What are the advantages and disadvantages of short guide rods versus full length guide rods?

If one uses a full length guide rod what are the pros and cons of one piece versus 2 piece.

I am looking at the Fusion and Wilson Combat for a 2011 Sig-Sauer 1911R Nitron.

I am having no problems with the pistol. I am just looking to customize a bit.

If one uses a full length guide rod what are the pros and cons of one piece versus 2 piece.

I am looking at the Fusion and Wilson Combat for a 2011 Sig-Sauer 1911R Nitron.

I am having no problems with the pistol. I am just looking to customize a bit.

Wayne Novak may have said it best (please forgive me if I've remembered inaccurately).

A full length guide rod does three things:

Change the point of impact Complicates disassembly Put money in the manufacturer's pocket

If any or all of these is in your life plan, by all means, go for it.

For most of my guns I prefer the short style. Easier take down and no perceived losses in function or accuracy. Sort of a win-win situation.

After posting my question I used the forum search function. On the music forums which I moderate and participate I often wish that people would search before posting a question. In any case, shame on me and thanks to both of you for putting up with me.

The response from both of you is right in line with what most people said in other posts by a wide margin.

Quote:

After posting my question I used the forum search function. On the music

forums which I moderate and participate I often wish that people would search

before posting a question. In any case, shame on me and thanks to both of you

for putting up with me.

The response from both of you is right in line with what most people said in other posts by a wide margin.

Thank you both for your reply and thank you for the forum welcome Joni.

Not a problem, Myles. None of us was born knowin' this stuff, and we all from time to time overlook the resources available to us!

I prefer a short rod in most Government and Commander models. It makes disassembly simple and is true to the original design of these weapons. With a bushingless cone barrel you don't have a choice. I do prefer a full length rod in my Delta Elite as I run a much heavier spring in it and the rod will prevent any binding or potential kinking and it adds a tiny bit of weight to the pistol.

I tried a two piece full length rod. I think I used it three times before coming to the realization that the darned thing was likely to unscrew itself no matter how tightly I screwed it down. It also meant I had to have an allen wrench just to field strip the pistol, so it went into either the parts bucket or the trash can.

Quote:

I prefer a short rod in most Government and Commander models. It makes

disassembly simple and is true to the original design of these weapons. With a

bushingless cone barrel you don't have a choice.

Of course you have a choice. The fact that a bushingless barrel requires a reverse recoil spring plug in no way mandates the use of a full-length guide rod.

Given a choice, I prefer the short recoil spring guide, but I'm happy to use whatever comes with the pistol. Spending money to switch from one to the other seems pointless to me, although I'd be inclined to switch out a two-piece full-length recoil spring guide, if I ever buy a pistol with one.

It has been proven that FLGRs neither help nor hurt accuracy.

It is impossible for a .45 auto recoil spring to bind & / or kink inside the gun regardless of what length guide rod is used.

2 piece FLGRs are considered more troublesome than a 1 piece FLGR as they can come loose, and other than a "tool-less" FLGR require a allen wrench for assembly and disassembly.

.45 autos having FLGRs in some cases are easier to assemble and disassemble than those that do not have a FLGR. Depends entirely upon the experience of the shooter and which system he has the most time with.

FLGRs add a little weight to the muzzle end of the gun, thus reducing recoil tip-up and aiding in back on target time.

FLGRs can and probably will smooth out the cycling a tad.

Some FLGRs are available in tungsten, increasing the weight at the muzzle a tad more.

Most of the gamers and competition shooters use them in one form or another.

They do remove the "twang" sound when cycling your .45 auto by hand if it does so. Some .45 autos have that "Twang" and some don't. that is the the recoil spring rubbing against the frame recoil spring tunnel generally.

I do not recommend that people other than myself use FLGRs and / or Shok- buffs. Regardless or what others tell you it is strictly a matter of personal preference.

FLGRs & Shok-buffs both have quite a few haters, that's for sure.

FWIW, IMHO, & HTH.

