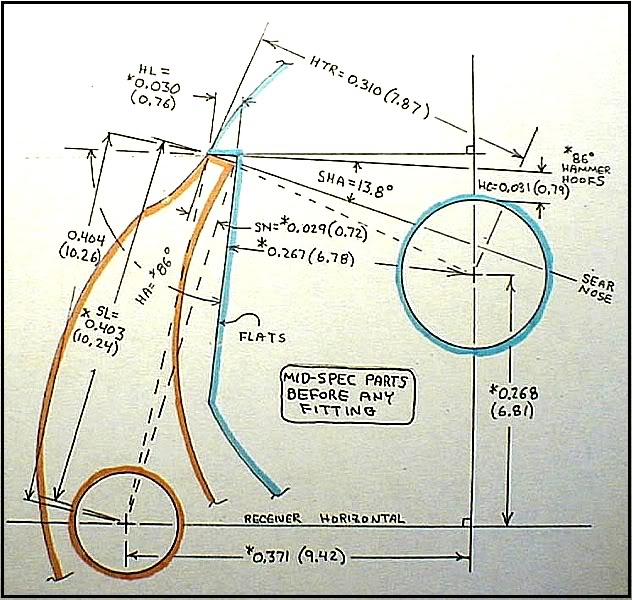

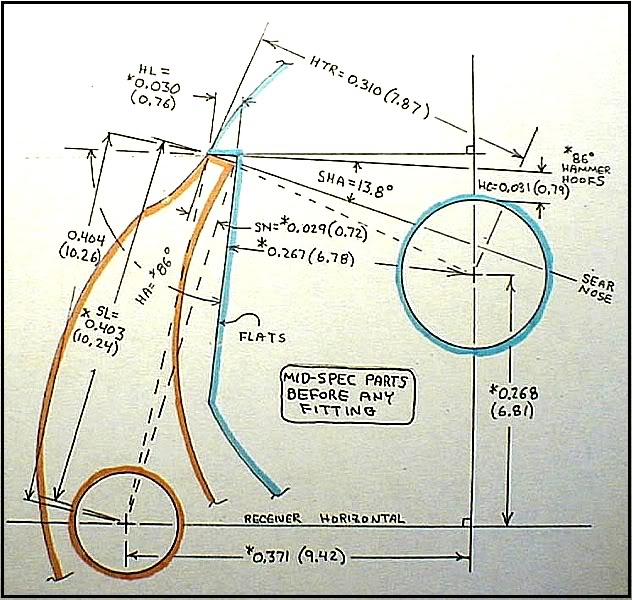

This picture was posted by niemi24s in another thread.

As shown in the image, the sear is negative is it not? So the sear nose has to be thinner than the hammer shelf. Have I got this correct?

I thought that was the drawing of positive engagement.

As the sear rotates out from the hammer hooks it would raise, ie, slighlty cock the hammer so that's positive engagement.

The thickness of the sear nose isn't the issue. The amount of sear/hammer contact doesn't determine negative - neutral - positive types of triggers as was discussed here previously.

Here's how I see it works.

Because the hooks are about 0.001" higher than the sear nose width, the hook tips overhang the front of the sear nose a wee bit. As a result of this, the sear will cock the hammer a teeny bit during its first 0.001" or so of travel.

Once the front edge of the sear nose gets to the hook tips, the distance between the hook tips and the sear pin center will decrease from the 0.404" to the 0.403" shown during the remainder of the sear nose's travel to release.

So just based on that analysis of the blueprint-perfect theoretical parts I guess it's positive at first and then goes negative.

But, a gun made from real blueprint-perfect parts may not behave that way. And if it does behave that way when first assembled, it may not behave that way for too long. These parts may tend to conform to each other.

Did I muddy it up enough?

What you show in your drawing is the same thing I get in my AutoCAD. This trigger system is negative. The system is only as positive as it's least positive component.

Just trying to get my head straight. The Colt DA revolvers use this type of negative system. It cuts creep to only the amount of positive engagement over the sear the hammer hooks have. Yes the hammer will cam back as it should for a positive system, then the system goes negative as soon as the outside edge of the sear goes past the hammer hooks, with the hammer forcing the sear off of it the rest of the way.

As drawn it works, as long as the hammer hooks engage over the sear. But my AGI video on the Ultimate 1911 shows a conventional style positive angle sear, with a completely different primary sear surface angle.

