Thinking your 7-round mag springs might be weak, you look on the Wolff website

http://www.gunsprings.com/SemiAuto/...MagazineSprings

and find 9.5 pounds is the factory standard rating when fully loaded. You take all your mags and 7 dummy rounds to the lab at work where they have an accurate, certified force gauge. With a anti-skid pad on the gauge's push rod and the 7 dummy rounds loaded, you find it takes only about 6 pounds to just start moving the top round downward from being in contact with the mag's feed lips.

"Aha" you exclaim, "these springs are all weak" and order a bunch of 9.5 pounders from Wolff.

The springs arrive, you put them in all your magazines and (wondering how good these new Wolff springs really are) you repeat the tests with the same force gauge at work the next day - and get exactly the same results!

These brand-new, 9.5 pound mag springs hold the top round of 7 up against the mag lips with a force you measure of only about 6 pounds!! Same as your old ones!!!

What's wrong here?

Buy the 11 pounders.

Maybe they mean what's the force on the... last round? Not the first one, but the bottom last one?? I would expect the force to be the same, either on the last or the first one, but... not enough coffee in my system to answer this.

Wolff makes 9.5 pound mag springs?

Interesting...

Here's the thing about springs. They take a set after a little use, which closes up the spaces between the coils. That essentially changes the spring's rate, which is much more meaningful than its maximum loading in pounds. How fast the mag spring unloads its stored energy is the key to its reliable function.

The other thing about springs is that there are few suppliers who actually adhere to original specs... correct specs IMO. 9.5 pounds may be "standard" by today's approach... but that doesn't mean squat. The "Standard" recoil spring for 5-inch guns has somehow become 16 pounds, and 18 pounds for Colt Commanders... but where that notion came from is still a mystery.

Back to spring set. The engineers take it into account, and allow for that, while still providing correct tension AFTER the set. This is why springs are heavier when new, but "weaken" after a little use. The same goes for Wolff's 11-pound springs.

Once a spring has taken its initial set, it "settles in" and holds the post- set tension for a long time. The 11-pound spring is designed to "set" to the maximum allowable tolerance for ordnance-spec springs and thus won't reach the minimum figure for several thousand cycles. I installed Wolff springs in 72 range beaters about 8 years ago... and I've had no mercy on those magazines.

They still work perfectly, and I can't remember the last feed malfunction that I've had that couldn't be traced to a bad reload... and I've had very few of those. Probably less than one in a thousand... and virtually all of my ammo is reloaded using my old funky cast bullets. I'm not all that careful during the seating process, and generally go for volume rather than perfection. As much as I shoot, I just don't have time to be anal about perfect reloads with a single-stage press.

Military armories typically change parts as they show signs of wear...or on a regular schedule... depending on protocol. There is usually little actual testing of springs, and the call is left to the armorer to judge on "feel" rather than gauging. Springs are cheap. Uncle Sugar probably didn't have more than 2 or 3 cents invested in a mag spring. So... if it could mean the difference between reliable feeding and saving a man's life as opposed to saving a few pennies... "Chuck it and replace it" is the order of the day.

Finally... the spring's loading is often determined at full compression... just at the point of coil bind... rather than as installed at its maximum point of compression. Since the spring's resistance increases in a linear fashion, the tighter it's compressed, the stronger it gets... what you read on the top round may not be representative of how it's rated. The most important measured reading is on the last round in the magazine, when tension is at a minimum... which is why when magazine springs grow worn and tired... we start seeing last-round misfeeds. Bolt-over base is common, but very often, the first indication of a weak spring is the little trick of ejecting live rounds... actually ejecting the next-to-last round, and feeding the last one. Or... Locking the slide on empty and having the last round lying on top of the mag, loose in the port. When you see that, you've already had push feeds going on for some time, and you may notice a change in the extractor's tension as a result. Sometimes, you'll break the hook... and this can occur even with a new magazine if the spring isn't to spec.

Would the Wolff 11 lb springs work in the Wilson Combat 7 round mags?

Quote:

Would the Wolff 11 lb springs work in the Wilson Combat 7 round mags?

Probably not. The Wilson followers aren't compatible with the way the spring has to fit inside the skirt. Wolff 11-pound/7-round springs are compatible with the standard 7-round followers. There may be a few other designs that they'll work with that I'm not aware of, though.

I believe that Wolff does make an extra-power spring that is compatible. Give'em a call.

