I have a new sear spring I am installing into a USGI 1911A1. I was wondering how tall it should be. When I installed the new spring the tab sticks out into the mag well and rubs on the mag.

So my question is it supposed to do this? and how far?

Here's a picture of what I am taking about.

I looked and did a search of the forums and didn't find an answer.

The tab on your sear spring is too long. It should not ever protrude into the magazine well. I would shorten its just less than flush with the inside of the magazine well.

Now I'm interested as to who made that sear spring. Its hard to beat an original Colt sear spring for 3-4 bucks.

I ran into the same thing at a local dealer with a new Taurus PT1911. Fred was cussin' and fumin' about havin' to send it back, so I fixed it for him and scored a tray of free pistol primers. Took about 5 minutes. Your file is your friend. Become one with your file.

A 6-inch smooth mill files works best. Also much easier to do it with the sear spring out of the gun.

Hmm-m-m. If it's bent too long on the lower end - and it was the correct length before being bent - could that mean it's too short on the upper end?

Quote:

Hmm-m-m. If it's bent too long on the lower end - and it was the correct

length before being bent - could that mean it's too short on the upper

end?

If the OP still has the original sear spring, a side-by-side comparison should be useful.

Quote:

Hmm-m-m. If it's bent too long on the lower end - and it was the correct

length before being bent - could that mean it's too short on the upper

end?

A good point. I had a sear spring like that once. Now that you mention it, that was the same gun that often required two pulls of the trigger per shot. The first pull resulted in a nearly-inaudible "click" somewhere inside, then a repeat pull would fire the round.

Turned out the sear spring wasn't long enough to properly reset the disconnector. The first pull disturbed it enough to reset, thus allowing the second pull to fire the round.

A genuine Colt sear spring resolved the issue.

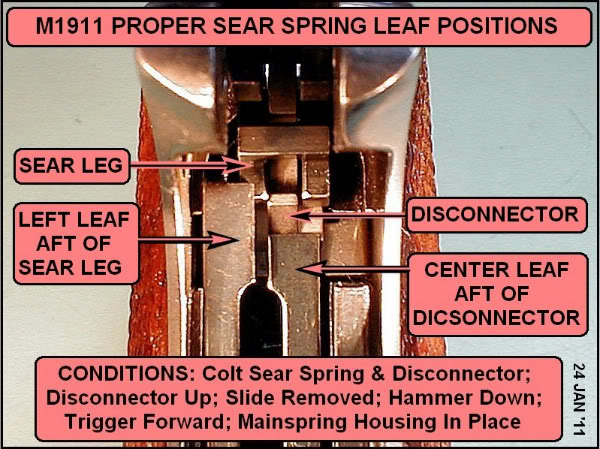

This is about what the upper end of a sear spring should look like when held in place by the mainspring housing:

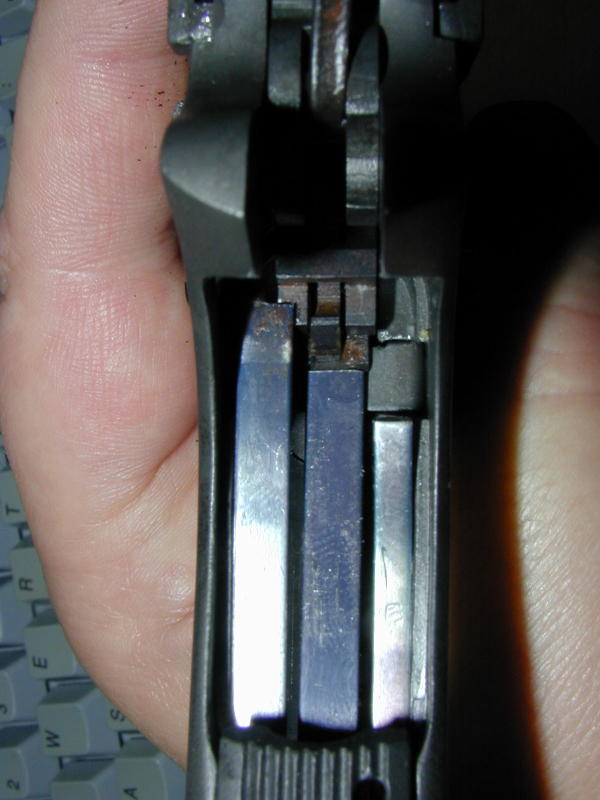

The spring makes contact with the sear and disconnector. The pistol did pass a function check. Here's a picture. What do you folks think?

As for the original it's toast and not good to compare. I don't know who made the spring. It came in a "spring kit"

Looks to me like the middle finger is slipping off the bottom of the disconnector surface. IMHO it should ride a bit higher than that.

Quote:

Looks to me like the middle finger is slipping off the bottom of the

disconnector surface. IMHO it should ride a bit higher than that.

It has not sipped off the disconnectorand it in contact. It seems to be sitting a tad lower than the original judging form the marks on the disconnector. Like I said it passed all function tests.

With that said is it sitting to low and should I get another spring?

It is sitting low. I had a gun with a sear spring that looked like this, causing the disconnector to stay up, thereby hanging-up on the slide, in the corner between the breechface and the disconnector rail.

Thank you... I found the problem. The tab on the bottom seems not to be correct. Learned something new everyday.

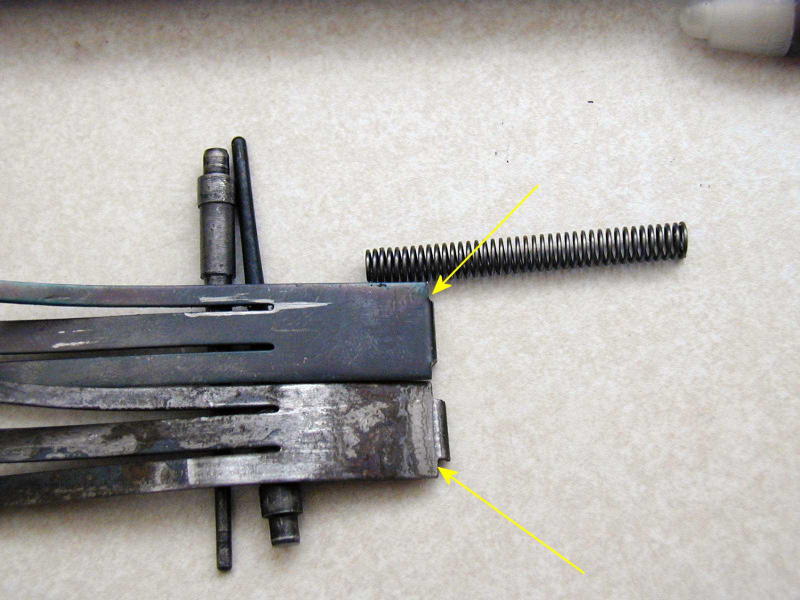

Here is a picture of two srpings. One is the new one ans the other is out of a friend's

Yep its too short, and thats obvious from the pic.

What Hawkmoon said in post #10, should ride a bit higher...

AND; it looks like the disconnecter has a groove wore into it where the previous spring was riding. Should be a smooth surface where that spring has to ride. Consider some light polishing in that area (or a new disconnecter). Stone/break the sharp edge on the spring where it rides on the disconnecter so the same doesn't happen going forward.