Am I looking at it correct in that the USGI trigger system as JMB designed it is a negative system?

Quote:

This trigger system is negative. The system is only as positive as it's

least positive component.

To me, these are oversimplifications which do not fully describe it.

It's positive for the first little bit - then negative the rest of the way. It's both. It's +/-. It may well be negative for the majority of the way, but nothing is gained by ignoring the positive minority. That first little bit of positivity when the hooks first fall on the sear nose may be what keeps the thing from going BRAAA-AP!

The degree of negativity here is tiny; I don't have time to calculate it out because I'm tending to a sick child, but it looks like a little under 2 degrees , so it seems to me the horizontal component of the hammer's force is going to be vastly less than friction or sear spring pressure. And indeed, I'm not convinced that you could really reliably control that angle to within two degrees unless you had some talent and a pretty nice jig.

I just finished a trigger job on an overly thick sear that overlaps the hammer hook nose, but with the stock settings on a marvel jig, I took it from negative (from the factory) to either neutral or positive (sear doesn't squirt out under pressure in the absence of springs). I have no idea what the exact angle is, but it works.

Quote:

It's positive for the first little bit - then negative the rest of the way.

It's both. It's +/-. It may well be negative for the majority of the way, but

nothing is gained by ignoring the positive minority. That first little bit of

positivity when the hooks first fall on the sear nose may be what keeps the

thing from going BRAAA-AP!

The school'in I got was that this type of trigger is negative. Any system with either the hammer hooks or the sear cut at a negative angle makes the system negative.

I'm not ignoring the hammer hooks being over the sear nose and holding. With this system it's like the sear angle is something like 70-80 degrees with one heck of a de-creeping relief cut.

So I guess my question is, do you recut the angle on the sear to make it positive? Or do you adjust the sear engagement to control creep and keep the sear angle as shown in the ordinance drawing?

If you leave it, what kind of engagement do you use?

I can't answer any of those questions simply because it's been too long since I did any of that sort of trigger work. But I think there's lots of answers in this old thread http://forum.m1911.org/showthread.p...ht=roll+trigger and perhaps enough material to provoke additional questions.

The drawing in Post #1 is nothing more than a composite based on Ordnance drawings for the sear, hammer and frame, done simply to see how they would fit together. Although it took (IIRC) about 3 days to do, the really hard part is probably trying to describe how they come apart!

I assume that you are analyzing the engagement as shown in the fully cocked position. I don't think you can use the drawing itself to tell much. However if you use the actual dimensions on the drawing and you still come up with negative, then so be it. In the real world, there is no way to take these angles and dimensions and transfer them to tiny parts thinking that you can predict the outcome. Engagement drawings are a way to conceptualize what is happening at a scale that you can't easily see (with or without a microscope).

The results are what is important, and the success of your trigger work is easily confirmed by operating the parts on a pin block. Consider further that a real world trigger can easily be positive when it is cocked, neutral somewhere along the way and negative just before letoff. The system is dynamic as soon as the trigger pull begins.

Quote:

In the real world, there is no way to take these angles and dimensions and

transfer them to tiny parts thinking that you can predict the outcome.

Engagement drawings are a way to conceptualize what is happening at a scale

that you can't easily see (with or without a microscope).

Having been a machinist off and on for 40 some years doing a lot of tool and die work, making tiny parts move from the drawing to the tool room is what I do. With all due respect, my training allows me to not only conceptualize what is being shown, but also make it work.

Quote:

The system is only as positive as it's least positive component.

I am confused about this concept. I think the original statement was "A chain is only as strong as its weakest link." However when we are discussing trigger engagements, a single part alone is neither positive or negative, unless a number of basic dimensions are first specified. The qualities of positive and negative usually describe the relationship between 2 parts and not to an individual part by itself. Since no two hammers or sears are identical I don't see the point of analyzing each part separately. Trigger jobs are done empirically - by trial and error. The only exception would be a manufacturer that is turning out hundreds of parts that are nearly identical and can live with a fit that is less than optimal.

All this chit-chat about positive & negative triggers and what they look like on paper reminds me of the first time I looked at mine with a 60X shop microcscope. It's a pretty nice trigger, but I couldn't decide what kind it was by feel. I thought an up close look-see would tell me.

Wrong! It looked absolutely scary! Put the gun back together and vowed to never look at it that close again.

