Have a fairly new RIA nickel gov model that after 300 rounds or so shows some excessive peening at the slide - frame stop point. Felt recoil seems to have gotten increasingly more violent during its short life. Has cycled fine from the start, but don't like what I am seeing after a couple of months. All mild 230 gr factory loads.

Suspect a weak, faulty recoil spring setup.

Opinions? Solutions? Warranty? Thanks.

If that were my RIA FS GI I would send it in for warranty repair. I would think they will replace the pistol.

+1 for warranty repair/replacement... it looks like the frame was never hardened...

Started the ball rolling with an email and pics to Ivan. Realize they are a little busy now with the show and all. I've got plenty of other things to shoot...

But I'm still interested in other opinions.

Your recoil spring appears to be about 5 3/4 inches long. That's 1/2 inch shorter than the new Colt 16lb springs I have and about 3/4 inch shorter than the Ordnance spec. However, the free length of a spring can be deceptive. If it was just taken out of the gun when the picture was taken, it may get longer with time.

I think we are all at a loss to provide an opinion. I don't think this could have anything to do with your recoil spring. Two thoughts come to mind. 1) Frame not hardened correctly. 2) Someone snuck in and let the slide slam closed on an empty chamber several thousand times. Whatever caused this please do not shoot this weapon again until it is repaired.

Halito, all. Almost looks like the piece had a 9mm spring in place of a .45. Also, you can definitely see that the lower lugs are SLAMMING the VIS with some authority. Hello warranty work. Love the 1911, PI (I Love my Rocks) and the forum.

C, that sounds very logical. 9mm spring. 10#-13#.

Either way, I don't think the spring is doing its shock absorbing duties.

The slide is battered, too. So the hardening theory ??

Is there a way a civilian can measure that spring strength? That might tell the tale.

Send the gun back for replacement and don't take no for an answer. There is something very wrong with the guns metal hardness.

Quote:

Is there a way a civilian can measure that spring strength?

A very crude method is to place a 2" length of 3/4" ID PVC pipe over the muzzle and push the pipe down on a bath scale until the slide is almost (but not quite fully) back. It'll take a bit of practice. Very crude may be an understatement.

Quote:

Send the gun back for replacement and don't take no for an answer. There is

something very wrong with the guns metal hardness.

ABSOLUTELY!!!

I have a Colt that has had tens of thousands of rounds through it. The dust cover is cracked at the recoil spring guide abutement, but the pistol does not show this kind of battering or anthing close to it. Neither did my old .38 Super.

Something ain't right and it isn't the recoil spring.

Quote:

A very crude method is to place a 2" length of 3/4" ID PVC pipe over the

muzzle and push the pipe down on a bath scale until the slide is almost (but

not quite fully) back. It'll take a bit of practice. Very crude may be an

understatement.

I like it. I'll try that. Got some PVC around here somewhere. Not a true hillbilly method because that would involve a hanging catfish scale somehow.

Quote:

Not a true hillbilly method because that would involve a hanging catfish

scale somehow.

Those'll work too. Just lock the slide open, put the hook into the ejection port and on the breechface and pull straight down on the frame until the slide's aaaalmost all the way back.

And probably more accurate at around 15 pounds than the average bath scale.

Measuring a recoil spring in the ways described will be crude, taking the hammer out of the frame will improve the results a little, but......still.

Quote:

Measuring a recoil spring in the ways described will be crude, taking the

hammer out of the frame will improve the results a little, but... still.

Or just have the hammer back already when you measure. I'm having a hard time thinking it's just the recoil spring.

How about this - put the spring inside a toilet paper holder tube and do the scale thing. This way the only thing measured is the actual spring resistance.

I'll have to look around for a decent scale. 250# bathroom scale, even with 1% accuracy, could be 3# off either way. I've got time, it's been a few days since emailing RIA without response. Big gun show in Vegas coming up.

Quote:

How about this - put the spring inside a toilet paper holder tube and do

the scale thing. This way the only thing measured is the actual spring

resistance.

To test the spring outside the gun, you'll need:

* a piece of tubing a bit longer than the spring's free length and just big enough inside inside to keep the spring straight while being compressed.

* a rod to compress the spring inside the tubing that is marked so you can tell when the spring is compressed to 1 5/8".

* a good supply of aspirin for the headache caused by the exasperation of testing recoil springs. Don't ask me how I know.

