OK guys, be patient with me, I am new at this. I have shot the guns, but never worked on them.

Well, it turns out that the new topend I just purchased has a ramped barrel and the one I removed was not. Now I know that the frame has to modified to fit the ramped barrel, but how much trouble is it? Am I better off selling it and just getting a new one. I have a series 70 alum frame. The slide and components are series 80 ParaOrdance in SS. I do not have a mill, only a dremel and a shaky hand.

If anyone has any pics of a properly installed ramped barrel or a link that explains how to modify the frame that would be great. I have checked Pvt Ryans logs and BlindHoggs site, but didn't see anything. I just don't want to ruin the frame.

You need a mill to make the cuts for a ramped barrel. I know ,I know some one will have done it with a dremel and an Exacto knife.

Well the good news is the Para barrel is the easier of the two styles of ramped barrels to modify the frame for. The bad news is I beleive a milling machine is in order for this modification. I can post the specs for the modification here but a milling machine will be necessary. Let me know if anyone is interested.

You can always sell the barrel on Ebay and just get another non-ramped barrel to put in your blaster, or get a smith to modify your frame.

Thx for the input. That's pretty much what I was thinking.

Good advice Blindhogg. I will look for a replacement barrel and get rid of the old one. I believe having the frame modified by a smith is just money wasted. I think the biggest advantage of the ramped barrel is for some one that is shooting hot loads with higher pressures in the barrel. I don't have to worry about that.

it's really not a bad idea to use a rammped barrel with an alum. frame -for reliability reasons if nothing else.

blindhogg, pleas post that info. -i'm very interested in your write-up on that procedure.

There are two different style ramped barrels and I only install the Clark-Para type of ramped barrels because it is the easiest to modify the frame for. Only two cuts are needed to be done for this barrel and only regular end mills are needed to make these cuts, no fancy tooling. First clamp frame to angle plate etc chuck with frame rails parralel to top of table,chuck a 3/8 bit center it to the center of your frame and zero table once it is the same height as the top of your frame. Lower the bit .315 and make a pass therefore cutting out the ramped part of the barrel, first cut now complete. Next lower the bit again .270 and start cutting again, this cut allows the barrel to fully enter the frame and positions the integral barrel ramp in the right place. This cut must be stopped when the flat on the just machined area between the mag well and the second end mill cut are .210, I stop early and try the barrel in place and cut and go, the new barrel ramp may be a few thou back from the mag well but must not extend into the mag well, cut and fit time is time well spent here.

I am trying to install a Clark/Para barrel made by Schuemann. In the instructions that came with the barrel it says to make the second cut stop .600" from the slide stop pin. This puts the ramp into the mag well. Should I not cut as far on the frame and trim the lower lugs on the barrel? I really wish Kuhnhausen went over this in his books. Also do different caliber barrels have different dimensions for the hood and lugs?

I've been thinking about installing a Clark/Para barrel on a new build of mine - I'm glad I caught this thread! :D

A ramped barrel is the only way to go if your installing one in a alloy frame... The reason is the alloy feed ramp that is an intregrated part of the frame wears really fast and will cause reliability problems, the solution is install a ramped barrel...

On the other side of this if your shooting a 45acp 1911 with a steel frame there is no need for a ramped barrel unless your pushing the ammo cases to the breaking point...

In fact the ramped barrel is designed to and has to have a steeper ramp angle then a regular 1911 frame and therefore makes magazine feed lips and all sorts of variables more delicate and therefore have to be more perfect then the same gun set-up with a regular style barrel...