FWIW, I use FLGRs in all 5 of my 1911 platform .45 autos.

Plus one on Hawk's post.

My four inch W/C Professional model has a bull barrel with no bushing, reverse recoil spring plug and a short "guide rod."

Takedown is extremely quick and easy, too.

QUOTE:

2 piece FLGRs are considered more troublesome than a 1 piece FLGR

as they can come loose, and other than a "tool-less" FLGR require a allen

wrench for assembly and disassembly... Depends entirely upon the experience

of the shooter and which system he has the most time with

I keep an Allen wrench in my gun bag, but I've never needed to use it other than for disassembly and assembly after cleaning.

I had three of them, and sold two on GunBroker. With that said my XSE LWT GM has one as does the XSE Commander. I'm not sure if I'd spend the money for one anymore, maybe the Sprinco type for a Delta Elite if I was going to shoot it a lot with the heavier loads.

They don't come loose if you wrap the threads with teflon pipe thread tape. Find some of the green (oxygen service) or yellow (fuel gas) and wrap the threads until some force (like a lock nut with a nylon insert) is required to screw the pieces together. Then relax.

I use them and like them. They are much smoother than the OEM setup.

Quote:

They don't come loose if you wrap the threads with teflon pipe thread tape.

Find some of the green (oxygen service) or yellow (fuel gas) and wrap the

threads until some force (like a lock nut with a nylon insert) is required to

screw the pieces together. Then relax.

I lost interest when a wrench was needed to take down the pistol. I now use a Wilson Combat one piece at times and the stock setup at other times.

The one piece really needs one to carry a bushing wrench to make things easier which is not needed on the stock setup and I could go that far but to carry an allen wrench and now teflon tape and lock nuts to set up things and ... well ... seems as if the complication is contraindicated in my mind as to what a pistol is generally for.

I shoot a lot of sporting clays and generally shoot an over/under but at time shoot a Beretta AL391 autoloader. The new Beretta 400 series carries electronics and batteries in the pistol grip to count the shots and give you all sorts of data. I don't think I will ever own one of those shotguns, my same sort of logic I suppose. Maybe a great feature for folks that grew up with a Wii controller in their hands or think the reason to turn on a TV is to fire up the Sony Play Station. Perhaps folks that cannot recall when a phone did not have a camera built in.

I have been in high tech from 1973 when I worked for Control Data. I have crossed oceans on sailboats using the sun, moon and planets to find my way, no batteries required. I like my guns to be simple and reliable. Two piece guide rods cross a personal line with me. Full length one piece are still fine with me. In the end there is no right or wrong, it is all personal preference and taste and we all use our equipment differently as well.

Just my two cents on teflon tape inside a pistol in a very round about way I suppose

Quote:

The one piece really needs one to carry a bushing wrench to make things

easier which is not needed on the stock setup...

[snip]

Yes and no - it depends how tight the bushing is fitted. If it's not too

tight, an improvised tool used to press the plug inward, is perfectly

adequate. If you have at least one magazine with a plastic basepad, the base

of the magazine is the only takedown tool you need...

There are several reasons I choose teflon tape. It is clean, it will not wash out, it is not affected by most common chemicals and I don't think there is any way it can interfere with the operation of a firearm because it is encapsulated in the threads of the guide rod.

You're telling me that a little tape and a few tools is too complicated? Why aren't you shooting a flintlock? Why do you have sails on your boat? Ever heard of paddles? BTW, how's your horse doing?

Just kidding. I also think a lot of things are to complicated, but I don't think "progress" will ever slow down.

If you stop and think about it---how far can the recoil spring really move with a short guide rod? The barrel's right on top of it with the frame below. I go for JMB's original setup.

I once read through an article pertaining to the recoil spring. It went on to explain that the recoil spring was actually a torsion spring. I am not a spring expert, however I have noticed something. After twisting and capturing the recoil spring into the tab in the recoil spring plug and completely reassembling the 1911, firing a magazine or two will result in the recoil spring twisting out of the tab. I don't think this spring compresses as neatly as everyone thinks.

