Can the rails and top mating surface a frame be welded to oversize prior to machining without warping? I fear that even if I preheat the surfaces with a torch and will weld using a TIG, I might distort the rails or the frame. I would like to increase the top mating surface of the gun and the width of the rails and then mill them down to about 0.08" and 0.04 respectively prior to hand fitting.

Can it be done without the risk of ending up with a warped frame?

I know that there are gunsmiths who do indeed weld up the rails for a tighter fit, but I don't know how exactly they go about it. I would be a bit concerned about a preheat messing with the hardening of the frame; you wouldn't want to anneal the VIS or the abutment where the slide stops, so you'd want to be careful about how hot you let things get. However, I am most certainly not a welder, and as a gunsmith I'm only one step above "Bubba," so my advice isn't worth much.

The fact that you say that there are gunsmiths that use welding methods is very interesting! The bad part is that even an experienced welder most likely don't know how the frame would react. You make a good point with the annelaing. The frame seems to be quite soft compared to the slide, and I don't think it would be hard to achieve a good hardening of it after all machining is done. Not letting heat spread too far while welding seems like a must, and the more I think about it the more a MIG welder fits the bill. The seams doen't pull as much or heat the surrounding areas as a TIG does, the downside is a much harder seam that will be difficult to machine.

There aren't exactly a lot of 1911 experts over here, so I need to figure this one out my self. Worst case: 500$ for a new frame.

I can see my self doing quite a lot of investigation before going at it considering the cost of a new frame. Over here a new frame would also mean having to re-license the gun

Most often done by GS by TIG. The front 1" and the rear 3/4". Normally the object is to widen and lower the rail in those areas to pull the slide down on the top of the frame, not raise it up. Rod for chrome-moly should be used and a pre-heat and post heat will yield a mid-30 HRC. Better than the frame to begin with. ER80S2 is the rod by common designation.

As a welder for over 40 years I would use 80sb2l (1-1/4 chrome) 80s2 is only carbon steelthis item would have to be controlled welded, stress relieved. Re tempered to whatever hardness it should be (?) I would not do this to my gun. I would buy a new frame or slide, whatever I needed. I know there are gunsmiths that do this, but it is a risky job as far as MIG welding, it is not a very good quality job. TIG is the way to go

Also this type of steel would have to be heated to around 250 deg. as a certified govt. welder we were required to preheat chrome moly before welding.

Bophi, your welding expertise is most welcome, but did you notice that the gentleman with the problem is in Sweden? I doubt very much that replacement 1911 receivers are as readily available in Sweden as they are in the U.S. If we accept as a given that he pretty much has to work with what he's got, would your advice be any different?

Here's an alternative to welding up the rails or peening them down... http://www.acc-u-rail.com/ ...just in case you were not aware of it.

On the assumption the frame/slide fit is very sloppy - and that's why the subject of welding was brought up - why not just forget about welding (and the chance of ruining the frame) and do what everybody else does: just peen down the frame rails and squeeze the slide for a nice tight fit?

No heat is involved and the process is well-understood and documented. Brownells has the needed tools and the instructions are in one of Kuhnhausen's 1911 books. It can't be too difficult - I have even done it!

I have read your posts and witnessed your expertise for some time. Your comment "I have even done it" doesn't make me feel anymore warm and fuzzy about weather or not I could do it.

Captain Awesome, You seem to have a decent understanding of tolerance and fine measurment. I do however think you could get it done. You wouldn't have the idea to even weld the area and remachine it if you didn't have an industrious bone in your body. If you do weld it I perfer TIG welding it is so much cleaner with more fine control of the heat. The fact that you recommended it I assume you understand the finer points to it. +1 on the preheat. Good luck and please let us know what and how you did it. I like pictures.

Thank you all for tons of good info and suggestions.

I will try to answer most of you in one single post. Here it goes:

BigJohn/bophi - Thanks for suggesting good ChrMo steel rods to use and ideas on how to proceed. One reason to why I aim at applying material on top of the rails is because even if I push the slide down by hand so the lower part of the slide touches the frame beneath the slide's rail, I still have a gap between the slide and the top of the rails.