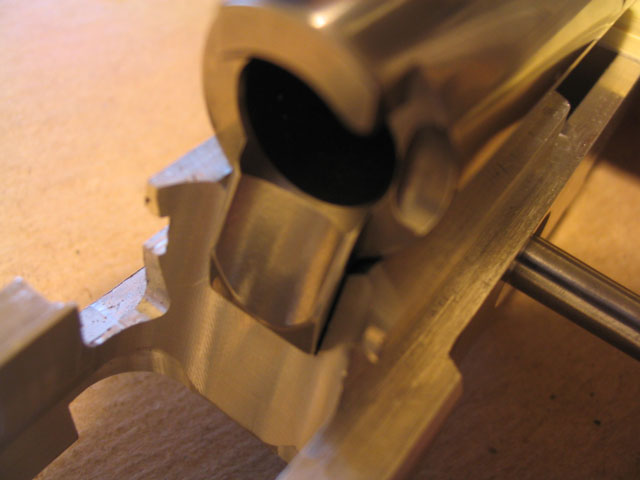

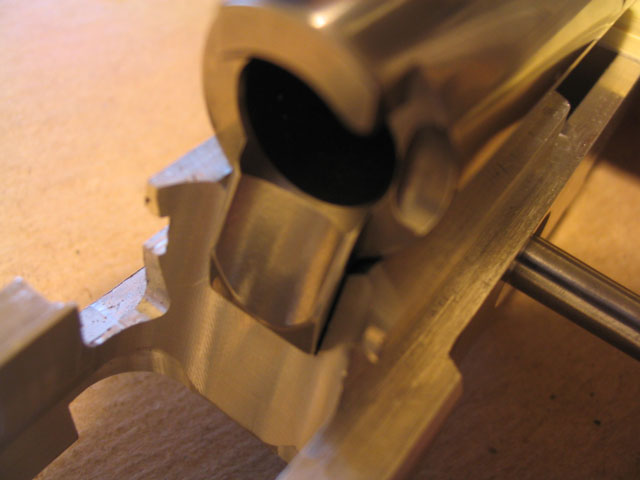

Here are some pictures that show my dilemma.

By following the directions that came with the barrel a cut was made from the slide stop pin to .6" aft of the pin.

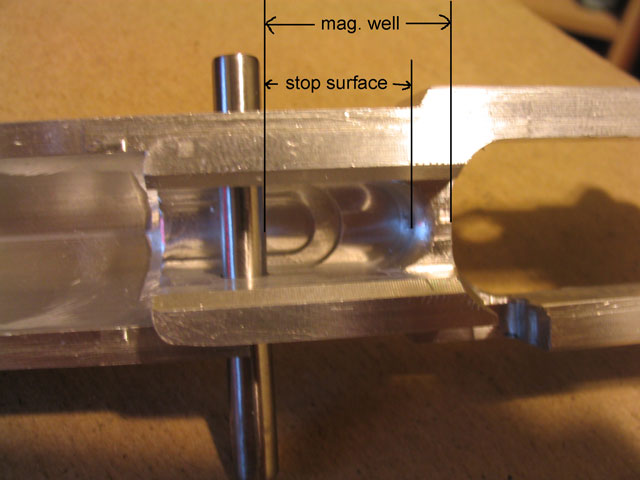

As you can see the feed ramp is in the mag well. If the stop surface is not cut as far back the lower lugs will be in the way of the slide stop pin.

Can any one give me these two dimensions or inform me how to properly install this barrel?

