I am new to 1911's and I need your input on a gun I purchased at a gun show.

I purchased a Mark 4 Ser. 80 in ss, I found out it was built in 1993.

My question is when I put some pressure on barrel when the slide is closed I can move the barrel down about .03.

Should I install a longer link to take up the play? The barrel contact in the slide is about 1/4 of the way in the groove.

Also when I broke down the gun the barrel link fell out, it was not staked in. The barrel is a Colt.

The key word here is "play". You need to find out where the "play" is. In most cases the longer link may cause problems. So go thru the link, pin, lower barrel lugs, and slide stop to make sure everything's in spec.

Me thinks you'll find the "play" problem there.

The "play" is normal for a barrel that is fitted to ride the link. Since the link goes over center when the barrel is pushed into battery the link clearances are compressible and can be felt when pressing on the chamber end. If the barrel were fit so the lower lug stood on the slide stop pin it would be tight and not push down. Without fully understanding the link-down timing of your pistol a longer link could not be recommended and will not "fix" this.

Is there a post telling you how to check them?

I purchased a # 4 link and installed it and it seemed to help.

There is just about maybe .01 play now. The gun went together OK.

Should I put the original link back in.

I have not shot the gun with the longer link installed...

Quote:

...when I put some pressure on barrel when the slide is closed I can move

the barrel down about .03.

The average link-riding M1911A1 will have 0.010" of play in its link system. Your 0.03" indicates something is either worn out or was made the wrong size. The dimensions in inches that establish how much play any 1911 has are:

* ID of the link pin hole in barrel = 0.154 + 0.001

* OD of the link pin = 0.1555 - 0.0010

* ID of the small hole in the link = 0.1565 + 0.0010

* ID of the large hole in the link = 0.2045 + 0.0010

* OD of the slide stop pin = 0.2005 - 0.0020

* ID of the holes in the frame for the slide stop pin = 0.201 + 0.002

Quote:

I purchased a # 4 link and installed it and it seemed to help.

Do not shoot the gun with the longer link installed!

You come to us for advise, the first two responders tell you not to install a longer link and what do you do? You put in a longer link!! If you want to risk serious damage, press on and ignore my advise in the first sentence of this post. You've bought a used gun at a gun show which is, as far as I'm concerned, about the riskiest purchase you could possibly make. If you want to fix it please heed our advise. IIRC, it's what you came here for.

The reduction in play with the new link indicates one or both holes in the original link (undoubtedly a standard 278 link) were too big. Install a new 278 link and see if it reduces the play.

Unless you know how to check a 1911's linkdown timing, a longer link could ruin the barrel or slide when fired.

Quote:

I purchased a # 4 link and installed it and it seemed to help.

The #4 may be fine, but will affect link-down timing, barrel to inside of slide clearance. I do not believe you will note an accuracy change, except it may shoot lower. You may also note with either link that the barrel is tighter with a round in the chamber when you are at the range.

And the "...barrel to inside of slide clearance." mentioned by CAW is what can ruin things. It is imperative that it be checked before firing the gun with a longer link. Instructions for checking it as a part of linkdown timing are available in our Tech Issues section - from Schuemann Barrels.

But I would urge you to first find out precisely why the gun had so much barrel play - rather than just throwing in new parts and hoping for the best. My guess of too-big holes in the link was just that. A guess. Keep in mind you (probably) have no idea who the previous owner was or how badly the gun was "Bubba'd" or abused before you got it. Please proceed with caution.

Quote:

Do not shoot the gun with the longer link installed!

Something did not seem right to me that's why I asked for advice... (I will take your advice).

I have held and fired friends 1911's and they had no play and thought it was a link problem.

I guess there is no easy fix...

Quote:

I guess there is no easy fix...

Probably not. The fact that the link pin falls out is the first clue as to where to look. The pin should be a press fit into the barrel feet (while still allowing the link to move freely).

Our guru, 1911Tuner, has in the past discussed addressing the problem of an oversized hole by using drill rod of a diameter .001 or .002 larger than the pin and making your own oversized pin. This, of course, probably means having to get an appropriately oversized reamer to enlarge the hole in the link so that it can still rotate on the larger pin.

Quote:

I have held and fired friends 1911's and they had no play...

