I picked up a Foster frame today from my FFL for a build, and was looking it over. Looked good, but I wanted to take some measurements.

Using a metal machinist protractor, I got a measurement of 17.5 degrees for the magazine well. However, when I took a measurement of the frame's feed ramp, it came out as 29.5 degrees.

Now, to be honest, I may have been off on these measurements, but I did measure over and over and over again paying very close attention. I hear that the 1911 demands a feed ramp that is 31.5 degrees exactly. If not right on the money, there will be problems.

On the order sheet, they listed it as one of the services performed (feed ramp cut for .45 ACP), so it doesn't sound like something that would need extra attention with a mill or anything.

Now, I just wanted to check here with the experts - does this sound like something that I need to contact the manufacturer about? I trust they'll take care of me but I just wanted to double check on the dimensions and specs since I am still fairly new to the platform.

FYI, Army Ordnance dimensioned blueprints for the M1911A1 frame (as well as all the other parts) are available in our Tech Issues section via the link "M1911 Full Blueprints (Courtesy CNC Gunsmithing)".

If you're going to build a gun, you should become familiar with finding these invaluable references. Might even want to print some.

Nothing on the 1911 is "exact", as that implies the dimension has a tolerance of zero. Every practical dimension in the real world has a non-zero tolerance, including the 1911. And those are all on the blueprints.

Thanks for your post Niemi24s, and I have consulted those blueprints. I've found where on the blueprints it indicates a 31.5 degree feedramp, but I did not notice any tolerance specs either + or - for that measurement.

It has been my impression after spending some time on the forum that an out- of-spec part on a 1911 can have a considerable impact on the subsystems that all work together to produce reliable operation and that one of the most crucial is the feed ramp angle. My understanding is that if left uncorrected, a feedramp with the wrong angle will at best hold off inevitable problems for a little while, and at worst produce a non-functioning weapon. Either way you look at it, I get a little jittery when measurements on the 1911 don't look the way they should.

If the frame ramp really is off-spec, could the frame still be used, after being cut for a ramped barrel?

Yes.

Quote:

I've found where on the blueprints it indicates a 31.5 degree feedramp, but

I did not notice any tolerance specs either + or - for that measurement.

Tolerances for any dimension not specified along with the dimension in regular part of the blueprint can be found in the "Tolerances On" block at the bottom of each blueprint, in Zone 3A.

All that is pretty difficult to see clearly on our versions of the blueprints, so for the frame the blueprint tolerances are (unless otherwise specified):

* Degrees = +/- 0.5 deg

* Decimal Inch = +/- 0.002"

* Fractional Inch = +/- 1/64"

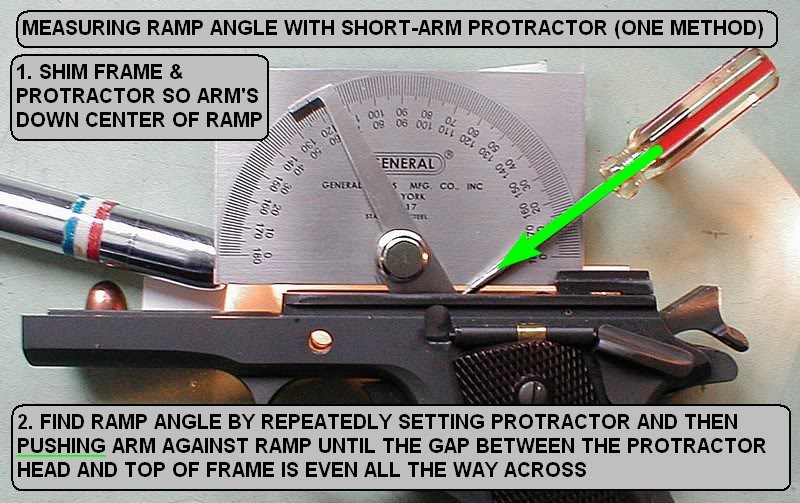

Your measurement of the frame ramp angle indicates it's too steep by 2.0 degrees and I can just about guarantee that'll cause problems - if it really is 2.0 degrees too steep. However, the shortness of the ramp (about 3/8") makes its angle measurement difficult. Here's the best way I've found to do it with a protractor:

Other ramp angle measurement details can be found here: http://forum.m1911.org/forumdisplay.php?f=53

Thank you again for your incredibly informational posts - it confirms what I've been trying to do. I'm a visual learner, so I appreciate the picture!