Talking about springs, along with free length, some important things to consider are diameter of wire and number of windings. Of course one needs the properly heat treated wire and annealed spring to begin with.

Though a frame/slide can be battered by a weak or removed spring, the battering shown on the VIS is not normal. VIS do not get battered that way by weak recoil springs. The link insures the barrel pivots identically each time it goes to link down, regardless of whether the recoil spring is weak or missing. Any contact marks, from the barrel hitting the VIS, would only be from the barrel's bottom lugs. Yet the photo clearly shows other damage caused to the VIS that is not from the barrel lugs. Though a broken link could cause some damage to the VIS , the damaged depressed circular area in the VIS is not normal.

Halito, all. Thanks CJR, that's what I'm talking about: the recoil spring may be under-size, it might be the wrong one, but when you look at the VIS...what in the world has been going on in this puppy to cause this and yet, as the OP said, "running fine" (paraphrased). Hello warranty work, and I am sure we all want to know what the problem was/is. Love the 1911, PI (I still like my Rocks) and the forum.

Quote:

Felt recoil seems to have gotten increasingly more violent during its short

life.

I keep coming back to this clue, but there's nothing in any of the pictures - except the seemingly short recoil spring - that points to a cause for the change in felt recoil.

This sounds far-fetched, but could a link that was stretching (and stretching in the web area between the holes) cause such a change by gradually goofing up the linkdown timing?

Halito, all. Well niemi, if what you are thinking is far-fetched you are not alone, because I was pondering the same thing. What IF, not only there was an improper recoil spring, but the initial build timing was out of whack to begin with. I really don't know because I have not gotten to the point I can properly fit a barrel (getting good at trigger/sear fitting, thumb safety, etc., but barrels...Good Lord!). Is it possible the timing was right on the verge of improper link-down, and over a few hundred rounds went to a catastrophic link-down failure? Causing the barrel to unlock late and slam down on the VIS? In which case, improper recoil spring would be of secondary concern, no? Love the 1911, PI (still looks like the 9mm spring in my Tac) and the forum.

Well, if the barrel & slide lugs weren't totally disengaged by the time the lower lugs hit the VIS, that would certainly, I think, beat up the VIS. And the VIS looks pretty beat up for only a few hundred rounds. But if that was happening, the barrel & slide locking lugs would be beat up too, and KCT hasn't said anything about that. Hmm-m-m.

KCT: Do the corners of the slide & barrel locking lugs shown any signs of crashing?

I would like to see more pics of this unusual problem. OP would you post pics showing the whole weapon disassembled with all parts showing?

The spring is 5.625" The wire diameter is .047" Here's a few more pics, but tell me what you're looking for and I'll get closeups...

Guess it was too far-fetched. I see no sign of barrel locking lugs crashing. Just maybe a little lower lug knee bumping (on the SS pin) in the first photo.

But a 5 5/8" recoil spring doesn't look like it would help at first glance except its wire diameter (0.047") is 0.004" above spec - which might turn it into a 16lb spring for all I know.

Methinks Eric nailed it in Post #3 - frame never (or incorrectly) heat treated.

In my view, I find the statement that the frame was not hardened properly to be extremely unbelievable. I own two Armscor 1911s; a Charles Daly and a RIA. What impressed me most with these pieces is the number of Rockwell hardness marks I found on them. This indicated to me that they were extensively tested to insure hardness/strength. Secondly, Armscor is an ISO 9001 certified company. That means it meets stringent international quality standards and quality manufacturing standards. Likewise, an ISO9001 certified company is audited periodically to make sure it is complying with the ISO standards. It typically costs a company about $100,000 to $250,000 to obtain ISO 9001 certification and as a result there are not many arms manufacturers that have ISO9001 certification.

Likewise, there is no way that I know of to damage a VIS as shown ( i.e. depressed area) in a normal manner. Furthermore, typical links fracture catastrophically and if a link were to stretch excessively, the piece would jam and lock-up. What purpose does it serve to post these questionable "damage" photos? These RIA 1911s have lifetime warranties and all one has to do is send it back for repair or replacement. If one doesn't want to send it back, what's the ulterior motive?

Quote:

Started the ball rolling with an email and pics to Ivan.

Based on this from Post #4 it seems (to me, at least) that KCT does indeed want to send this gun back to Armscor/RIA/Ivan. So unless I'm missing something here (and I am moderately literate) there doesn't appear to be any ulterior motive at all.

