OK guys I have a Springer Mil Spec that I bought used last year, shot it a couple of times and put it away because cash has been tight this year. With the arrival of my tax refund I'm now in the position to make a few mods and fixes.

I bought the gun last year from a guy who is a retired state patrollman and avid gun nut, he had been using the gun for IPSC use. There had been a few changes made to it but none that looked to be of the permanent, Dremel butchery type. The previous owner doesn't strike me as the kitchen gunsmith type so I don't think that anything funny has been done to this one.

The problem I have noted is that 3-4 rounds in a hundred would catch the bullet meplat in the lower sharp edge of the barrel feed ramp, usually with quite a bit of bullet set back and a nice 'smile' being made in the front of the bullet. When the gun did it last year I assumed it had a mag issue and bought a few different types. This didn't fix the problem though so and then I ran into the cash flow issues. So, fast forward to last week and I'm shooting my reloads through it, Hornady 230 XTP/5.5 WW 231, and dang if it didn't hang up with those bullets too!

Closer inspection after the shoot shows that the barrel ramp is actually over hanging the frames feed ramp by a few thou! All barrel parts are OEM and the ramps have not been dremeled, edges are sharp and well defined.

Any thought on how to fix this?

Probably a ramped barrel or frame insert. But... I had a cash strapped friend with a .45, same problem and I just broke the lower edge of the barrel without getting into the chamber. Works better but definatly not a recomended fix IMHO.

IMO, the best way to set about fixing it is to find out why the overhang exists. It can exist because:

* the top corner of the frame ramp is too far forward,

* the top corner of the frame ramp is too high,

* the bottom corner of the barrel ramp is too far back or

* some combination of 2 or all of these.

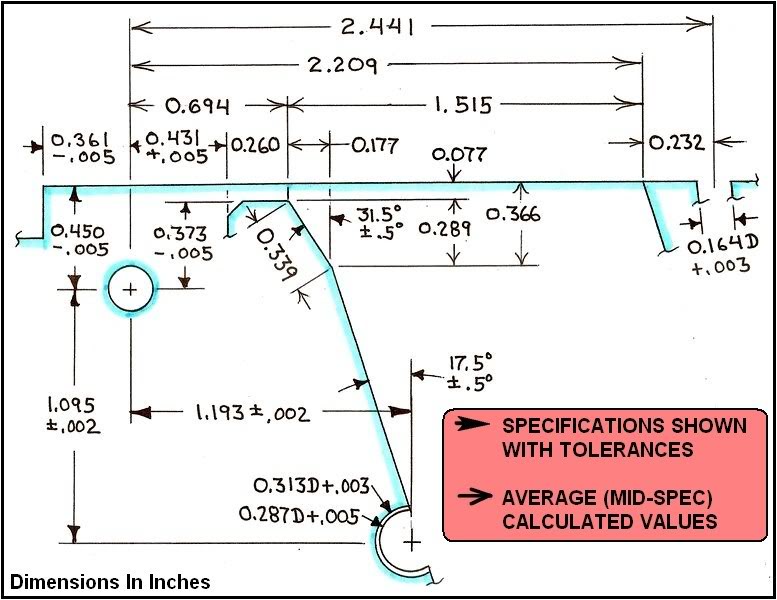

If you've got the measuring tools & skills, here's a drawing with dimensions for the average (mid-spec) Gov't Model M1911A1 frame:

Ashmesajim's fix is, however, the only easy one.

Send a photo and description of the malf. to Springfield Armory. If truly unmodified original parts are in the gun it is on them to diagnose and fix it.

And because the frame vertical impact surface is set too far rearward, or the barrel lower lug is located too far forward.

Most often, the condition is fairly easy to correct as long as it's not compounded by other issues such as the vertical impact surface, and if the headspace dimensions allow a little adjustment on the barrel ramp.

Sometimes, though, the condition is a symptom of a more involved problem. Using Dan's drawing, check the dimensions to determine what exactly is out of spec.

Quote:

And because the frame vertical impact surface is set too far rearward, or

the barrel lower lug is located too far forward.

Oops, forgot those.

The aft surface of the barrel lower lug should be 0.255" forward of the chamber face.