I was messing with it last night, and time after time, the most consistent measurement I got was 60.5, when it should be 58.5. I tried setting the protractor (I have the same one as the one in that picture) at 58.5 (correct angle) and matching it up with the feed ramp to see what happens. If the protractor base it not resting directly on the frame rails and the arm is setting flush against the feed ramp (being pushed and noted for no gaps), there is a very visual 'off level' discrepancy between the bottom of the protractor base and frame rails. Likewise, when protractor is flush against the frame rails (with even spacers) and the arm/feed ramp relationship is observed, there is a visible gap at the bottom of the feed ramp between the ramp and the protractor arm when the protractor is set at the correct angle.

Sad, looks like this one is going back.

Here is another question - does anyone know how most manufacturers cut the feed ramp? It seems like this issue right here is why the 'jammomatic' reputation of the 1911 is perpetuated. I'm not a machinist, but I still can't understand how after what, 98, 99 years, manufacturers who specialize only in 1911 building can take something so fundamental to reliable operation and just 'get it wrong'? I mean, shouldn't manufacturers have a permanent 31.5 degree jig? If something so minute as a degree or two can affect the entire operating principle of the weapon, wouldn't it make sense to spend the time to make sure that if anything, that is one thing you really, really get right? I know this is not an isolated incident to just one manufacturer. And I'm not so much upset as I am confused that companies who do this for their livelihood don't have a more consistent way to control it. After all, if it is something serious enough to choke the pistol, there should be no room for error, correct? Just trying to learn.

In any case, I'm confident that Foster will take care of it - they seem like good folks. I'll be in touch with them.

Thank you, especially to Niemi24s, for your input. If it wasn't for this forum, I wouldn't even know to check these things in the beginning. One other question - I tried to find the number in the blueprints but could not (maybe I just missed it?) but I was looking for the correct length of the frame bed, from the VIS to the top edge of the feed ramp? If Foster has to recut the ramp (hopefully they'll be able to do so since it is just too steep) I'd want to make sure that didn't play havoc with having enough meat in that area so the proper barrel/frame gap could be maintained.

Quote:

...I was looking for the correct length of the frame bed, from the VIS to

the top edge of the feed ramp?

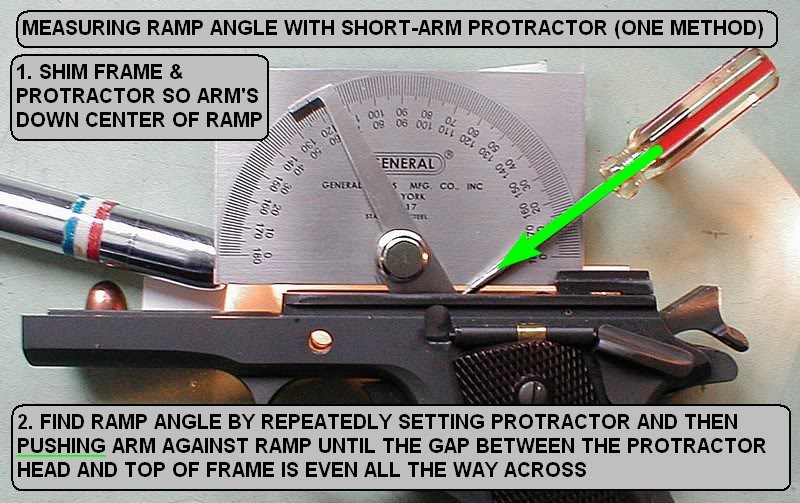

That is not given and has to be calculated from the other dimensions given on the blueprint. There are lots of frame dimensions like that, such as the length of the feed ramp. Here are the average (mid-spec) values of some of them:

Okay, so I went out and got myself a digital caliper and have been taking some measurements.