I think it's simply that KCT was curious about what might be wrong with his gun, could only think of a weak recoil spring and came here for other opinions & solutions (as clearly stated in Post #1).

I would still like to see pics of the whole weapon field stripped. I would like to see the condition of the exterior of this faulty RIA product.

My only motive is to ask a group of knowledgeable peope why my gun is so beat up after very mild usage.

1) I posted added pics becaus I was asked.

2) ISO standards is a boondoggle and a shakedown to extort money mainly from US manufacturing companies. Not unlike The BBB, EPA, OSHA or the Global Warning farce. All it means is that somewhere, sometime Armscor published the standards they use to track quality. No more, no less (besides the blackmail fees). Home Depot and Walmart have aisles full of ISO blessed Chinese junk that gives me heartburn everyday.

3) I have contacted the US rep in NV by email a week ago. No response yet, realize they are busy with gun show. I included pics.

4) I am quite willing to send it back if they agree it's defective and pick up the freight both ways. If they push back saying it's my fault (don't know how) then I will fix it myself and never buy another RIA. Therefore, I am preparing for that outcome.

5) Do you really believe I took a perfectly good gun and beat it with a ballpeen hammer just to get a rise out of a sensitive few? and with doctored pics? or just to tarnish the RIA brand?

Come on, man.

When your new flat screen shoots craps after 9 months, peel off the ISO sticker and take it into Best Buy and see how much love you get.....

OK, let's play this game. This is fun! After all, this is my area of expertise; material failures. Customers pay me to diagnose material failures world-wide. So let's start with examining the info/photos supplied. There were only 300 rounds fired and supposedly only heavier recoil was noticed. Besides the damage I discussed earlier to the VIS; i.e. barrel lug impressions and a circular depression, let's look at the barrel.shown in the photo;

1. Where's the impact marks from the top slide lugs hitting the bottom of the

grooves in the barrel?

2. Where' the impact marks to the rear of the barrel lugs caused by the slide as it goes into and comes out of battery?

3. Where's the wear marks on top of the barrel top lugs as the slide moves over the barrel and rearward?

4. Where's the wear marks on top of the chamber area of the barrel as the slide moves rearward over the barrel?

5. Where's the wear marks on the sides of the chamber as the slide moves rearward? What I see is what I'd get taking a new piece and racking it a couple of times.

6, The photo of the VIS clearly shows impact marks near the top of the VIS that are caused by the barrel's bottom lugs. Where's the marks on the back of the barrel's bottom lugs?

7. The barrel looks like a standard 1911 barrel and not a bull/bushing-less type. If that's the case, where's the wear marks on the barrel that are caused by contact with the bushing during recoil?

Typically, slides are heat-treated separately from frames. So getting a soft slide and a soft frame, though possible, are highly improbable. Materials typically fail more easily from low shear stresses than higher compressive or tensile loadings. That's why the more stringent stress analysis ASME (American Society of Mechanical Engineers) Codes are based on insuring shear stresses are not exceeded. Likewise, 1911 slide dust covers typically shear off, regardless whether they're soft or brittle. Yet this slide's dust cover is severely deformed. This is truely a "magical pistol". If I wanted to damage fully annealed steel parts, I'd have to do some heavy, heavy pounding on them to get them to deform. Deformation results from making the material exceed its yield stress. Backsmiths anneal metal and then start pounding the metal to yield it and reform it.

300 rounds? Yeah sure! Only slightly heavier recoil? Of course!

I'll play... without turning on the SEM (Scanning Electron Microscope)

All marks are on the surfaces of the slide and frame that stop the slide's reward motion. The first step of a root cause analysis would be to ask why at lease five times.

Why were there such sever impact marks on the frame and slide when these surfaces are designed to stop the slide?

The first order of business is to do a Rockwell hardness check on slide and frame.

On the rather brazen assumption this gun is/was made to average (mid-spec) M1911A1 Army Ordnance specifications (paragraph numbers correspond to those in Post #38):

1. There will not be any any contact in the bottoms of the barrel grooves as shown here:

There will not be any impact to the rear of the barrel lugs when the gun goes to battery because the barrel is driven into battery by contact between the breechface guide blocks and the chamber face and there will be 0.0125" of clearance between the vertical surfaces of the radial locking lugs, as shown here:

PICTURE 404

After firing (when the front of the barrel lugs impact the rear of the slide lugs), barrel linkdown involves little or no significant impact between the slide & barrel radial locking lugs.