Quote:

Wolff makes 9.5 pound mag springs?

According to their website they make 6, 7, 8, 9.5, 10 & 11 pounders

Quote:

Finally... the spring's loading is often determined at full compression...

just at the point of coil bind... rather than as installed at its maximum

point of compression.

According to the Wolff website: "Please note: load ratings indicated are with the magazine fully loaded.", or 7 rounds in the example given.

So how come it only takes about 6 pounds to push the top round (of the 7 loaded) down just a teensy bit from the feed lips - when the spring is supposed to have a 9.5 pound rating with a fully loaded magazine?

Quote:

So how come it only takes about 6 pounds to push the top round (of the 7

loaded) down just a teensy bit from the feed lips - when the spring is

supposed to have a 9.5 pound rating with a fully loaded magazine?

Either your scales are off, or they ain't givin' ya the whole story... or they're lyin'. Gotta be one of the three...

Knowing Niemi, I can't believe his scales are off. No way!

Quote:

Either your scales are off, or they ain't givin' ya the whole story...or

they're lyin'. Gotta be one of the three...

You got the problem's possiblities identified - and it's not a problem with the scale being off. Its max error at these weights/forces is under 2 ounces.

That leaves two. Hmmm-m-m-m.

I vote for incomplete information. To describe a spring's full function would serve to confuse and addle the layman. "Pounds" he understands. Get into rates per inch at varying compression distances... and you've lost him.

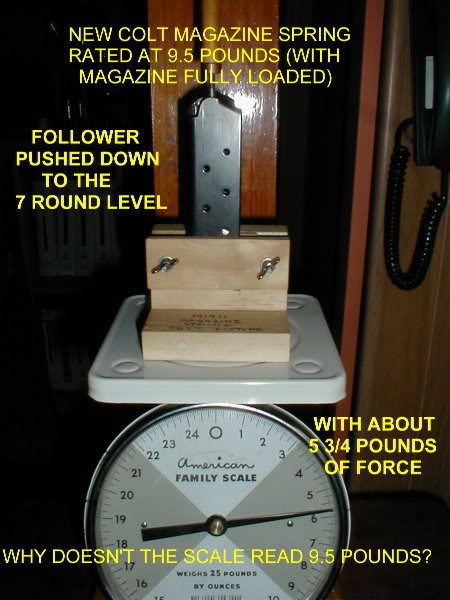

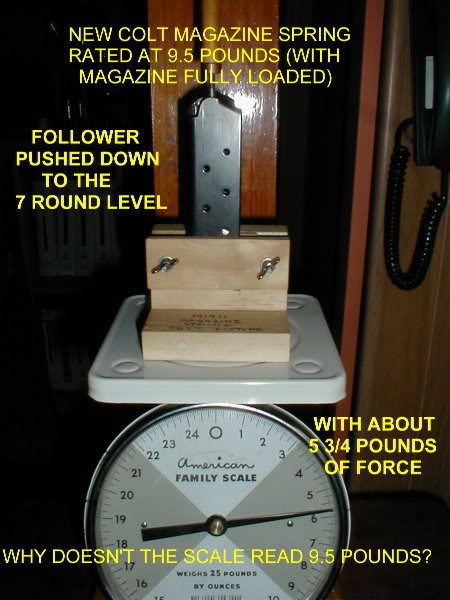

Here's a visual summary of the puzzle, and the spring's rate need not be known to solve it (I don't even know what it is):

Here's some other spring info that might help folks come up with the solution - no math involved:

* Free Length = 7 to 7-1/2 inches

* Installed Length = 4.3 inches

* 7 Round Compressed Length = 1.23 inch

* Solid Length = 0.66 inch (measured)

P.S.: I'm pretty sure I know the answer to the puzzle. But, what I'm looking for is an independently arrived-at solution (from anybody), without me leading anybody astray. I may have already led myself astray!

Quote:

Maybe they mean what's the force on the... last round? Not the first one,

but the bottom last one?? I would expect the force to be the same, either on

the last or the first one, but... not enough coffee in my system to answer

this.

You are correct. If the weight of the individual cartridges are ignored (neglected here) and nothing is in motion, the spring's force on the follower and bottom round will be the same at the force holding the top round against the feed lips.

While the 7 cartridges weigh, perhaps, 5 to 6 ounces this is ignored for simplicity because the puzzle involves the disappearance of 3 to 4 pounds!