Compared to the image above, here are my measurements:

Image measurement A (feed ramp) : 31.5 degrees

My measurement: 29 degrees

Image measurement B (VIS to top of feed ramp) : .260

My measurement: .255

Image measurement B (VIS to bottom feed ramp): .437

My measurement: .415

Image measurement C (top feed ramp to bottom feed ramp): .177

My measurement: .160

To me, this indicates that the feed ramp is too steep (duh) but also that the VIS is already too far back. Were I to get the ramp straightened out on this frame to the appropriate angle (31.5), I would get a feed ramp horizontal measurement of .177, which would make the VIS to top of feed ramp length .022 too short (.415 - .177 = .238 Measurement B length), which would most likely lead to barrel over hang issues?

What is the minimum spec for this .260 length? I can't imagine it would be .235 or .240

Am I worrying about these measurements too much? I just don't want to have jammer (wrong feedramp) just to turn around and fix the feed angle to then have barrel overhang issues and still have, yep, a jammer. Its starting to sink in now how the various systems of the 1911 have to all work together to produce a functional pistol. I don't want to fix one problem just to have the solution create another.

Quote:

To me, this indicates that the . . . VIS is already too far back.

Not really. If you make yourself a copy of the frame blueprint that's in our Tech Issues section and study it, you'll notice that the center of the slide stop pin hole is the reference point for virtually all of the dimensions - including the horizontal location of the VIS.

The spec for the SS pin hole center to the VIS is 0.431 + 0.005 inch, or the 0.434 in the pic, above. To see if the VIS is really in the wrong place, you'll need to measure that 0.434 by putting the SS through, measuring from the SS back to the VIS and adding half the SS diameter. That should get you within 0.003" - maybe 0.002".

And knowing that will tell you a bit more about your frame.

Quote:

To me, this indicates that the feed ramp is too steep (duh) but also that

the VIS is already too far back.

Not necessarily.

The VIS may be too far back, or it may not. Those measurements don't tell you anything in that regard. The center of the slide stop hole is the reference point for virtually every dimension on the 1911. The VIS, as shown in Niemi24s' sketch, is .434" back from the centerline of that hole. THAT's your reference for locating the VIS ... and all the other dimensions. You need to convert the various dimensions such that you can measure each of them relative to the slide stop pin -- otherwise all you're proving is that they are not the same as theoretical "mid-spec" dimensions, but they aren't fixed anywhere relative to the overall frame so they mean nothing.

Niemi24s, Hawkmoon,

You both had nearly identical posts. I understand what you are saying. So, lets assume that the slide stop hole is in the correct place relative to the VIS. While that may get the barrel in the same position, wouldn't I still end up with a frame lug that is too short since it is already hovering at .255 and that is without any more meat taken away to accommodate an 'in spec' feed ramp, which could cause problems with the frame/barrel ramp gap? I unfortunately don't have a slide stop or barrel to try it out with right now since my father has the rest of the parts and will be bringing them with him when I meet up with him in about a month.

I just don't know how critical that .260 from VIS to frame ramp is, because with this frame, to get the feed ramp in spec, it most certainly will be shortened. I would just hate to spend the time/money to get the feed ramp corrected, and to even have the SS in the correct location, just to end up with a problem fitting an in-spec barrel since there is no lee-way with regards to a barrel ramp gap. I hope I'm making sense. My knowledge at this point is theoretical and I think I am being crazy anal about all these numbers because I'd like to keep most horrific errors theoretical as well

At this point I haven't really factored in the frame bed, but I'm hoping that spec won't drastically change enough to throw the current measurements completely out of whack. Of course, I could be completely wrong

Is there a certain order in priority which is given to different specs? Maybe that sounds dumb, but its sounds like high up on that list would be SS pin to VIS, frame ramp degree, etc. Does the thickness of the VIS-to-frame ramp play a big part in reliability, or barrel fitting, or barrel gap (I would think the latter, at least). Because, as I had mentioned, its already shy of .260, and will be even less if it were to make room for metal being removed to correct the feed ramp angle.

So I've found a detailed blueprint of the barrel online. It shows a measurement of .257 on the under radius from the back of the lower lugs to the bottom edge of the barrel's feed lip.