3. There may be no wear marks on the top of the barrel from the slide simply because this gun will have about 0.008" of clearance between the barrel top and slide, as shown here:

4. (See 3., above) Remember that the barrel is virtually parallel to the frame when linked down.

5. The absence of significant wear marks simply indicates there is sufficient clearance between the barrel and slide so that when the barrel links down it can fall all the way down to its bed in the frame free of interference from the slide. This gun will have almost 0.003" of vertical clearance between the barrel and slide bore as shown above.

6. Can't see the back of the barrel's lower lugs well enough in the photos to answer that question.

7. I can see faint beginnings of such marks located about 1 3/4 times the barrel's diameter, forward of the lugs.

Niemimeister,

With all due respect to your sketches, I have yet to see any 1911 that doesn't have some wear marks where I've described them to be. That includes FS,MS, CS Colts, Kimbers, Para Ordnances, Charles Dalys. Remington Rands, RIA , etc., etc., etc. I've been looking at 1911s since 1957 and have seen a bunch. Sure, I can set-up some 1911s to minimize say the wear marks on the top and sides of the barrel chamber area, but I think the piece we're talking about was a standard issue.

When 1911s dynamically recoil, it is a major violent event and parts are moving around. If barrels are not set up properly(hitting HIS) they are bouncing up from link-down during slide movement (leads to broken links) and rocking laterally (barrel torque), nosing down, recoil springs bulging out and contacting barrels, etc. and making contact with the slide and recesses in the frame. There are many 1911 references available, Kuhnhausen is one, that shows how to clearance said parts, remove impact burrs from top barrel/slide lugs, etc., etc., etc.

Likewise, there are references which show how to three-point fit barrels so there is hard contact between the slide lug and two points in the barrel groove in battery. I've seen some 3-point barrel fit-ups from the factory as well. When the 1911 fires, the barrel reacts (reaction force) by violently moving rearward and it pulls the slide with it for a short distance until they separate as the barrel links down. The barrel lugs and barrel hood both share in pulling/driving the slide rearward, i.e. contact/wear surfaces. So, though there are some 1911s with excessive headspace (no barrel hood contact with slide in battery) and no lug contact in battery, there must some lug contact during recoil in order to pull the spring loaded slide rearward.

This required lug contact results in visual wear marks and sometimes soft metal burrs on both the barrel and slide lugs when the slide/barrel separates. It is common practice to magic-mark barrel/slide lugs and with the slide in battery to lightly tap the rear of the slide with a soft mallet to induce contact marks on the lugs to determine the amount of engagement between the barrel/slide lugs. Soooooo, if light tapping on the slide can show lug contact points, surely a fire breathing 1911 in action can produce contact/wear marks as well.

Great info, Cap. Thanks. You didn't paint that gun shiny silver before you dumped it?

The peening doesn't bother so much me as long as the frame doesn't crack. I'm sure I'll end up putting a stiffer spring in and just living with it.

CJ, much of what you wrote was well over my head.

But you seem to know what you're talking about, so I'll ask..

Based on what little you see and have read from the OP's posts, are you able to speculate just what is the problem with his pistol?

Or if even consider that amout of battering a problem...

Can we stick to the topic of finding an answer for this gentleman instead of this self-serving puffery?

The answer to this gentleman is simple. No one on this forum can give him any help to fix this problem, the gun needs to be replaced. Extensive weld repair could be done $$$$, but then one would have to expect weld distortion or cracking, etc. and always worry about reliability.

I act the way I act, because of people who use this forum to trash manufacturer's products with millions of photos. Could it be to blackmail the manufacturer into doing warranty work? The RIAs have a lifetime warranty all you have to do is send it back to the manufacturer. How hard can that be?

This 1911 is not fixable from anyone on this forum just by looking at photos. Sure we can make guesses, based on our own experiences, but they are still guesses. What is typically done with failed parts is the following:

1. hardness measurements

2. chemical analysis on the material

3. determine physical properties (tensile/yield strengths etc.) if enough material is available,

4. finally look at the crystalline structure of the material.

5. stress calculations from operating loads

Alloys are defined by "chemicals and Physicals", hence the chemical testing and physical properties testing. Hardness and photomicrogaphs (crystalline structure) testing determines if the heat-treat was proper. Weld build-up repair would be very risky and $$$$ and there would always be the possibility of weld cracking. Why is that? Well proper welding requires either annealng or proper preheating to prevent weld shrinkage and cracking or distortion. It''s more cost effective to just get a new part .

