I've an old habit of pressing down an the barrel hood when handling a new gun. Just dawned on me (this tells you I'm not the sharpest tool in the shed) that I don't even know why I do this... does this procedure tell you anything useful? I'd guess it might tell you the lower lugs are fit snug against the slide stop? Then again... swapping links could give a false sense of snugness. If the barrel moves down a bit with thumb pressure, while in battery, does that mean anything... or is it no big deal? It it indicative of anything at all?

It does indicate that there is some clearance between the barrel's bottom lugs and the slide stop pin. This lack of contact is common in mass produced 1911's and most of those actually lock up on the link, so the push down is the sum of clearances between the holes in the link and their respective pins.

The sum of those clearances Stans referred to amounts to 0.0100 +0.0050/- 0.0045 inch in a Government Model M1911A1 when measured along the axis of the link. But after compensating for the link's tilt in battery and measuring at the front of the ejection port, the total play at that location would be 0.0086 +0.0043/-0.0039 inch.

And as Stans mentioned, the average 1911 with a non-fitted barrel will stand on the link when in battery - with the link holding the barrel lugs off the slide stop pin by the amount shown here:

PICTURE 404

But the "pushing down on the hood" test can be misleading if the gun is put into battery slowly. That's because the link will be in light compression and when you push down, the only slop being removed is that between the SS pin and its holes in the frame. To avoid this, invert the gun when putting it into battery to get the link into light tension. Better yet, put the gun in battery and then force the aft end of the barrel up into the slide as far as it will go by using a length of wooden dowel down the bore.

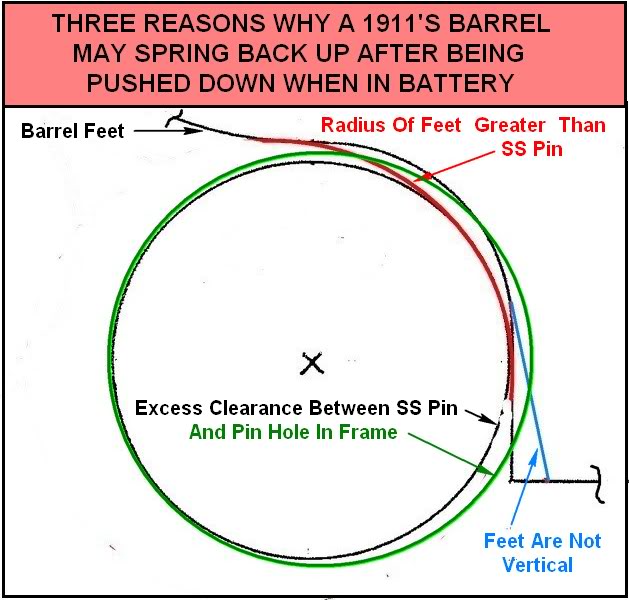

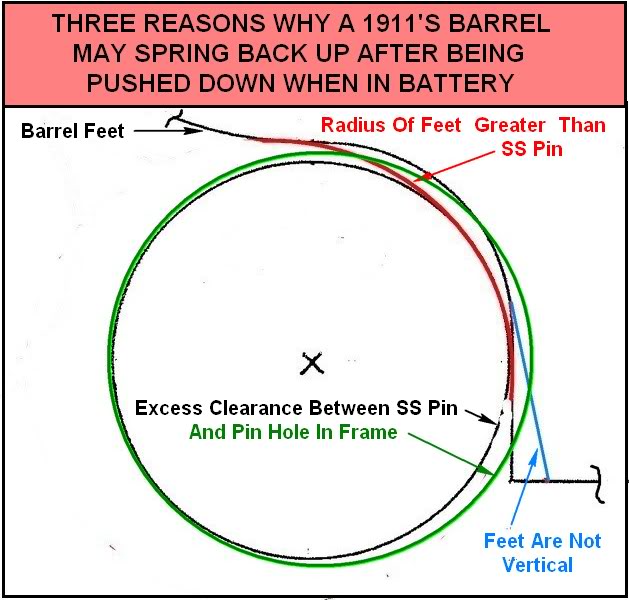

Another thing to look for after pushing down on the barrel is what the barrel does after the downward pressure is released. If it stays down - good. If it comes back up - not good and indicates either the barrel is being sprung up by the bushing or perhaps one of these problems:

...related question...