That makes sense with the frame bed spec at .260, which would indicate the 1/32 spacing needed between the two.

Since my frame is already at the .255-.260 mark, losing what, .005-.010 or so to get the ramp corrected would put it at .245-.250 or so. With a correct barrel, we're looking at .257 on that lower measurement, which looks like it puts us over the frame ramp when the lugs make contact with the VIS.

Does that scenario seem correct? All these little numbers are driving me crazy... I wish I just had a barrel to throw around in w/ the frame.

By the way, I really, really appreciate your input. It is helping me to learn a lot, and this is knowledge I won't soon forget. Thank you very much, I am very grateful.

The blueprint dimension for the distance from the centerline of the slide stop hole to the VIS is .431" +.005".

The distance from the centerline of the slide stop hole to the frame ramp is not a "derived" dimension (it is not reached by locating the top and bottom of the ramp measuring horizontally). It is given as a direct dimension, measured perpendicular to the ramp surface. The ramp is shown at an angle of 31d-30'. Measured on that angle, the ramp is .79" - .01" from the centerline of the slide stop hole.

Quote:

To see if the VIS is really in the wrong place, you'll need to measure that

0.434 by putting the SS through, measuring from the SS back to the VIS and

adding half the SS diameter. That should get you within 0.003" - maybe

0.002".

And knowing that will tell you a bit more about your frame.

That distance will also tell us a bit more about your frame.

Q: What is that distance?

Hawkmoon, from the center of the slide stop pin to the frame ramp, at an angle that is perpendicular to the ramp (as a direct measurement), I am getting roughly .787 - This is w/ the 29.5 feed angle.

Niemi24s,

From the center of the slide stop pin to the surface (bowtie) of the VIS, I'm getting EDIT: .4425... it's a little hard to measure here. I wouldn't take that number as gospel, but it doesn't look like its going shorter than .440.

I hope these number help in your assessment. I'm not sure yet how they tie in to everything else.

Quote:

I hope these number help in your assessment. I'm not sure yet how they tie

in to everything else.

Well, the VIS is a little too far back and there's little (or nothing) than can be done about that - as far as know. Whether the gun can be made to run OK with that condition, I honestly don't know.

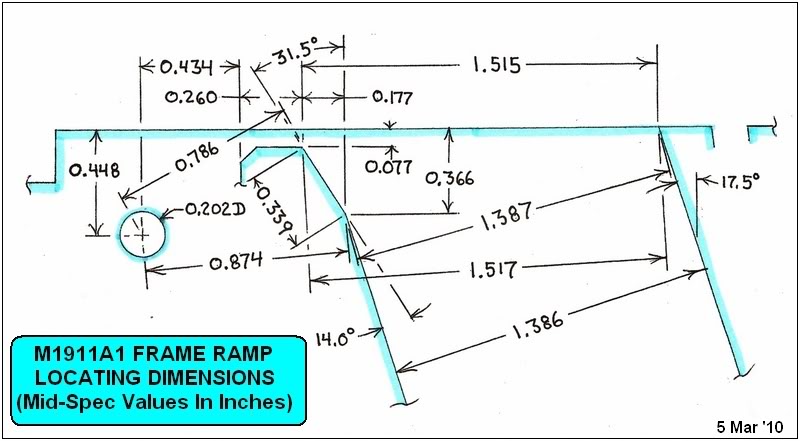

As far as the "short" barrel bed goes, here's a thought. If the bed is not deep enough (the 0.077") it will shorten the bed, and deepening the bed will make the bed longer. The center portion of this pic shows how I measure the bed depth - using a drill shank to "find" the curved bottom:

Maybe you're "lucky" and the bed needs lowering too!

Quote:

What is the minimum spec for this .260 length? I can't imagine it would be

.235 or .240

You imagined correctly. The minimum bed length works out to be 0.250" and the maximum is 0.271" when rounded to the nearest 1/1000th.

I appreciate you taking so much time with me on this. I'm learning a lot.

