The only thing that is holding me back from start ing my next project is how to cut the inside relief for the notch on the thumb safety. I'm talking about the part inside of the frame just above the channel for the trigger stirrup on the left side. I just can't figure how to make a cut in there. Any ideas?

It would help to know what frame you are working on. I can remember reading a post here about someone building the dlask 60% (or whatever they call it) that operation had to be done as well as a ton of other work. I don't recall how they did it. Now on the Amberdden (alum.) casting that I built it needed that done in order for the thumb safety to fully enguage. to do this I had to make a scraping tool out of a small screwdriver. It worked very well - I was surprised. Not sure how well it would work on steel but I'd be glad to lend it to you. If you want to give it a try let me know.

The frame is one of Willams stainless steel frames. It looks like there is alot of a material to take out of that area. It seems like a lot to scrape.

Dogbert finished a Tannery Shop frame about two years ago. Unfortunately, all the links to his post are dead and I have recently lost all contact with him. I knew he was moving out of his apartment, but he may have found another job out-of-state.

The text of his post is still there, though, and may provide you with some insight with regards to this operation. Be careful, as there are some tricky measurements that need to be calculated due to the angle of this "window." Dogbert's post will explain all this on page 4...

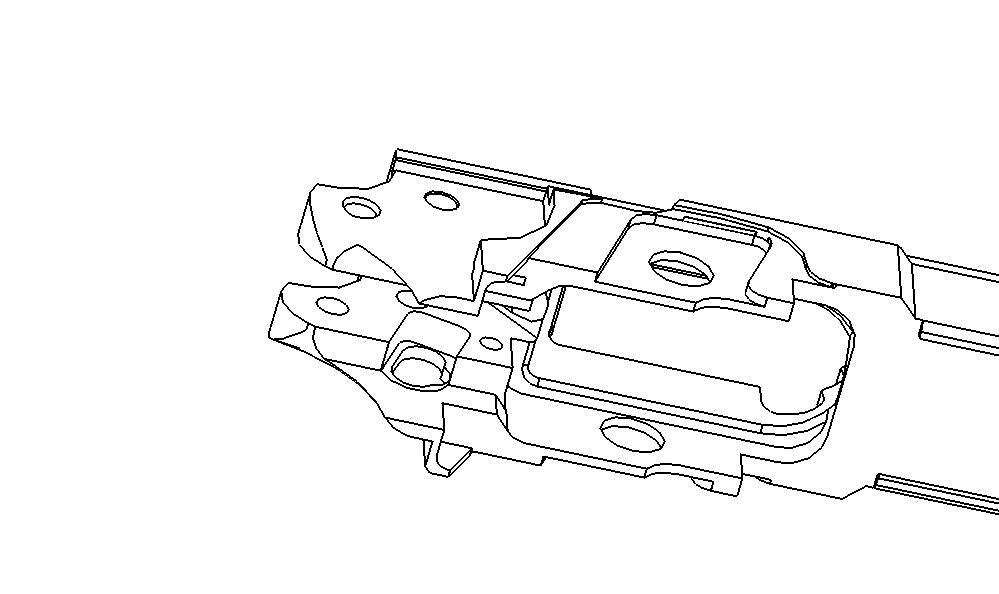

Thanks. Dogbert's post was very informative. I think I'm going to grind a small end mill into a sort of a T slot cutter to undercut the area where the notch in the thumb safety needs clearence. Right now the thumb safety will fit in the frame but will not rotate because there is no clearence for it. After I figure out how much material to remove I'll tackle the slot for the magazine release retaining stud.

Hi, if its the area I am thinking of, Justin gives a good description of how he does it in his CNC post on the 1911.

He also posts a picture of the tool he used, looks like a 5/16" endmill that has been ground into a T slot cutter, it is put on through the top holes then moves into position and raise, from what I can tell anyway.

That is how I will be doing mine, do the three holes that form the "slot" for the safety to move in first, then use a t slot cutter, nice and slow.

I think I have the picture and a nice close up of it all if you want, its from an STI fram but the cut is the same.

I will try and find it and attach it.

Here are the Dimensions for the detail cut.

This is what the cut looks like on an STI frame, I have a solid model of the original 1911 frame at home, I will do the same for it if you like.