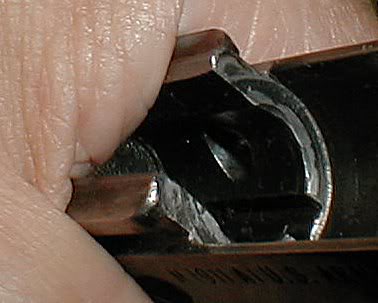

I recently purchased a new Colt 1991 NRM and after 150 rounds I have this. The guide rod has displaced metal on the frame. Is this normal?

Yes, this is normal. Your contact surface marks look uniform. These marks are from the spring guide rod which is hit by the slide's dust cover while the slide is stopped by the frame.

Or maybe the spring is stacking hitting the frame harder

There is actually an indention where the guide rod has impacted the frame. I haven't noticed this on any other 1911's I have owned in the past. In fact, I have a used 1991 ORM that does not have this indention.

"Plug"?

Are you referring to the marks made by the guide rod FLANGE?

Quote:

Are you referring to the marks made by the guide rod FLANGE?

Yes, I meant guide rod not plug.

Confirm or deny the possibility of your recoil spring getting compressed to its solid length by reading this thread: http://forum.m1911.org/showthread.php?t=94656

If the two lower "ears" on the flange of your barrel bushing are bent forward a little bit, that's a sure sign the recoil spring is being compressed to its solid length.

I want to remind the group that the force imposed on the frame to stop the slide is the same whether the force goes through a spring gone solid or a dust cover hitting the flange... the back of the guide rod doesn't care what hit the front of the flange... equal forces...

A quick spring stack check will put everyone's minds a ease...

A picture of the the back of the guide rod would be nice too...

Plus the owner has a lifetime service plan that would fix any problem like a soft frame.

I don't think it's spring stacking as the dustcover is definitely hitting the guide rod flange. If it has to go back, it will be my last new Colt as this will be the second one that has had a major problem. The first was an XSE Commander where the slide froze to the rear on the third shot. After seperating the slide and frame with a great deal of force I found the front of the frame rails severely damaged where the slide and frame had locked together.

Quote:

If it has to go back, it will be my last new Colt as this will be the

second one that has had a major problem.

Major problem?

With all due respect, I don't see this as even a minor problem. Is there any actual damage to either the frame or the guide rod flange?

After 150 rounds, the guide rod has made an indention in the frame. How will that affect the longevity of the frame? I don't know the answer to that question as I haven't seen this on any of the 1911's I have owned before. I had a Kimber with 7000 rounds on it that did not have this kind of wear. I have a 1991 ORM now that does not have this kind of wear. If it's normal, so be it, but nobody has answered the question definitively either way and I don't want to shoot the gun again until I find out.

Unless my eyes are playing tricks on me, I think the metal displacement Bradd_D is referring to is what the arrow's pointing at here:

If this apparent displacement is caused by the aft surface of the guide rod flange/collar not being flat, then the problem may just be with the guide rod. But if the guide rod flange/collar is nice & flat (as a good guide rod's should be), then this displacement seems way too much for after only 150 rounds. My calibrated Mk57/Mod2 eyeball tells me the displacement is about 0.005".

There's also a shiny ~1/2" longitudinal area below the arrowhead that shows contact with the fillet at the top of the barrel's lower lugs. The fit should be checked to make sure it's not keeping the barrel from falling all the way to the bed at linkdown.

You are correct on both counts. I will try to get some pics of the guide rod flange posted.

By "both", do you mean the metal displacement and the flange, or that (as one) plus the barrel not falling all the way down to the bed?

I stand behind my original opinion that:

"Yes, this is normal. Your contact surface marks look uniform"

I recommend that you shoot a couple thousand more rounds and report back...

If it helps set the OP then here is a picture of a custom build made from the best frame and slide combo available... it has the same frame contact area impact after about 600 rounds... does it matter... NO...

egumpher

egumpher

17th July 2011

Here is another example... this is a Springfield TRP Operator with about 4000 rounds...

Please notice how well beaten the frame is... still no problem... it is just now starting to "seat in".

I think a photo or two of the rear surface of the guide rod flange would be informative. It should be flat. If there's a small burr on the edge, just take a flat jeweler's file and smooth it off. End of "problem."

The indentation depth at the top of the photo is about 0.010" on this Remington Rand slide, acquired in about 1963. I've no idea of its round count up to then, but it's fired maybe 20,000 rounds since then and all mid range target ammunition.

Here's a

Thanks for the help, guys. Like I said, if it's normal wear I'll forget

about it. Here's the guide rod flange.

With all due respect to everyone, let me state the obvious then perhaps we

can progress to a solution. The marks on all of the frames pictured are a

result of metal to metal contact. In some cases rather hard contact, in others

less so.

Is it possible the recoil spring is too light for the loads being fired?

Would some type of cushion between the slide and recoil spring guide plate

mitigate some of the impact?

No solution is needed, as there is no problem. Others have posted photos of

their pistols showing similar marks. I looked at my Colt 1991 Combat Commander

and it, too, has similar marks. Of course it is caused by two metal parts

being in contact, but that's the way it was designed. It's just scraping the

finish, which is to be expected.

Is there just finish wear on your pistols or is there an indention in the

shape of the guide rod flange? My question is whether or not the indention is

normal and acceptable.

I don't feel any indentation if I run my thumbnail over the area where the

finish has been removed, but it can be detected if I drag the point of a

scribe over it.

Quote:

That's what I've got.

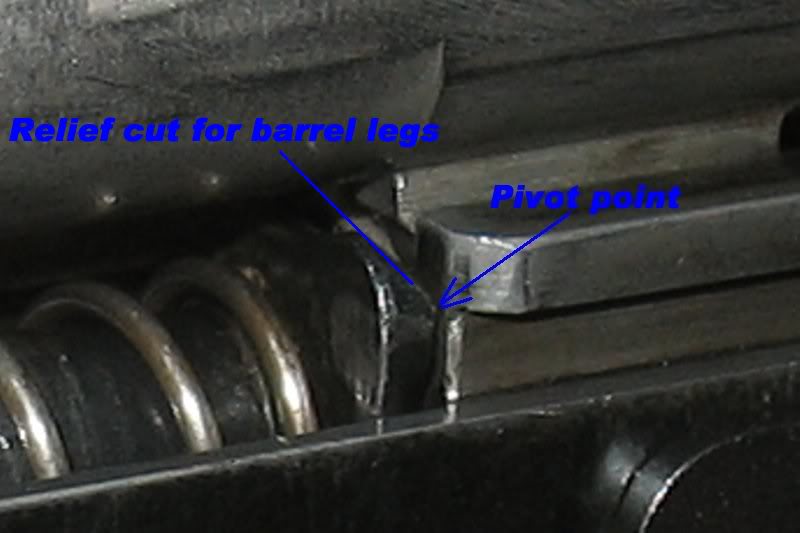

Here is one of my previous photos where I circled indentations on the frame

face. These are pivot points during recoil.

IMHO these are pivot point are normal and expected.

We may want to start a new thread to compare different guide rod designs and

their impact (no pun intended) on the frame...

IMHO, the indentations shown in you previous photo are NOT normal and

expected.

Not sure what you mean by "pivot point", but in my opinion one reason for the

really deep indentations on your frame's impact abutment after only 600 rounds

is because the flange/collar of your guide rod does not extend up far enough.

Here's a photo of the same frame in the top photo of Post #20 with its guide

rod installed:

Note how far up the "ears" extend, spreading the impact of the RSPT over a

larger area. Also note that RSPT contact is almost entirely at the top, but

whether that's be design or not I don't know. This guide rod has been in this

gun since I got it in 1964 and has seen at least 20,000 rounds fired - with no

shock buffer. I'm guessing the flange/collar of your guide rod doesn't quite

reach the top of the frame grooves because it's not made to Ordnance specs.

Quote:

I'd like to know how you conclude that the top corners are pivot points. The

word "pivot" implies the fulcrum around which something rotates, but there is

no rotation of the recoil spring guide flange. The flange is in intimate

contact with the frame abutment surface at all times, and is maintained in

intimate contact by the pressure of the recoil spring. As the slide moves

back, the contact pressure increases gradually as the spring compresses, then

spikes momentarily at the instant of slide contact. Irrespective of pressure,

contact remains intimate and uniform throughout the cycle.

What might cause the two upper ears to exert significantly more pressure at

impact (which would have to be the case to create indentations such as in your

photos) could be that either the guide rod flange is not uniform in thickness,

or the rear (impact) surface of the slide spring tunnel and the frame abutment

surface are not machined properly to be parallel.

Here are two Colts. One is a 1991A1 LCM produced between 1995 and 1997. The

other is the recent production 1991A1 mentioned previously in this thread.

Quote:

What is this photo supposed to show us?

It was in reference to niemi24s's post showing the guide rod flange ears.

And the flange/collar shown in my Post #28 has significantly higher "ears"

than do either of those in Bradd_D's Post #30. Gosh - maybe mine's the one

that's out of spec! Will check it against the blueprints and get back later.

I hope I can redeem myself after the "pivot" disaster...

What I was referring to in my picture is the pivot point created when there

is a relief cut made to the back of the guide rod flange to allow clearance

for the barrel legs/link like shown in this picture (an STI part is shown and

I believe the relief cut originated with Commander size pistols):

My pistol build had a slight interference between the barrel legs and guide

rod flange so I made a relief cut on the back of the flange.

Previous interference spot and relief cut (pivot point):

This relief cut together with my Caspian slide dust cover:

Which made these contact point on the guide rod:

All together made these pivot marks:

That are very similar to the pivot marks on my Colts Lightweight

Commander... the frame was refinished so the mark is faint...

Thus different style recoil spring guide rods make different frame marks...

I still think Brad's pistol is OK...

Here is another picture of a 1911 with about 5000 full power rounds down

range that shows the frame impact area:

She is pretty beat up but still a top shooter...

I also believe that a full length guide rod will help eliminate some of this

peening.