Is a new slide stop (slightly oversize vs previous) supposed to tighten the apparent slide/frame fit? I ask because now that the new stop is in place, there is noticeably less play between the slide/frame rails. My concern is that the barrel is riding a bit too high, taking up some slack in the slide/frame rails, when it should not be doing that.

You new slide stop pin is probably pushing the barrel and link up slightly and putting the upper locking lugs of the barrel in contact with the lug engagement surfaces in the slide, thus creating a slight upward pressure on the slide. As long as the barrel unlocks properly, there is no dragging or hanging up between the slide and barrel and no link down issues, it's probably just fine.

And what Stans means by this...

Quote:

As long as the barrel unlocks properly, there is no dragging or hanging up

between the slide and barrel and no link down issues, it's probably just

fine.

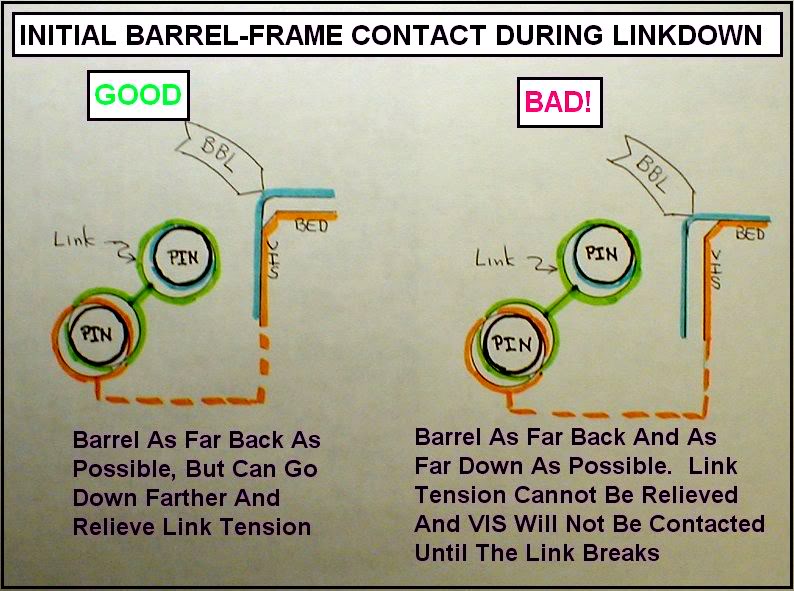

...is that the barrel must totally disengage from the slide prior to VIS contact and that the barrel make first contact with the VIS and then the barrel bed - not the bed before the VIS. Instructions for checking these things (linkdown timing) can be found in our Tech Issues section via a link to Schuemann Barrels.

Thank you. Will check timing tomorrow morning and report back!

Looks like the timing checks out, range test this afternoon.

Question, I can't seem to wrap my head around how a slide stop pin with a larger diameter will adversely affect timing / link-down? Not that I have any doubt that it could, just that my brain isn't fast enough (particularly this early in the morning) to visualize it!

If the barrel and link, with an undersized pin, are tightly fitted to the slide at lock up and have just enough clearance to allow the lugs to fully disengage during link down, the larger diameter pin can push the barrel and link up just high enough to remove that necessary clearance.

Remember, the pin is undersized and will fit loosely in the receiver, the barrel and link can push the pin to the lower edge of the holes in the receiver. The larger diameter pin can effectively move the link and barrel higher into the slide.

In addition to the reduction (granted, it would be quite small) in barrel- to-slide clearance that Stans mentioned, if the clearance between the barrel and bed is very small when the lugs hit the VIS, a slightly larger diameter SS pin could cause the barrel to hit the bed before the VIS. And if the barrel hits the bed before hitting the VIS, the tension in the link increases and cannot be relieved until either the link stretches enough to allow the lugs to hit the VIS or the link breaks.