LoRL, actually most things would look scary at that magnification!

In any sear system there are two components; the sear and the hammer. Double sear systems exist, but that's a topic for another forum.

In a positive system, both components are positive. Both the hammer and sear are cut so that the angle of either one will tend to pull the two together.

In a negative system, either component can be cut so that one will tend to push off or squirt off the other.

If you extend the line of the hammer notch to the center point of the hammer pivot point you will have one of three conditions.

First, the line goes below the center of the hole. This hammer is positive.

Second, the line goes through the center of the hole. This hammer is neutral.

Third, the line goes above the center of the hole. This hammer is negative.

The same thing holds true of the sear. If you draw a line from the center of the sear pivot hole to the center of the sear shelf and the length of the inside of the sear, the part closest to the hammer, measures more than the length of outside of the sear, than the sear is positive.

If the length of the inside of the sear measures less than the outside length of the sear, than the sear is negative.

If the lengths are equal, the sear is neutral.

These conditions exist in the hammer or sear independent of each other.

Niemi24s picture shows the sear just as the Ordnance drawings have it drawn. And the position of the sear is correct. Now I am making the assumption that the drawings are as JMB designed the pistol. That system is negative. The sear will tend to squirt out from under the hammer hooks as soon as the outside edge of the hooks go past the tip of the sear.

The AGI videos for this pistol recut the primary angle of the sear so that it is positive rather than keeping the angle the same as shown on the prints and using the negative trigger system. I just trying to determine what some of you do when fitting a new trigger? Did not mean to make it so hard.

I looking at a liability issue here. Do it as JMB did it or their way.

I've been trying to wrap my brain aound your Post #14, especially this:

Quote:

In a positive system, both components are positive. Both the hammer and

sear are cut so that the angle of either one will tend to pull the two

together.

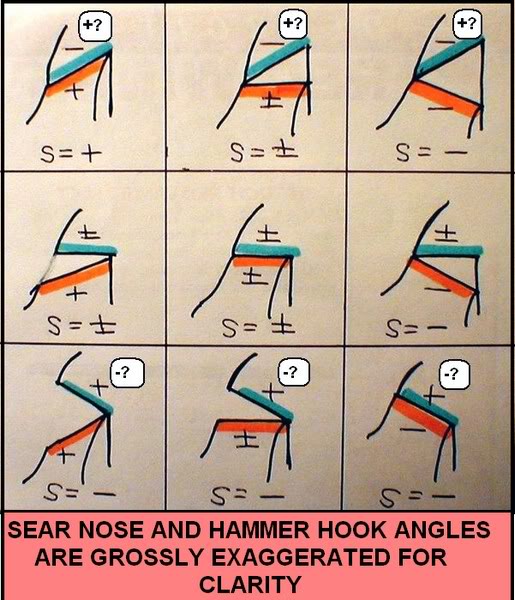

Made a little sketch [Edited: with hammer (blue) and sear (orange) angles highly exaggerated for clarity] to see if it would help me understand:

Didn't help.

Is there a chance you've got your definitions for + and - hammers switched (as indicated on the pic)?

I'm used to doing Ruger 10-22 trigger jobs which are upside down from the 1911. Sorry about that.

Assuming your hammer hole is at 90 degs from the center of the hammer hooks, your first row of drawings are positive hammer hooks.

Again assuming the hammer hole at 90, the second row is neutral.

Third row, with same assumptions, is negative.

Assuming the hole for the sears is at the bottom, first column is positive, second column is neutral, third row negative.

You can see that the negative part of the system would squirt out from under the positive part.

OK, now it makes sense - to me, at least. Whew!

niemi24s:

Is there a chance you've got your definitions switched?

Niemi;

One thing that has immense influence on the outcome, is the engagement

resting position of the sear angle in it's arch of movement. Is it resting at

the maximum peak, approaching the peak, or dropping away from the peak point

in the arch..?? With hammer hooks at .020, the actual raise or fall, if either

does in fact occur, as a result of the resting position, is quite small if

starting from a fully mated neutral engagement as shown. Without the

microscope, and proper fixtures, there is no way to know for sure, and it is

very difficult to actually achieve the full neutral engagement, and then make

micro adjustments necessary to get the required pull/feel.

Have you changed the primary angle of the sear in the photo?