I have seen a cut away 1911 made for training purposes, and the recoil spring did not compress straight. It had several nasty humps in it. I have also taken a few badly kinked recoil springs out of 1911s.

That's why I like a full length guide rod. I also run a counter sink in the open end of the recoil spring plug to assist the spring being compressed into the plug.

Of course, your milage may vary.

regarding either setup, how tight should the flange of the guide rod fit in the ID of the slide? Holding the slide upside down and the barrel in with the GR in place my GI style flange fits snug in the slide and my FLGR has slop side to side. Does fit matter?

What do you mean by 'flange'?

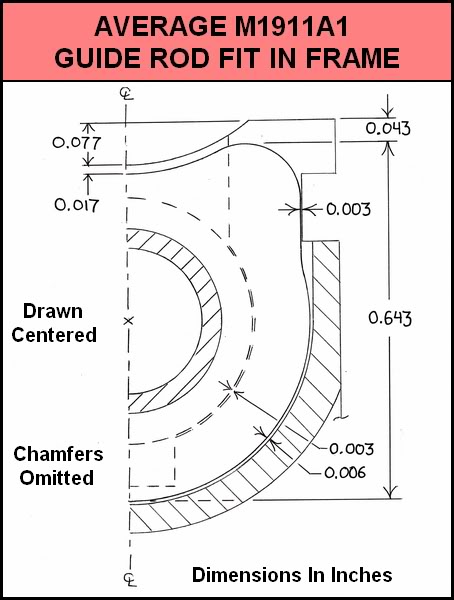

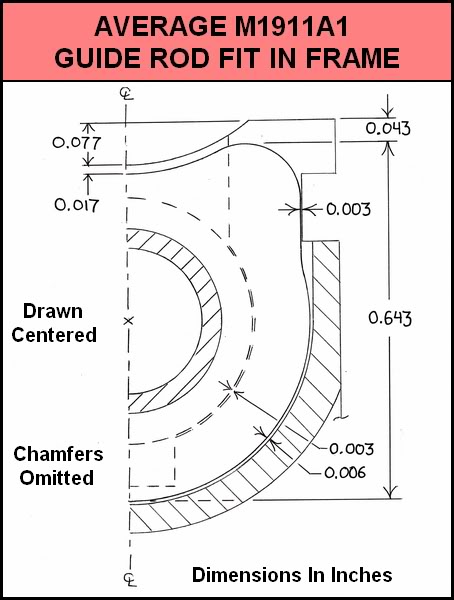

If I am reading the blue prints I have correctly;

.655-.006 for the recoil spring guide

.329R+.005 for the guide seat

A range of.003 to.014 clearance

Quote:

What do you mean by 'flange'?

The largest part of the guide rod, at the end that sits near the barrel lugs... it's the flat piece that is round except for the part that rests on the barrel.

the flat part that sits opposite the muzzle, where the recoil spring seats

Quote:

A range of.003 to.014 clearance

That's a pretty snug fit, the Wilson drop in FLGR has more slop than that. Does that cause problems?

OK, nope the slop should cause no problems, that's how my FLGR-equipped 1911 is.

Quote:

I am not a spring expert, however I have noticed something. After twisting

and capturing the recoil spring into the tab in the recoil spring plug and

completely reassembling the 1911, firing a magazine or two will result in the

recoil spring twisting out of the tab.

The only 1911s I have with the tab are a couple of Colts, and the springs do NOT twist out of the tab. There's something wrong with your pistol.

Quote:

I also run a counter sink in the open end of the recoil spring plug to

assist the spring being compressed into the plug.

I don't understand this at all. A countersink cuts a taper. The forward end of the spring wants to seat on a flat surface inside the plug, otherwise the taper will be trying to squeeze the end of the coil to a smaller diameter. This may explain why your springs are rotating when mine aren't.

Quote:

...how tight should the flange of the guide rod fit in the ID of the

slide?