I figure I'd double, triple, etc, check that SS to VIS measurement. The caliper I have has short 'teeth' so I have to be careful not to 'lean' the caliper down to the slidestop pin, skewing the measurement.

One of the original questions I had was that lets say my measurement turned out to be funky and the VIS was just fine, it looks like I'd end up with a prematurely ending (too short) frame bed, with it being in spec now but not necessarily so were the ramp to be cut to the right degree. If that were to be true, does it mean that the frame becomes a paperweight or that your job building a 1911 just got that much harder since you now have to shave the barrel breech back? Is this something that you just have to put the darn thing together to find out? With out a barrel, I know I'm making this whole thing much harder on myself!

Quote:

...lets say my measurement turned out to be funky and the VIS was just

fine, it looks like I'd end up with a prematurely ending (too short) frame

bed...

Until you measure how deep the barrel bed is (see Post #17) you really can't figure how long the bed will be after the ramp's cut to the correct angle. As out of whack as the rest of it is, maybe the bed's out of whack the "right" way too.

If the bed's about 0.077" deep, the bed will end up short. But if the bed's not deep enough, the bed will lengthen by 60% of however much deeper it's made. In other words if the bed's only, say, 0.067" deep, when it's made 0.010" deeper it will get 0.006" longer.

I know it's not much, but it's better than a poke in the eye with a sharp stick!

BTW if you get adventurous and decide to get some frame ramp length measurements, the drawing's 0.339" is the mid-spec value. The maximum is 0.409" and the minimum is 0.278". While that may seem like waaaay too much difference, those values are determined by 8 different specifications - and tolerances do indeed stack up.

You'll be proud of me... I've been working on more calculations haha. I measured the frame bed (accurately!) and came up with a .070-.072 depth. That good news (from a certain point of view) which means that I would be able to go deeper. If I go deeper by .006, that means that I gain .0036 in bed length. However, the bad news is that if I take my feed ramp measurement (.335) and do some triangle calculations to get the feed ramp from 29.5 to 31.5, it would mean taking away .014 away from the frame bed.

With the frame bed coming in right around .259, that would mean I'd end up with a frame bed length of .2486. Not promising.

In measuring the SS hole to VIS, I tried a different, more accurate method that kept my caliper straight. The most consistent measurement I have been getting is .4435, which is still a long ways off.

It would seem that if the VIS to SS center measurement was in spec, that would add around .010 to the length of the bed. If the frame ramp angle was milled/cut correctly, it would look something like: .259 + .010 (VIS to SS in spec) - .014 (moving frame ramp in spec) = .255

Although, that seems a little short (not bad, but a litte). When I measure SS pin center to feed ramp, I get .782-.786. If I was to factor in a correctly cut feed ramp, that would put my measurement at .782-.786 - .014, which would give me .768-.772 , which seems a little on the short side. Who knows, maybe the SS pin hole is a teeny tiny bit off as well? At this stage I have no idea.

Whew. Well, at least I think I know a little bit more to say when I return it. I don't know if it will do me any good to just ask them to recut the frame ramp, since all that will end up doing is shortening the bed below spec, and I still have a VIS to SS center that is out of spec.

Aahhhh... all these numbers!

You could just ask them to cut the frame for a ramped barrel...

Quote:

...I'd end up with a frame bed length of .2486. Not promising.

It would be a challenge - especially because the part of the barrel that goes onto the bed is 0.255 +/- 0.005 inch.

But at least you now know what you've got and that'll help when you talk with Foster. And because (IIRC) you said you didn't yet have a barrel, Rekladen's idea may be worth considering.

Anyhow, as I understand it Foster frames are somebody's factory rejects. If so, I wouldn't expect to get one with just a big scratch up inside the magazine well.

While Foster is a subdivision of Caspian that handles factory-seconds, it is my impression that the work only with cosmetic seconds. On their homepage (Foster), they state "The metallurgy is top notch and machine tolerances meet or exceed military specifications".

But who knows? When I send it back, I will all let you know their response and just what I receive back.

RE: the ramped barrel idea, I was also under the impression that a ramped barrel creates an excessively steep feed angle that is more likely to cause malfunctions (I've heard a lot of people who know a lot more about 1911s than me not recommend them). True? Untrue?

