Looking discussions about creating in this case a good safe crisp creep free carry trigger.

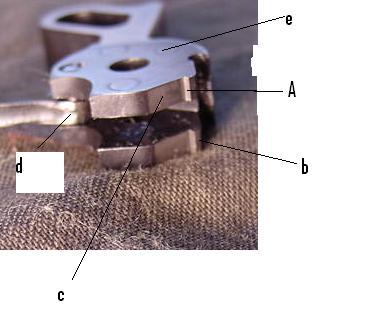

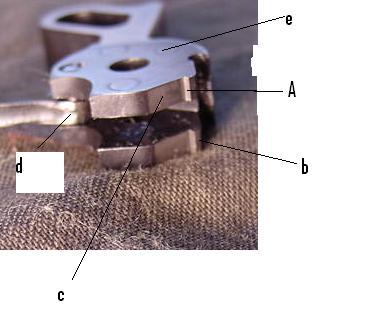

So with out further preamble I humbly invite our distinguished 1911 professionals to participate in this thread. I will attach a picture that shows a close up of a 1911 hammer the focal point being the hammer hooks. Note that it is labeled with lines pointing to various features. This may help our conversation.

So who is first... let's play name the parts!

A) full-cock notch (sear-engagement surface)

B) hammer hook @ full cock-notch

C) don't know what to call that surface, i think the sear kind of tucks up against it

D) Hammer strut and pin

E) don't know what to call that surface

The 1911 pattern pistol is a pretty simple affair, and any problems that arise are usually simple to address. Understanding how it works is the first step. There are a few misconceptions in a few areas, and once cleared up, things get a little easier.

When contemplating a trigger job, whether it's a full-blown match type, or a good working trigger on a carry or duty gun, they thing to bear in mind is that the cycle of a 1911 isn't smooth. It's a fairly violent affair and the hammer can and does bounce.

During the slide's recoil and resulting hammer-cocking action, the hammer doesn't ride the slide into full cock. It's slammed forcefully back against the grip safety, and is caught by the slide. At this point, the hammer isn't in contact with the sear. It then falls back to full cock as the slide lets go of it on the way back to battery. Inertia can cause the sear to move before it engages the hammer hooks, and spring tension is necessary to keep it in position to get a full grip on the sear. If the sear spring doesn't have enough tension to get the sear back into position on time, the hammer will follow.

As the slide goes to full battery, a weak mainspring can allow the hammer to lose contact with the sear briefly. This is known as hammer bounce, and can bring on the dreaded "Hammer Follow" if the sear spring doesn't keep the sear rotated into engagement position. Hammer hooks that have been cut too short can make this more likely, as the sear doesn't have much to grab. All the sear has to do is rotate away from the hammer for a short distance to miss the hooks. Followdown generally doesn't result in burst fire. Burst or full auto is pretty rare, and is caused by the hammer jarring off the sear as the slide slams to battery. When the trigger is released, the half-cock will probably stop it, but by the time the shooter can react, the pistol will probably be empty.

Another effect that inertia has is on the trigger itself. The pistol jerks forward, and the trigger stands still... maybe enough to nudge the sear.

If the hammer hooks are too short, it can bump the sear out of engagement. Again, this usually happens with the finger off the trigger, and the hammer falls to half-cock. Not good for the sear, but better than a slam-fire. Pulling the trigger before releasing the slide, but is in itself a dangerous practice.

Lighter components work to prevent these inertial effects. Hammer, sear, trigger can be lightened. The less the inertial mass of these parts, the less potential trouble on a 2 or 3-pound trigger job.

Now for the "Opinion" part. I don't feel that a carry gun has any business with a trigger pull of less than 5 pounds, nor do hammer hooks of less than .021 inch have any place on a carry pistol. The potential for an unintentional discharge is too great when adrenalin runs high. Most situations that require an unholstered pistol will turn out to be of the Threat Response/Threat Management variety, with no shooting needed.