That's because there are two categories of 1911's:

* Those having up & down barrel play, such as the Government Model and probably the majority of 1911's costing less than US$1,000. Barrels in these ride the link into battery and are supported vertically by the link (not the lower lugs on the slide stop pin) once in battery. Their barrels are best described as "drop in" as they need little or no fitting.

* Pricier 1911's with fitted barrels have no (or virtually no) up & down barrel play. While barrels in these guns usually ride the link most of the way into battery, just prior to reaching battery the link transfers the vertical support job to the barrel's lower lugs - which then rest on the slide stop pin when in battery. These barrels require hand fitting to acomplish their no-play lockup in battery and that's one reason why they cost more.

Quote:

* ID of the link pin hole in barrel = 0.154 + 0.001

I checked all of these dimensions the best I could with dial calipers and found that the slide stop pin measures 0.196 .005 small from the mean.

Looks like this is the problem. Should I stake the link pin?

I will get a new slide stop pin and see what that does.

Quote:

...the slide stop pin measures 0.196 .005 small from the mean. Looks like

this is the problem.

Perhaps only part of the problem. 0.196 is only 0.0035 below the mean pin diameter of 0.1995" If you originally had 0.03" of play, how much play will you have with a 0.005" bigger pin?

Quote:

the slide stop pin measures 0.196 .005 small from the mean.

A slide stop pins should measure from .2005 - .002 or 0.1985 to .2005 which has a mid-spec dim of 0.1995 which is .0035 above the .196 that you measure.

You may want to measure the pin with a micrometer instead of calipers.

Edit added: I just noticed that Niemi already pointed this out...

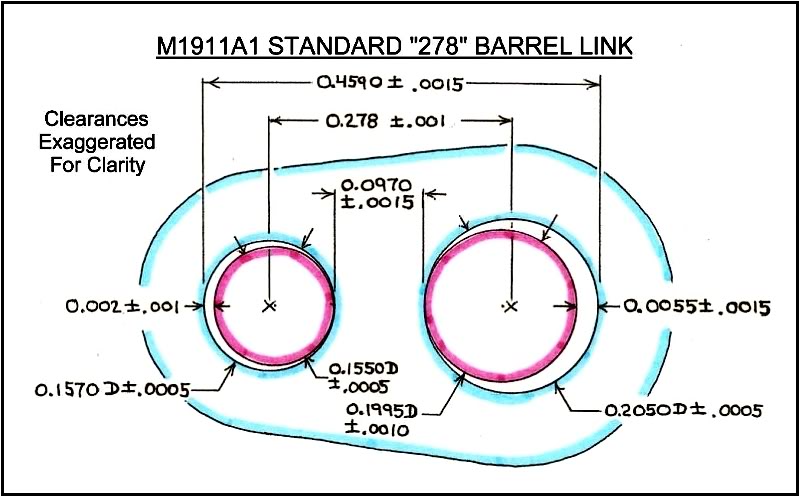

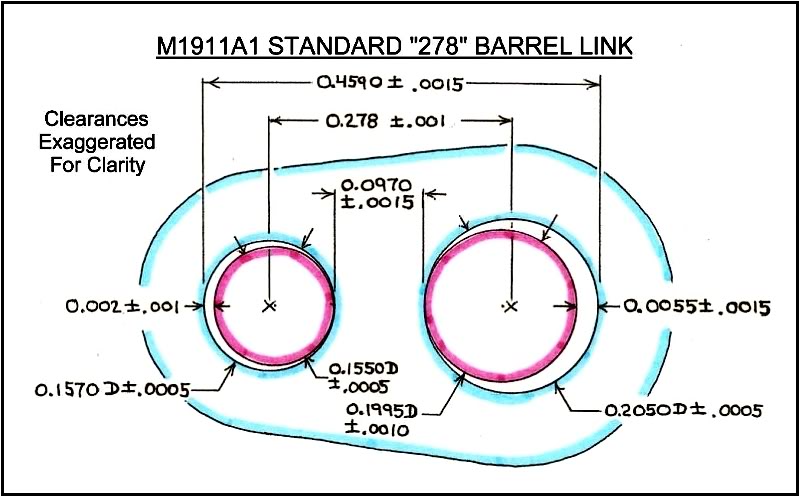

Where is the fine picture of a link and pin sizes you made Niemi? That was valuable.

Eric's post reminded me that slide calipers are usually awful at measuring small hole ID's - such as on the barrel, link and frame. A better method is to use a split ball small hole gauge measuring it with a micrometer. That's cheaper than a set of gage pins.

Or, if you know a machinist...

Quote:

Where is the fine picture of a link and pin sizes you made Niemi? That was

valuable.

Didn't think it would add much to the dimensions given in Post #6, but here it is:

Quote:

I checked all of these dimensions the best I could with dial calipers and

found that the slide stop pin measures 0.196 .005 small from the mean.

Looks like this is the problem. Should I stake the link pin?

I will get a new slide stop pin and see what that does.

Before you stake (or try to stake) the link pin -- what's the diameter of the link pin, and what's the diameter of the link pin hole -- both in the link, and in the barrel lugs? Is the pin uniformly smooth, or is it worn, either on one or both ends, or in the center where the link rides? Are the holes, either in the link or in the barrel lugs, at all egg-shaped?

Quote:

Perhaps only part of the problem. 0.196 is only 0.0035 below the mean pin

diameter of 0.1995" If you originally had 0.03" of play, how much play will

you have with a 0.005" bigger pin?

It felt like .03 maybe more like .01 or .015... (not really sure what it was)

niemi24s - you would have play at the link and also at the frame of the gun. Play at both points would add up.

A friend just happened to have a spare slide stop pin that measures .200. We installed it and now there is only about .002 play if that.

Quote:

Before you stake (or try to stake) the link pin -- what's the diameter of

the link pin, and what's the diameter of the link pin hole -- both in the

link, and in the barrel lugs? Is the pin uniformly smooth, or is it worn,

either on one or both ends, or in the center where the link rides? Are the

holes, either in the link or in the barrel lugs, at all egg-shaped?

I will check the pin again with a micrometer. I will also check the holes with pin gauges...

I know the people at a local machine shop they will let me use the gauges.

Quote:

A friend just happened to have a spare slide stop pin that measures .200.

We installed it and now there is only about .002 play if that.

Is that with the original link or the new #4 link?

Remember that long-linking a 1911 can lead to serious damage if linkdown timing is adversely affected.

Quote:

Is that with the original link or the new #4 link?

The original link was put back in, which measures out to be a standard 278.

So if I'm understanding you correctly, the aft end of the barrel now has only 0.002" of up & down play with the original 278 link and a 0.200" OD (0.004" larger) slide stop (SS)pin.

Q: Is my understanding correct?

If it is and if that play was measured with the aft end of the barrel being forced fully up (with a stick down the barrel) and then with the aft end of the barrel forced fully down, then I'd venture a guess this gun does not stand on the link in battery with a drop-in barrel but, instead, has a fitted barrel supported vertically in battery by its lower lugs resting on the SS pin.

Check to see if the barrel is indeed supported by the barrel lugs on the SS pin (with the link loose) by this method:

* Remove the recoil spring and plug

* Install the SS normally but with its arm hanging down over the trigger guard

* Push the slide forward to put the gun in battery and then point it down ward a little to keep it in battery

* Through the ejection port, push the barrel down

* See if the SS arm swings freely and whether or not how freely it swings depends on how hard you push down on the barrel

If your gun's barrel is not supported vertically by the link, it must (by default) be supported by the lower lugs on the SS pin - and the link will be loose (neither in tension or compression).

Another (perhaps better) way to tell how the barrel is supported is to:

* Remove the barrel, degrease the lower lugs and coat the lower lugs (on both sides of the link) with a magic marker

* Reassemble the gun normally but without the recoil spring, guide and plug

* While pushing down on the barrel through the ejection port, cycle the gun in & out of battery about ¼" about 10 to 15 times

* Remove the barrel and see if the magic marker was worn off its lower lugs by the SS pin.

Do all this with the 0.200" OD SS pin - you need a new one anyway.

Q: How is your barrel vertically supported when in battery - by the lugs or the link?

You may now notice a marginally tighter group or not.

As to the question of whether it is riding the link or standing on the pin, it is riding the link.

This conclusion out of hand comes from the fact that after cycling the slide, the barrel can be pushed down. When a barrel rides the link, the link is in compression, and forces the barrel as high as it can when at 90 degrees to it, then it goes past center .050", or so, and the clearances open up, but do not pull the barrel down with it. When you push down you are closing them up. When shooting it may/sometimes doesn't matter, and a barrel that rides the link can be accurate.

If on the other hand the lower lug were riding the pin into battery due to the larger pin, it would not push down after cycling as the barrel would not have had any mechanical reason to go higher. It is being pushed up to it's height in battery by the lower lug, and would feel solid after cycling the slide.

To think further as to the considered possibility that when cycled into battery, and pushed down, the lower lug is then contacting the pin isn't of any consequence as when shooting this won't be the case, and it will be still riding the link as most production 1911's do.

Yes there is only about .002 .003 play with the original .278 link and .200 slide stop.

I did the test you asked for and found that the ss does not move when pressure is applied to the hood while in battery position.

So am I OK to shoot like this??

Quote:

So am I OK to shoot like this?

Why wouldn't it be? It exhibits the same characteristics of most Colts out of the box from that time.

From Post # 1 to Post # 26, play was reduced from .03 to .003 by a link and pin swap?

I guess maybe I missed something. I don't doubt anything, just trying to stay on track.

Just the pin, the stock link is back. About covers a lot of territory.

The new slide stop cross pin measures a bit larger, but not enough to explain the .03" t0 .003" change.

Just maybe, the difference is due to different measuring procedure?

The difference from first post to last post isn't obvious to this thick headed dummy. The only change from #1 to # 26 was the diameter of the slide stop cross shaft.

Just a spectator trying to follow the track, but my train got de-railed. What did I overlook?

Wait!

Quote:

I did the test you asked for and found that the ss does not move when

pressure is applied to the hood while in battery position.

I was wrong in posting that "SS swings freely" test, and have deleted it from the post. Do the one with the magic marker on the lugs instead.

Sorry about that. Made that post too soon after leaving the dentist!

Quote:

Just maybe, the difference is due to different measuring procedure?

As I said on post 19 I was not really sure what the play was. I did not check it with a dial indicator.

Might have been .015 I don't really know. All I know is that the play was taken out with the new ss pin.

With all due respect, I don't think your measurements are accurate.

You began with a slide stop pin measuring .196" and vertical play of .030".

You swapped in a different slide stop that measures .200", which is only .004" larger overall and only .002" larger in radius, and you are now reporting vertical play of .002" (or maybe .003"). So you are saying that a change in pin diameter of .004" reduced the vertical slop by .028".

That's just not possible.

No... my first posting slop was only a guess as I said. The ss pin did mike out at .196.

You need to understand there was play in the link pin hole and the frame with the .196 pin. I don't know why it's right now but it is.

Well I finally made it to the range yesterday. The gun worked just fine no problems. It looks like my groups tightened up some also.

Unless someone has messed with it unsuccessfully, or a Colt QC guy was asleep at the wheel, betcha that barrel is capable of tight X-Ring performance at 25 yds.

Match grade chambers aren't very tolerant with less than Match grade ammunition.

I would go along with someone has messed with it.

How can you tell it's a match grade barrel? There are no markings.

Quote:

How can you tell it's a match grade barrel? There are no markings.

Generally, the only way to tell is by how the barrel is fitted to the slide and frame/slide stop pin. This fitting is done by equalizing the barrel's radial locking lugs to those of the slide, trimming barrel hoods that are intentionally too long and lower lugs that have too much metal on them.

When the slide is removed, turned upside-down on the bench, the barrel & bushing installed and the barrel fully aft in the slide (in battery) a fitted barrel will have little or no fore-aft play in the slide and when fully aft, the barrel hood will be in contact with the breechface.

When the gun's all put together and in battery, the barrel will be supported vertically by the lower lugs resting on the slide stop pin and the back end of the barrel will have practically no up & down play in the slide.

The muzzle end of an Army Ordnance National Match barrel has a slightly larger OD for the first 5/16". If the end of your barrel is like that it's a good indication it was born a National Match (or "match grade") barrel. Whether or not it was fitted well is another matter.

Can't speak for someone else, but I 'think'...

...what went unsaid was that some barrels are marked as 'MATCH', or 'Drop In with no, or little fitting required'.

They might actually be Match grade and capable of astounding performance, but to deliver that Match grade performance, they need to be fitted correctly by someone who knows what he/she is doing.

The quickest way to tell is if the first barrel lug recess is less than the next. This so it can be fit to make contact and not go too high. Normally a match grade barrels first lug recess will be about .040" and the next about .055".

I have a Kimber Team USA that has slight vertical movement and it shoots and works just fine.