The sear would be positive in the photo. And there is no need to get a full engagement to the hammer hooks. If the sear shown in the photo had more angle to it, so that there was some space to the right, the point of contact towards the inside of the hammer hook would work. The only time you will have a true flat to flat relationship between the sear and hammer hooks is only at one point of the sear's arc of travel. At any other point all that contacts is one edge of the sear or the hammer.

I think that between your photo and the drawing niemi24s did that you can better understand my question.

The system in the photo is different from the one in the drawing. Both will work. Niemi24s will have less creep when it is all said and done.

Which one does everyone use?

Disclaimer: I'm a newbie and have only "succeeded" with a few triggers thus far. They work (so far so good) during actual use at the range and rate between 4 3/4 and 5 1/2 lbs on the gauge. Not sure the exact sear angle, but if I number neimi24's diagram:

1 2 3

4 5 6

7 8 9

Hammer hooks are as square as I can get them (usually just leave them alone) and run between 0.023-0.024 deep. I think that makes them resemble diagrams 4, 5 and 6. I believe my sears end up looking something like 5. Maybe, maybe a dash of 4, but my eyes could be tricking me.. could be that I think my sears look a bit like 4 because they a bit "pointy" because I barely stone a relief angle, only stoning away probably less than 1/5 the surface of the otherwise untouched sear nose.

Other than polishing metal/metal contact points, I use unaltered Wolff sear springs and 23lb main springs.

I'm thinking I must be doing something wrong... with hefty springs, relatively beefy hammer hooks and what I think is positive or neutral hammer/sear engagement, my trigger pull weights should probably be higher than what I'm getting?

I'm confused... just ignore me. I'll go back and re-read this thread (and others) again.

I'm not convinced that the relationship of the hammer hooks to the hammer pin hole is relevant here. The sear will always push on the hammer along a line connecting the center of the sear pin to the point of contact, and the only way for the hammer to be released is sear rotation around the sear pin, so I think it's the relationship of the surfaces to the sear pin-sear nose line that needs to be considered.

Consider a hammer with hooks that are exactly in line with the hammer hole (putatively neutral) and a sear engagement surface that is a line of zero width running along the nose (neutral). Now imagine that the sear is really, really, long, so the hammer is overcocked to the point that the hammer hook surfaces forms a 45 degree angle with the sear pin-sear nose line. Is it not the case that this engagement should be considered negative? Imagine the sear is so short, the hammer is almost to the firing pin. Isn't that pretty positive?

I think the sear is positive if the back of the nose is farther from the sear pin hole center than the front, such that rotating the sear tends to overcock the hammer. Similarly, the hammer's negativity or positivity will depend upon the angle between the hammer hooks and the sear pin-sear nose line; square to that line, and there will be no tendency to overcock (or release) the hammer during the first moment of sear movement, and therefore the hammer will be neutral.

But you can't know the hammer hooks' angle to the sear nose unless you know the length of the sear and the precise (within tolerances, hopefully) placement of the pins. Mere reference to the hammer pin hole tells you nothing, because that's not where the force restraining the hammer is coming from.

BTW, that sketch in Post #15 is just that - a sketch. And the angles of the hammer (blue) and sear (orange) are highly exaggerated for clarity.

I'm doing the AGI Professional Gunsmithing Course. The positive and negative thing is what they are teaching. This is not something I invented.

I think your are taking it to extremes Rob. Just what trigger system has the sear so long that the hammer is overcocked to the point that the hammer notch is at a 45 degree angle to the sear?

Niemi24s drawings show the concepts very well. My thanks to him.

Unless you recut the primary angle on the sear, the system shown in the Ordinance drawings is negative. The hammer hooks have to hang or hook over the sear.

Quote:

I think your are taking it to extremes Rob. Just what trigger system has

the sear so long that the hammer is overcocked to the point that the hammer

notch is at a 45 degree angle to the sear?

Of course I'm taking it to extremes, because the extreme (and admittedly absurd) cases illuminate the principle you can't see when the angles are one or two degrees. In this case, I'm pointing out that you can take a system from positive to neutral to negative without altering the hammer hooks one bit, merely by changing sear length.

AGI may well be right that in a mid-spec 1911 the hammer pin hole is an appropriate reference point for deciding if the hammer hooks are positive or negative. But given that you can hardly find GI-spec parts, and everybody's got some crazy set of standards they're using, and you don't know how tolerances of even nominally GI parts might be stacking, it's not a great idea to make any assumptions like that.