This thread has been entirely informative. Thank you all! I will post up results when I hear back from Caspian/Foster!

Hmm-m-m. Here's a wacky thought. Your frame ramp is 29.5deg which is 2deg steeper than the mid-spec value of 31.5deg. That measly 2deg makes it harder for the bullet to glance up off the ramp and into the chamber when feeding. But...

...what if the magazine well is also 2deg too steep? And is 15.5deg instead of 17.5deg? Bullets are pretty stupid. The dumb things would see the frame ramp at the proper angle! Maybe feed slick as snot! Maybe no need to fiddle with the frame ramp angle! Maybe leaving the barrel bed long enough so the barrel ramp would only need to be moved forward a teeny bit! Lordy, that's a lot of maybes!

Q: What's the angle of the magazine well?

Quote:

...they state "...machine tolerances meet or exceed military

specifications".

Well yours doesn't, so they should welcome it back with open arms.

Quote:

RE: the ramped barrel idea, I was also under the impression that a ramped

barrel creates an excessively steep feed angle that is more likely to cause

malfunctions (I've heard a lot of people who know a lot more about 1911s than

me not recommend them). True? Untrue?

I don't know anything about ramped barrels.

Perhaps somebody who does will chime in with a comment.

I like your thought about the mag well angle! Unfortunately(???) it is the one spec that actually seems in spec haha. 17.5 exactly.

I'll do a little bit of research on ramped barrels... I'm always open to things I know little about.

Well I heard back from Caspian. Here is the deal-

They said my measurement of the VIS to SS center was not exactly correct, that is was measured not from the bowtie but from the relief cut under the bowtie. I can understand that. They said that their measurement of the VIS to SS center was .236, in spec.

However, the feed angle has been confirmed at 29.5 degrees. They said that is just what they cut them at now. He said that is was out of spec, but that it will still work fine.

My concern is that the ramp is out of spec, but if they were to cut the ramp to the right spec, the barrel bed would then be too short and I'd have barrel overhang issues.

He said what they could do is provide me a receiver has a 38 Super ramp cut and that it would leave me with plenty of material for a gunsmith to work with.

Aahhh, there are no good answers! Is it that hard to get a .45 frame with a 31.5 ramp?

Any suggestions on what I could do? They can either ship my frame back to me (with no changes made) or have a new one with a 38 Super ramp sent to me but since it is a different serial # they have to re-send it back through the FFL.

Thoughts?

Quote:

They said my measurement of the VIS to SS center was not exactly correct,

that is was measured not from the bowtie but from the relief cut under the

bowtie. I can understand that.

I can't understand that. The barrel hits the bowtie, so the bowtie is the critical dimension. You could put the relief anywhere and not affect operation.

Very weird. Even weirder that they're intentionally cutting the ramp out of spec. You'd think they'd at least have an explanation for that like "we have conducted extensive testing and this works better" or something along those lines.

Quote:

Well I heard back from Caspian. Here is the deal-

They said my measurement of the VIS to SS center was not exactly correct, that is was measured not from the bowtie but from the relief cut under the bowtie. I can understand that.

Well, I can't, because the barrel hits the bowtie, not the relief cut.

Quote:

They said that their measurement of the VIS to SS center was .236, in

spec.

No matter what oddball dimension I have ended up with, that is the same answer I have received.

Quote:

However, the feed angle has been confirmed at 29.5 degrees. They said that

is just what they cut them at now. He said that is was out of spec, but that

it will still work fine.

Well, if that is the way they cut them now, then it actually is in spec - for them anyway.

It was also my understanding that F. I. sold cosmetic blems that were otherwise correctly machined. Now as you will read below, that statement might not mean a whole lot.

Let me try to be delicate about this, so as not to be accused of rash commentary. I will mention only things that have happened to me personally without implying that everyone else has had the same trouble. I have heard the identical commentary as AdventureWolf given to me when I called to ask about some questionable dimensional oddities. One terrific example - among many - is that the frame rails on the slide are tapered front to back. The answer was that "gunsmiths everywhere demand it". To a half-dozen similar dimensional difficulties, I got this same response, or that the part was within spec. Whose spec? Certainly not JMB's!