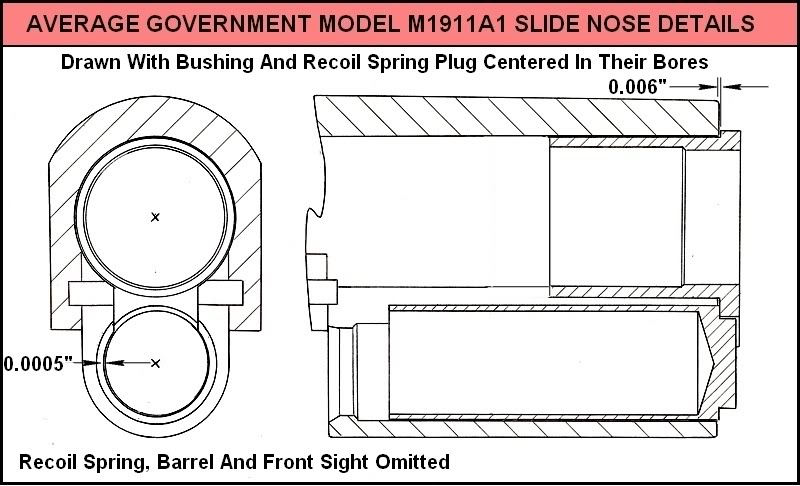

The answer may be somewhere in this:

Ordnance drawings for these and all other parts are available in our Tech Issues section, 14th link down.

Hawkmoon, When the recoil spring is being compressed after firing, I'm pretty sure that some of the coils of the recoil spring are forced into the recoil spring plug. On my 1911, cleaning up this area of the plug did lower that spring skrunching noise. I just do this to allow the spring coils a smoother path into the recoil spring plug. Is it necessary? Probably not. Will it hurt anything? Probably not. Will it help anything? It may. I use a 45 degree counter sink and cut about half the thickness of the plug away. I'm talking about the inside open end of a standard plug. The other end from where the spring seats.

I'm thinking that in the article I mentioned, the author stated that as the recoil spring was compressed it would try to uncoil (torsion) itself. I believe this could possibly cause the plug to rotate. EGW has a monogramed bushing and plug set that is machined to stop the rotation of the plug. The reason I noticed the plug moving was that I always turn the plug so the checkering is plumb and level with the gun. Just looked neater. After a range trip, the plug was never in the same position. And yep, when I turned the bushing, the plug took off for parts unknown again. Maybe that tab is just there to keep the spring from being forced down in that taper?

THANK YOU!!! Excellent response, do you know if a sloppier fit FLGR (like a drop in) would cause problems or damage?

Do GI spec models usually have the sloppier fit?

You're welcome. Never dealt with any type of FLGR, so I don't know anything about them or whether they have sloppier or tighter fits. The only thing I've ever done to a guide is add a little tab on the aft end...

...to keep it from clocking and rubbing on the slide rails.

Quote:

...When the recoil spring is being compressed after firing, I'm pretty sure

that some of the coils of the recoil spring are forced into the recoil spring

plug. On my 1911, cleaning up this area of the plug did lower that spring

skrunching noise. I just do this to allow the spring coils a smoother path

into the recoil spring plug.

This illustrates why Iron Bottom's treatment of the back end of the plug is worthwhile...

...especially if it sounds like you're winding an old alarm clock when racking the slide.

Magwell1, note that Niemi's referring to the fit of the guide rod to the frame, not the slide. The slide doesn't really feature in all this, except during field stripping.

Excellent art work as usual, Niemi. Thank you. You are my favorite artist, even if you never get in the Googleheim.

Thanx for the kind word, Iron Bottom. Had a "senior moment" and drew the barrel bushing waaay too long, but have since corrected the image. If you're still seeing the initial long & wrong version, "Ctrl + F5" should bring up the corrected version.

Looks good now Niemi. Anyway, around here, I am only allowed to touch the mouse and suspicious looking electrical wires.