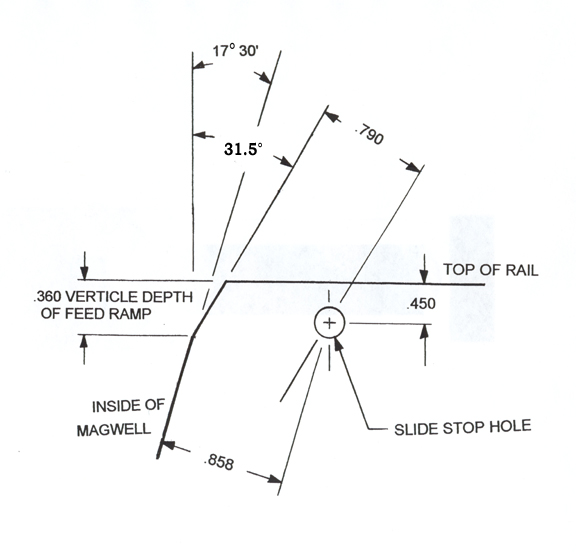

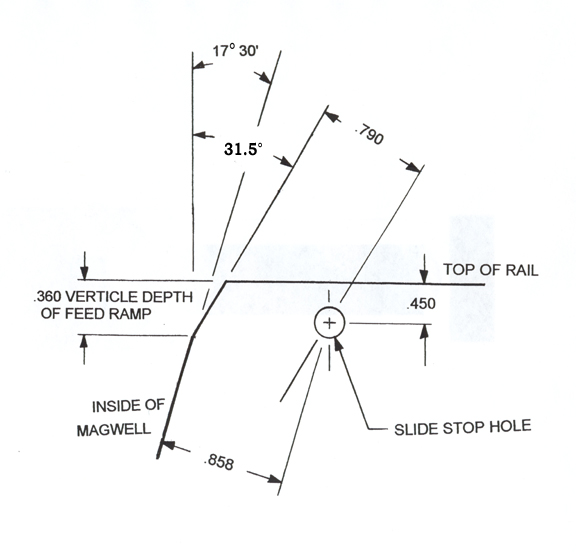

I do not know the source of this picture. I believe it to be fairly accurate, although I prefer a bit deeper for reliable function with modern hollowpoint ammo.

Slightly shallow original feedramp. Measures .335" deep.

Setting it up for re-machining at 31.5 degrees

After final polishing. Now measures .400" deep.

Just a couple questions for my first post.

Was the weapon being worked on in the photos having feeding problems before the work was performed?

What is the tolerance on the feed ramp depth and angle?

Did you indicate the slope after getting it close with the angle gauge?

Is the .360" vertical ramp height a minimum? How was the angle height measured? I would imagine a coordinate measurement machine is needed to get the intersection of the magwell and ramp relative to the "top" to get three decimal place precision.

Is the angle and the depth more important than the location of the ramp relative to the hole (.790" dimension)?

Am I being to picky? .360" min +1/16 and 31.5 degrees +- 1 degree close enough?

Is there a spec for flat land between the radius cut of the endmill? Is that a standard size endmill?

By the way some beautiful work done over at rogers precision.

I guess that was more than a couple.

The trick with getting an old style (unramped) 1911 like this to feed is to get the ramp angle polished out to match the bullets you want to shoot, as pictured, and at the same time to match the small feed ramp on the barrel itself to the new frame ramp. I do mine with 600 grit paper and often take the gun to the range a couple of times before it's considered finished. Yes, it does take a lot of time and effort. But I'm still enjoying the first Colt National Match that I did in 1993 and it still shoots as well as ever with even 152 gr. lead semi wadcutters and countless thousands of rounds in IPSC, PPC and whatever else I could find to shoot it in. So it's well worth the time and effort.

Great pictures and explanations. Thanks for taking the time and effort to explain it all so thoroughly and well.

A fine point that I borrowed from 1911 Tuner in another thread though; "For another, the bottom of the barrel ramp isn't supposed to match the top of the feed ramp... feathered or not. It should sit slightly forward...a minimum of .030-.035 inch. It can be a little more... but not less." ... I've seen more than a few guns that the owners of gave up on shooting semiwadcutters in because the "gunsmith" who worked on their guns didn't know this point. They would still work OK with hardball, but not with hollowpoints or most lead bullets.