yeah, I noticed that too... I was comparing O/S FPS vs. standard, shot mine with the O/S FPS, 18.5# in my right (strong) hand, no roll. My buddies standard FPS, 16# left hand, came over and smashed my left thumb against the hammer or something on mine. Ouch, that was dumb... I switched guns/hands and held them farther apart, the O/S FPS does seem to make a little difference.

I think the gun takes the path of least resistance = thumb...

Quote:

I think the gun takes the path of least resistance = thumb...

And that may well be the answer.

Maybe it's not the twist caused by the bullet going down the barrel but the twist caused by the thumb (and which side of the gun the thumb is on) when the gun goes straight back in the hand.

I recall somebody once posted the calculated value of the rotation of a 1911 caused by the bullet. It was quite small. Probably unfeelable. (Unfeelable? )

All dustcovers on standard 1911s should have relief of the top of the dustcover from the rails to the front of the dustcover, .5 to 1.0mm at the end, to compensate for the flex in the pistol under function... so... Niemi in #2 was right:

"File down the dust cover" To prevent cracking in the future.

Even the oldest Ordnance frame blueprint I've got (last changed in 1944) shows the top of the dust cover in line with the bottom of the way/groove - with no relieving taper to avoid contact with the slide. Maybe it was purposely made that way to slightly reduce the vertical slop of the slide on the frame?

The taper that I suggested has nothing to do with Ordnance drawing specs. It comes from high speed photography that was done by the military to see the 1911 under function. I believe the study was done at Quantico. In the film it is noticable under slow motion the flexing and torquing of the slide and the frame in returning to battery. I viewed the film at John Nowlin Sr.'s pistolsmithing course in Claremore, Oklahoma before he past away.

The custom smiths I know always do a relief of some kind to prevent dust cover battering or cracking under use, especially in competition or high round count pistols. If not a taper a lowering of the top of the dust cover if you want the line to look uniform without a taper. The looseness in the front of the rails can come from the torque wearing the frame as you have been discussing. In custom builds with frame and slide fit from over size frames and slides the wear is minimized but will still occur in high round count pistols in front of the rails.

Accu-railing will eliminate most of this if not all of it due to the 100% frame to slide fit initially, and as the accu-rails wear refitting with larger rails eliminates this movement from wear if it occurs.

Quote:

The taper that I suggested has nothing to do with Ordnance drawing

specs.

I know. Just wanted to make make sure folks didn't get the idea that a taper was specified by Army Ordnance - then get upset because their gun didn't have a taper there.

There are some interesting high speed videos of the 1911 from Virgil Tripp and http://www.kurzzeit.com/ , but found nothing about the military video you mentioned on YouTube - except a throbbing headache. Maybe it's there someplace.

I don't know if everything can be found on U-Tube. However, when I was at his Pistolsmithing course there were several people from various agencies that brought these films. We did not ask too many questions about their job description. Also, John gave many "closed courses" to various government agencies which came first and no matter how I tried to reason with him to get into the courses, short of getting on my knees and begging, it wasn't going to happen.

Unfortunately he passed away before he could organize a more advanced course for students that wanted to really get into the esoteric techniques of building high end 1911s. More on the line of upping your skills for future APG membership if the student desired to go that direction. As far as I know, his son John Jr., also an APG member and highly skilled 1911'smith is not giving anymore 1911 courses.