Where did the 3 to 4 pounds disappear to?

Quote:

Where did the 3 to 4 pounds disappear to?

C'mon, Dan! You're smarter than that! I know you can find it! Getcha thinkin' cap on, mah brother!

I can't believe the trouble this is causing...

Quote:

Where did the 3 to 4 pounds disappear to?

It's obvious that since we're discussing single stack magazines that the answer is Slimfast.

On a less mirthful note, isn't a spring's weight given at it's fully compressed length?

Late edit: oops, just re-read the thread and saw that Tuner already posted that issue... But, is the fully loaded magazine (7 rds) fully compressing the spring? And if not, how much of an increase is there at decreasing increments to full compression? Just wondering when graphed, if it'd look like an exponential graph.

Quote:

I vote for incomplete information.

Not incomplete but, after re-reading the original post, perhaps somewhat misleading. Edited it to fix it up. Sorry if anybody went off on a wild goose chase because of it.

Quote:

I know you can find it!

Well, I think I already have - several months ago. Started the thread in the form of a riddle to hopefully elicit a solution agreeing with mine without letting on what mine was/is.

Springs are simple things, but testing them is sometimes not so simple. When I first did this same test I was befuddled by the seemingly imposible results. Took me nearly 2 days to figure out what was going on. Just trying to find out if I did figure it out correctly.

Quote:

...But, is the fully loaded magazine (7 rds) fully compressing the

spring?

No. By my measurements, the spring is about 0.57 inch away from being compressed to its solid length when 7 rounds are loaded in a 7 round standard Colt magazine.

In that picture you posted, I can't see (brass in the witness holes) any rounds in that magazine. And what does that wood weigh?

Quote:

...I can't see (brass in the witness holes) any rounds in that

magazine.

There are no rounds in the magazine. The follower is being depressed to the 7 round level by a wood dowel with a steel rod in its end. The steel rod fits into a copper & brass adapter locked on the follower which keeps the rod in place on the follower. The copper and brass adapters are the same thickness and together equal the cartridge OD. These are what's seen in the "7 round hole".

Quote:

And what does that wood weigh?

Don't know. I just zero the scale with the wood mag holder, the magazine and the pushrod on it before starting, compensating for whatever they all weigh.

This might not have been as good a hint as I thought it might be:

Quote:

Here's some other spring info that might help folks come up with the

solution - no math involved:

* Free Length = 7 to 7 1/2 inches

* Installed Length = 4.3 inches

* 7 Round Compressed Length = 1.23 inch

* Solid Length = about 0.7 inch (estimated) 0.66 inch (measured)

And, as many may not have an actual spring tester, here's another hint:

And I can't think of any other hints without giving away the solution.

Something tells me there may be a problem with using a moving spring to check another moving spring. Oh, and by the way, that's a family scale. NOT a magazine scale.

Ah, isn't that setup problematic for measuring the spring force? I mean you are pressing down on a spring, which compresses, and then that spring (through the mag body and the wood and the scale platform) is pressing down on another spring, the one in the scale. Why would you expect the scale to show you the mag's spring rate? I would attach the dowell on the top of the mag spring and add weights on top of the dowell, to see how much weight is necessary to keep the spring compressed.

Or am I still asleep?

The same test rig works OK when (with a different spring holder) it's used to test recoil springs. When a new 16lb recoil spring is compressed from its free length to 1 5/8 inch, the scale reads within a few ounces of 16 lbs.

The mag spring test method differs from recoil springs because the mag springs are tested wihile installed in the magazine - at least the way I test them. Because of this, the tester begins to apply and measure the force when the spring is already compressed to its installed length of 4.3 inches and already exerting about 3 pounds of force (see second pic).

When the tester pushrod is adjusted downward, the follower does not begin moving downward to further compress the spring until this strored-up 3 pounds is overcome. As the pushrod is moved downward beyond this point, the scale reading increases from 3 pounds to 5 to 6 pounds at the 7 round level.

After trying to figure out why the scale didn't read about 9.5 pounds, I came up with the goofy notion that maybe the initial 3 pounds (to get the spring installed in the magazine) needed to be added to the 5 - 6 additional pounds needed to further compress it to the 7 round length. The 8 to 9 pound sum was lots closer to 9.5lbs.

Anyway, it seems that a 9lb mag spring shoves the 7 rounds up with only 6 pounds of force - the other 3 pounds mysteriously lost during installation in the tube - or someplace else.