I have had catastrophic failures of new 1911 by the best makers. I simply packed them up, enclosed a letter, and shipped them back to the maker. A brand new gun was returned to me. I did not have to take 50 million photos, plaster them on every 1911 forums i could find to seek advice or bash the maker. Why? Because I know many parts are subcontracted out for heat-treating in batches (1000s of parts). Sometimes a part doesn't get heat-treated properly. Why bash a maker if he stands behind his product? Likewise, if I get a new 1911 and the grip safety or beavertail cuts my hand, I just get out a file, polishing paper, and cold blue. I remove the sharp edges, polish it and blue it and go on with life. Unfortunately, there are those who take millions of photos and post them on the 1911 forums and proceed to bore us with how cut-up their hand is. A lot of gunsmith provide this deburring service because that's the way standard guns are. You don't want that? Fine, buy a custom 1911 that is all smooth and burr free for about $3000 to $5000 or get another type of gun.

Quote:

...I have yet to see any 1911 that doesn't have some wear marks where I've

described them to be.

That probably just means, as an example, that the guns you've seen whose barrels showed contact marks at the bottom of their lug recesses were far from being average. Even if the link is placed in tension when the gun's in battery, that 0.020" gap will only be reduced to perhaps 0.010". Some (or a lot of) tolerance stacking must have been involved in the ones you've seen it in.

And to expect a single example of a 1911 to exhibit all of the examples of contact you gave based on many, many different guns is highly unrealistic. The probability of all of them existing in a single gun would, I think, be quite small.

Quote:

When the 1911 fires, the barrel reacts (reaction force) by violently moving

rearward and it pulls the slide with it for a short distance until they

separate as the barrel links down. The barrel lugs and barrel hood both share

in pulling/driving the slide rearward...

I'm afraid you've got what pulls what backwards... well... backwards. It's the slide that drags the barrel backwards with it after firing while the bullet is still in the barrel, as shown here:

While the bullet (due to friction) is pulling the barrel forward in the slide, the slide (and barrel) are being pushed aftward by the combustion gases pushing on the case head/breechface.

Quote:

So, though there are some 1911s with excessive headspace (no barrel hood

contact with slide in battery) and no lug contact in battery...

No Gov't Issue M1911A1 can have contact between its barrel hood and breechface unless it is out of spec. The complete derived specification for that gap is 0.006 +/- 0.004", so the minimum gap is 0.002". And I'm referring strictly to GI 1911's - not to any with gunsmith fitted barrels.

Quote:

...there must some lug contact during recoil in order to pull the spring

loaded slide rearward.

No there mustn't. There cannot be. As explained above, the barrel doesn't pull the slide back. The slide gets pushed back by the fired case while the bullet's in the barrel. Once the bullet leaves the barrel (after maybe 0.1" of aftward slide travel) the combustion pressure goes to zero, the case no longer pushes on the breechface and the slide coasts the rest of the way back.

There's some good info in the Stickies on how the 1911 works.

Any follow up calls to the company yet to find out if/when they'll take a look at it?

I have no doubt RIA will make good on that pistol-

They are NOT the type of company who will blame the owner of a defective pistol and refuse repairs. ARMSCOR has a reputation for excellent customer service, and from my little experience with it, they surpass that reputation.

I also have no doubt that Ivan or someone there will answer your questions after they have examined the piece.

They will replace the gun I'm sure. We acquired a Colt Defender and the frame was cracked, sent it to Colt, Colt replaced the frame applied same serial number, nu question, no charge.

I've been shooting 1911s for almost 40 years, and still have my first one, and have owned quite a few of them. Never seen these before.

I could not disagree with you more on every statement you have made. Nor do I wish to discuss physics with you or your drawings on this thread. Let us just agree to disagree. I stand behind my statements as written here. Here's a reference for you reading pleasure

file:///www.Colt%20M1911%20-%20Gunpedia.desktop

If this doesn't open try searching for "Newton Third Law applied to 1911s". Gunpedia should open then.

The Technical Overview describes Newton's Third Law as it applies to 1911s. Likewise, any good Physics book describes Newton Third Law as it applies to fired projectiles and their reaction forces..