These parts were not cosmetic blems by the way; they were from the main factory. They use the same CNC machinery that is so highly regarded by other forum members. So how was it, we might speculate, that they could cut a 31.5 degree ramp back in the good old days?

One thing we have all learned from reading this forum is that the frame ramp must be at the correct angle and correct depth for the gun to feed reliably. Depth of the frame bed is another critical area. But I have personally received a number of units that displayed no concern for these critical dimensions (and others) in both frame and slide. And every time I made the call, I was given the above explanations. Of course, this was just my personal experience. I now find that at least one other person, AdventureWolf, has been treated to the same red carpet service. Just some food for thought, nothing more.

Lazarus

p.s. the nominal frame bed depth is .077". When I found mine to be .068, and called the manufacturer, the answer was that this dimension cannot be calculated until the slide and barrel are fit. And thus it is left "raw" to promote a better fit.

Quote:

Any suggestions on what I could do? They can either ship my frame back to

me (with no changes made) or have a new one with a 38 super ramp sent to me

but since it is a different serial # they have to re-send it back through the

FFL.

Unless your state has different requirements, Federal law does not require that a new frame be transferred through an FFL. You had a frame transferred to you legally. You sent the frame to the manufacturer (legally) for warranty work. The manufacturer can substitute a replacement frame and return it directly to you, if that's the route you and Caspian wish to go.

I was not aware that Caspian's frames are not to Browning's specs, and I have to say I am disappointed.

Quote:

They said that their measurement of the VIS to SS center was .236, in

spec.

Did you mean to write .436?

Yes, I did mean .436 haha. I think I had the frame bed length in my head, and then my brain just tacked on the rest of the other dimension. Whoops

Regarding the other comments, the reason why I was told it was in spec was because he said I was measuring from the SS center to the relief cut, not the bowtie. However, I know that was not the case (how could I measure from the relief cut anyway?), but because my methods were not as precise as maybe theirs is, I can see how it would be different. I was using a 4" digital caliper which has small arms, so that may have been part of it.

The reason why he said it would have to go back through my FFL is because if I received a difference receiver, it would have a new serial #, which would necessitate a whole new process. I don't think they would send back a different receiver to my address, as it sounds like that is their policy, even if the law checks out.

Maybe I should just ask for a refund? Is that possible on a part like this?

I, too, am slightly befuddled that after 100 years of knowing the tolerances, the feed ramp is intentionally cut 2 degrees off, and actually acknowledged to be out-of-spec. When I asked if I'd have enough room on the barrel bed to have the proper spacing between the barrel feed ramp and the frame feed ramp if I was to get the frame cut to the correct 31.5 angle, I was told they couldn't guarantee it.

Maybe I should just try to go with a Fusion?

Quote:

Maybe I should just ask for a refund?

That's what I would do. Then I'd go elsewhere and get a frame that wasn't a "1911 Frame Of The Month Club" rendition.

Oh, I get it. Yeah, I'm not sure how you'd measure to the relief cut, either, and you'd certainly be aware you were doing it. It's not the sort of thing you could do accidentally.

Quote:

...I'm not sure how you'd measure to the relief cut...

Bearing in mind that it is not mandatory for a frame to even have a relief cut (by which a bow tie is created) here's how:

* Insert SS pin, #7 drill or pin gage in frame

* Use a slide caliper's depth rod/bar to measure from the front surface of the SS pin (etc) back to the bottom of the relief cut with the end of the caliper's depth rod/bar on the relief cut

* Subtract 1/2" the SS pin (etc) diameter and add 1/2 the slop between the SS pin (etc) and the frame holes

If the caliper's physical size didn't preclude it, the distance from the bow tie to the bottom of the relief cut could be measured directly using the same technique.

Ok, now tell me why anyone should want to do it.

BTW, nice game for the Blackhawks the other night. How's it feel to be a target?

Quote:

Ok, now tell me why anyone should want to do it.

Can't think of any practical reason, so maybe just out of sheer boredom?

Could this be another source for frames? www.floridaarms.com