Hawkmoon - You made a very good point there. I actually can get hold of a new receiver here in Sweden, but I am very limited in my selection. I can get a ParaOrdnance, STI and some others for roughly two times more than you would pay. The whole idea with this project is to end up with a high-performance Colt, and thereby the idea of welding the frame for a super-tight fit. Changing out the receiver would mean stepping away from the initial idea. That is something I will do when/if I mess things up and don't have a choice.

niemi24s - I know the frame can be fixed using that method. Thank you for suggesting it though! The local gunsmith and 1911 aficionado suggested it too. The reason I am thinking about welding is because that all hardened metal constructions i have seen that have been altered usually end up at the same position they started in after a good while. I don't know if it is true for a slide as well, but to me it just feel wrong to squeeze a hardened metal construction to get it to size.

bophi - I have a good machinist/1911 gunsmith an hour away, and a really competent welder in about the same distance.

I might do the work myself. I just haven't decided yet.

niemi24s - If I go along with that process i still have frame to slide play from side to side, and as mentioned earlier i do not like the idea of squeezing the slide to achieve the right fit.

Mechanized - Thank you for the kind words. I do not have much experience with guns in particular, but i do understand cause and effect in most constructions, and what makes things tick as well as how to optimize them if they aren't too advanced. What I don't know, I will learn by reading and applying some good old trial and error. So far I haven't got enough heaps up's and general warnings to keep me from welding the frame. I might even do it myself because of pride of worksmanship. I would even be honest enought to tell if I messed things up as I tried to improve my skills and knowledge.

I'd like to start for apologizing to Niemi and the rest of those who posted before. When I posted that it was a partial thought. I was "working" at the time and got called away. When I write I read over things and cut and paste the order of my ideas. What I wrote the first time is hard to follow. When I came back to the computer I thought I had finished my thought. So here is what my post should have said.

Niemi,

I have read your posts and witnessed your expertise for some time. Your comment "I have even done it" doesn't make me feel anymore warm and fuzzy about weather or not I could do it.

My personal thought on this is, why don't you follow Niemi's advice and clamp the rails and keep the repair as simple as possible. You would still have a weapon to shoot and you could order a new slide to fit later if your unhappy. If you do screw it up you won't have a weapon to shoot. I understand that you have difficulties getting parts in Sweden. I'm not aware of the hurdles that you may have to go through. If you only have to wait and your willing to take on such projects why not build a pistol entirely from parts. It would be much more rewarding.

You seem to have a decent understanding of tolerance and fine measurements. I do however think you could get it done. You wouldn't have the idea to even weld the area and re-machine it if you didn't have an industrious bone in your body. If you do weld it I prefer TIG welding as it is so much cleaner with more fine control of the heat. The fact that you recommended it I assume you understand the finer points to it. +1 on the pre-heat. Good luck and please let us know what and how you did it. I like pictures.

P.s. go slow.

To answer your question if you are going to go ahead with it why not keep it going here. Your in the right forum and you have an appropriate subject title.

I apologize again for how rude my original post must have seemed to all of you.

I'm not certain, but I suspect that heat treat is less critical in the receiver than it is in the slide. And I know slides can be TIG welded to build them up, because I had my Para-Ordnance P12.45 welded and re-machined by EGW to correct severe peening that had occurred at the disconnector notch.

BigJon can correct me if I'm wrong, but the top of the frame should be a clearance cut, right?

After some finer inspection of the receiver and slide together, I could see that the edges of the rails are pointing slightly upwards when looked at from the front or rear. There is plenty of headroom between the slide and middle section of the receiver. On my other guns, the middle of the receiver and the surface beneath the firing pin makes contact in a sliding action. Those guns are of a different construction, and i have no knowledge of how, or if, these surfaces are supposed to touch in a 1911. Logic and wear on my receiver tells me that they should. - Or at least have been in the past on my specific gun.

The fact that the rails are slightly concave tells me that I'm forced to peen the rails down before I even think about touching them with a TIG. If I get the rails peened straight I will have a much better chance of filling the top surface later on for a perfect fit. - If I still have a gap when the peening is done. Am I thinking the right way here? It feels like I do, but I might be fooling myself. I will try to post a few pics of the how the gap between the slide and receiver looks like.