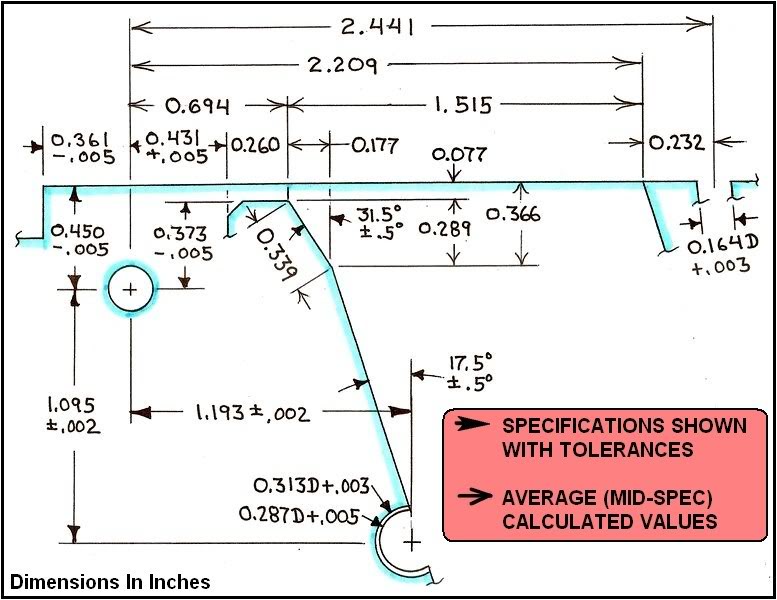

Here's what the average Gov't Model barrel looks like when snuggled up all the way aft & down in the average Gov't Model frame:

The barrel 'ramp'/feedway/angle/or whatever the proper term, is 35 degrees?

Quote:

The barrel 'ramp'/feedway/angle/or whatever the proper term, is 35

degrees?

Yes. With a tolerance of +/- 1 degree.

Thanks niemi24s, tuner and everyone else who replied.

Well I have a few measurements and with niemi24s drawings it seems I have a feedramp that is out of spec. Between the rear of the magwell and the top of the feedramp I'm getting 1.530 and the drawing shows 1.515, .015 over or to far forward in this case which makes sense given the original problem.

Other measurements are:

SS pin hole center to the VIS .433, drawing shows .431

VIS to frame ramp corner .240, drawing shows .260

Frame ramp length .378, drawing shows .339

Additionally the dimension between the rear of the barrels lower lugs and the edge of the rear of the chamber is .247 on my barrel which is short by .012 according to niemi24s. I guess I'm lucky it isn't in spec of the problem would be far worse.

Basically it looks like my ramp angle is cut into the frame leaning too far forward, causing the problem of the barrel ramp overhanging the frame ramp by around .005

Is it possible to releive the lower edge of the barrel ramp to at least eliminate the overhang? I know this will change the angle of the ramp on the barrel, making it steeper if I retain the upper edge for case head support.

Quote:

Is it possible to releive the lower edge of the barrel ramp to at least

eliminate the overhang?

Sure, just like Ashmesajim said in Post #2.

Quote:

know this will change the angle of the ramp on the barrel, making it

steeper if I retain the upper edge for case head support.

Just whittle off the bottom of the barrel ramp (vertically) to eliminate the overhang, then round over the corner at the top of the whittling a tiny bit.

A good sharp, stiff pocket knife blade works good on carbon steel barrels. Don't know about stainless steel barrels.

But before whacking on anything, re-read Jolly Rogers' comments in Post #4 - expecially in light of your frame ramp measurements.

* Barrel Bed Length = 0.260 +/- 0.010 inch

* Frame Ramp Length = 0.339 + 0.070 / - 0.058 inch (or 0.345 +/- 0.064 inch)

The problem with providing mid-spec values only is that it may lead someone to declare something out of spec that is within spec. The other problem is that most dimensions for the M1911 design were not +/- dimensions (as in .750 +/- .005), they were more often specified as being at one end of the range, and the entire tolerance was either all plus, OR all minus, not plus-or-minus.

Which is to say that a pistol built entirely to exact mid-spec dimensions would NOT be built to optimum dimensions.

Quote:

The problem with providing mid-spec values only is that it may lead someone

to declare something out of spec that is within spec.

With all due respect, anybody that gets misled into thinking that "The mid- spec value is 1.234 inches" means that if it measures 1.236 inches then it's out of spec - has no business whatsoever measuring something to the nearest 0.001"!

Quote:

The other problem is that most dimensions for the M1911 design were not +/-

dimensions (as in .750 +/- .005), they were more often specified as being at

one end of the range, and the entire tolerance was either all plus, OR all

minus, not plus-or-minus.

There's no problem with that. It's simply common practice that the nominal dimension given is for the MMC (maximum material condition): smallest hole; biggest pin.

Quote:

Which is to say that a pistol built entirely to exact mid-spec dimensions

would NOT be built to optimum dimensions.

"Optimum" is a subjective term, implying one specific dimension within the allowable range of dimensions is best. I'm sure there is no way to correlate the nominal dimension with any optimum dimension - if there is one. I'm not saying a particular part in a particular gun doesn't have an optimum dimension. That's what fitting is all about. But my dimensions are for all parts in all guns because they're based on Ordnance blueprints.

