What I am after is how to fit a match slide to and oversize frame and how to also fit a supported match barrel to the frame (barrel is already fitted to the slide)

The barrel and slide combo I have came off a friend's race gun (STI .38 Super 5") gunsmith fitted and as new.

I want to fit it to an uncut, new oversize STI/SVI frame.

The slide (no barrel) wont even look at going on the rails.

Where do I start?

I don't want to mess up a new frame.

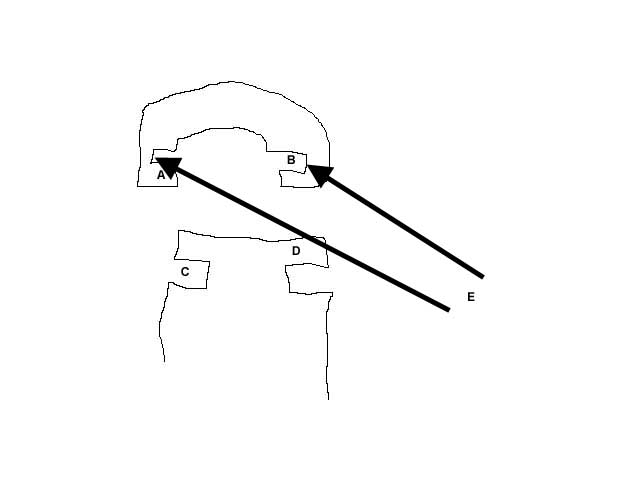

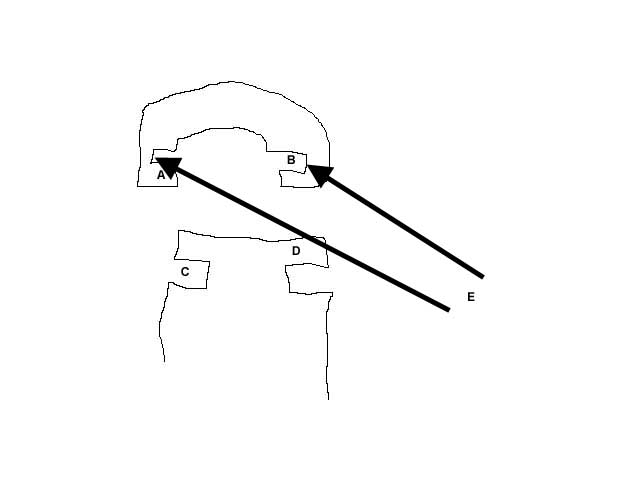

There is not any links that I am aware of but you are in luck cause I have fit a few oversize frame/slide combos. Last time I fit one up I had to remove metal from the top of the frame, the sides of the rails on both sides of the frame and the bottom of the slide. How much metal to remove is determined with a good micrometer. Works like this, measure the "C" on the frame, next measure the part of the slide that engages that groove (A) to determine how much to take off the bottom of the slide. Next measure the width of the slide grooves in the slide (E) to determine if material needs to come off the sides of the frames rails and lastly measure the (B)on the slide and compare to the measurement of (D) to determine if material needs to come off the top of the frame. I use a milling machine to remove offending material but a good file and stone would work also.

No laughing at my high end drawing, it took me awhile to do that one in Photoshop.

After you get frame and slide close to going on you will want to lap them

together, lapping compound is available from Brownells.

Hey Blindhogg, help me out some more! Actually fitting the slide is another of the 1911 mysteries that i'm not sure about. Your explanation is pretty much what I figured, but the question is, how do you take the measurements? Better question is with what? I saw the slide fitting micrometer in Brownell's($$$$;), i just can't figure out another way to get inside there and measure. my dial caliper won't fit. I know you can use stones and files to get it into the ballpark, but when do you start the lapping compound? I mean, if you force the slide onto the frame when it's too tight, are you gonna gall the rails up and ruin them? I read of some guys hammering the slide onto the frame, but that doesn't sound like a good thing!

Great question. First, it is possible to measure the rails grooves and rail width with a conventional micrometer taking careful measurments at the end near the firing pin. But you are only measuring the end and not seeing if there is any variation along the length, so for that I use something called a groove micrometer. Below is a pic. This particular groove micrometer can measure grooves from .051 to 1 inch. So it is perfect for a slide. As for when to start lapping, you should not very forcefully make the slide go onto the frame or you will gouge and gall either the slide or frame. I wait till the slide will almost want to get close and keep hitting the high points with a stone until the slide will start to go on without much pressure, once I can get it on about an inch or more I will start lapping.

Izzat the groove micrometer that's in the brownell's catalog? If not, where to get one?

Nope, that's not a groove micrometer in the Brownells, its a micrometer head that has a special anvil made for it to measure slides. A groove micrometer is a common tool in the machinists world and is available from any machinists supply house like MSC or Travers or J&L. But the best place to get one is ebay.com I got mine for about $80; just ensure that it is a 0-1 inch version. You will not be sorry you got one. Just type in (groove micrometer) and you will always get about 3-6 hits. If your patient you will score one for a good price.