Holding a bad guy at gunpoint with an unlocked, single-action pistol that has a 3-pound trigger is pretty hairy, and if you should nudge the trigger, the civil litigator won't leave a greasy spot of your financial security.

Good training can negate this to a degree... Leave the safety on until the bad guy stops or escalates, at which point we make a decision to shoot or stand down... but what if he surrenders just as we wipe off the safety... and your shot hits him just as his hands start to go up? Another pound or two of trigger pressure might have allowed you to stop in time.

1911Tuner: Respectfully, bud, I think you made a boo boo.

In your third paragraph you wrote about the cocking action of the pistol where the slide kicks the hammer back until it hits the grip safety and the hammer full cock notch or hooks is past the sear. The next sentence you say the slide goes forward and the hammer falls to half cock. I think you meant full cock. Just to clarify.

BigG caught me in one...

1911Tuner: Respectfully, bud, I think you made a boo boo.

In your third paragraph you wrote about the cocking action of the pistol where the slide kicks the hammer back until it hits the grip safety and the hammer full cock notch or hooks is past the sear. The next sentence you say the slide goes forward and the hammer falls to half cock. I think you meant full cock. Just to clarify.

Ahh... Sometimes haste gets my fingers movin' before the brain is in gear.

I had hammer follow on my mind. Kudos BigG... You've got a sharp eye. I'll go back and correct that.

Quick question... my SA Mil-spec hammer has a half-cock ledge, not a notch. I can drop the hammer from half-cock. Is there a reason for eliminating the half-cock hammer hooks? Is it truly ascertained that there wouldn't be enough inertia, momentum, whatever, to discharge from half-cock under these circumstances?

You got it. The ledge doesn't hold the hammer back far enough to let it gain momentum and bust a cap. A very weak firing pin spring might make a liar out of me, but it would have to be VERY weak.

Colt Series 80 hammers have the same ledge. I'm going to assume that it's being copied mainly for the sake of saving money by eliminating the machining operation of a true half-cock notch. It would also be more gentle on the sear in the event of a followdown to half cock, since the only contact would be on the backside, away from the primary angle.

I use the McCormick hammer precisely because it has a captive half-cock notch rather than a shelf. That particular hammer, though, has an unusual feature: rather than a half-cock notch of uniform size, the center portion stands proud of the rest of the notch such that a hammer falling to half-cock will only contact the sear dead center - not on the edges where the hammer hooks make contact. This saves the critical areas of the sear nose in the event that the hammer does fall to half-cock, but still provides the notch rather than shelf.

Edited to remove brain fart.

Manevitch said:

I use the McCormick trigger precisely because it has a captive half-cock

notch rather than a shelf.

Trigger with half cocks! Who woulda thunkit?

Just funnin' witcha Manevitch... I do brainfarts all the time. I know the design you speak of, and it's not a bad idea at all.

Quick question... when it's said that the hammer hooks should be set at .020 or .025 or whatever, are we talking about the depth at A in the picture? If the hooks are less than that, say .18, would you then remove material at C? and at B if they are, say, .030? Sorry, I can't find my old Kuhnahusen for some reason...

The hooks are measured from the tips to the flat area... B to C.

Removing material from the tips (B) is a matter of using a feeler gauge on the flat (C) and stoning the tips flush with the feeler gauge... The thickness of the gauge determines how long the hooks will be. Be careful to keep the gauge flat.

Removing material from the flat (C) is tricky, and should actually be done on a mill, and the hammer should be hardened throughout. Some cheapo hammers are softer under the skin than on the surface. Not case-hardened, just poor heat- treatment procedures. Pretty sure MIM hammers are soft under the skin too... I could be wrong, since I've never worked with one.

Prepping/adjusting the hammer on a mill ensures that everything is true and square... assuming a proper set-up... and it allows C to be deepened and the hooks to be squared up at the same time, again assuming proper set-up and a sharp end mill. (Cutting tool)

Light squaring up of the hooks with a safe-edged square file is okay, as long as you are careful, patient, and take no more than necesary to get'em square.

