Hammer Design

original:

forum.m1911.org

Retrieved: November 23, 2011

Last Post: February 20, 2011

Noelsidewinder

19th February 2011

I have noticed, if it is not my imagination, that there seem to be a lot of

variations on the 1911a1 hammer design; in respect to the length and shape of

the striking face. It would seem that some of the new design hammers have

different lengths measured from the hammer pin hole center to their upper

edge. Also, some are straight while others seem to have a "cam" end design.

Can anybody explain the reasons behind these variations and if they have an

inter relation with the sear/hammer engagement?

And more importantly, do they have an effect of easing and smoothing or even

reducing the slide recoil effect?

Hawkmoon

19th February 2011

Those all look flat/straight to me, and the length looks about the same, as

well. What is this photo supposed to be showing?

Noelsidewinder

19th February 2011

The hammer on the left seems to show a slightly different length and top

radius (cam).

BigJon

19th February 2011

Design only, by the time the hammer is cocked the upper cam area will not be

touched.

niemi24s

19th February 2011

Quote:

The hammer on the left seems to show a slightly different length...

With that image copied and two parallel lines drawn (one through the pin hole

centers, the other through the upper limits of the faces of the two on the

right) the hammer on the left does certainly seem to have a longer face. Or

the two on the right could be said to have shorter faces. That's in comparison

with each other, but it's hard to say how any compare to the Ordnance face

that ends about 0.915" from the pin hole center.

They do appear to be long enough to hit the firing pin.

wjkuleck

19th February 2011

Quote:

They do appear to be long enough to hit the firing pin.

...and that's how long they have to be for function. They are longer so that

you can have a spur (or rowel) with a pleasing shape that's easier on the

thumb.

Or so I imagine.

Dave Waits

19th February 2011

Oh, I thought he was referring to the slight angle you see at the top of

some hammer-faces to ease the slide hit. My Wilson Value-line has one.

niemi24s

19th February 2011

Here's the copy mentioned in Post #9, but with another line added at the top

- my guess on where the face of the hammer on the left ends:

PICTURE 404

egumpher

19th February 2011

Don't forget that the longer the hammer flat the more the hammer pivots back

and unloads the sear. Some 'high grade" hammers attempt shorten the hammer

flat to minimized sear motion.

DuckRyder

19th February 2011

Wait a second, you lost me...

How does the length of the hammer (the upper portion) impact the sear if the

relationship between the notches, hammer pin and hammer strut pin remains

constant?

niemi24s

19th February 2011

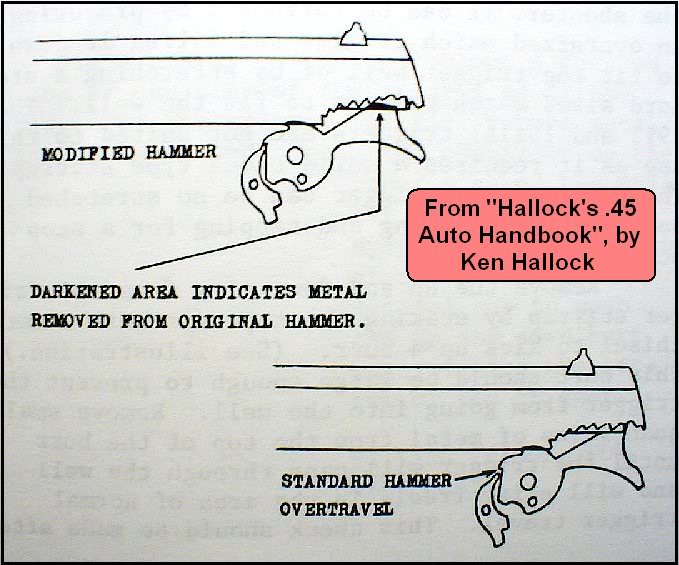

Perhaps what Eric is talking about is hammer overtravel (overcocking?), as

illustrated here:

The author (Hallock) states reducing overcocking also reduces the momentum

the hammer can gain from the time it's released by the slide (on its way back

to battery) to the time the hooks contact the sear nose. This would reduce the

impact stress on both.

DuckRyder

19th February 2011

AHH, I see!

The slide did not even enter my mind...

Hawkmoon

19th February 2011

I believe in reality the hammer travels farther than the slide can push it by

contact anyway. The hammer over-travels, then bounces back and impacts the

slide. It is the impact of that upper corner hitting the slide right at the

point where the firing pin safety occurs in Series 80 pistols that accounts

for the damage to some pistols at that point.

I have a very early Para P12.45 that I bought used. I knew the previous owner

had shot it a lot, and after reading a post on this forum about the problem

for another member, I inspected mine and was horrified to discover that the

underside of my slide was badly eroded (or pounded) at that point. I sent the

slide to EGW and they welded it up and recut it, so now it's as good as new.

The point is that a minor difference in the height of the hammer face to the

start of the radius or chamfer actually doesn't mean much of anything.

egumpher

19th February 2011

Quote:

Perhaps what Eric is talking about is hammer overtravel (overcocking?)

Yep... that what I meant to say... thanks Niemi.

niemi24s

19th February 2011

Quote:

I believe in reality the hammer travels farther than the slide can push it

by contact anyway.

How true, because after firing when the slide's going back, the hammer gets

whipped back and actually loses contact with the slide - whacking the bottom

of the disconnector rail when it rotates back the other way as you mentioned.

The idea behind the modification in Post #13 has nothing to do with how far

the hammer goes back when it whips off the slide - it'll get whipped back

until the spur hits the grip safety whether it's modified or not.

But after the hammer regains contact with the slide, the slide stops and then

starts going forward into battery - with the hammer in contact with it. The

idea behind the modification is to reduce the distance the hooks arc through

on their way back down to the sear nose (after the FPS gets forward of the

hammer face).

In other words, while the slide is going forward into battery the

modification will see the hammer overcocked just a little bit - instead of

being overcocked a lot.

Whether it all amounts to a hill of beans, I don't really know. But maybe it

helps the hooks stay on the sear nose - and avoid hammer follow on light pull

triggers?

Noelsidewinder

20th February 2011

niemi24. Thanks for your drawings and comments.

You might be interested in seeing the type of hammer Hallock describes. If

you follow the below link you will see a gun by Jesse E. Harpe along with a

reprint of a April 1942 article from 'The American Rifleman' titled "Revamping

the .45 Colt". In the article he does not mention the hammer modification as

such, but it is plainly visible. The article in itself is very interesting

along with the rest of the thread. The idea behind the modification would seem

to be, besides your mentioned softening of the sear/hammer reset, a smoothing

of the final recoil stage. If you are up to it, it might be interesting for

you to draw an accurate plan, as Hallock's drawing does not seem very precise.

http://www.louderthanwords.us/forum...314&hilit=Harpe

As always thank you for your help.

Return to 1911 Archive