However, it still seems weird to me. Expecially when compared to recoil springs, which do exert their rated force when the slide's all the way back.

Did you happen to check the force of the mag spring before you zeroed the scale?

Not intentionally. I usually always zero the scale with all the stuff on the pan to compensate for its dead weight (about 10 ounces). If I'm running on all four cylinders, I'll also check the scale's zero setting after the measurements are taken.

Even if the scale read zero with nothing on the pan, the final reading would be increased by the dead weight of only about 10 ounces.

just re-measured a brand new Wolff 10 pound mag spring and got about 3 pounds pressure with nothing in the mag and 7 pounds at the fully loaded point. The total is 10 pounds, but it still seems like it ought to measure 10 pounds at the fully loaded point.

The problem may may well be with my measurement technique, but I'll be dipped if I can figure out what I'm doing wrong.

I'd even wondered if that funny little upper coil with the loop on its end could be the cause, but that seems pretty far-fetched.

Springs: Bah, humbug!!

Quote:

Ah, isn't that setup problematic for measuring the spring force? I mean you

are pressing down on a spring, which compresses, and then that spring (through

the mag body and the wood and the scale platform) is pressing down on another

spring, the one in the scale. Why would you expect the scale to show you the

mag's spring rate?

I'm not trying to find the spring's rate (force ÷ distance compressed), just the force. The fact that a spring scale is being used to measure the force on the magazine spring is no problem as long as equilibrium has been reached - nothing is moving.

If you put one spring scale atop another spring scale and zero the bottom scale (to compensate for the weight of the scale on it) and then place a, say, 2 pound weight on the upper scale both scales will indicate 2 pounds.

Quote:

I would attach the dowell on the top of the mag spring and add weights on

top of the dowell, to see how much weight is necessary to keep the spring

compressed.

Just followed up with your suggestion and am sure glad I did. While the force remained about the same, the dead weight test gave a much better indication of just how serious the friction problem was.

With 7 pounds of weights on the dowel, the weight could be pushed down by hand until the follower bottomed in the mag tube and when hand pressure was released the follower stayed on the bottom!

When lifted up by hand (with the same 7 pounds on weights on the dowel) and slowly released, the follower would stop going down at about the 5 round hole!!

That's a range of about 1¼ inch in which the spring alone (no tapping) was unable to overcome the magazine's internal friction. And this test was done using my smoothest magazine and follower - both painstakingly deburred and smoothed. Tried molybdenum lube, Teflon lube and then plain oil. No real change.

I sure would love to know how they test them at the factory.

Thanks for the suggestion. It was a real eye-opener!

Were the tests made with the follower in place... or with just the spring?

If the follower was there, it's the limiting factor in how far the spring can be compressed. With 13 turns of .045 wire, the theoretical stacked height is .585 inch. The 7th hole is an inch from the bottom.

Can you come up with a way to test the spring outside of the magazine tube... in order to eliminate friction?

Quote:

Were the tests made with the follower in place... or with just the

spring?

The follower was in place. The follower is what an adapter for keeping the pushod in place locks onto.

Quote:

If the follower was there, it's the limiting factor in how far the spring

can be compressed.

No problem with that. Was only interested in force readings with the follower pushed down to the 7 round level.

Quote:

Can you come up with a way to test the spring outside of the magazine

tube... in order to eliminate friction?

Had thought a little about that, but it seemed like a lot of fussy work just to measure a crummy magazine spring! Besides, the internal friction is a fairly minor problem when using the test rig in the pictures.

In addition, when using the test rig, internal friction could only increase the scale reading above what it should be when the rig is adjusted to slowly depress the follower. I'm still trying to figure out why it reads less than it should! At least less than I think it should.

My thought is that the spring is rated when it's at full compression...just at the point of coil bind. Test it like that. Methinks you may find your lost pounds.

Quote:

My thought is that the spring is rated when it's at full compression...

Splendid thought! And the folks at Wolff got the words wrong on their website!

Shouldn't be too hard to figure out how to do that, methinks.

And The Winner Is... Tuner!

You nailed it, my friend.

When compressed to just a smidgen before their solid lengths, the Colt magazine spring (presumably a 9.5lb factory standard) was 8lb - 14oz and a new Wolff 10lb was 9lb - 8oz. Close enough for Mrs. Niemi's little boy!