CJR, so you are dismissing the x-ray photo evidence showing the barrel being pulled forward by the projectile while the slide is being pushed back by the case...

I equally dismiss your statements.

For every action there is an opposite and equal reaction.

Therefore the bullet and barrel are forced away from the case and the case and slide are being forced in the opposite direction.

Back on track, if we can...

I am in the "soft frame" and "send it back" camps. The great thing here is that if the first is erroneous, the second will address whatever the issue really is.

I find myself wondering not only about the recoil spring, but the mainspring as well. I f the frame is soft then the weight and rate of these springs is moot; once it gets back from Pahrump, I would change the springs to 16 and 23 pounds respectively, and fit an EGW oversize/small radius firing pin stop. Something about the increase in recoil is giving me a brain cramp...

WOW! This is a long thread. With good reason though. If nothing else, the volume of responses should be enough for anyone to see the severety of this problem.

I didn't notice anyone asking about the rounds themselves here and I wonder if that's a possibility. Can the factory accidentaly make overpowered batches?

I also wonder about the slidestop hole possition and the slide itself.

This could even be multiple bad things merging into a big super bad thing.

Hot loads, weak springs and questionable frame/slide specs all at once maybe?

Good luck anyway and I would really push for a new weapon if I were you, not a fixed weapon that has beaten itself half to death.

Follow up with this please as I'd like to see how it's diagnosed and resolved.

OK, I was wrong the first time around. I went back to the 1st 2 photos again and now I think it's the slide alone causing the problem. Pic 2 shows where the slide has begun shearing at the top of the frame and you can see where they met in pic 1 on the slide.

Call it a gut feeling but I think it's the slide.

Good luck once again though and do try to have the entire gun replaced.

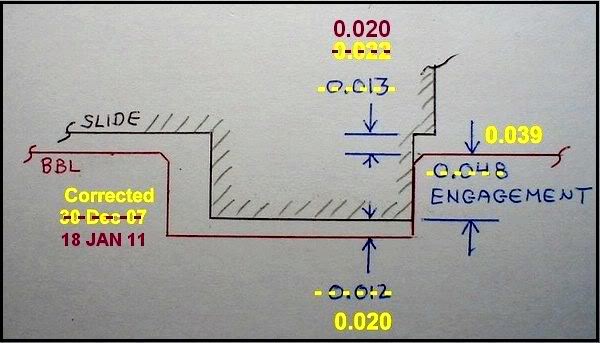

This drawing replaces the first two in Post #41:

Dimensions in this one based on Ordnance blueprints in the set from Nicolaus Associates which are the most recent I know of.

Quote:

I agree Armscor should look at it, but I don't feel like dropping $50-$100

for a round trip to NV to be told like they told Cap: "that's just the way it

is, nothing wrong with it"

Yours is much worse than mine was, KC.

BTW, shipping costs are only one way... they'll ship it back on their dime.

If you bought it locally, you can ask your dealer to ship it back.

He'll get a much better rate than a non FFL, because he's under no "overnite" restrictions like we are

I think I'm with what CAP posted on this one.

Edit: Or at least with his responce from RIA/Armscor.

I have a brand new (never fired) RIA receiver in my hand right now and the surface of VIS shows all the same ugly tool marks that the OP's does. The imprint on the VIS from the lower lugs is going to occur within the first few hundred of round as the tool marks get hammered back into the surface of the VIS. This is more noticeable because of the excessive tooling marks on this particular frame.

I also have brand new (never fired) RIA slide that again looks identical to OP's. Its pretty rough in that dust cover area. Lot of burrs that will "imprint" in a very short time.

I'm not really sure I see any problem. Did you do all the function and timing test in our stickeys. If it works OK... well maybe it ain't broke.

Hardness (if in doubt)...

If in doubt stop by your local machine shop with a case of beer or a gift certificate to Applebee's. They'll be able to take a couple of hardness measurements in about 5 min. Probably less expensive and less effort than shipping everything back to Nevada.

Ivan at RIA has responded by email and said they would take care of it. Send it in.

Anybody know a good way to cajole them into paying for the ship fees both ways? $60 one way on a $430 gun? If this gun is flawed, shouldn't they? Or is this just tough shitsky? Too bad, dude.

Quote:

Ivan at RIA has responded by email and said they would take care of it.

Send it in.

Anybody know a good way to cajole them into paying for the ship fees both ways? $60 one way on a $430 gun? If this gun is flawed, shouldn't they? Or is this just tough shitsky? Too bad, dude.