At bottom, the only question that matters for positive/negative determinations is: what happens when the sear moves a tiny bit? If the hammer overcocks, it's positive, if it starts to fall, it's negative, and if neither, it's neutral.

I agree that the system as drawn is very slightly negative once the sear nose moves past the tip of the hammer hooks. It's less than 2 degrees, though, so I'm not sure how likely it is to cause a problem.

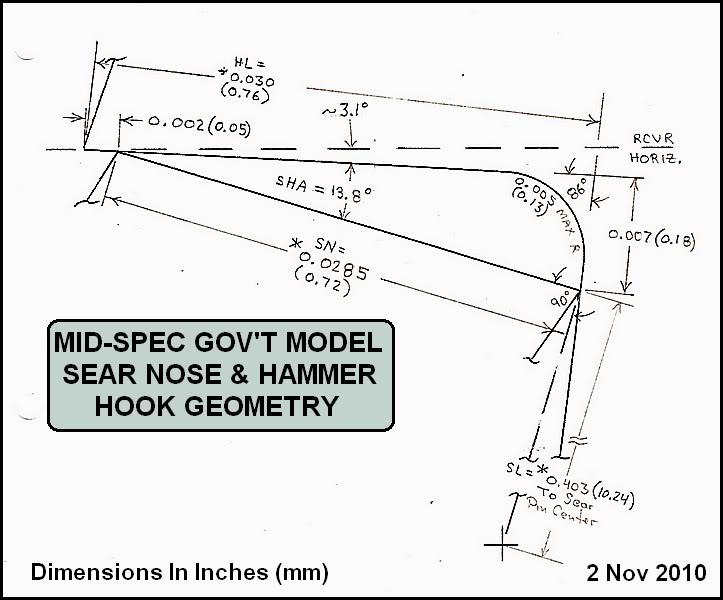

FWIW, here's a close-up view of the sear nose area shown in Post #1:

Again, it shows mid-spec parts with no fitting, boosting, tinkering or use. During the first 0.002" of sear nose travel, the hook tips get lifted about 0.0005" and overcock the hammer by about 0.09deg. After that, the hooks drop about 0.001" until let-off.

Quote:

If you extend the line of the hammer notch to the center point of the

hammer pivot point you will have one of three conditions.

The above design was actually not used by JMB. For purposes of simplification, the concept that the hammer hooks are on a line through the center of the pin hole is fine. But AGI notwithstanding, it is only a simplification and not a mandatory pre-condition for correct trigger operation. Refer to the ordnance drawings of the hammer and note how many calculations are necessary to describe the location of the hammer hooks with reference to the hammer pin hole. Note also that every aftermarket part manufacturer has their own idea of where they might be located. Quite an interesting mix of dimensions to work with!

There is no such thing as a positive hammer floating somewhere in space. The concept of positive/negative implies a relationship between the hammer and the sear. I think Gene and Bob would agree.

Check sear engagement illustrations on 1911 Forum.com. A wealth of info there by log man and others.

I gotta be careful reading all this stuff. It's starting to make sense.

That was the 1st time that I ever saw a 1911 drawing with metric dimensions. Cool.

Quote:

The concept of positive/negative implies a relationship between the hammer

and the sear. I think Gene and Bob would agree.

I went back through the course work again, and with all due respect, the concept of positive and negative is to the individual parts, not their relation ship to each other. You have to look at the forces and how they are applied. Just as niemi24s shows in his drawing of the 9 conditions, you can have a positive hammer and a negative sear in the same system.

Quote:

I went back through the course work again, and with all due respect, the

concept of positive and negative is to the individual parts, not their

relation ship to each other. You have to look at the forces and how they are

applied. Just as niemi24s shows in his drawing of the 9 conditions, you can

have a positive hammer and a negative sear in the same system.

You certainly can have a positive hammer and negative sear; that's what the original drawing that kicked off this thread shows, as you pointed out. But what you can't know is if the hammer is positive or negative without sticking it into a particular frame with a particular sear. Just look at Niemi's original drawing: what happens if the sear is, say, .010 longer (or, alternatively, the frame holes are spaced .010 close, or the holes are .005 closer and the sear is .005 longer)? The hammer rotates back a bit more, and becomes a bit less positive. At some point, it goes back so far that it becomes negative--without altering its relationship to the hammer hole at all.