I was led off on this wild goose chase for the missing 3 to 4 pounds by the (apparently incorrect) words on Wolff's website.

Thanx for your help in clearing up this mess. It had me on the verge of profanity a time or two.

Quote:

When compressed to just a smidgen before their solid lengths, the Colt

magazine spring (presumably a 9.5lb factory standard) was 8lb - 14oz and a new

Wolff 10lb was 9lb - 8oz. Close enough for Mrs. Niemi's little boy!

Yup. If you'd gone ahead and compressed'em right_up_TO their solid stack height... they'd have been even closer. If you'll check random examples at different times throuout the year, you'll find that they vary a little from lot to lot. The next ones may go over the specified rating. *shrug*

Quote:

If you'd gone ahead and compressed'em right_up_TO their solid stack

height... they'd have been even closer.

Got some readings closer to their advertised ratings, but not sure how meaningful they are.

Biggest problem is telling exactly the solid stack height really is. There seems to be a point where the coils all finally get the spaces between them closed up and then a little further compression causes the round coils to move laterally over each other a little bit, allowing for a wee bit more compression.

A tremendous amount of technique is involved with this and I'm still in the process of refining mine.

FWIW, called Wolff about the 7 round or solid length business and didn't get much but "all spring testers are different" - perhaps meaning both the hardware to do the testing and the person doing the testing.

Thanx again for clearing up the mystery. Slept like a log last night!

Quote:

Got some readings closer to their advertised ratings, but not sure how

meaningful they are.

Not very. As noted earlier... There's more to the way a spring behaves than its maximum resistance... regardless of how that figure is determined. Rating it in "pounds" is just easier for the layman to understand. The spring's rate is more definitinitive... but try writing that on the package, and the phones will soon be a-janglin'.

I contacted Wolf a couple of years ago, and asked what was the compressed length of some springs at their rating. I got a quick response (which I posted here).

Maybe an email request might be forwarded to someone who knows/does spring ratings. Or maybe 11 1/2# is a trademark. If it a measurement at full compression, it's meaningful. Different followers will yield different readings.

Well, the quest for the compressed length at which the spring was rated was mostly to make sure my test gear and test methods were OK. Now that Tuner's solid length suggestion proved to be the key (as opposed to the 7 round length) all is well here in magazinespringville.

My main goal was to find the upward force on 7 rounds and the last round by a factory standard 9.5lb spring. This would be something anyone with a 10 or 20 pound capacity scale could measure to maybe answer the question "Is this magazine spring tired and in need of replacement?"

Measuring the force at coil bind is complicated because the follower will not allow coil bind in a standard 7 round magazine. Don't know about other types of magazines.

Quote:

This would be something anyone with a 10 or 20 pound capacity scale could

measure to maybe answer the question "Is this magazine spring tired and in

need of replacement?"

The tension on the last round in the magazine is more critical. The yardstick is when you start to see misfeeds on the last round or two in a normally sprung pistol... it's time to replace the spring.

Quote:

Measuring the force at coil bind is complicated because the follower will

not allow coil bind in a standard 7 round magazine. Don't know about other

types of magazines.

The follower is supposed to limit the spring's compression so that nobody inadvertently overload the magazine. Putting a spring into coil bind... like stretching one... hastens its demise.

(How ya like all them Ivy League words?)

Refined my test rig technique a little more and came up with these forces with 1 and 7 rounds loaded in the new Colt 7 round magazine:

* 1 Round = 28 ounces +/- 3 ounces

* 7 Rounds = 96 ounces +/- 7 ounces

Tried these measurements without using the test rig by just pushing the top round down by hand on the scale until I could visually detect its movement. The "iffyness" in the 1 round reading was about twice as much as when using the test rig. The 7 round reading was much worse than when using the test rig - to the point of being almost useless.

And, FWIW, the spring's rate calculated from the 1 to 7 round lengths worked out to 1.05 pound per inch.

And, WIW? Like some other things I've done, about the square root of zero point diddly!

In a nutshell - buy a few spare mag springs. If a magazine starts to give last round feed problems just put in a new spring and shoot it. Don't bother trying to test the darn thing!!

Just a thought Neimi, could you somehow use ultra high molecular weight slick strips, available from Woodcraft or Woodworkers supply of New Mexico, in your test rig to reduce the friction?

Splendid idea! I even have those catalogs, but it sounds more like a project for this Winter - if I ever decide to test another magazine spring!