FYI, This is part of the SVI/STI wide body 1911 project

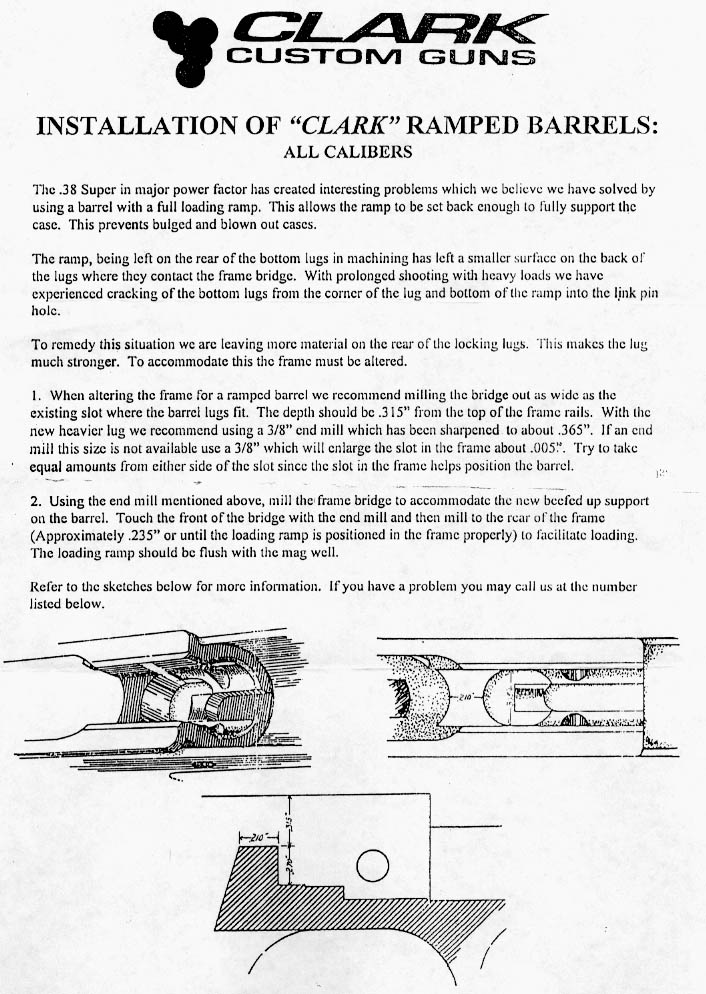

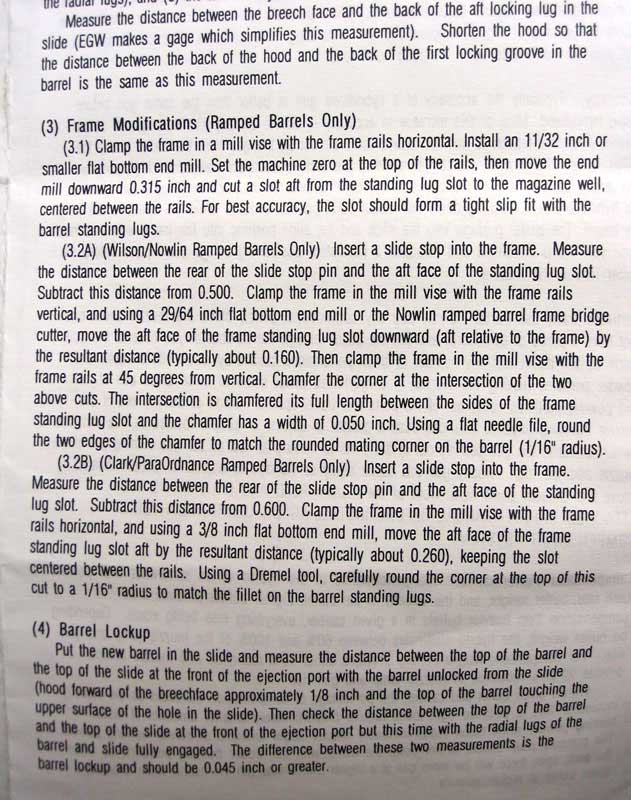

Here are the instructions that I got with my Clark barrel, this is for a standard 1911 frame, I have seen these figures elsewere also. There is no mention of .600 any where, perhaps your application is different as it is not a standard 1911.

FWIW, when I installed my ramped barrel in my SVI the ramp was overhanging into the magwell area. In the AGI video on a widebody frame the one they installed it did the same thing. They said to just file the ramp area so it was flush with the frame. I did that and it worked fine and the gun feeds well too.