The first, third and fourth photos in your Post #34 show that the aft, upper

surfaces of the flange's ears were unnecessarily tapered when beveling the

central boss to clear the barrel lugs. All that was necessary was the bevel on

the central boss. Carrying that bevel over laterally to include the ears (and

tapering their tops) was not necessary and did nothing but reduce the contact

surface area of the aft surface of the flange. And that reduction seems (to me

at least) to have unnecessarily increased the metal displacement on the

frame's vertical impact abutment.

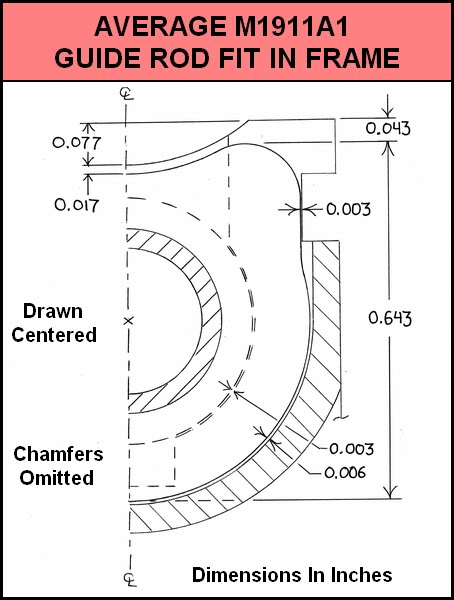

After a little time with the blueprint, I found the average flange will be

0.643" from the tops of the ears to the bottom of the flange. The one in my

photo of Post #28 measures 0.012" more at 0.655", but I don't know yet whether

that is out of spec.

I mimicked my Colt Lightweight Commander guide rod:

When I made that cut that extended into the ears...

I'm not entirely happy with the set-up and I am considering a one piece FLGR if I can find one in blue. The bevel cut is prone to rocking with the high contact pads that my Caspian slide has......just another project...

The VIS looks pretty rough, too. Soft frame maybe?

Seems odd that Colt, of all people, would make a guide rod like that. It's

easy to see why the shorter 1911 may need the the boss (for lack of a better

term) beveled, but carrying it outward into the ears doesn't make sense. Of

course, it's probably easier to just buzz it off all the way across than to

just do the central part.

And easier = less expensive = big bonus for some corporate bean counter.

Bottom line, bottom line...

Quote:

Does your pistol shoot, or does it jam? I'm seeing a lot of complaints, but

none that seem to say the pistol doesn't work.

I think you're just looking for things to complain about. This discussion

went on for three screens about the guide rod and abutment, then as soon as it

became obvious that your "problem" isn't a problem .. TA DA! Right on

schedule, up pops another "problem."

Just shoot it. If it breaks, send it back and Colt will fix it.

It's an issue of longevity not function. If the frame abutment and VIS are

both getting beat up this early in the game, then that could be indicative of

a problem. Since I don't have your vast experience with the platform, I have

to ask questions. Perhaps you could do something constructive like post

pictures of the wear on your pistols.

Here's what the Ordnance blueprints for the guide rod and frame look like

when put together as a sectional view just forward of the guide rod's

flange/collar, looking aft.

Well, Colt sent me a shipping label for the pistol so I'll let them take a

look at it. I'm going to go ahead and get a little work done, too.

I thought I would post an update for those who are interested. When I

shipped the pistol back to Colt I had about 350 rounds on the gun. The bowtie

was flattened to the point that the legs of the lower lug began making contact

with the circular area below the VIS. There was also displaced metal at the

top and bottom of the bowtie. When I received my pistol back from Colt

everything looked the same except they had ground the bottom of the legs of

the lower lug back so they wouldn't make contact with the area below the VIS.

I appreciate everyone that contributed and at least tried to answer my

questions.

...and it looks lots better to me than Bradd_D's. All it has is contact marks

with zero metal displacement. I dunno. You've seen a lot more 1911's than I

have, so I'l defer to your judgement.

...and it looks lots better to me than Bradd_D's. All it has is contact marks

with zero metal displacement. I dunno. You've seen a lot more 1911's than I

have, so I'l defer to your judgement.

Bradd_D

18th July 2011

Xventurashooter

18th July 2011

Hawkmoon

18th July 2011

Bradd_D

18th July 2011

Hawkmoon

18th July 2011

Bradd_D

18th July 2011

I don't feel any indentation if I run my thumbnail over the area where the

finish has been removed, but it can be detected if I drag the point of a

scribe over it.

egumpher

19th July 2011

niemi24s

19th July 2011

Hawkmoon

19th July 2011

Here is one of my previous photos where I circled indentations on the frame

face. These are pivot points during recoil.

Bradd_D

19th July 2011

Hawkmoon

19th July 2011

Here are two Colts.

Bradd_D

19th July 2011

niemi24s

19th July 2011

egumpher

19th July 2011

egumpher

19th July 2011

niemi24s

19th July 2011

egumpher

19th July 2011

Bradd_D

19th July 2011

niemi24s

19th July 2011

Greywolf

19th July 2011

The VIS looks pretty rough, too. Soft frame maybe?

Bradd_D

19th July 2011

niemi24s

20th July 2011

Bradd_D

21st July 2011

Bradd_D

12th September 2011

Return to 1911 Archive