I personally always thought that a company should at lest cover shipping the first year however most don't. I suggest you break it down, put it in a the box and send it as machine parts using up to 5 day ground as it is a lot cheaper. That is how I do it with those that won't pick up or pay for shipping to them. Just be sure to insure it regardless.

While I wouldn't want to suggest a possibly illegal method of shipping a pistol, you should only be on the hook for shipping to Armscor. They should pay for the return trip. Glad they got back to you and are going to take care of you properly. Keep us updated!

My FFL guy will ship it for his fee ($15) plus USPS priority + Confirmation + insurance which is about half what "overnight" fee is. If you look around you may be able to find a guy like that. It will be a private FFL guy and not Gander Mountain or gunshop. Good luck.

My guy will do it, but I can tell from his tone that it's a pain for him. Understandable. And he wants a transfer after it comes back. Now heartburn for me + another $20.

I wouldn't be very happy if it got back there and they took a dental drill to smooth out the peened surfaces. Same spring, you're all set, amigo... hmmm.

I'll probably get a new spring and live with this one.

Quote:

My guy will do it, but I can tell from his tone that it's a pain for him.

Understandable. And he wants a transfer after it comes back. Now heartburn for

me + another $20.

Is this a local shop you bought the pistol at?

If so, I'd find a new place to buy and never set foot in that joint again

If they can repair the pistol, like fitting a new slide, there's no reason it has to be shipped back your FFL.

It can be shipped directly to your residence.

Check that... that's unless you live in one of the odd ball states that has a separate state reg that applies, cause there are no federal guns laws prohibiting it

Quote:

I suggest you break it down, put it in a the box and send it as machine

parts using up to 5 day ground as it is a lot cheaper.

Wrong!

The receiver is considered a firearm by Federal Law.

The shipper requires you notify them if the package contains a firearm.

If your FFL guy sends it in he has to log it in and out and you will have to fill out a 4473 when it gets back. If the pistol is flawed they should reimburse you shipping costs. They cannot determine what if anything is actually wrong to it until they inspect it.

Doesn't UPS do next day with handguns?

This was an interesting thread! Looking at the damage, the only way I can see to get to that level of damage is to fire the pistol without a recoil spring.

Even a broken spring will have some dampening effect.

This is all merely my opinion, FWIW.

It's in NV right now. They picked up the freight after a little belly- aching. Been 3+ weeks and haven't heard anything. Seem to be a bit of miscommunication between CS and Service Dept. Am sending them a mail next week to see where they're at.

Probably had 4 detailed email exchanges with pics about the problems and then when it showed up in NV, they called and and didn't know why it was there? Then they said they couldn't find my phone and address - and I replied - didn't you just call me?

We'll see. I'll certainly add what I know when it happens...

Hello. This is like a soap opera. If you don't mind, could you tell us what the Service Dept. says about your pistol's root problem?

They will be replacing this pistol. Was informed by email today.

They will be getting back to me in the next week with more info. Probably trying to track one down now. Good news so far.

New one showed up today. Cosmetically looks good. Paperwork included makes note of 8 rounds fired in NV to tune it. Unfortunately the same areas are showing slight peening.

This is a nickel gun, so maybe something in the plating process is causing this metal weakness.

Haven't shot it, but I'm going the heavier spring route. 3 pack from Wolff. Start with the heaviest, and any ejection issues, I'll back off one step.

Anybody else out there have the polished nickel GI model? Any marks where the slide/frame contact each other at full recoil? Thanks.

Would you please post a picture of the internals of the new one before you shoot it? If others have had this same problem you'd think we would hear about it. Did RIA offer you an explanation of what caused this problem?

No explanation from NV. As I stated, it's already been fired - 8 times. Soot still in it. Lots of oil. No sweat.

Peening looks similar, only smaller in scale. Taking closeups with my camera is a big production. So I'll get to it when I give it a good clean. Gonna wait until the springs show up anyway.

Like I said earlier in this saga, I'm not really worried about marks, just don't want to crack something. If a heavier spring can slow it down a little, that's OK with me. I'll be able to tell from the recoil and the slide jolt if it's beating itself up again.

Remember that spring forces work both ways.

I have fired 3600+ rounds through my RIA GI FS with no peening or battering at all, just normal wear on the slide rails. Are you saying they sent you a brand new pistol, test fired with 8 rounds, and it is already showing signs of peening/battering? If that is the case I don't think any # recoil spring is going to help. Good luck and be sure to keep us posted!