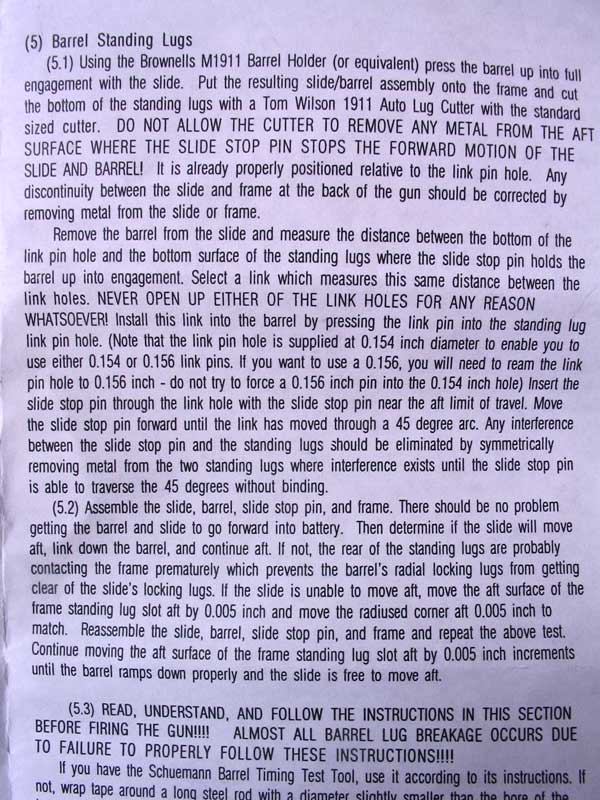

Thanks for the information BD; I think that is what we will have to do although I hate making the ramp any steeper. Here are the Instructions that came with the Schuemann barrel.

I was thinking I would have to trim the lower lugs but I don’t think that would be a good idea.

Read section 3.2b carefully - it says to subtract a number FROM .600 and mill to the rear using that number, around .260.

It DOESN'T say to MILL to the rear .600 of an inch.

The instructions say to measure the distance I have listed as "stop surface" in a previous picture and subtract that from .6". Then mill the slot that distance more which will make that measurement .600" when you are done. I think I am reading that right if not let me know.

308flinger, thanks for posting the instructions! I will add these to others I have and sort of take an average of all of them as a start for milling the frame. I will also keep a look out for the position of the ramp as I procede. Your statement " The instructions say to measure the distance I have listed as "stop surface" in a previous picture and subtract that from .6. Then mill the slot that distance more which will make that measurement .600 when you are done" seems to be correct. I wonder if there is some difference in your frame and a standard 1911? You could actually machine the frame untill the ramp fits as it should and then take measurements, to see if all you need to do is cut the lugs for the stop pin. Seems to me kind of funny to have a ramp to hang so far out and then have to grind it to fit and thereby change the angle to a much steeper one, not to mention the thinness of the area between the mag well and the stop surface.

If you just mill until the feed ramp fits the lower lugs would need to be cut including the cam radius. This would affect the link size you need. IMHO that is not the way to do it but I have no experience with this either. The alternative grinding of the feed ramp does not seem all that appealing to me either. ?

If I am not mistaken (and frequently am) the lower lugs have to be cut and a link selected based on the cut - that is unless the barrel is supposed to be a DROP IN and comes with the link. I have a ramped Clark barrel and the lugs will need to be cut as well as the cam shaped, the only thing finished is the chamber. It would be odd that there would be no fitting (lug cutting and link selection and caming surfaces formed) on a ramped barrel, due to the frame machining and its inherent nonstandardness (is that a word?).

From my research into this, most barrels have extra material on the lugs so that they can be properly fitted. However the lugs need to be fit to the slide in the locked position not to the frame for link down. The lower lugs do not even normally contact the slide stop pin during link down; all of the forces are directed though the stop surface and the link itself (it takes the entire vertical load).

Please remember that this is like the blind leading the blind. I have never done this before, if any one else has please feel free to comment.

Has anyone else seen the AGI videos? I would like some reassurance before I start cutting on a barrel.