I fitted one yesterday, possibly incorrectly. I will let the photos speak for themselves. I have not added the bevel yet. It seems that the stop sticks out to the left a little and it has a huge gap on the right so it won't really meet the whole hammer as far as I can tell. Is this normal? Is it a problem? Did I file off the wrong side of the EGW stop when trying to make it fit into the channel? If so, boy do I feel like an idiot ruining a 20 dollar part. Live an learn.

First the original beveled stop:

PICTURE 404

PICTURE 404

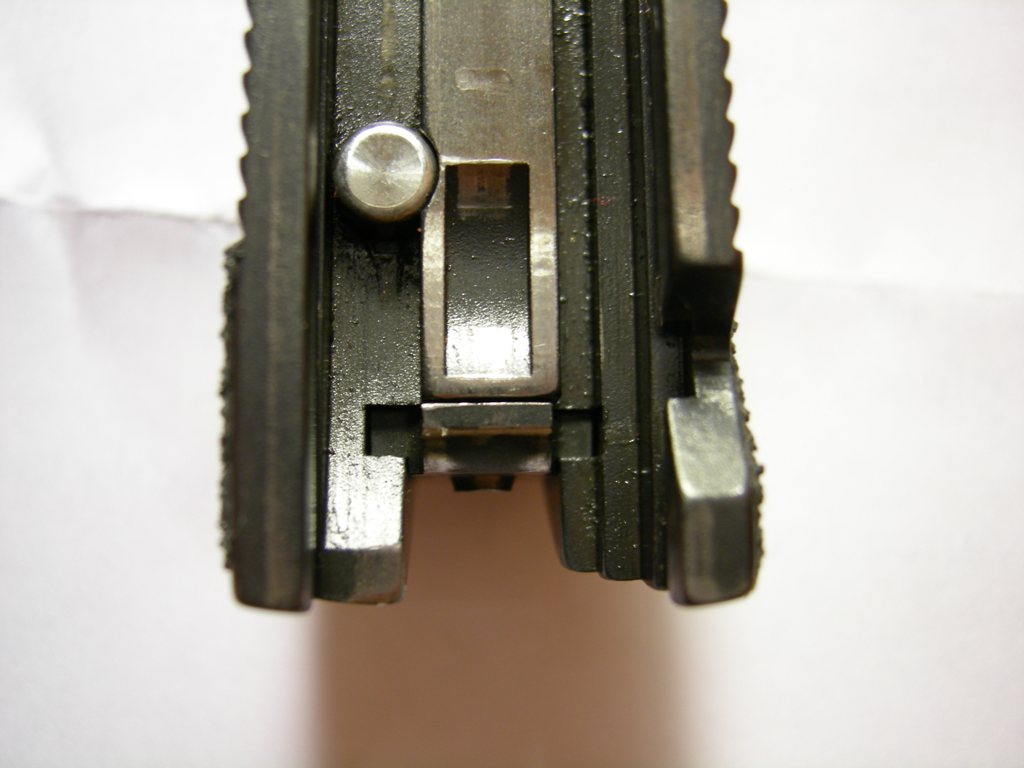

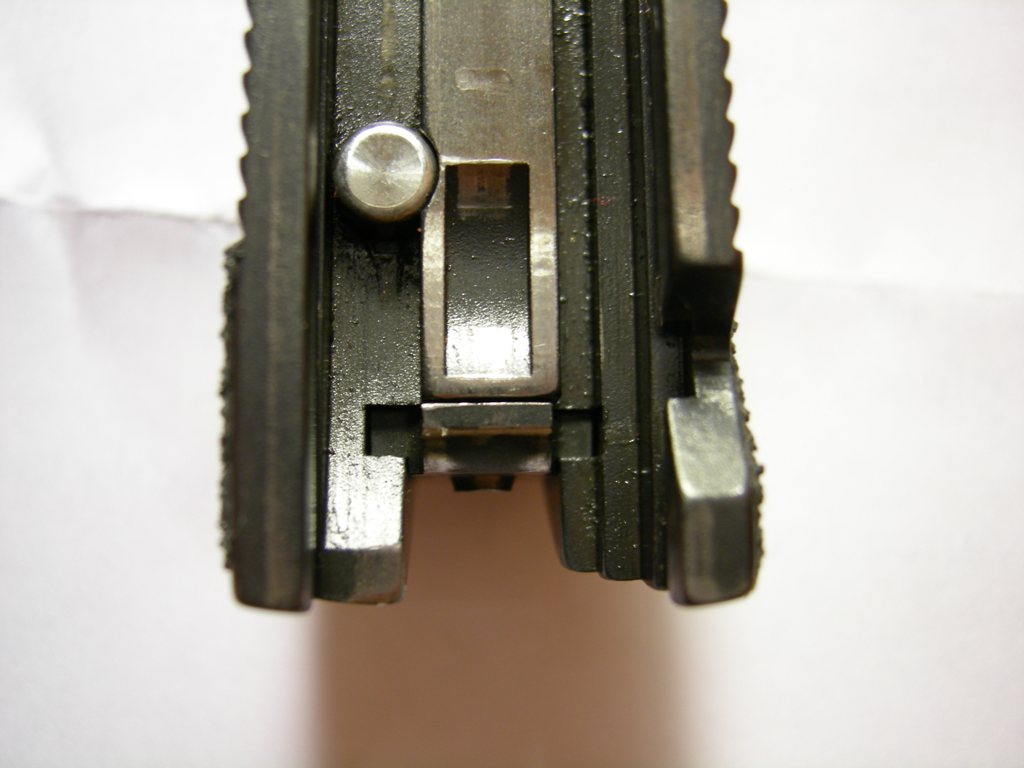

and now the new EGW stop:

PICTURE 404

Hmmm... From the pictures, it looks like one that's got extra clearance for the offset Commander ejector. Some of those do sit just a little off-center... even from Colt... and it doesn't seem to hurt anything as long as the radius is straight across. Haven't seen one that far off though. They're usually flush on the extractor side, or very close. A call to George Smith at EGW may shed some light on it.

It also looks like the stop isn't sitting straight and square in the slide. I'd have to see a photo of just the stop to be able to make a call on it. Clamp it between the jaws of a caliper to see if it's out of square... and take a picture of it.

The radius in each corner, looking from the rear... I've never seen one come from EGW like that. Did you do it to make it match the factory stop?

The last one I put in was offset to the side like that, but mine was dead square to the slide.

I decided that mine was a 38 Super cut stop and just went with it. When I blued it and the hammer up (sharpie marker) and cocked the gun a half dozen times it was about 75% engaged with the hammer. Contact was even across the hammer and stop, so it was judged as 'good to go'.

The worst part of putting mine in was cutting it down for the low mounted Bo- Mar, it was nearly as hard as woodpecker lips and my access to a mill is about an hour drive. Yup, I filed it down, and it took a while.

Alas, I am an ill equipped bubba. Calipers are on my list for when I start reloading. For now I guess I will do a go or no-go with the mod, mark up the hammer to see if contact is even.

Can you describe what you mean better by not being straight and square with the slide? I am not sure what axis or side you think it is crooked on. Is this something you see from the top down view or the rear view? The top down view is most likely not my fault. If it looks crooked in the rear view it is probably because I removed too much material from one side or another when filing it to fit.

I think it may still work okay because under pressure I think it will seat itself correctly, but may not hold that way when it wears. Might be best to chuck it and try again later with a new part, that is what I probably need to decide.

The radius on the stop is not my doing, came that way from EGW. I will try and take pics of the two stops together for comparison, any recommendations on what angles would help?