What happens if the sear nose grows in width? At some point, it pushes past the tips of the hammer hooks, and then it doesn't matter how "positive" the hammer hooks are; they could be shaped like a half-cock notch, but the relationship is still negative because the sear is only touching the tip anyway. The same thing would happen if (somewhat more realistically) you were to start stoning the hammer hooks down looking for a lighter pull.

That's what Lazarus means by the "positivity" being determined by the relationship, and there being no such thing as a positive hammer floating out in space. The same hammer can be positive or negative depending on the length of the sear, and the hammer, regardless of how positive, can find itself in a negative engagement with an extra-wide sear.

When you say you need to look at the forces applied, that's true, but you can easily get confused if you're drawing vectors and trying to break things down into components. The simple way to decide what's going on is to look at what happens when the sear moves a little bit: does the hammer overcock, fall, or stay in place?

Quote:

You certainly can have a positive hammer and negative sear; that's what the

original drawing that kicked off this thread shows, as you pointed out. But

what you can't know is if the hammer is positive or negative without sticking

it into a particular frame with a particular sear. Just look at Niemi's

original drawing: what happens if the sear is, say, .010 longer (or,

alternatively, the frame holes are spaced .010 close, or the holes are .005

closer and the sear is .005 longer)? The hammer rotates back a bit more, and

becomes a bit less positive. At some point, it goes back so far that it

becomes negative - without altering its relationship to the hammer hole at

all.

Although it will become less positive, you would have to overcock it to the point of being absurd to change it's relation to the sear, and the hammer would still be positive. The fact that the sear is negative would not change under any of the conditions you site.

Quote:

What happens if the sear nose grows in width? At some point, it pushes past

the tips of the hammer hooks, and then it doesn't matter how "positive" the

hammer hooks are; they could be shaped like a half-cock notch, but the

relationship is still negative because the sear is only touching the tip

anyway. The same thing would happen if (somewhat more realistically) you were

to start stoning the hammer hooks down looking for a lighter pull.

And at that point the trigger is unsafe because the only thing keeping the hammer from falling is spring tension.

Quote:

That's what Lazarus means by the "positivity" being determined by the

relationship, and there being no such thing as a positive hammer floating out

in space. The same hammer can be positive or negative depending on the length

of the sear, and the hammer, regardless of how positive, can find itself in a

negative engagement with an extra-wide sear.

Again, you have to take it to the point of being absurd in changing the sear length to change the hammer being positive. And yes, there can be a hammer floating in space that has a positive hook angle. It all goes back to the hammer pin location and the angle of the hook in relation there to. You have to reinvent the gun to make what you are suggesting make any difference. The hammer will always be positive. The sear will always be negative. Change the sear nose width to the point that the sear is now wider than the hammer, the sear has the negative engagement, not the hammer. The positive hammer will squirt the negative sear out from under it and fall.

Quote:

When you say you need to look at the forces applied, that's true, but you

can easily get confused if you're drawing vectors and trying to break things

down into components. The simple way to decide what's going on is to look at

what happens when the sear moves a little bit: does the hammer overcock, fall,

or stay in place?

Yes, if you don't work with these concepts and understand them they could get one confused. But if you do understand vectors and applied forces it really is not that hard.

Thanks for the input.

Quote:

Again, you have to take it to the point of being absurd in changing the

sear length to change the hammer being positive. And yes, there can be a

hammer floating in space that has a positive hook angle. It all goes back to

the hammer pin location and the angle of the hook in relation there to.

The first sentence here contradicts the second two. If you can change the hook angle to positive by changing the sear length, then you can't have a positive hammer floating in space, and the hammer pin can't be the right reference point for deciding positivity. And it isn't; the sear pin is the right reference point, because that's the axis about which the relevant action occurs.

Now, assuming all parts are in-spec, maybe you can go by the hammer pin. But if you've been a machinist for 40 years, you know all about tolerance stacking. If one of the many parts makers decides that a somewhat different hammer hook configuration is a good idea, and another decides the sear should be a bit different, and along comes a gunsmith with his files and stones to fiddle with it all, and it then gets put into a "gun show special" frame of dubious parentage, well, then, who knows what you've got?

Quote:

The first sentence here contradicts the second two. If you can change the

hook angle to positive by changing the sear length, then you can't have a

positive hammer floating in space, and the hammer pin can't be the right

reference point for deciding positivity. And it isn't; the sear pin is the

right reference point, because that's the axis about which the relevant action

occurs.