Squaring up the hammer hooks on a mill? Now that sounds like a good idea. Time to sacrifice a few more hammers.

BTW, first 1911 trigger job came back as 4 pounds, 3 ounces, with no creep and a nice soft release. All factory parts save for the hammer. I'm staring to like this old gun...

Excellent! That's known as a "rollout" break, and gives you a little more leeway than a similar break point that's like the proverbial glass rod.

Quote:

That's known as a "rollout" break

I really prefer this kind of release over a glass-rod break. How should one go about setting this up on a 1911?

Consistently and on demand? Not sure, since I'm not a trigger man, but since most newer Colts seem to have this type of break, studying the parts might provide a few good clues.

Fairly long hooks, as compared to aftermarket hammers that are geared toward crisp trigger break. Sears without breakaway angles, but with smooth edges on the tip of the primary angles. Untweaked sear springs that have been thinned a little for a little lighter tension.

A new, sharp sear without a breakaway angle can be altered slghtly to provide a smoother disengagement by simply knocking off the sharp edge. As before, lay a .020 feeler gauge under the legs and lay the sear on a hard Arkansas stone. Push the sear along the stone while keeping the gauge in place. Move it upward, toward the top of the sear to prevent kicking up a sharp edge. Just a very small amount off the backside of the tip is all you need. 4-5 light strokes on the hard stone should do it. When you get through, tape a piece of old denim on a flat surface... glass will do... Smear a little J&B Bore Cleaner on the work area,and swipe the sear tip across it a few times to finish polishing any sharp edge.

Assemble the gun, and cock the hammer past full cock. Dribble a few drops of oil into the area between the hammer and frame to get some oil on the sear, and boost the hammer 8-10 times. You should have a smooth rollout break. Shooting the gun a couple hundred rounds should burnish everything nicely, and work harden the surfaces a little. I call it the poor man's trigger job.

Boosting the hammer is simple. Cock it, and push forward firmly on the hammer with your thumb while pulling the trigger until the hammer falls. If more than about 10 pounds of pressure on the trigger is required to drop the hammer, you're either pushing WAY too hard, or both hooks aren't on the sear evenly. Many times, simply boosting the hammer will give you a noticeably better trigger, especially if the release is gritty or has a lot of creep.

I believe the half-cock notch on the McCormick hammer is the same thing we used to call a "Swensonized" hammer. Armand Swenson advocating doing this and did it on most of the ones he customized.

I have been doing it to all of my hammers since 1975.

This way the only things that touch the engagement surfaces on the sear are the full cock hooks.

If the hammer should fall to half cock only the middle unused portion of the sear gets bumped. Also for dry fire practice cocking the hammer doesn't drag the half cock notch or shelf over the sear.

My first step as taught...

Using the picture supplied,

Surface A, is where almost all feel of creep comes from, (on every firearm this surface makes the heart of the trigger pull, find it and make it mirror and the trigger will get better) when this surface has any irregularities at, is when you feel or hear that a trigger feels like it grates.

So my first step and that of all smiths that have let me see what they do, is stone this as smooth as possible!

When this is right, even a pistol that has over strength springs and over long (deep) sear shelves, starts to feel good!

After this all other tuning is a matter, of touch, pride or prejudice!

.018 shelves

I was taught another length, but for this forum I am going to let others post the length they are comfortable with. The shelf I was taught to do is less then .020, and down to 2 1/2 pounds pull, is reliable. Although my preference is in the 4 to 7 pound range, that's heavy enough to feel my flinch and not lose a shot.

A three pound 1911 trigger truly is the lowest practical weight, sometimes you do something to prove you can or have been prodded just right, thats why I can say 2 1/2 but I don't do that after I proved I can, because once is ------- when twice is ---(inesrt bad words and or thoughts here) -------