Someone suggested that I should just peen the rails and be done with it so I would be able to shoot the gun. Thank you for the advice. However, I do have other guns that I compete with. If this project takes a while it won't matter much, but it would be nice to have it done by August.

Quote:

Here I am pressing the slide down to show the gap.

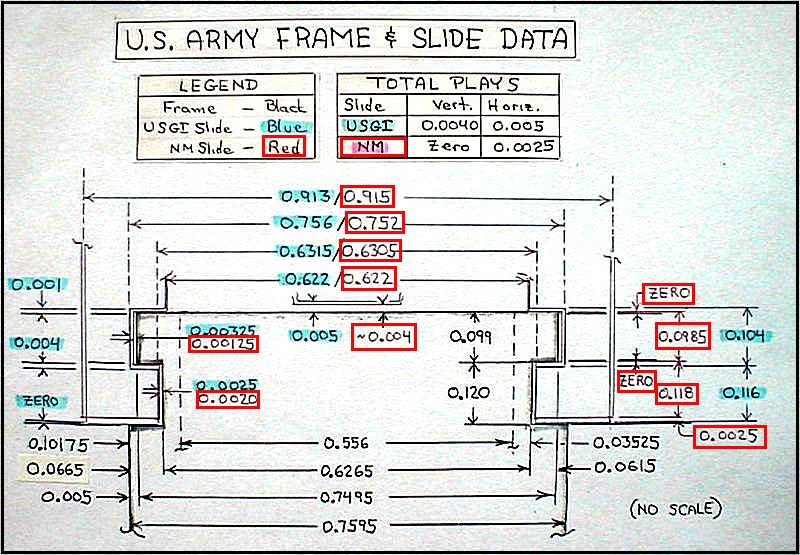

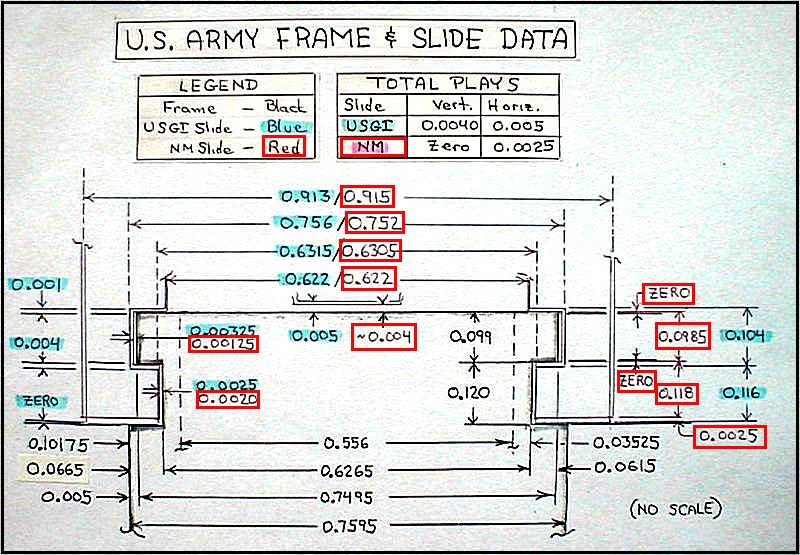

You may have already figured this out from the blueprints in our Tech Issues section, but if the gap you are referring to is the gap between the center (disconnector) rail of the slide and the top of the frame - that gap is supposed to be there - even on a National Match (NM) M1911A1. I think that may be what Traxxis was referring to in his post about the "clearance cut". Here's a rather busy composite drawing showing an NM slide (as well as a USGI slide) fitted to an average (mid-spec) receiver:

But if the gap you are referring to is a vertical gap between the between the frame rails and the slide grooves - kindly disregard all the above!

Personally, I would NOT peen down before welding, but I'm unclear if your comment about concave refers to along the length of the rails (in other words, the ends are higher than the center), or in cross section. But either way, why pound it down so you have to add metal everywhere, rather than only building up where it needs to be built up?