I believe it is you that suggested that by changing the sear length, you change the +/- of the hammer. Nothing you do to the sear length effects the angle cut of the hammer hook. With a 4 degree hammer hook angle, as shown in the ordinance drawings, you would have to lengthen the sear beyond all reason to do what you claim will happen. I doubt the sear could even reach the hammer hooks if the hammer was overcocked to create the conditions you describe.

Quote:

Now, assuming all parts are in-spec, maybe you can go by the hammer pin.

But if you've been a machinist for 40 years, you know all about tolerance

stacking. If one of the many parts makers decides that a somewhat different

hammer hook configuration is a good idea, and another decides the sear should

be a bit different, and along comes a gunsmith with his files and stones to

fiddle with it all, and it then gets put into a "gun show special" frame of

dubious parentage, well, then, who knows what you've got?

You have nothing else to go on but the sear pin hole. If the inside length of the sear is shorter than the outside length, from the pin hole center, then the sear is negative.

We can come up with 'what ifs' all day long to discuss. I was asking about the sear angle and hammer engagement of the ordinance drawings, as presented. And I understand completely tolerance stacking. Stack all the tolerances + or - and I think you will see my point. If not, I think we can just agree to disagree.

Quote:

Nothing you do to the sear length effects the angle cut of the hammer

hook.

Nothing you do to the sear affects the angle of the hammer hook relative to the hammer pin hole. But changing the sear length changes the angle relative to the sear pin hole, which is the angle you should care about.

Quote:

With a 4 degree hammer hook angle, as shown in the ordinance drawings, you

would have to lengthen the sear beyond all reason to do what you claim will

happen.

If the hammer hooks are 4 degrees positive (I haven't studied the drawing to work it out), you need to to add about .022 in length to get to neutral, and beyond that you go negative. Is that "beyond all reason," or is that something you might wind up with if you get an aftermarket sear? And in any case, how confident are you that the Super Tactical Match-Grade Bullseye hammer you just got from Brownell's is cut to Ordinance Dept. specs?

Quote:

If the inside length of the sear is shorter than the outside length, from

the pin hole center, then the sear is negative.

I agree completely with this, and also with your assessment that the drawings as shown have a slightly negative sear that will be bad news if you start stoning the hammer hooks down. I'm just saying that your evaluation of the hammer hooks should also be based upon a comparison with the sear pin, not the hammer pin.

Quote:

If the hammer hooks are 4 degrees positive (I haven't studied the drawing

to work it out), you need to to add about .022 in length to get to neutral,

and beyond that you go negative.

It would take 0.052" of increased sear length to overcock the hammer enough to make the system neutral. The hammer hooks would still be positive.

Since the drawing gives a dimension of 0.4045" -0.0030" from the center of the pin hole to the tip of the sear, yes sir, I believe you are pushing the discussion beyond reason, with all due respect.

That would seem to imply you could take a hammer with "positive" hooks, add to it a sear with a "positive" nose, and, given enough sear length, wind up with a negative engagement which is unsafe

With respect, that would seem to me to be stretching the definition of "positive" beyond all reason.

No sir. What you are describing is poor firearms design. There would be no reason to design a firearm using the conditions you ascribe too.

You can take a + hammer and a + sear and push the system negative, but it would be an unsafe design, flawed from the start.

Oh, it would definitely be a bad design. But not one that is impossible to achieve for a 1911, given the wide variety of parts makers out there with differing notions of the "right" design. So an analysis of trigger engagement shouldn't be dependent on assuming anyone is sticking to Army specs.

It would also be a bad design to, for instance, have the distance between the upper locking lug recesses of the barrel and the horizontal surface of the barrel feet be less than the distance between the bottom of the slide's lugs and the top of the slide stop pin. Yet people pay hundreds of dollars for barrels advertised as having this property.

Again, I believe you are incorrect. Taken to the point you wish to push it, the flat of the hammer at the hammer hooks prevents the sear from engaging the hammer hooks.

Certainly, if the hammer flats are cut to GI specs, and the sear is not relieved as is, for instance, this one.

Write to C&S and ask for they will make you a sear 0.052" longer than spec and see what they say.

Dude, lets get real.

I was going to ask you to make one. Also, I want my hammer hooks cut with a dovetail cutter so that the whole system remains positive.

I'll get right on it.