And I very seldom use anything but mid-spec (average) values in my calculations anymore. That's mainly because somebody clouded up and rained all over me a few years ago when I started calculating stuff using the full range of tolerances. I got crucified for saying the barrel ramp could overhang the frame ramp by something like 0.019" with parts that were within the specifications. Using just the mid-spec values also saves me a lot of time as my work is all done with pencil, paper & calculator.

Dunno what prompted me to post those tolerances (figured out years ago) in my last post. Temporary insanity?

Quote:

But before whacking on anything, re-read Jolly Rogers' comments in Post #4

- expecially in light of your frame ramp measurements.

Thanks niemi24s, I bought the gun used and I think it was manufactured in the early 90's, the previous owner had shot it quite a bit from the look of things. I doubt I would get any support that didn't come with a price tag attached though.

I was thinking about upgrading the barrel sometime in the future with a Cart or such... Not sure I want to chance it now though.

Anyway I went ahead and took the 5 though off the bottom of the barrel ramp and blended into the rest of the ramp, flattening it out. This, of course, makes the ramp speeper in profile, headed towards the chamber. I guess I'll see how it shoots tomorrow.

Well I just got back from the range and I have to report that I didn't have a single round hang up on the barrels feedramp, mission accomplished, at least where that problem was concerned.

I did have an assortment of other little issues with the gun though. The first to crop up is that I had 3 failures to extract, the fired case was sticking half way out of the chamber with the slide bearing on the next round in the mag, puzzling as I have never seen this problem with this gun before.

Next came a single 3 point jam that happened on the last round fired of the day. I was shooting 200 gr LSW reloads and all 49 before this one chamberd and fire fine. Perhaps this was due to a pretty dirty chamber and breechface hanging things up?

Last but not least I had a hammer follow when loading that last round to expend it. Repeatedly dropping the slide with the slide stop reproduced the problem about 50% of the time and pulling the slide back and slingshotting it caused it almost every time. I did replace the trigger, thumb safety and added a S&A beavertail GS to the gun this weekend. The trigger stop screw was adjusted using the proceedures found here in the stickies so I don't think I have an issue there.

Any ideas guys?

Quote:

...3 failures to extract, the fired case was sticking half way out of the

chamber with the slide bearing on the next round in the mag...

Make sure the hook's not broken off the extractor. If the hook's there, check the extractor's tension.

The extractor looks fine as far as I can tell, no idea what those jams were about, perhaps it was just excessively dirty.

I'm pretty sure my hammer follow is the result of trigger bounce since I can't duplicate it by doing the proper proceedures to isolate the disconnector. I'll probably increase the spring tension on the disco anyway just to be sure though.

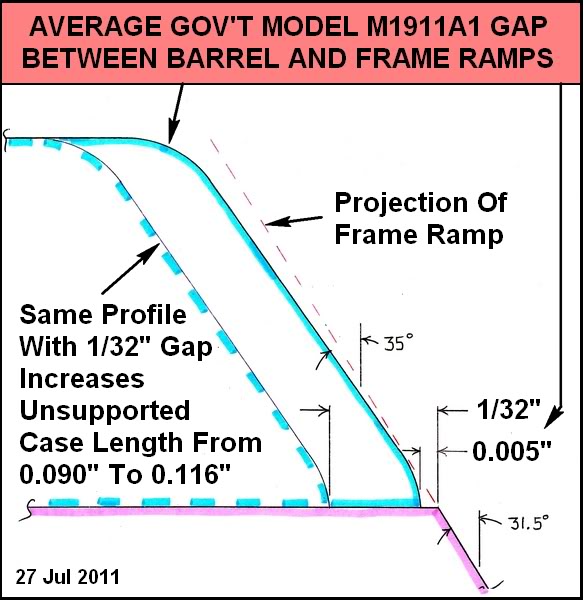

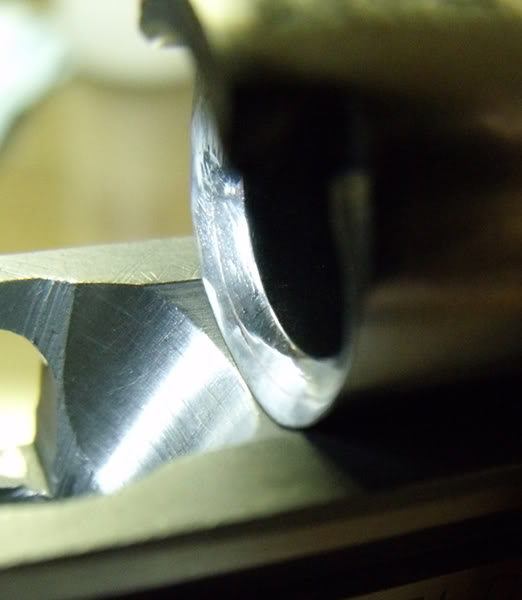

Thought you guys might like to see the edge of the barrel ramp after the fix.

Before firing:

After todays range session: