Can anybody give me a reference on how and how much heat treat was performed on 1911 frames and slides?

Not the original ones, but the heat treatment specs for the 1960's vintage slide can be found on the slide blueprint in our Tech Issues section, 14th link down. TheSight has some older blueprints that may have something for you.

On the originals? None. They were dead soft.

In 1936, Colt added a hardened insert in the breech face to prevent peening by recoil forces.

In 1941, spot-hardening of the slide came about. Colt again.

In 1946, they started heat treating the whole slide, and the frames soon followed.

Quote:

On the originals? None. They were dead soft.

Isn't this why the 1911 design has three barrel locking lugs because the soft metal cold worked themselves together?

And now we all try (well, at least me) try to get three hardened lugs to match.

"Flame hardening":

http://forums.1911forum.com/showpos...130&postcount=2

http://www.flamehardening.com.au/ar..._id=2&page_id=8

http://webcache.googleusercontent.c...=www.google.com

State of the art in 1911: Composition and heat treatment of steel

http://www.archive.org/stream/compo...age/n7/mode/1up

Full hard steel is too brittle for most applications.

Flame hardening is great for tool steels when a tool room machinist needs to fix a machine but can create full hardness zones prone to cracking.

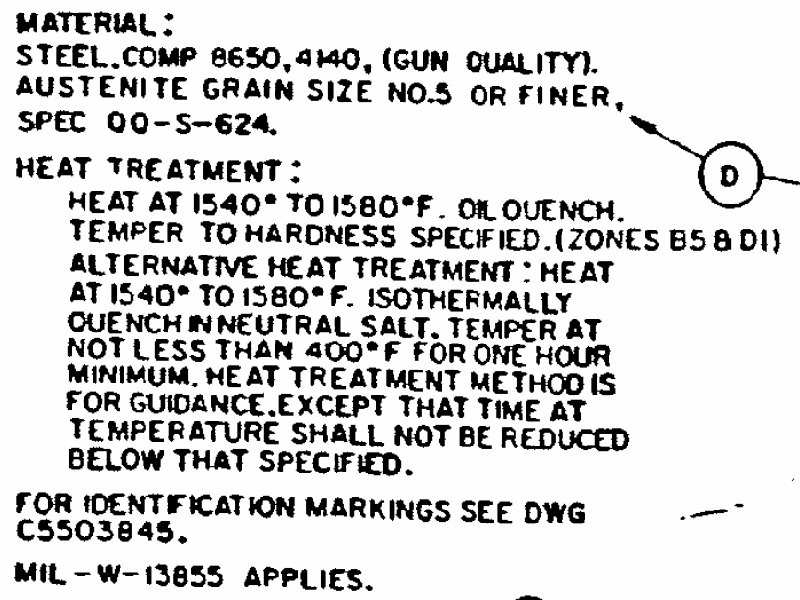

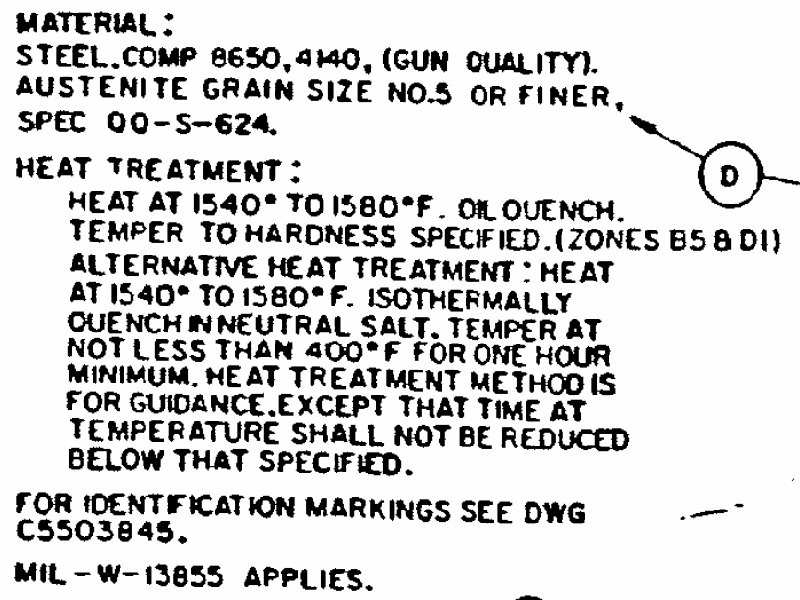

Here is the slide's heat treat requirement from the 1911 Army print dated Nov-11-1960

Notice that they temper the steel down from it's full heat treat hardness which is probably in the Rockwell 50s on the C-scale. This is commonly denoted Hardness Rockwell C-scale (HRC) as HRC 50-55. A full hard 4140 (Chromoly) would probably be too brittle and crack.

This is why they temper (soften or anneal) the metal down to HRC 40-46.

I checked the hardness of my MetroArms slide before I customized it to assure that the slide was hardened to spec

So if I have one of Sarco's unfinished slides, that needs to be heat treated, how would I go about raising it to 1550 degrees for an hour? And what kind of oil would I quench it in - motor oil? Should it be heat treated and annealed before or after machining?

I am under the impression that the discolored slides on the 1911A1 pistols was because of certain areas being heat treated, slide stop notch, muzzle, etc.

Quote:

So if I have one of Sarco's unfinished slides, that needs to be heat

treated, how would I go about raising it to 1550 degrees for an hour? And what

kind of oil would I quench it in - motor oil? Should it be heat treated and

annealed before or after machining?

You can buy heat-treating ovens for thousands of dollars. You can also jury- rig something with firebricks and a MAPP torch, although that's not the most reliable method.

I'm not sure about the oil, although I have heard people recommend vegetable oil over motor oil simply for the smell.

I would heat treat and temper (not anneal) before machining to minimize the risk of dimensional change and also so that you'll be machining the scale off.

I have found that my local tradesmen (welders and machinists) are usually very receptive to doing tiny jobs on guns for me at very reasonable prices (far less than a gunsmith and also far less than their normal rates) simply because they find the idea of someone who builds his own guns interesting and want to talk about the process. Maybe a heat treater would be the same.

Hawk, I would do all the work on the hardened slide, and try to find a local machine shop that sends out parts to be hardened to similar specs as the slide calls for, they may be able to slip the slide in with a batch of their own parts for a very minimal fee. Never hurts to find out what kind of beer they drink You will probably need carbide tools to machine the hardened slide.

Whatever you do invest in a Rockwell hardness tester to check the work. (I'm not very trusting)