This is new, untouched, unshot (by me) from factory.

This is same spot, Colt Defender, shot 1000s of times.

OK then... This thread and the photos with the added results after requesting assistance from the importer/service department has made a decision for me.

Scratch RIA from my possibles.

Just eyeballing from the first photo, I'd guess that unless the flange on the recoil spring guide is awfully thick, the slide will wedge itself to a stop when the forward ends of the frame rails get smacked by the forward ends of the slide groove/way cuts.

This speculation is based on the partial cuttings by the cutter for the frame grooves/ways into the aft end of the recoil spring plug tunnel. The second photo shows the cutter had gone forward enough to make a full, normal cut.

I'm with Joe - no RIA's for Mrs. Niemi's little boy!

These are the area's on KCTanfoglio's RIA slide I was trying to describe in my last post:

Marks circled yellow are actually rough finishing leftovers where slide was undercut. Could have been buffed off at factory. The peening areas are right above both of those - larger flat areas.

This is no way meant to bash RIA. I like them. I'm just trying to figure out the "why". I think it's light springs and not a lot of time spent in the finishing dept.

I realize these are $400 guns and don't expect a lot of fine finish work. Part of the fun of owning these actually. I'm sure this one will shoot fine. The other had no feed/fire eject/issues and will bet this one doesn't either.

I probably wouldn't have noticed it on the 1st one except it beat on my hand much harder than my Defender and Glock 36.

Quote:

Marks circled yellow...

I'm not referring the the little marks circled in yellow. What I am referring to is the cuts do not extend into those areas circled in yellow - like on your Colt slide.

Another way to demonstrate what i'm trying to say is: remove the barrel, bushing, recoil spring & plug; put the slide back on with only the guide rod in place; push the slide all the way back; try to wiggle the front end of the guide rod.

* If it doesn't wiggle it indicates there is sufficient clearance between the frame rail fronts and the slide groove fronts to allow the guide rod flange to stop the slide's rearward travel. That's good. But...

* ...if it does wiggle it means the slide's rearward travel is not being halted by the guide rod flange but is, instead, being halted by contact between the curved fronts of the slide grooves and the curved fronts of the frame rails. That's bad because it creates a sort of wedging action that tries to squeeze the fronts of the frame rails together and the spread out the slide.

Is your guide rod loose or tight?

Quote:

I'm not really worried about marks, just don't want to crack something.

You have no need to worry about cracking. That metal is way too soft to crack.

There is absolutely no way that I would accept what you have been given from any manufacturer regardless of purchase price.

Got my spring pack from Wolff yesterday and tried the 18# last night. Ran perfect. 150+ rounds. Accuracy about the same as #1.

Happy to report back that the suspect areas found on #1 were fine on #2. I did do a little finishing beforehand and cleaned up the meeting surfaces on slide and frame. So they were fairly smooth and flat before I started shooting.

My take on the whole deal is that there was some extra metal left in the finishing process on gun #1. The extra metal that was left was getting pounded into spec during recoil collision - but it looked ominous. May have caused the sharper recoil as well.

Truthfully, I wish I had #1 back because it was a nicer gun. Plating was better, edges were smoother and not as many finish marks around the slide area. I'd just finish those 2 surfaces as flat and true as I could get them, stouter spring and I'd be brand new.

Maybe I'll send them a letter to see if I could buy the old one back, if they haven't destroyed it already.

Happy ending. It's what you can expect on a $400 gun that came from a sweat shop. But - both always ran fine without any shooting issues at all except for the metal mashing and sharp recoil (which a little polish and stronger spring would fix).

Glad you got it taken care of. I checked my RIA GI tonight, it's got a little over 4,000 rounds through it. Here's what your gun should've looked like(The first one you had).

The Impact area;

The Rear of the Dust cover;

It looks like yours also has the rectangular buttons of metal at the impact point. At this time I also have a Colt and an ATI and both of those show flat smooth surfaces at impact areas. Pic of Colt on post #84.

Seems to me a flat surface all around there would make for a better impact absorbing area. Maybe a final finishing step being overlooked on some. My ATI shows finishing marks there (but flat) and the Colt looks like much more attention paid there.

Part of a 1911 I never paid any attention to before. Will from now on. Wished I knew then what I know now.